Blast furnace smelting method for sefstromite

A vanadium ilmenite and blast furnace smelting technology, applied in the field of blast furnace smelting, can solve problems such as increased viscosity of slag, influence on vanadium recovery rate, and indistinguishable iron from blast furnace slag, reduce dissolution loss, improve slag fluidity, and ionization degree big effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

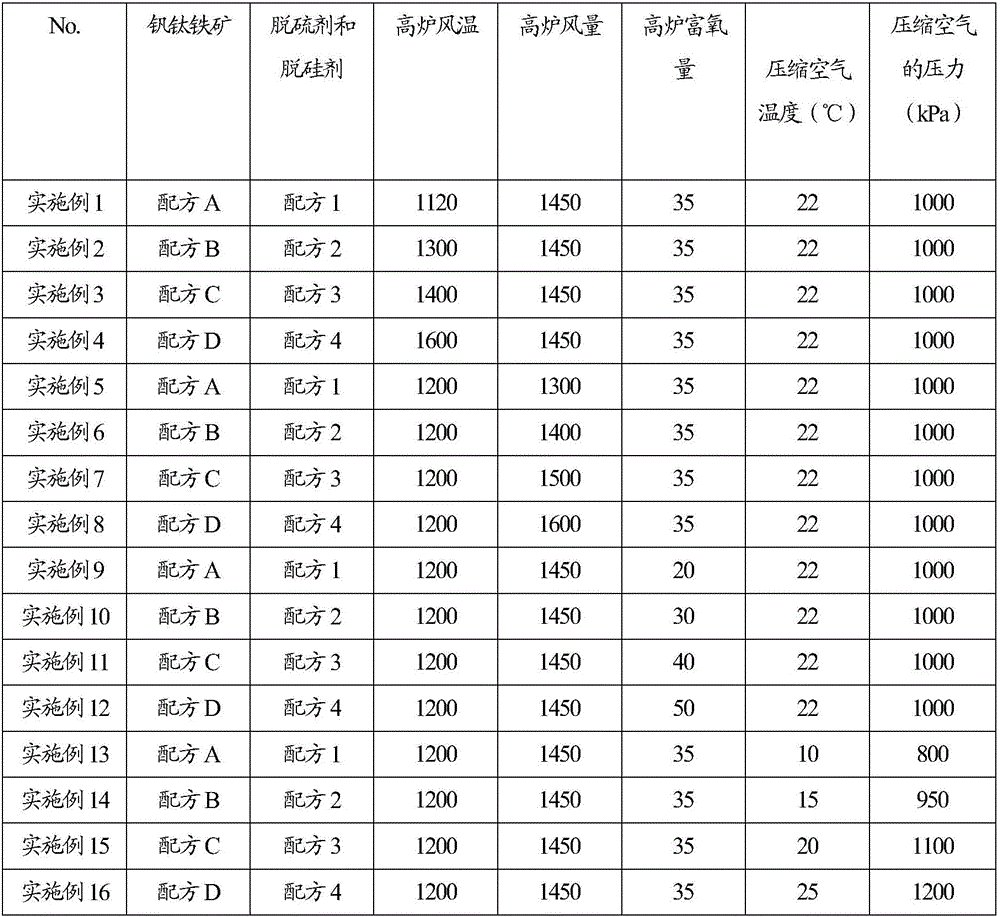

Embodiment 1~16

[0022] The invention provides a blast furnace smelting method of vanadium-titanium iron ore, which is beneficial to the recycling of vanadium and titanium and reduces the cost of blast furnace smelting.

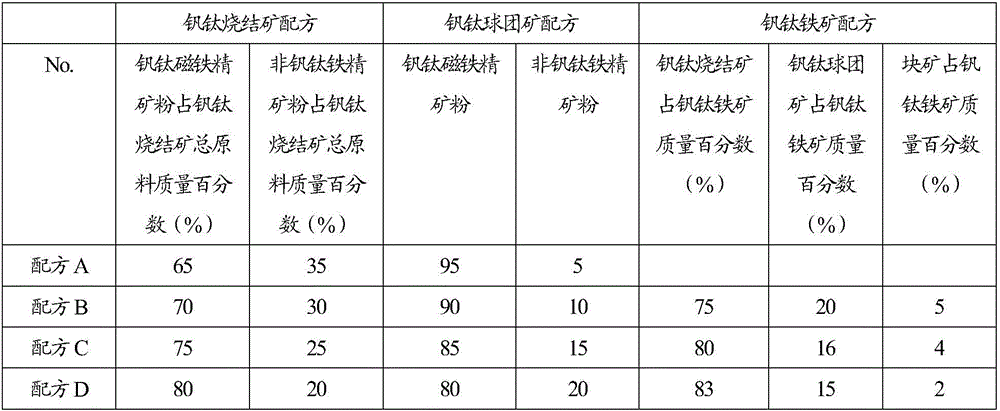

[0023] The invention provides a method for smelting vanadium-titanium iron ore in a blast furnace, comprising the following steps: using vanadium-titanium magnetite concentrate powder and non-vanadium-titanium-iron concentrate powder as raw materials to sinter vanadium-titanium sintered ore; using vanadium-titanium magnetite concentrate powder and Non-vanadium-titanium iron ore concentrate powder is used as raw material to roast vanadium-titanium pellets, and the obtained vanadium-titanium sintered ore, the obtained vanadium-titanium pellets and lump ore are mixed to obtain vanadium-titanium iron ore with high vanadium-titanium content. The formula is shown in Table 1

[0024] Table 1

[0025]

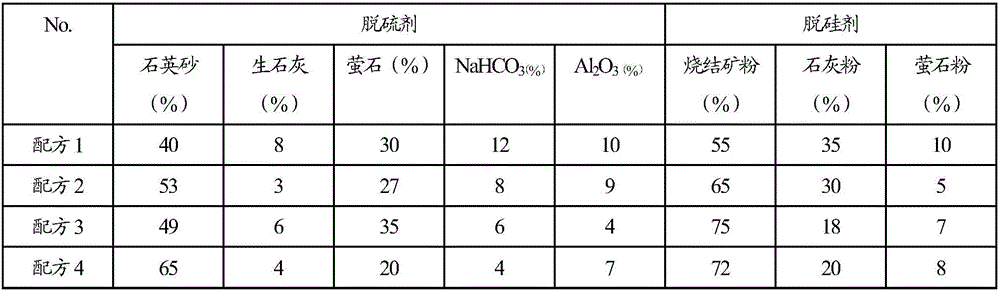

[0026] Quartz sand, quicklime, fluorite, NaHCO 3 with Al 2 o 3 Prepare des...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com