A new energy vehicle battery explosion-proof flame retardant device

A new energy vehicle and battery technology, applied in the direction of batteries, electric vehicles, secondary batteries, etc., can solve the problems affecting passenger safety, combustion, explosion, etc., and achieve the effect of simplifying the operation of battery replacement and strong practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

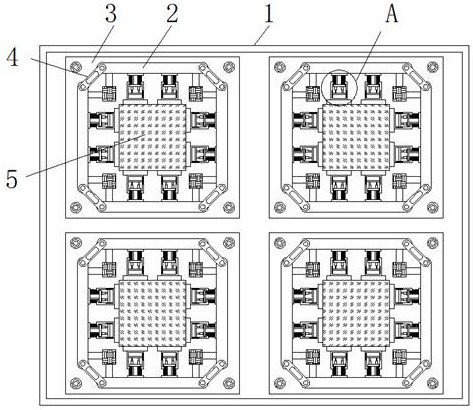

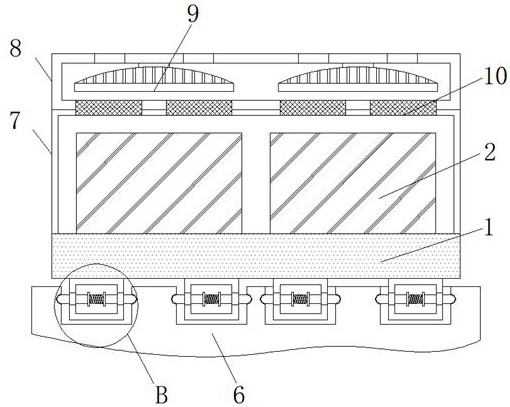

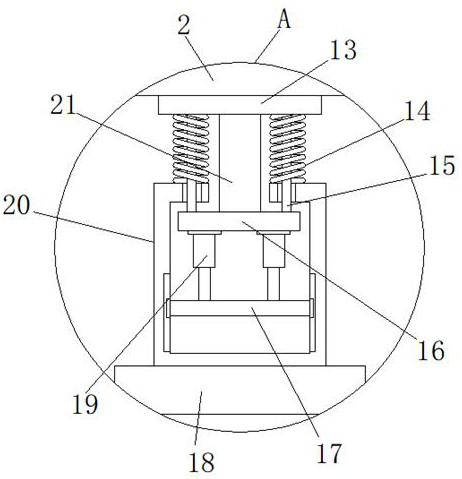

[0023] Embodiment 1: as Figure 1-Figure 5 As shown, a new energy vehicle battery explosion-proof and flame-retardant device proposed by the present invention includes an installation frame 1 and a chassis 6. The top of the installation frame 1 is fixed with four sets of mounting seats 3 by bolts, and the tops of the mounting seats 3 are placed with Battery 5, after the battery pack is hit, the surroundings of the battery 5 are initially supported by the fixed plate 2, and at the same time, the connecting rod 4 transfers the shaking of the fixed plate 2 to the rubber block inside the fixed plate 2 for the first buffer , eight connection blocks 18 are welded around the battery 5, and a third box 20 is welded on the side of the eight connection blocks 18 away from the battery 5, and the inner wall of the third box 20 is slidably connected with a movable plate 17, and the movable plate 17 is welded with two hydraulic rods 19 away from the side of the battery 5, and the end of the...

Embodiment 2

[0024] Embodiment 2: as Figure 1-Figure 5 As shown, the side of the fixed plate 13 away from the second movable column 21 is welded with the fixed plate 2, and the aftershocks that are not filtered by the fixed plate 2 will impact the fixed plate 13 and the connection from the inner side of the fixed plate 2 and the surroundings of the battery 5 respectively. On the block 18, the side of the fixed piece 13 away from the fixed plate 2 is welded with two first movable columns 15 that penetrate and extend into the third box body 20, and one end of the first movable column 15 located in the third box body 20 is Welded with the side of the movable block 16 away from the hydraulic rod 19, when the movable plate 17 slides to the limit of the chute, the hydraulic effect of the hydraulic rod 19 is transmitted to the movable plate 17 for support, and the fixed piece 13 is far away from the fixed plate 2 One side is all welded with the second movable column 21, and the other end of the ...

Embodiment 3

[0025] Embodiment 3: as Figure 1-Figure 5 As shown, the inner walls on both sides of the third box body 20 are provided with chute, and sliders are arranged in the chute, and the ends of the sliders that are close to each other are respectively welded to the two ends of the movable plate 17, and the cross section of the chute is T One end of the fixed plate 2 close to each other is hinged with a connecting rod 4, the side of the fixed plate 2 close to the battery 5 is welded with two steel bars, the end of the steel bar close to each other is welded with a rubber block, and the top of the chassis 6 is provided with four chamber, the inner walls on both sides of the chamber are provided with grooves, the tip of the protruding rod 23 is arc-shaped, and after the protruding rod 23 inside the fourth box body 22 touches the inner wall of the chamber, the protruding rod 23 The tip slides on the inner wall of the chamber, and the protruding rod 23 will be squeezed by the inner wall ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com