Amorphous protection corrosion resisting steel bar and preparing method thereof

A steel bar and corrosion-resistant technology, which is applied in the field of amorphous protective corrosion-resistant steel bar and its preparation, can solve the problems of toxicity, poor breathing, corroded skin, etc., and achieve the effect of excellent corrosion resistance, low oxide content, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

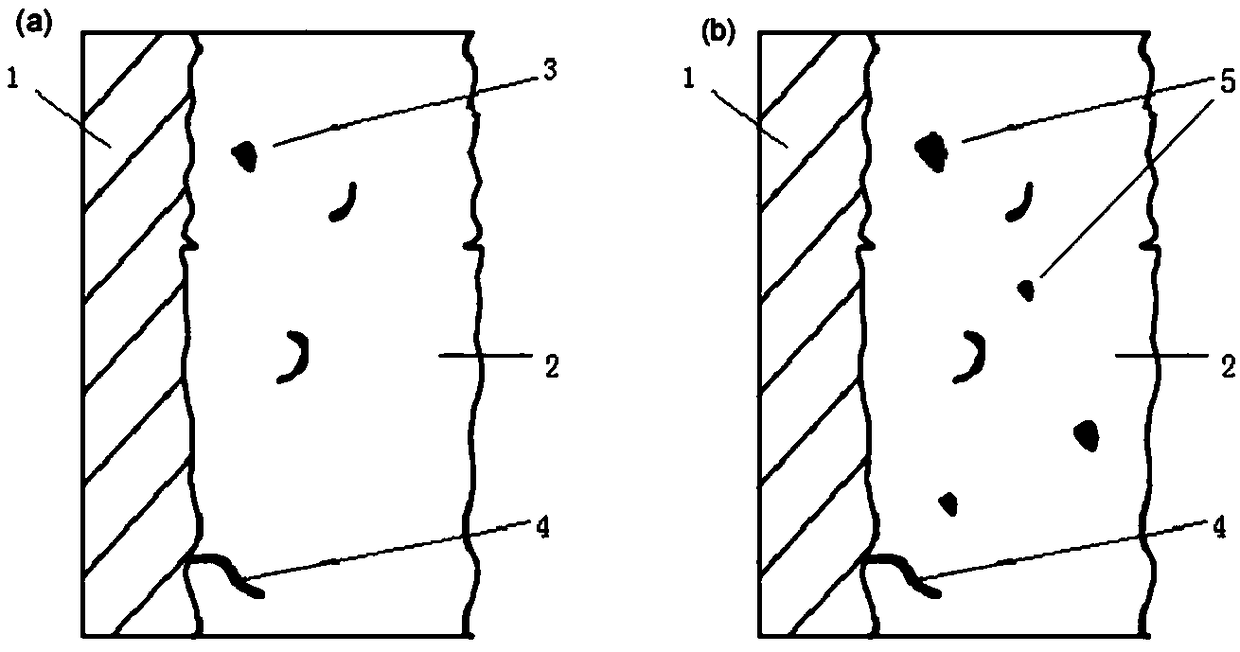

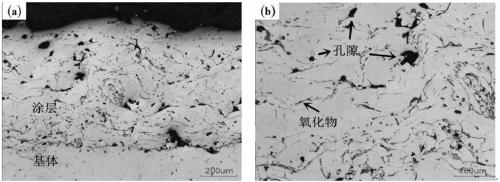

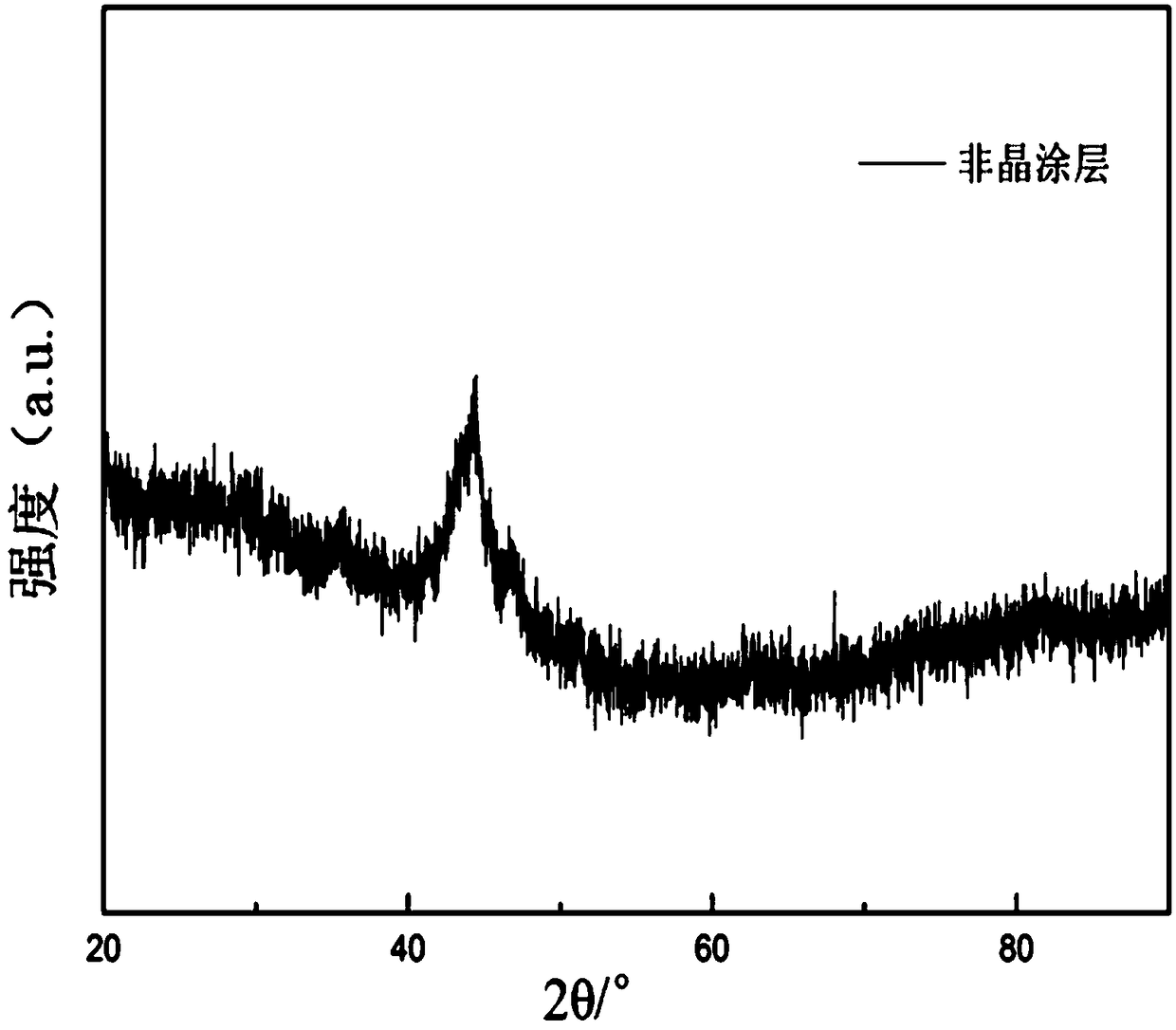

[0033] An amorphous protective corrosion-resistant steel bar, comprising a steel bar body and a coating with a thickness of 300-500 μm, the coating is sprayed on the surface of the steel bar body, the coating is formed by spraying a powder core wire, and the powder core wire Including the following components by weight percentage: 27.7wt% Cr, 13wt% B, 0.7wt% C, 2.5wt% P, 4.5wt% Cu, 3.5wt% Ni, 9.5wt% Mo, 4wt% Mn, 0.45wt% %Ti, the balance being Fe; the diameter of the powder core wire is 2mm, and the filling rate of the powder core wire is 37%.

[0034] The preparation method of the above-mentioned amorphous protective corrosion-resistant steel bar comprises the following steps:

[0035] Step 1. Weigh the powder containing 10 elements required for the core wire material, dry the powder at 95°C for 1.5 hours, put it into a powder mixer and mix it at room temperature for 2 hours to obtain mixed powder A;

[0036] Step 2, select 304 stainless steel strips, tie it into a U shape as...

Embodiment 2

[0042] An amorphous protective corrosion-resistant steel bar, including a steel bar body and a coating, the coating is sprayed on the surface of the steel bar body, the coating is formed by spraying a powder core wire, and the powder core wire includes the following by weight percentage Components: 27.3wt% Cr, 12.5wt% B, 0.57wt% C, 0.65wt% P, 4.13wt% Cu, 3.2wt% Ni, 8.75wt% Mo, 3.5wt% Mn, 0.45wt% Ti, remaining The amount is Fe; the diameter of the powder core wire is 2mm, and the filling rate of the powder core wire is 37%.

[0043] The preparation method of the above-mentioned amorphous protective corrosion-resistant steel bar comprises the following steps:

[0044] Step 1. Weigh the powder containing 10 elements required for the core wire material, dry the powder at 95°C for 1.5 hours, put it into a powder mixer and mix it at room temperature for 2 hours to obtain mixed powder A;

[0045] Step 2, select 304 stainless steel strips, tie it into a U shape as the cladding layer,...

Embodiment 3

[0051] An amorphous protective corrosion-resistant steel bar, including a steel bar body and a coating, the coating is sprayed on the surface of the steel bar body, the coating is formed by spraying a powder core wire, and the powder core wire includes the following by weight percentage Components: 26.5wt% Cr, 12.5wt% B, 0.45wt% C, 0.15wt% P, 3.75wt% Cu, 2.5wt% Ni, 7.5wt% Mo, 3.5wt% Mn, 0.45wt% Ti, remaining The amount is Fe; the diameter of the powder core wire is 2mm, and the filling rate of the powder core wire is 37%.

[0052] The preparation method of the above-mentioned amorphous protective corrosion-resistant steel bar comprises the following steps:

[0053] Step 1. Weigh the powder containing 10 elements required for the core wire material, dry the powder at 95°C for 1.5 hours, put it into a powder mixer and mix it at room temperature for 2 hours to obtain mixed powder A;

[0054] Step 2, select 304 stainless steel strips, tie it into a U shape as the cladding layer, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com