Porous composite material partition and preparation method thereof, composite-structure cell and lithium ion battery

A technology of porous composite material and composite structure is applied in the field of preparation of composite structure cells, lithium ion batteries, and porous composite material separators, which can solve the problems of diaphragm damage, unfavorable promotion and use, short circuit, etc., and achieve guaranteed performance and performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

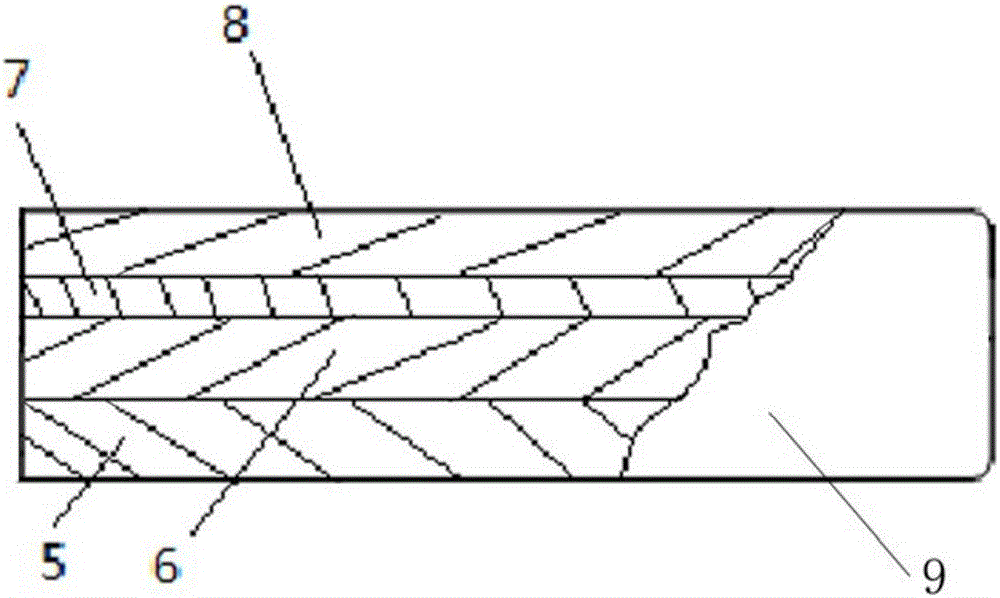

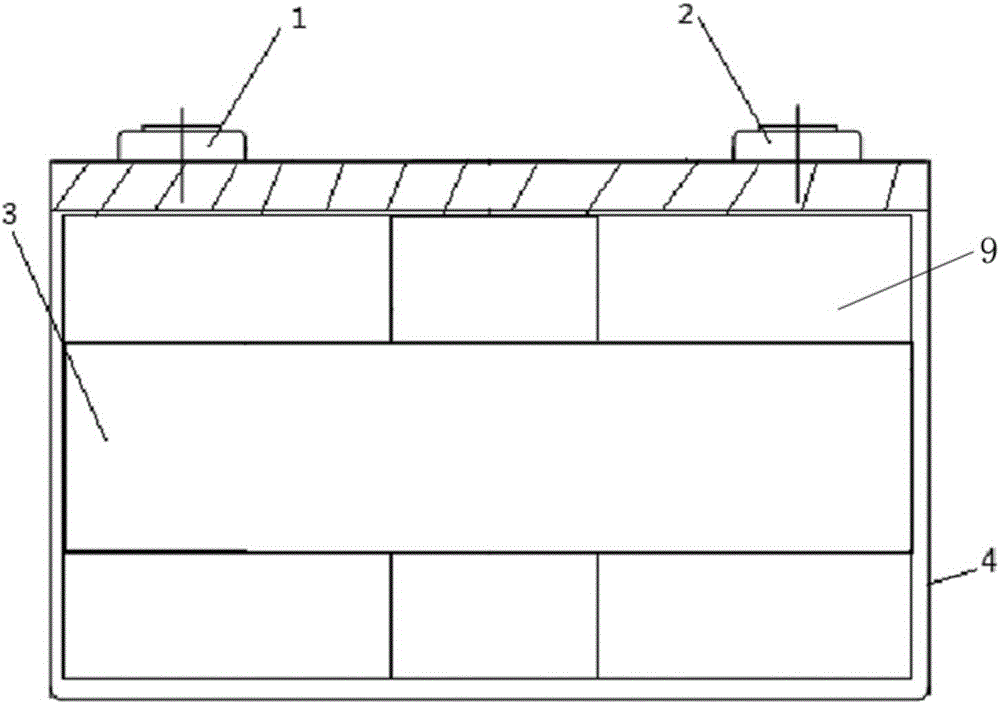

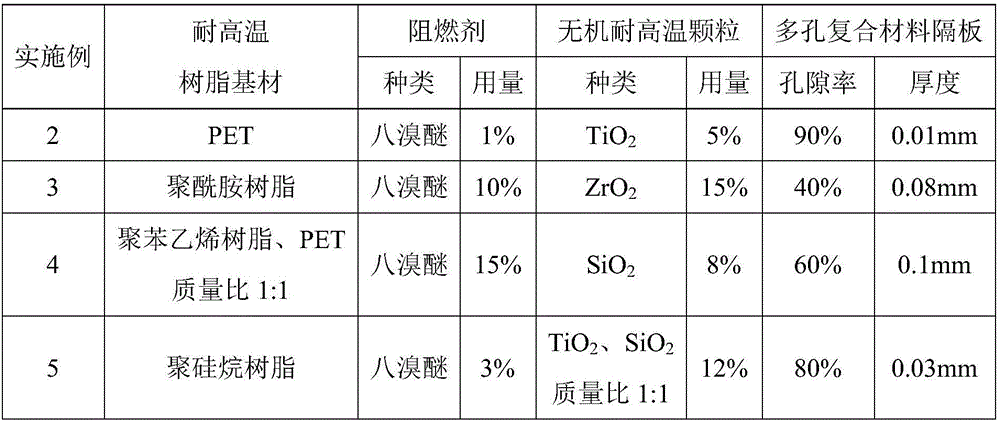

[0035] The porous composite separator of this embodiment includes a high temperature resistant resin substrate, a flame retardant and inorganic high temperature resistant particles, the high temperature resistant resin substrate is polyimide resin; the flame retardant is octabromoether, The consumption of flame retardant is 5% of the mass of high temperature resistant resin base material; The inorganic high temperature resistant particle is Al 2 o 3 , the amount of inorganic high-temperature-resistant particles is 10% of the mass of the high-temperature-resistant resin substrate. The porous composite separator has a porosity of 70%, a pore diameter D50<0.5 μm, and a thickness of 0.05 mm.

[0036] The preparation method of the porous composite separator of this embodiment comprises the following steps:

[0037] 1) Under the condition of 300 °C, the formula amount of flame retardant octabromoether and inorganic high temperature resistant particles Al 2 o 3 Add it to the high...

experiment example

[0050] In this experimental example, the lithium-ion batteries of Examples 1-5 were tested for safety performance, and the results are shown in Table 3.

[0051] The safety performance detection result of table 3 embodiment 1-5

[0052]

[0053] The porous composite separator of Examples 1-5 is a composite separator with high temperature resistance above 200°C, and has the properties of high temperature resistance, flame retardancy, corrosion resistance and impact; Battery, the lithium-ion battery of the present invention will not melt and burn when short-circuited, and can completely isolate the positive and negative electrodes, avoiding accidents of the lithium-ion battery under high temperature or impact conditions, and large-area short-circuit inside the battery. The problem that caused the battery to explode and catch fire.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com