Patents

Literature

52results about How to "Shocking" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

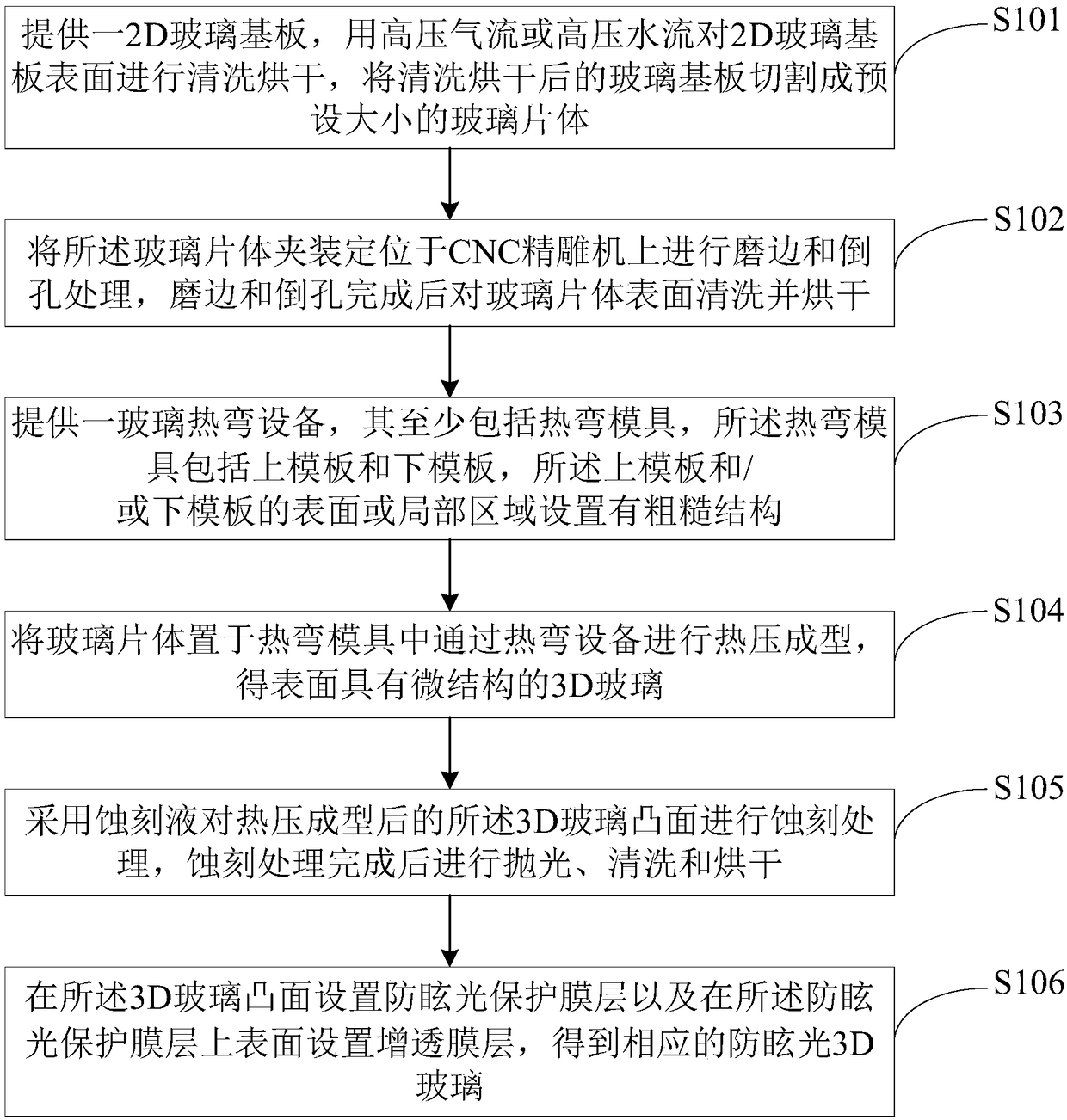

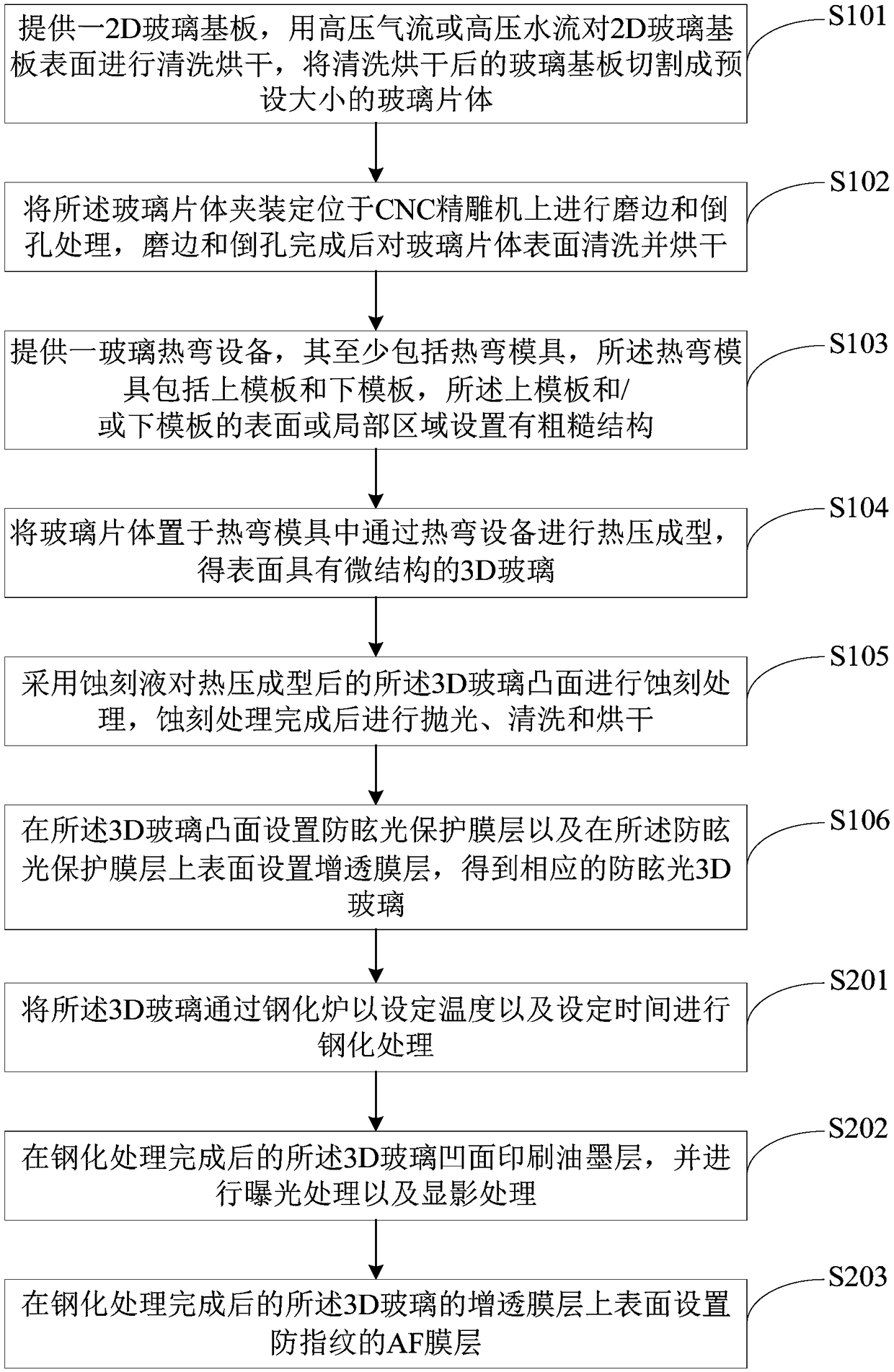

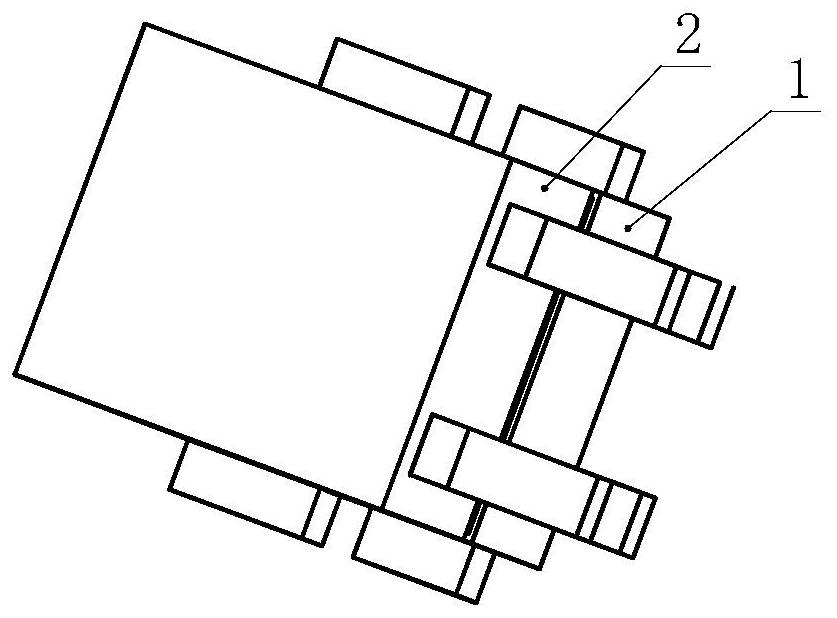

Production method of anti-glare 3D glass

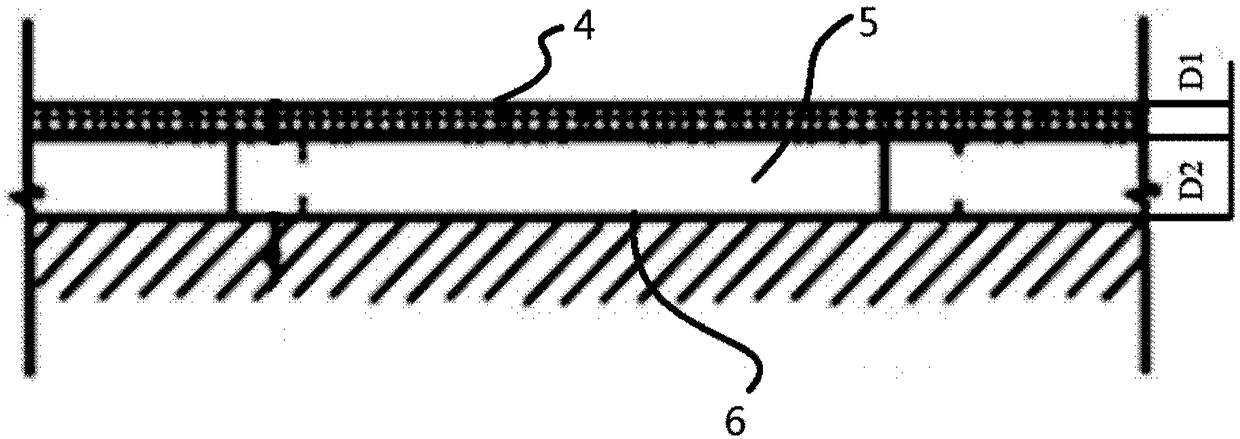

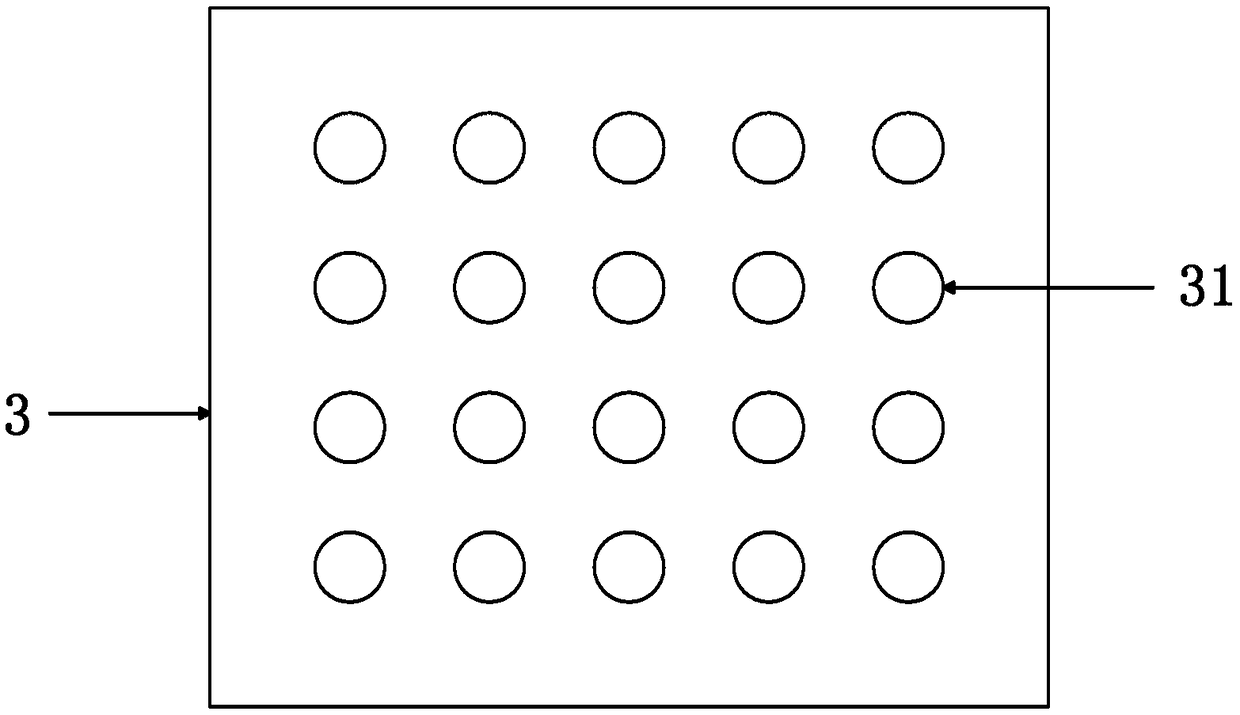

The invention is applicable to the technical field of glass production and provides a production method of anti-glare 3D glass. The production method comprises the steps as follows: providing a 2D glass substrate, cleaning and drying the surface of the glass substrate, and cutting the glass substrate into glass pieces in preset size; clamping and positioning the glass pieces on an CNC carving machine for edging and chamfering treatment, and cleaning and drying the surface of the glass pieces; providing a glass hot-bending device at least comprising a hot-bending mold, wherein the hot-bending mold comprises an upper mold plate and a lower mold plate, and a rough structure is arranged on the surface or in a local area of the upper mold plate and / or the lower mold plate; placing the glass pieces in the hot-bending mold for hot-press molding by the hot-bending device to obtain 3D glass with microstructure on the surface; etching the convex surface of the hot-pressed 3D glass by an etchingsolution, and performing polishing, cleaning and drying after etching treatment; arranging an anti-glare protecting film layer on the convex surface of the 3D glass and arranging an antireflection film layer on the upper surface of the anti-glare protecting film layer to obtain the corresponding anti-glare 3D glass.

Owner:仙游县元生智汇科技有限公司

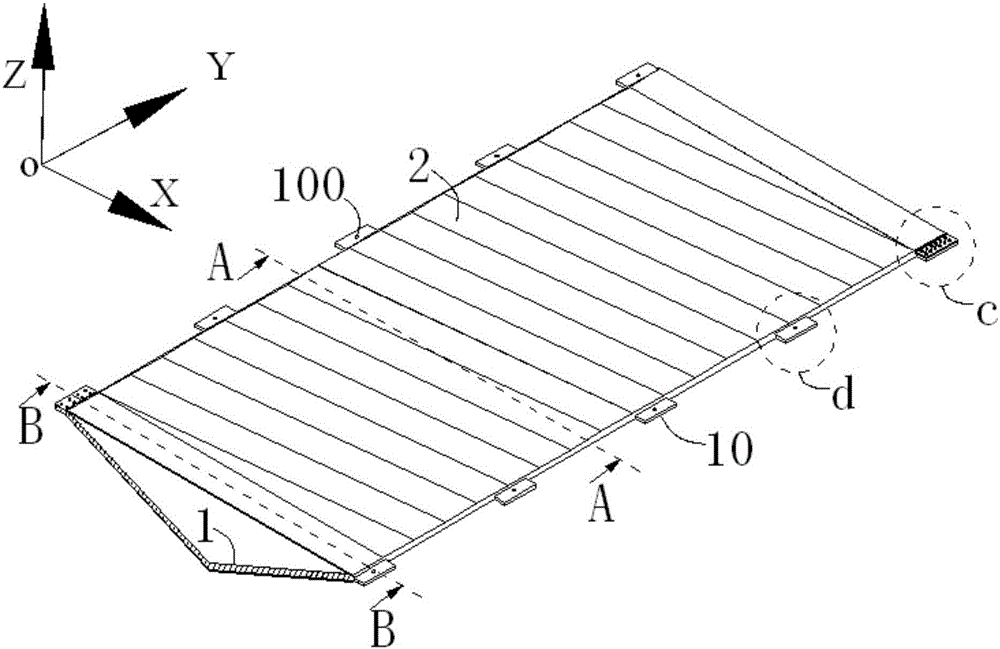

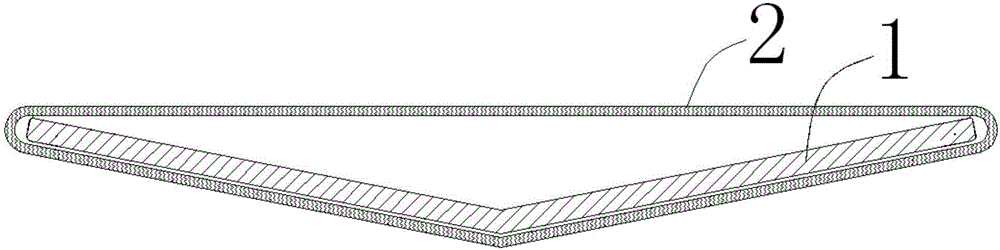

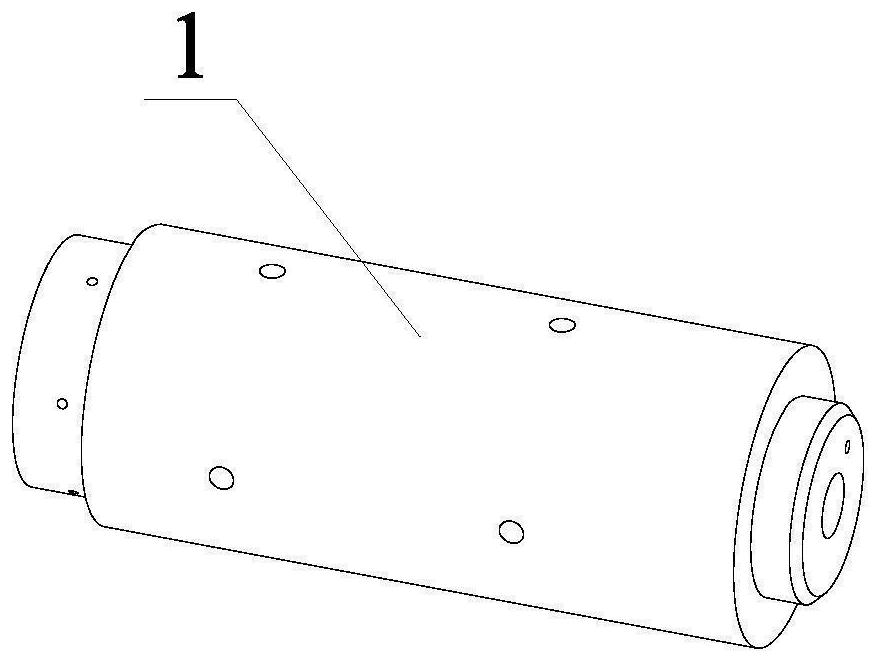

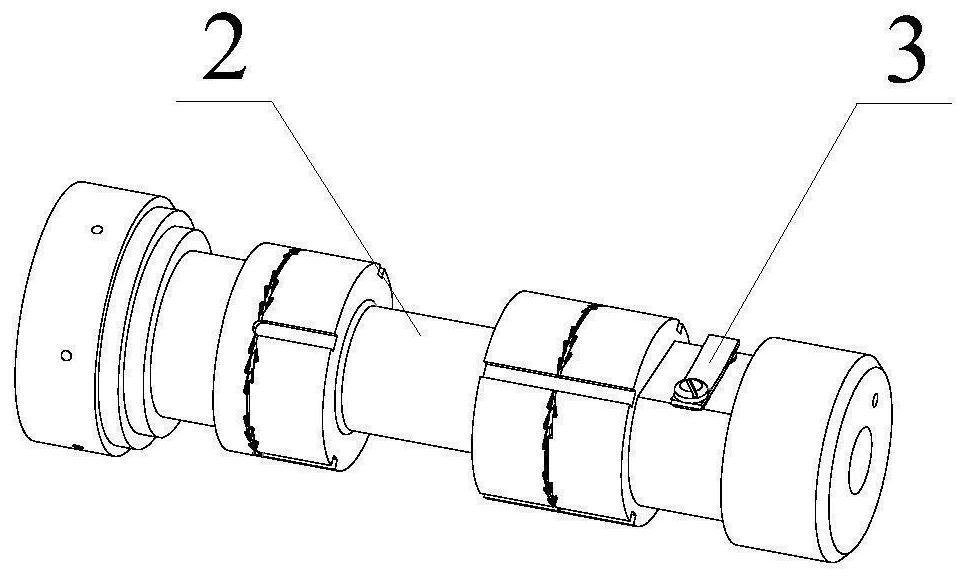

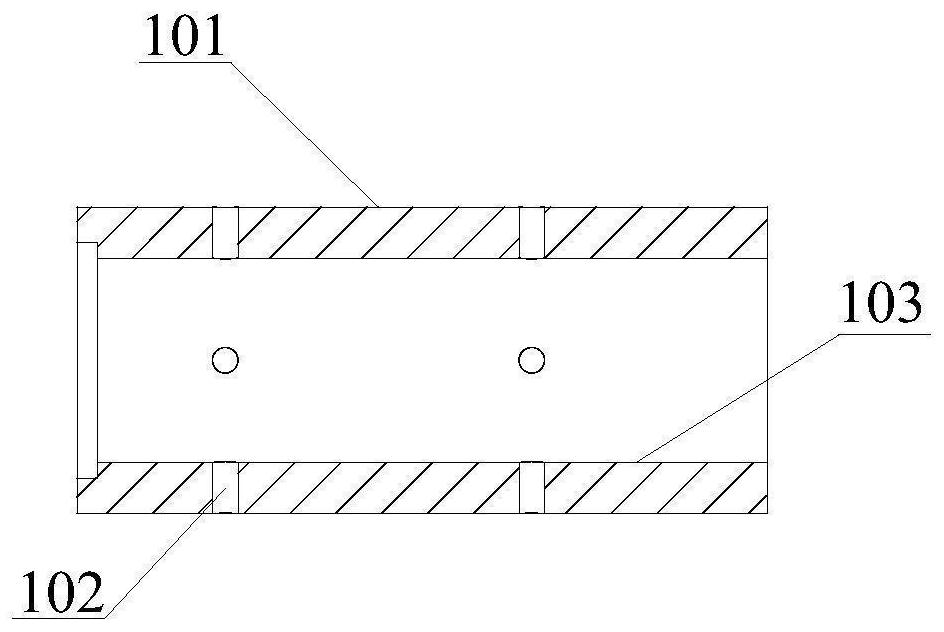

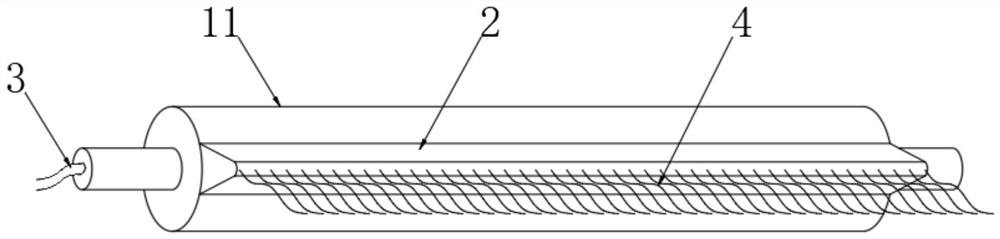

Vehicle bottom plate

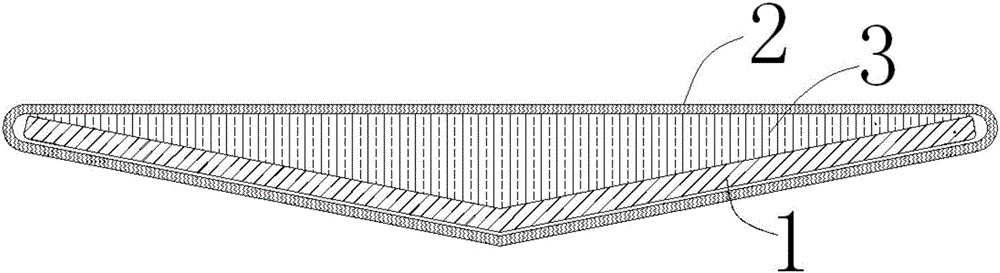

PendingCN106370060AReduce shockReduce casualty rateVehicle componentsArmour platesBand shapeEngineering

The invention discloses a vehicle bottom plate. The vehicle bottom plate comprises a base plate and a coating layer which is formed by uninterruptedly winding belt materials on the periphery of the base plate; the base plate forming the vehicle bottom plate has certain explosion resistance and impact resistance; the periphery of the base plate is provided with the coating layer which is wound uninterruptedly, and thus impact of explosives can be further reduced; moreover, when the base plate is broken into fragments due to explosion, the fragments are coated through the coating layer, and persons in a vehicle are prevented from being injured by the fragments of the base plate. The casualty rate of the persons in the vehicle during explosion can be effectively decreased by assembling the vehicle bottom plate in the anti-explosion vehicle.

Owner:浙江美盾防护技术有限公司

Shock-resistant anti-impact shell fabric

InactiveCN103211339AHarm reductionShock resistantSynthetic resin layered productsProtective garmentCarbon fibersBasalt fiber

The invention discloses a shock-resistant anti-impact shell fabric. The shock-resistant anti-impact shell fabric comprises a shock-resistant fiber composite layer, an anti-impact fiber composite layer, a fluorescent protective coating and a pearly-lustre polyurethane (PU) nylon taffeta layer; the pearly-lustre PU nylon taffeta layer, the shock-resistant fiber composite layer and the anti-impact fiber composite layer are arranged on the inner surface of the fluorescent protective coating in turn; and the shock-resistant fiber composite layer is woven by carbon fibers and basalt fibers in the weight ratio of 2:3. The shell fabric has shock-resistant and anti-impact performance, high flame resistance, and prompting and pre-warning performance, and can effectively reduce the harm to a worker in a construction site caused by the impact of a heavy object.

Owner:王红

Multifunctional torque wrench

The invention discloses a multifunctional torque wrench. The multifunctional torque wrench comprises a machine shell, a handle and a nut sleeve, wherein a motor is arranged inside the machine shell. The motor is connected with the nut sleeve through a transmission shaft. The motor can drive the transmission shaft to rotate forwards and reversely. A torque sensor is arranged between the transmission shaft and the nut sleeve. The nut sleeve is detachable. The torque sensor can also be connected with a drill bit through a detachable connecting piece. Switch keys of different gears are arranged on the handle. According to the structure, the motor can rotate forwards and reversely; when the motor rotates forwards (the motor can also rotate reversely), the motor has impact, the torque sensor is connected with a connector and the drill bit, and the multifunctional torque wrench can be used as a drilling machine to drill holes; when the motor rotates reversely (the motor can also rotate forwards), the motor does not have impact, the torque sensor is directly connected with the nut sleeve, and the multifunctional torque wrench can be used as a torque wrench to tighten a nut. The multifunctional torque wrench has two functions and is convenient to carry and use, particularly suitable for high-altitude carrying and capable of reducing the operation load.

Owner:南通高盛机械制造有限公司

Organosilicone-modified epoxy powdery paint

The invention discloses a silicone-modified epoxy powder coating, which comprises the following components by weight: 25-30 parts of silicone-modified epoxy resin, 0.5-1.5 parts of dicyandiamide, and 0.1-0.5 parts of amine catalyst 450-540 parts of low-melting point glass powder and 15-30 parts of silica powder. The melting point of low-melting point glass powder is 410-430°C. The silicone-modified epoxy powder coating with the above formula has a lower cost than the existing coating formula, and the overall film layer is stable after the product is sprayed and formed, which has a good application prospect.

Owner:袁传江

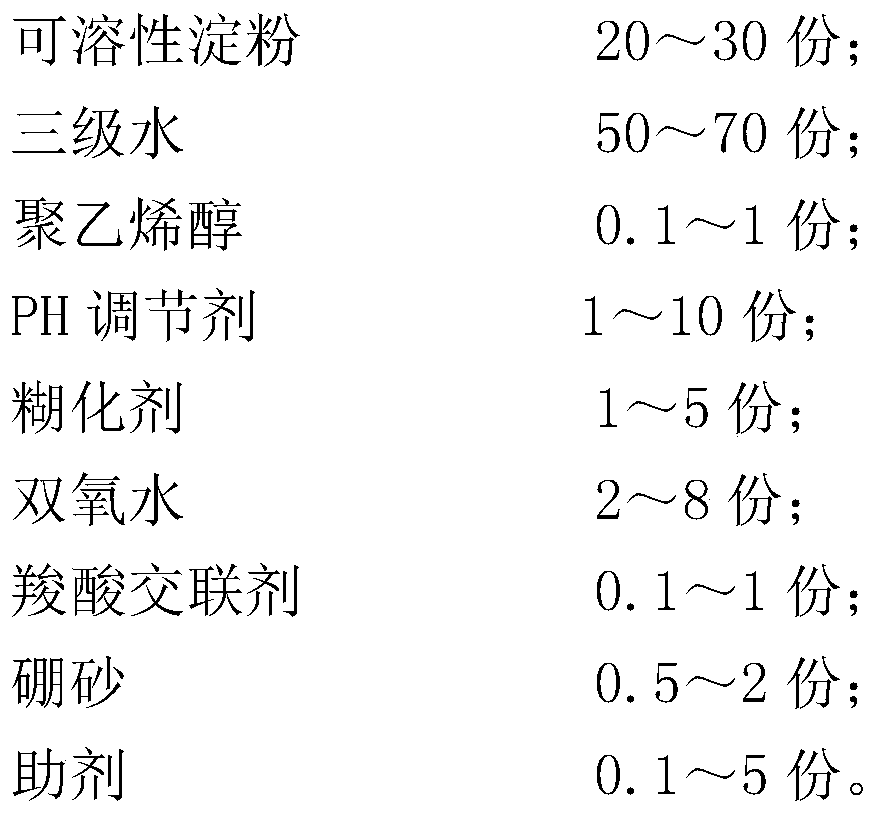

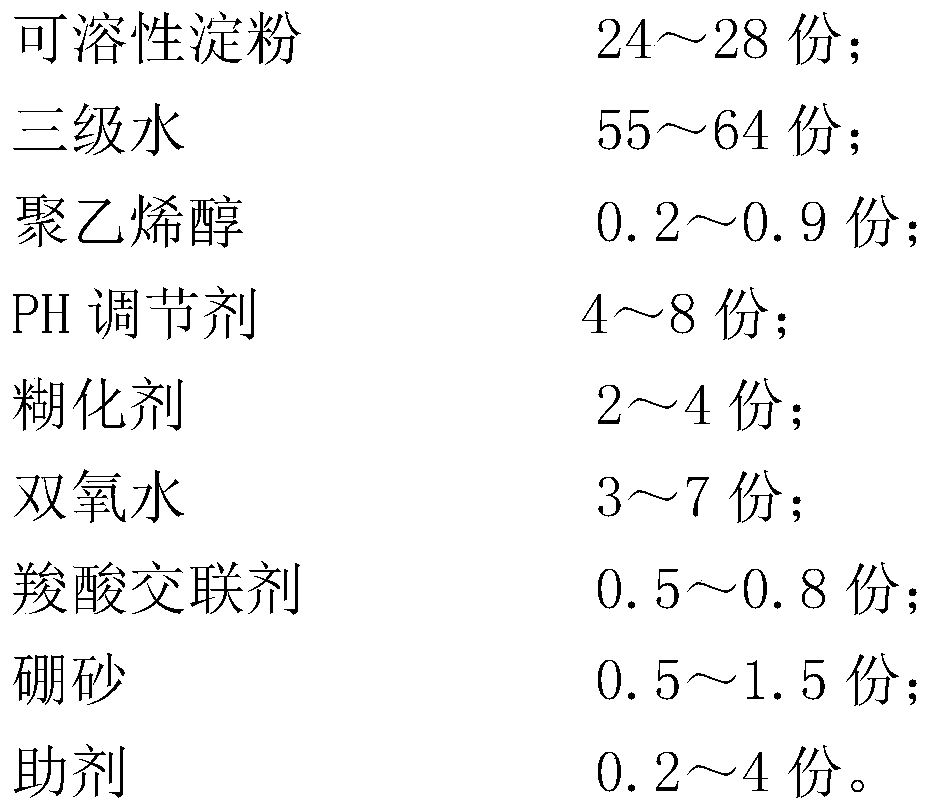

Environment-friendly, high-viscosity and weather-resistant modified starch adhesive and preparation method thereof

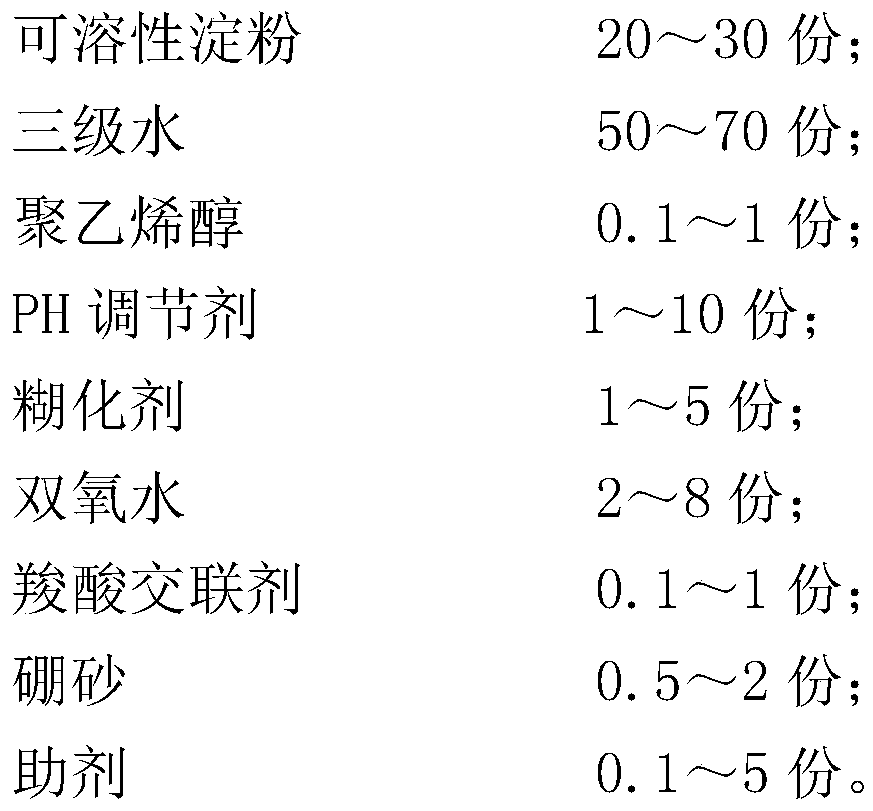

InactiveCN110551462AHigh temperature resistantStable network structureStarch derivtive adhesivesMacromolecular adhesive additivesPolyvinyl alcoholAdhesive

The invention discloses an environment-friendly, high-viscosity and weather-resistant modified starch adhesive and a preparation method thereof.The environmentally friendly, high-viscosity and weather-resistant modified starch adhesive is prepared from the following components in parts by weight: 20 to 30 parts of soluble starch, 50 to 70 parts of tertiary water; 0.1 to 1 part of vinyl alcohol, 1to 10 parts of a PH regulator, 1 to 5 parts of a gelatinizer, 2 to 8 parts of hydrogen peroxide, 0.1 to 1 part of a carboxylic acid crosslinking agent, 0.5 to 2 parts of borax and 0.1 to 5 parts of anadditives. According to the environmentally friendly, high-viscosity and weather-resistant modified starch adhesive, the polyvinyl alcohol, the starch and the tertiary water are mixed, then the hydrogen peroxide is added in an alkaline environment for oxidization to destroy the hydrogen bond of the starch for modification, the carboxylic acid crosslinking agent is added to form a stable network structure,and then gelatinization, complexationand dispersion are conducted to prepare the environment-friendly and highly-viscosity modified starch adhesive with the abilities to withstand high temperature and high humidity, low temperature and high and low temperature cycling impact.

Owner:永发印务(东莞)有限公司

Formula of composite coating

The invention discloses a formula of a composite coating. The formula of the composite coating comprises the following components in percentage by weight: 37-44% of epoxy resin, 12-15% of water-based acrylic emulsion, 8-11% of a curing agent, 3-5% of an auxiliary, 5-6% of a flattening agent, 6-15% of an optical brightener, 4-5% of titanium dioxide, 1% of master batch, 3-5% of a power increasing agent, 2-4% of an antioxidant, 2% of a mildew preventive and 2% of silicon carbide, based on 100% in total. The formula has the advantages of good covering performance and low cost.

Owner:袁传江

Alkyd resin coating

The invention discloses an alkyd resin paint, which comprises the following components by weight: 22-32 parts of C5-9 synthetic fatty acid, 30-35 parts of tung oil, 8-12 parts of rosin maleate, and pentaerythritol 14-18 parts, phthalic anhydride 11-15 parts, xylene 45-65 parts and turpentine 40-45 parts. The alkyd resin paint of the present invention has excellent adhesion, excellent impact resistance, surface hardness, toughness, adhesion and other mechanical properties, and can be used for steel bars, water pipes, valves, steel cylinders, agricultural machinery, automobile parts and building steel structures. Surface spraying. The invention is suitable for spraying by the method of high-voltage electrostatic spraying.

Owner:唐咸俊

Stage feedback loudspeaker box

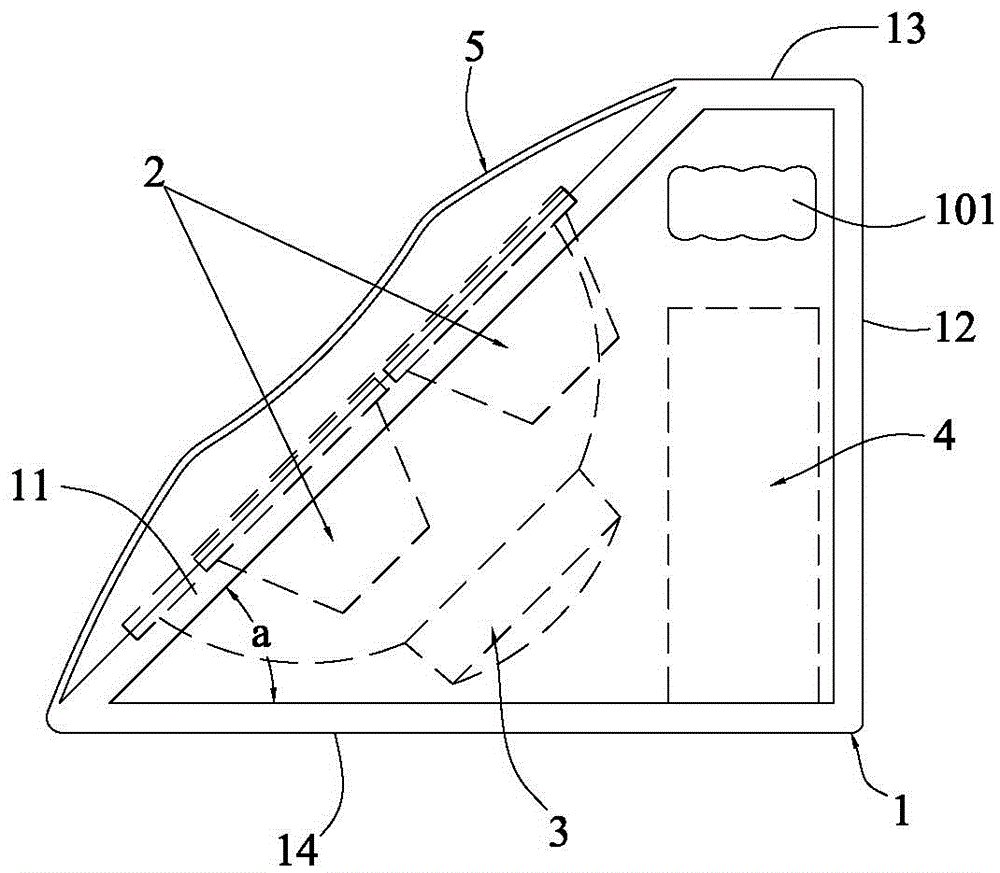

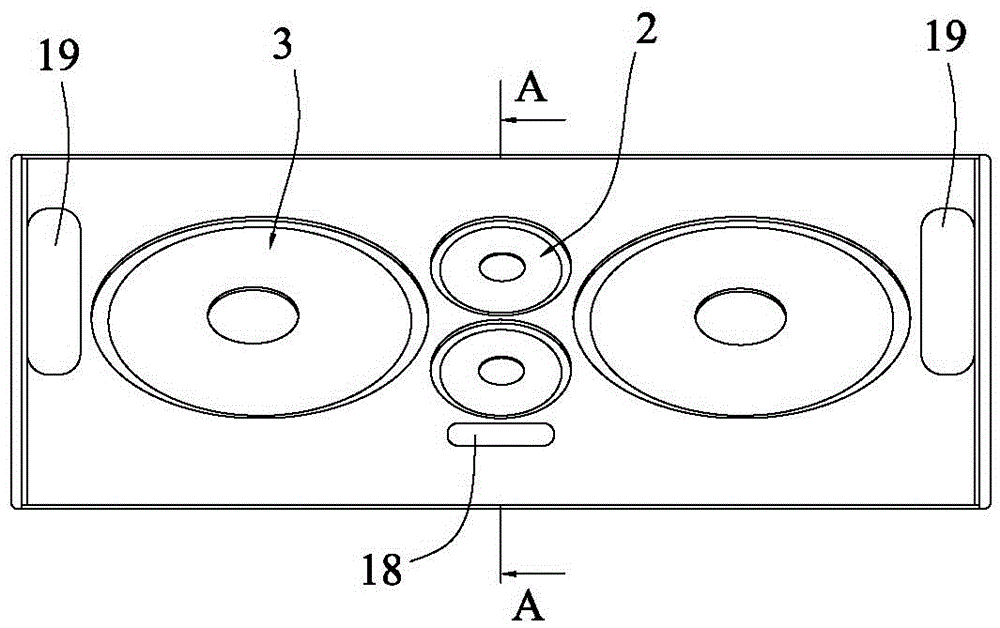

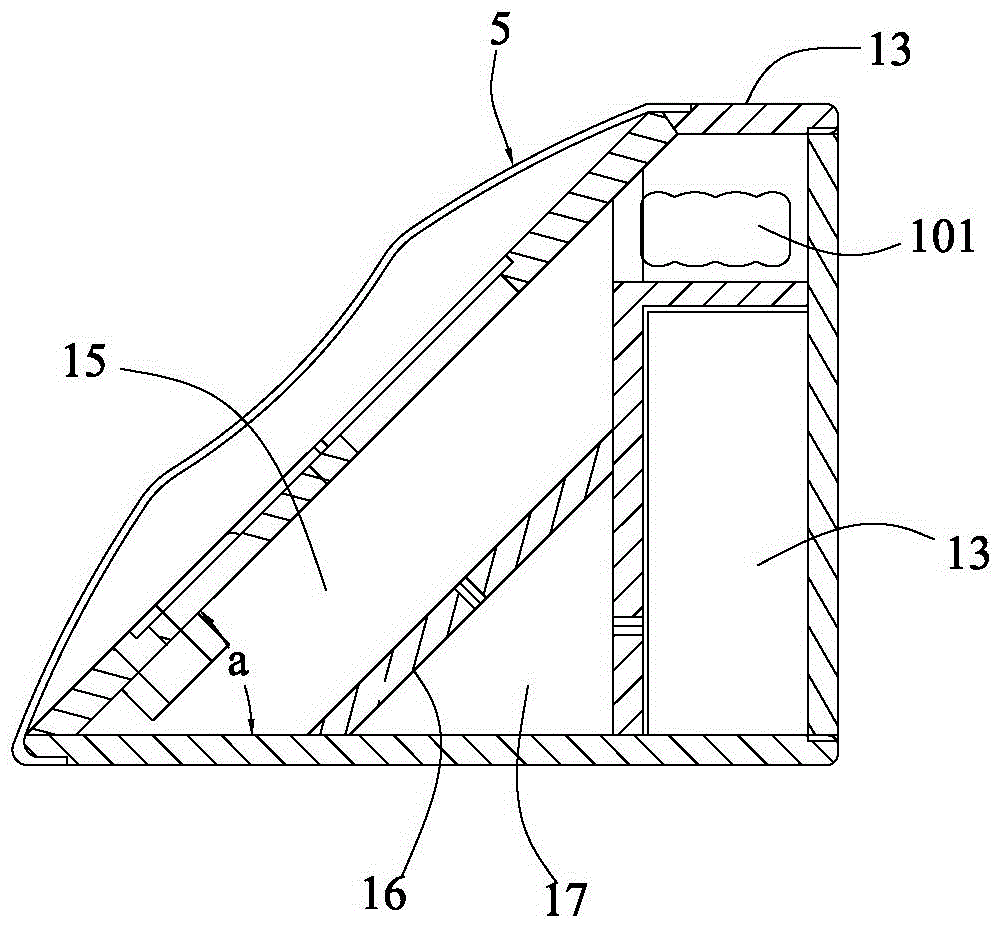

ActiveCN105681957ASmall standing waveEasy to sitFrequency/directions obtaining arrangementsMiddle frequencyEngineering

The invention discloses a stage feedback loudspeaker box. The stage feedback loudspeaker box comprises a box body, wherein the contour of the cross section of the box body is shaped like a right trapezoid; two mid-range loudspeakers and two coaxial loudspeakers are arranged on an inclined panel of the box body; a sound amplifying module is arranged on a vertical back plate; the inclination angle of the inclined panel is between 40 degrees and 50 degrees; the width of a top flat plate is between 3cm and 30cm. The stage feedback loudspeaker box provided by the invention has the advantages that the box body adopts an irregular structural design, so that standing waves in the box body can be reduced, and the tone is cleaner; with the top flat plate, a singer can conveniently sit or place his / her feet on the box body, so that the interactivity with the audience is effectively enhanced; the inclined panel is arranged at an angle of 40 degrees to 50 degrees, so as to effectively ensure that the sound axis can be directly oriented to the ears of the singer, and achieve good radiation effects; the two coaxial loudspeakers and the two mid-range loudspeakers not only achieve a large volume, good layering effects and high appealingness, but also achieve an ampler frequency allocation of the loudspeaker box, smooth cohesion among high-frequency tones, middle-frequency tones and low-frequency tones, and a wide sound field, so that the overall tone quality is improved.

Owner:DONGGUAN DONGYUAN AUDIO LIGHTING ENG LTD

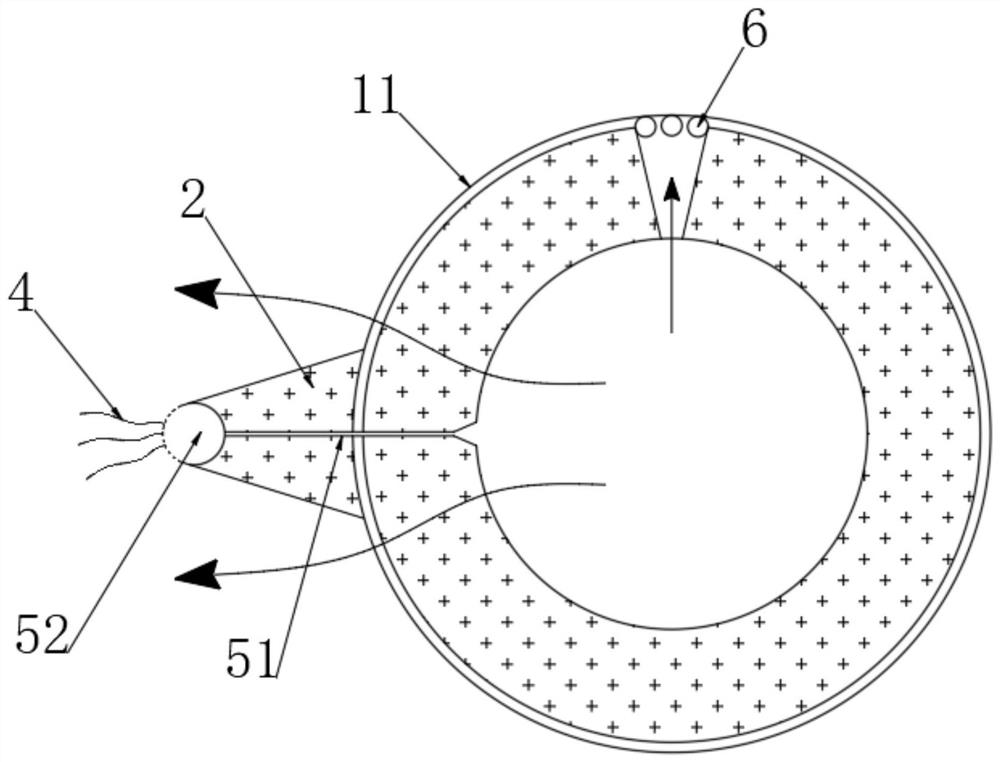

Tesla micro-channel throttling type air bearing

The invention discloses a Tesla micro-channel throttling type air bearing. The Tesla micro-channel throttling type air bearing comprises a piston sleeve, a piston and a valve assembly, the piston sleeve and the piston are connected in an interference fit mode, the piston and the valve assembly are fixed through a straight screw, high-pressure air storage cavities are formed between the outer wall face of the piston and the inner wall face of the piston sleeve, Tesla micro-channels are distributed in the circumferential direction of the piston, the Tesla micro-channels are in a Y shape, and the Tesla micro-channels comprise a straight channel, an arc channel and an inclined channel. The Tesla micro-channel throttling type air bearing has the following advantages that a adopted Tesla micro-channel throttler has the advantage that local resistance and on-way resistance are in direct proportion to n times of the flow velocity, so that the area of flow passing through the Tesla micro-channel throttler can be much larger than that of a common capillary throttler, however, the resistance effect is much more obvious than that of an accurate throttler composed of a glass capillary tube with the length of 10 mm and the diameter of 60 micrometers, and the machining difficulty is greatly reduced.

Owner:南通智能感知研究院

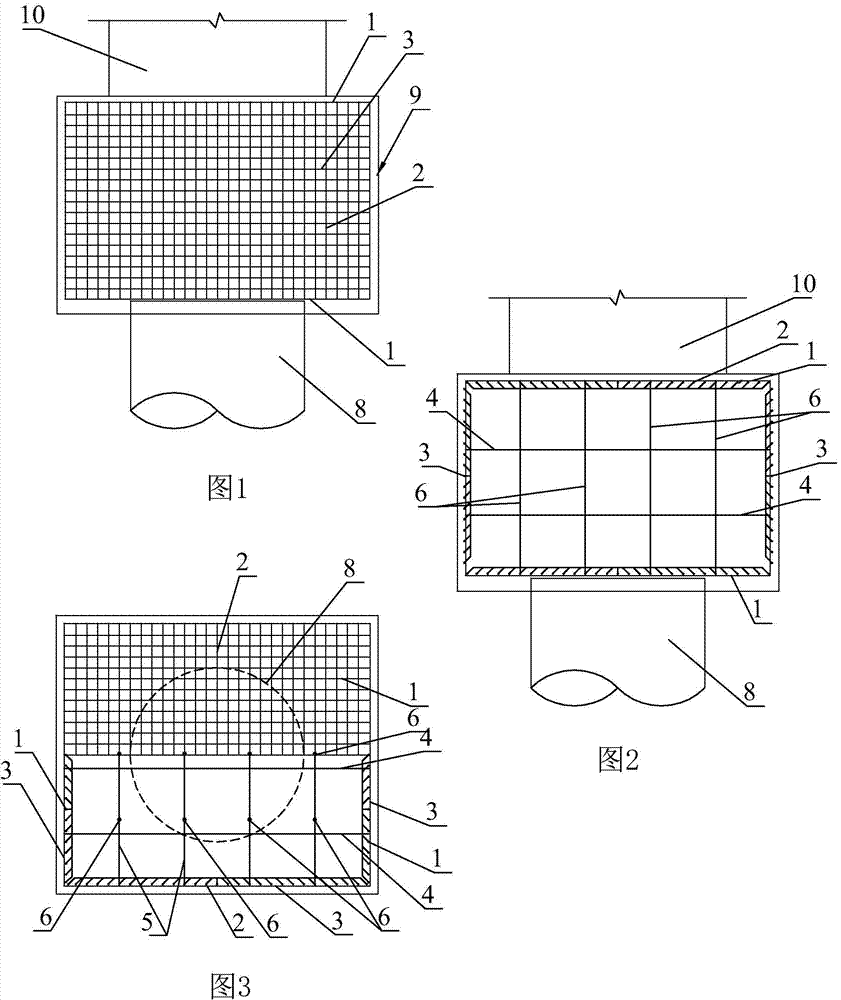

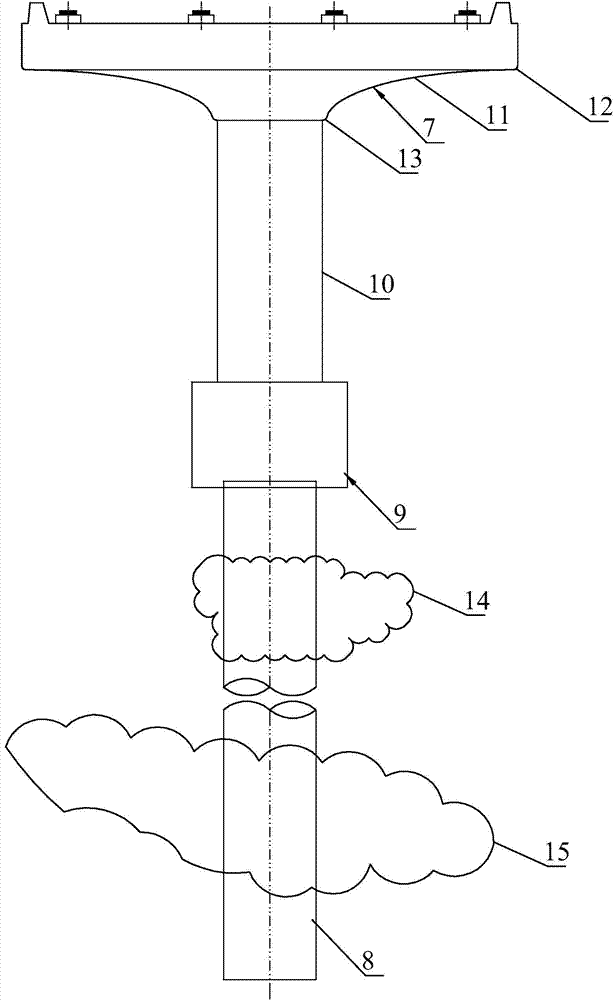

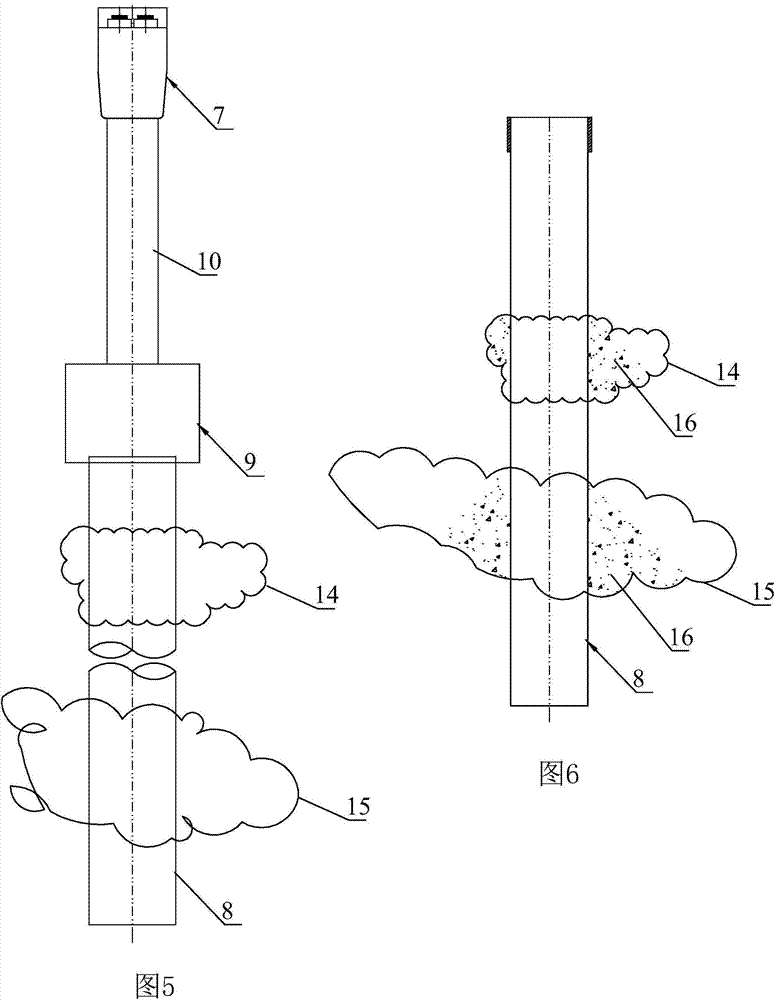

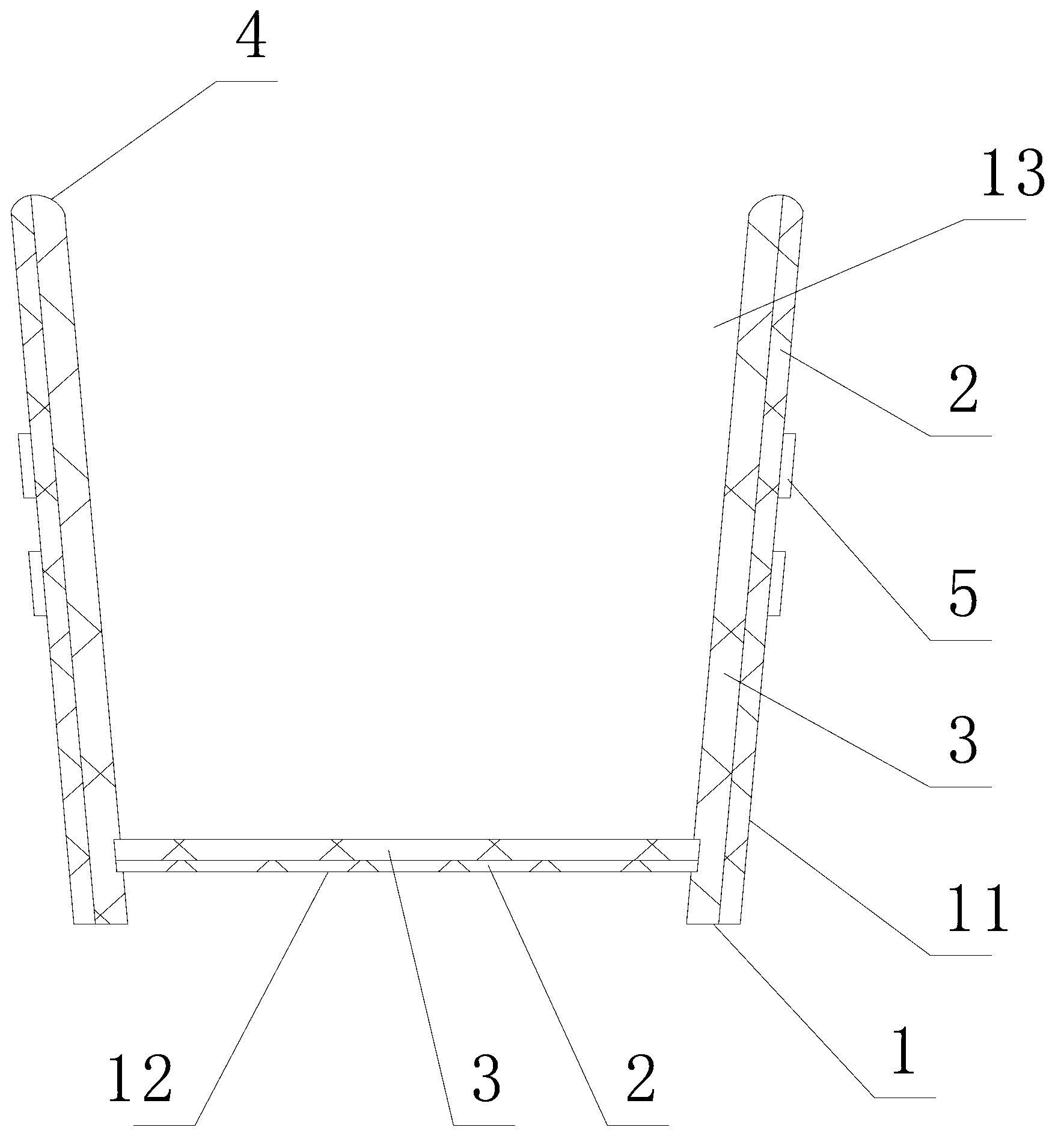

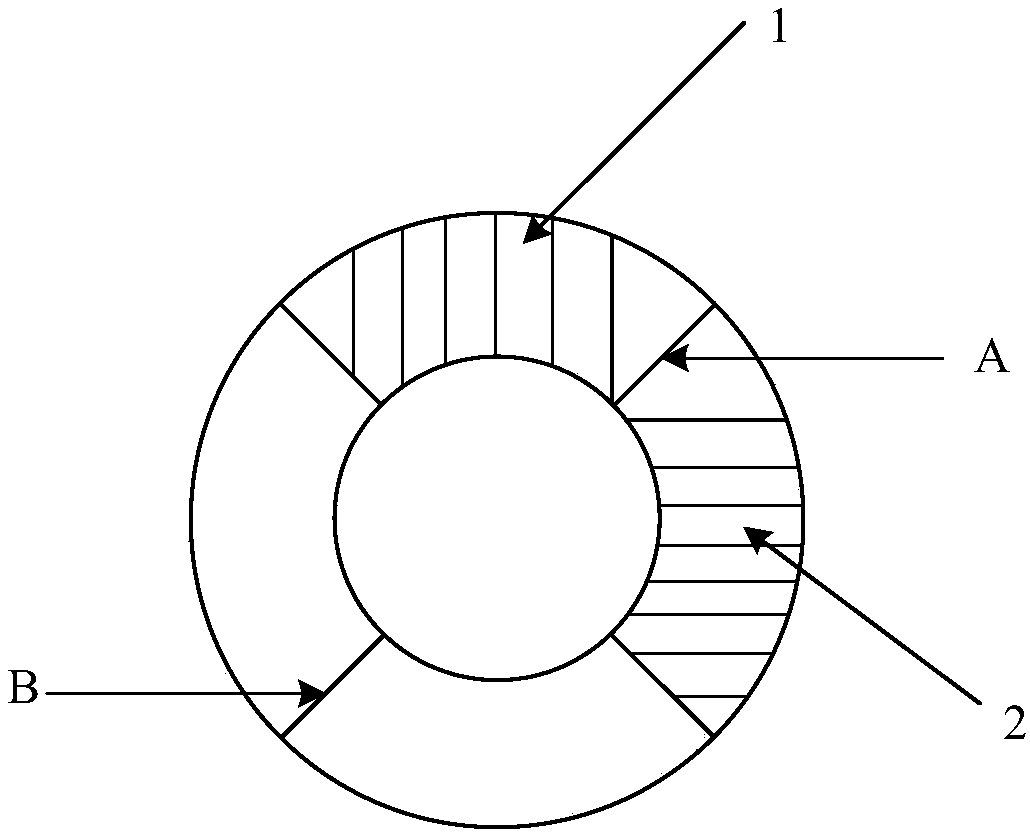

Key-joint bearing platform and landscape pier comprising same and being used for karst geology

InactiveCN103866686AImprove triaxial stress strengthHigh strengthBridge structural detailsHoopingKarst

The invention discloses a key-joint bearing platform and a landscape pier comprising the same and being used for karst geology. The key-joint bearing platform comprises concrete and a cage-shaped frame, wherein the concrete is poured into the cage-shaped frame; the cage-shaped frame mainly comprises a group of horizontal ring-shaped stirrups and two groups of vertical ring-shaped stirrups which are mutually vertical and are sheathed and hooped mutually in a two-two manner; all the horizontal ring-shaped stirrups are distributed in parallel and in the vertical direction, while all the vertical ring-shaped stirrups are arranged distributed in parallel and in the horizontal direction. The key-joint bearing platform and the landscape pier disclosed by the invention have the advantages that the stirrups in the three directions are nested and sheathed to tightly encircle the concrete inside and form a cage-body sheathing and hooping effect, so that the three-dimensional stress intensity of the concrete is increased and further the core strength of the concrete is improved compared with concrete in a single-direction stress state; three-dimensional orthogonal-stressing closed stirrups form a space-isotropic-orthogonal closed stressing system, so that the smooth transferring of complex stress flow of pulling, pressing, bending, shearing and twisting from an upper structure of a cross joint to a lower structure is realized.

Owner:GUANGDONG PROVINCE COMM PLANNING & DESIGN INST

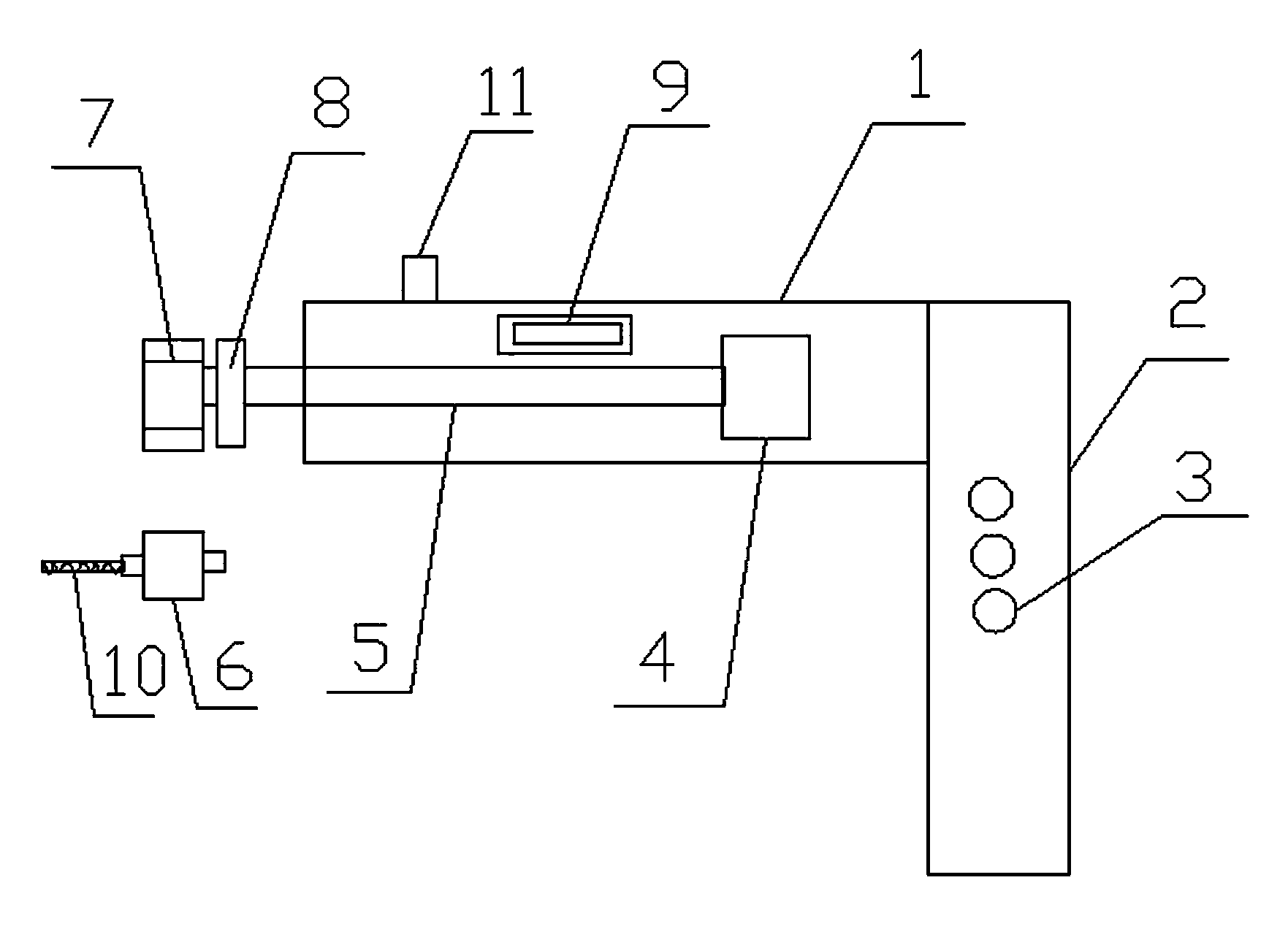

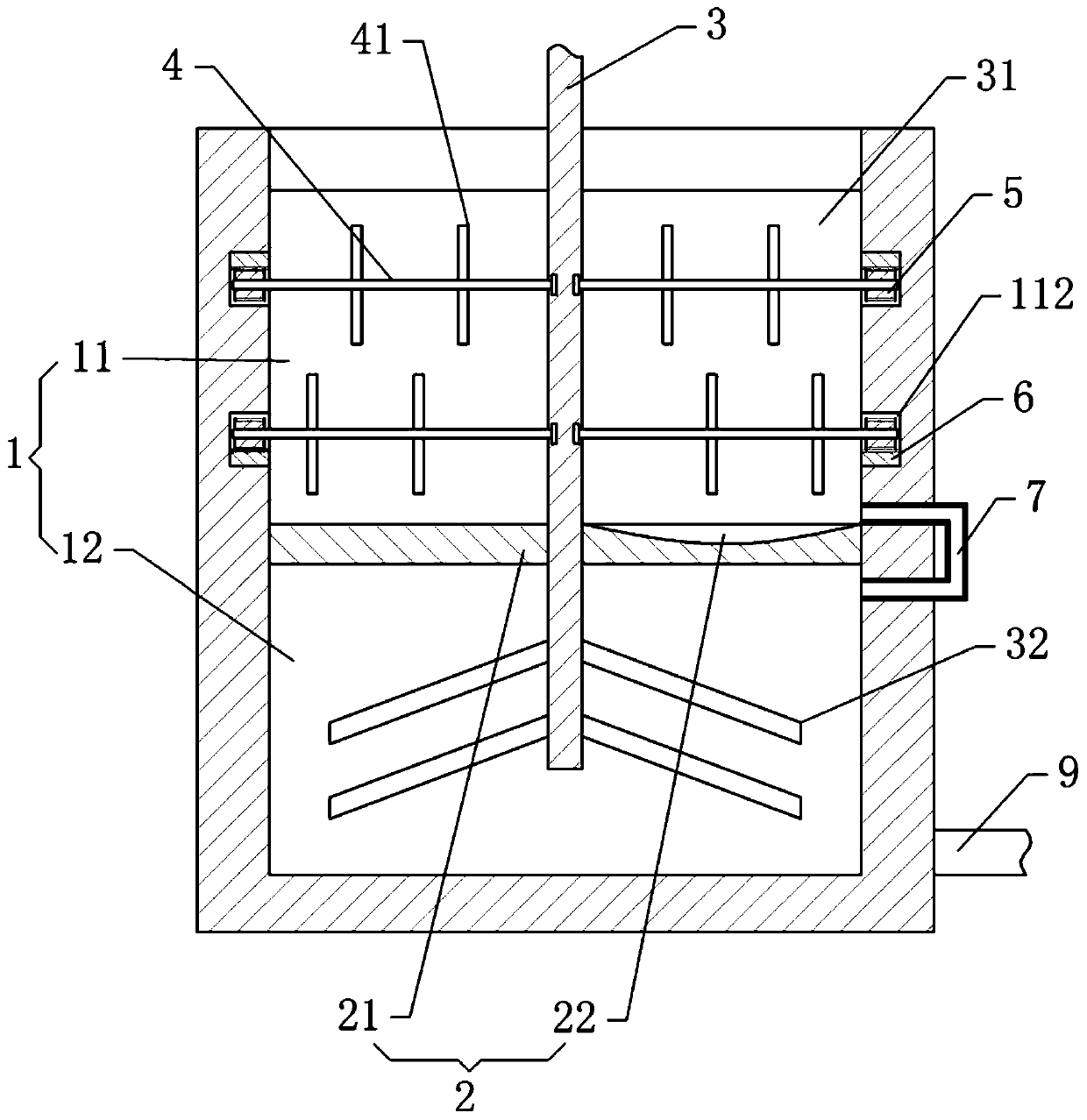

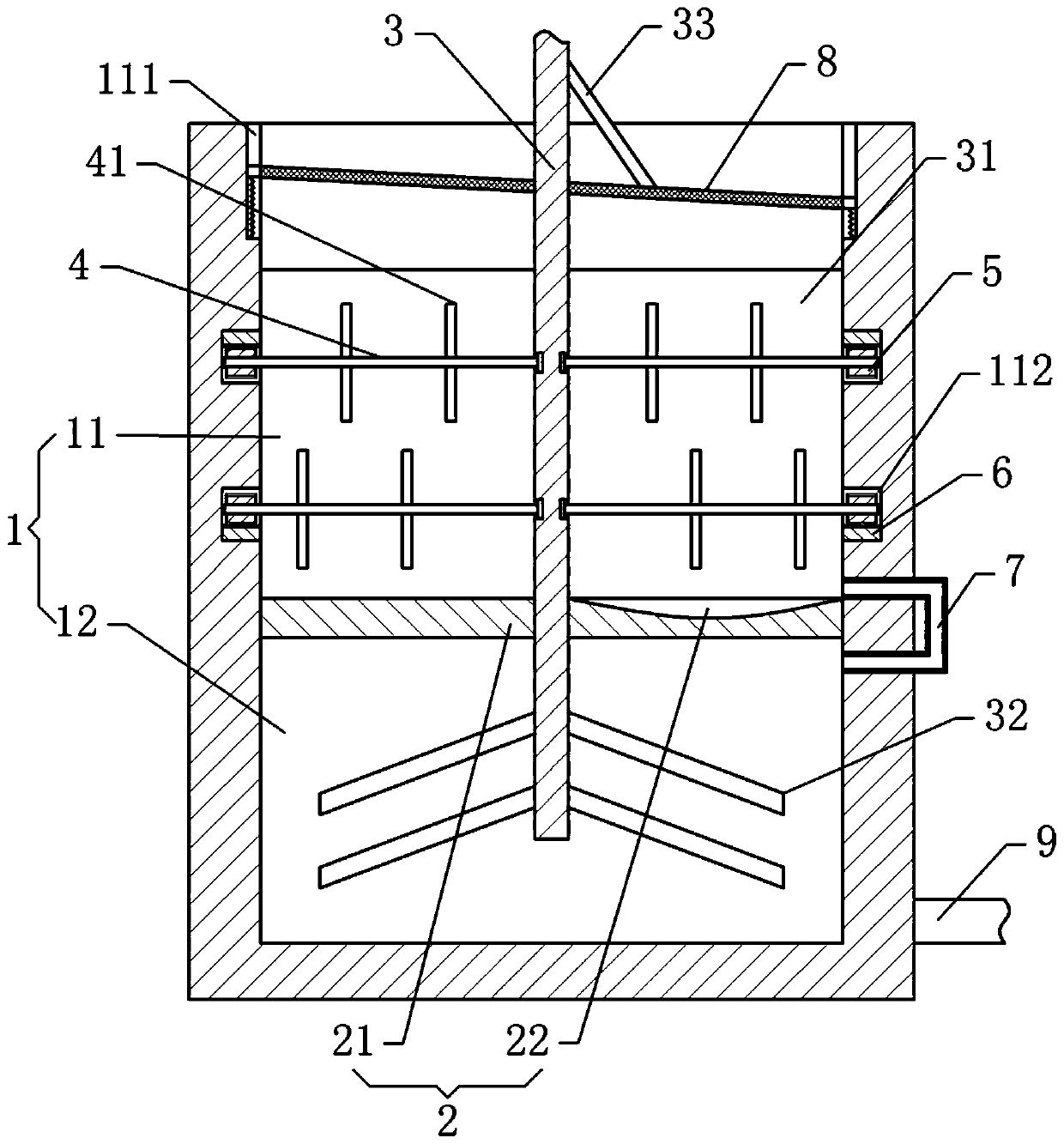

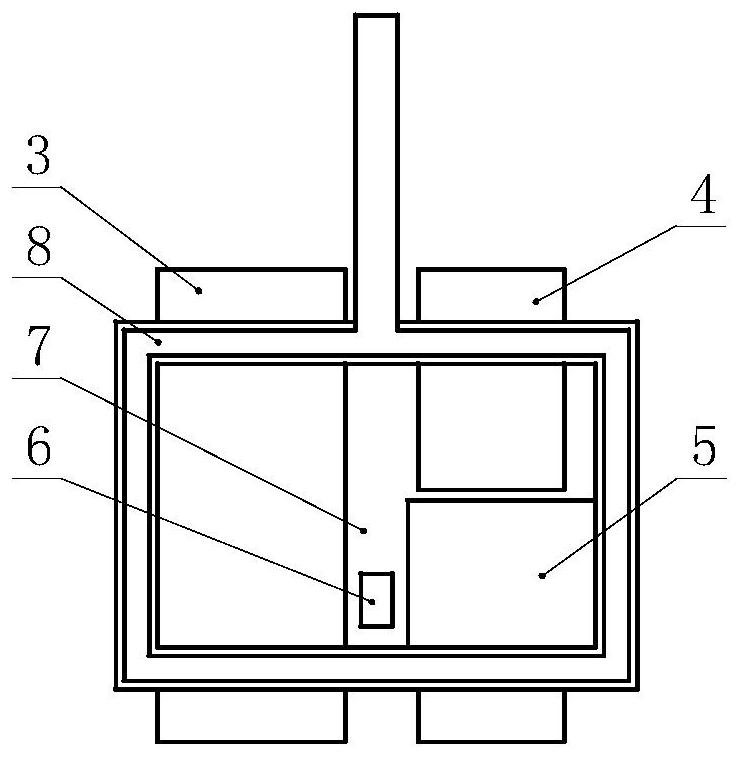

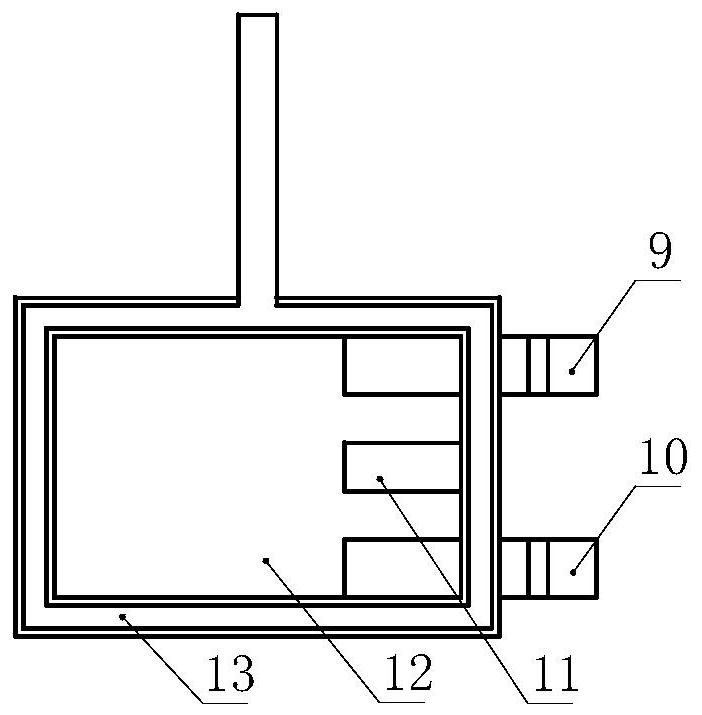

Gypsum preparation device for orthopedic treatment

InactiveCN110861212AAchieving stirringAchieve hybridRotary stirring mixersMixing operation control apparatusSurface toothOrthopedic department

The invention belongs to the technical field of medical mixing equipment provided with a rotating container and discloses a gypsum preparation device for orthopedic treatment. The gypsum preparation device comprises a mixing drum and a rotating shaft rotationally connected to inside of the mixing drum, multiple stirring pieces are arranged on the rotating shaft, a feed delivery pipe communicates with the mixing drum, stirring shafts, located between the adjacent stirring pieces, are rotationally connected onto the rotating shaft and vertical to the rotating shaft; and ring-shaped mounting grooves are formed in the inner wall of the mixing drum and coaxial with the mixing drum, end surface tooth rings are mounted in the mounting grooves, and inner diameter of the end surface tooth rings isconsistent with that of the mixing drum; gears meshed with the end surface tooth rings are arranged at one ends, away from the rotating shaft, of the stirring shafts, and multiple stirring rods are arranged on the stirring shafts. According to the gypsum preparation device, the problem that mixing uniformity of gypsum powder and water is low when an existing device is utilized for mixing is solved.

Owner:THE FIRST AFFILIATED HOSPITAL OF ARMY MEDICAL UNIV

Cured epoxy resin powder coating material

InactiveCN108300132AImprove performanceLow costPowdery paintsEpoxy resin coatingsColloidal silicaAcetic acid

The invention discloses a cured epoxy resin powder coating material, which comprises, by weight, 110-120 parts of a bisphenol A type epoxy resin, 9-12 parts of phenyl glycidyl ether, 1-4 parts of ethylenediaminetetraacetic acid, 40-60 parts of aromatic hydrocarbon modified polyamine, 90-110 parts of talc powder, and 1-5 parts of colloidal silica, wherein the bisphenol A type epoxy resin has the epoxy equivalent of 180-190. According to the present invention, the cost of the cured epoxy resin powder coating material prepared according to the formula is reduced compared to the coating material in the prior art, the whole film layer is stable after the product is subjected to spray molding, and the good use prospect is provided.

Owner:袁传江

Paint formula with good paintability

The invention discloses a paint formula with good paintability. The paint formula comprises, by weight, 28-38% of high-chlorinated polyethylene resin, 18-21% of curing agents, 3% of auxiliaries, 3% of flatting agents, 10-15% of barium sulfate, 2% of sensitizers, 5-6% of titanium dioxide, 2% of color master, 3% of electric power increase agents, 5-6% of thickening agents, 6-12% of mildew preventives and 2% of silicon carbide, and the weight sum of the components is equal to 100%. The paint formula has the advantages of good covering performance and low cost.

Owner:袁传江

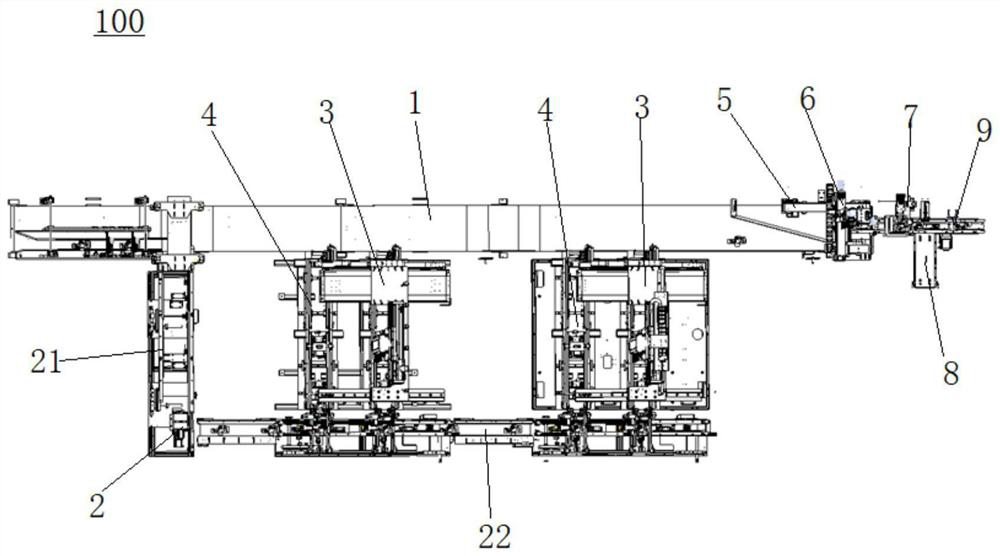

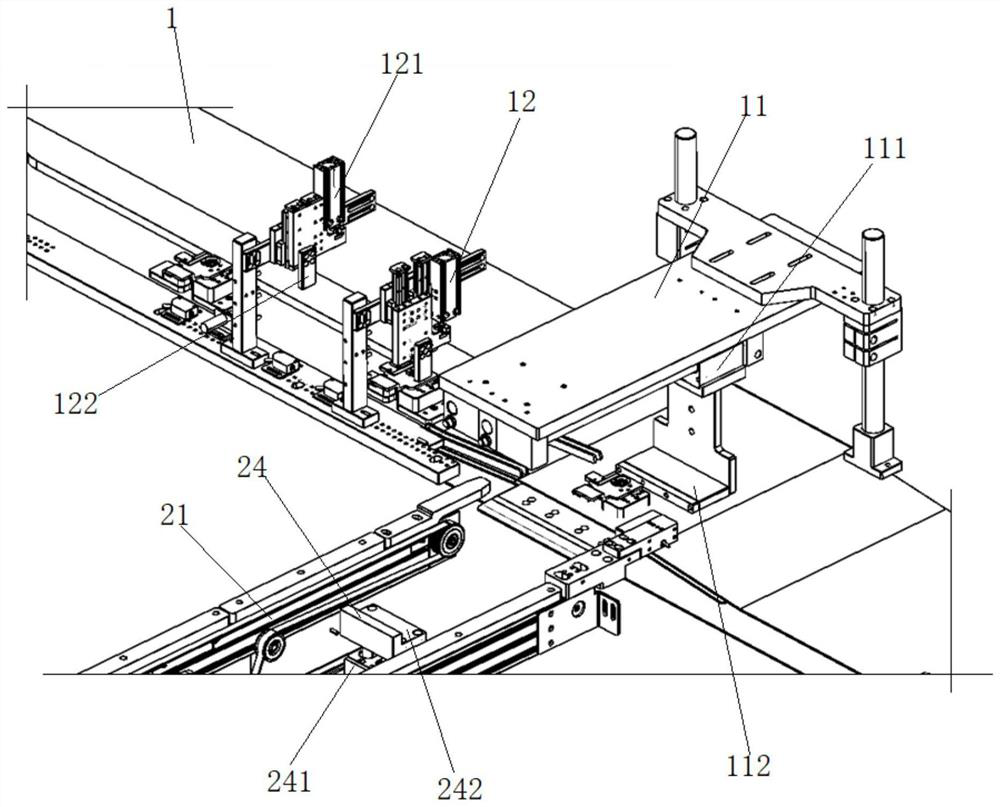

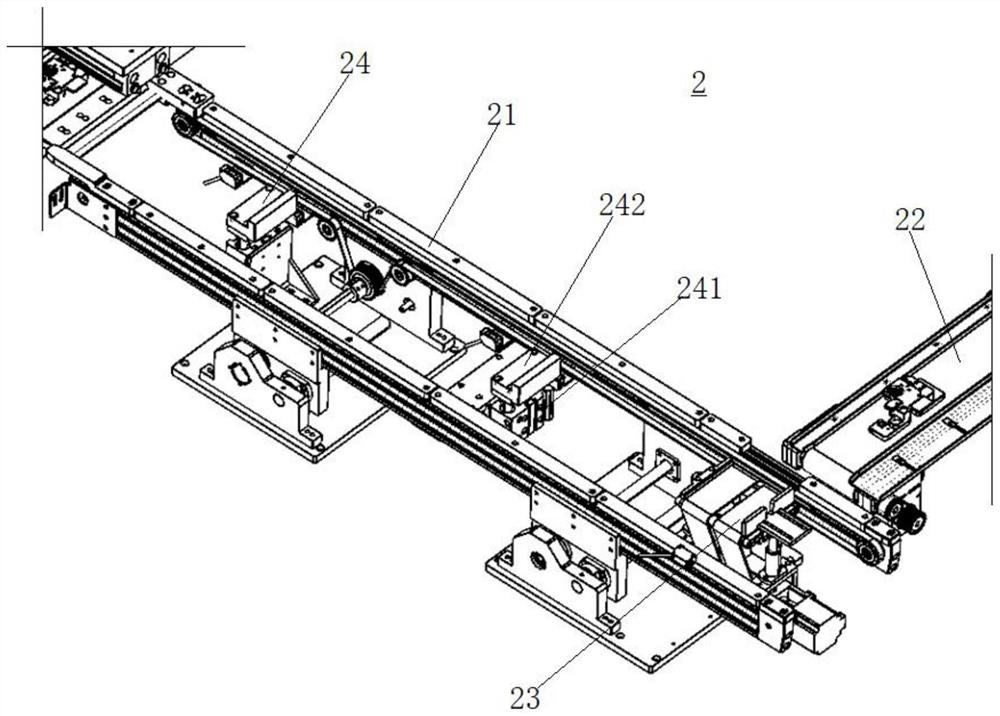

Detection production line for full-automatic welding of loudspeaker based on fused tin soldering and AI visual detection

PendingCN113325002ARealize fully automatic feedingImprove reliabilityOptically investigating flaws/contaminationSortingProduction lineSolder ball

The invention discloses a detection production line for full-automatic welding of a loudspeaker based on fused tin soldering and AI visual detection. The detection production line comprises a main assembly line, a welding feed conveying line vertically butted with the main assembly line and integrally distributed in an L shape, welding units arranged along the main assembly line, a welding in-out conveying line having one end vertically butted with the welding feed conveying line and the other end vertically butted with the main assembly line and flowing through the welding units, a carrying and clamping mechanism arranged above the tail end of the main assembly line and used for taking down a welding cover plate on a product and placing the welding cover plate on a cover plate backflow conveying line, an AI visual inspection unit used for carrying out welding spot detection on a product and a waste discharging mechanism. According to the invention, a welding purpose is achieved by spraying laser melting solder balls to the position of a bonding pad, and meanwhile, an AI deep learning model is matched for automatically detecting welding spots, so product welding and detection efficiency is greatly improved, the reliability of a welding spot detection result is improved, welding quality is improved, and product quality is guaranteed.

Owner:LUXSHARE ELECTRONICS TECH (KUNSHAN) LTD

Coating formula suitable for surface layer of refrigerator

InactiveCN106554698AImprove performanceLow costAnti-corrosive paintsEpoxy resin coatingsEpoxySurface layer

The invention discloses a coating formula suitable for a surface layer of a refrigerator. The coating formula comprises the following components in percentage by weight: 31-40% of epoxy resin, 15-19% of a curing agent, 6% of an auxiliary, 3% of a flatting agent, 10-15% of barium sulfate, 1% of an optical brightener, 5-6% of titanium dioxide, 1-2% of color master batch, 2% of a power increasing agent, 5-7% of an antioxidant, 7-12% of a fuel gas resisting agent and 1% of silicon carbide, based on 100% in total. The coating formula has the advantages of good covering performance and low cost.

Owner:袁传江

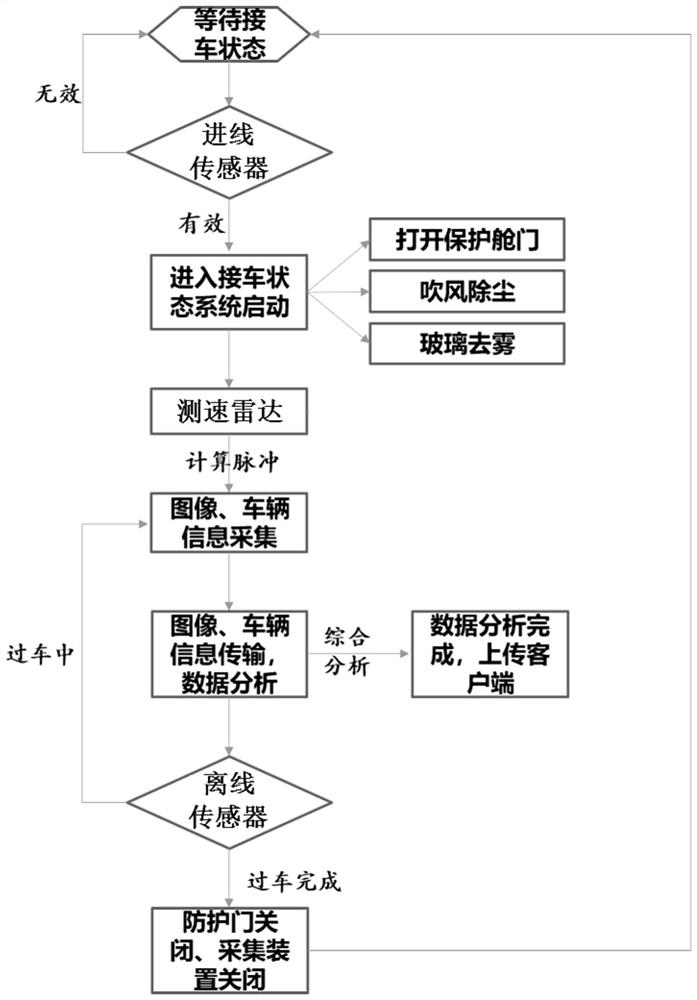

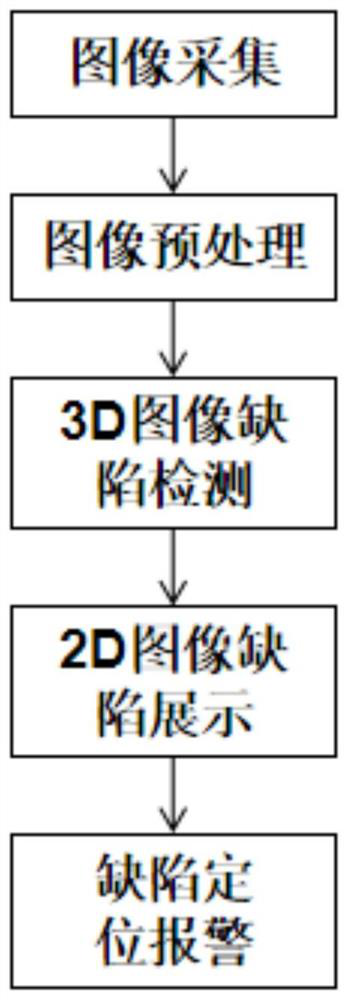

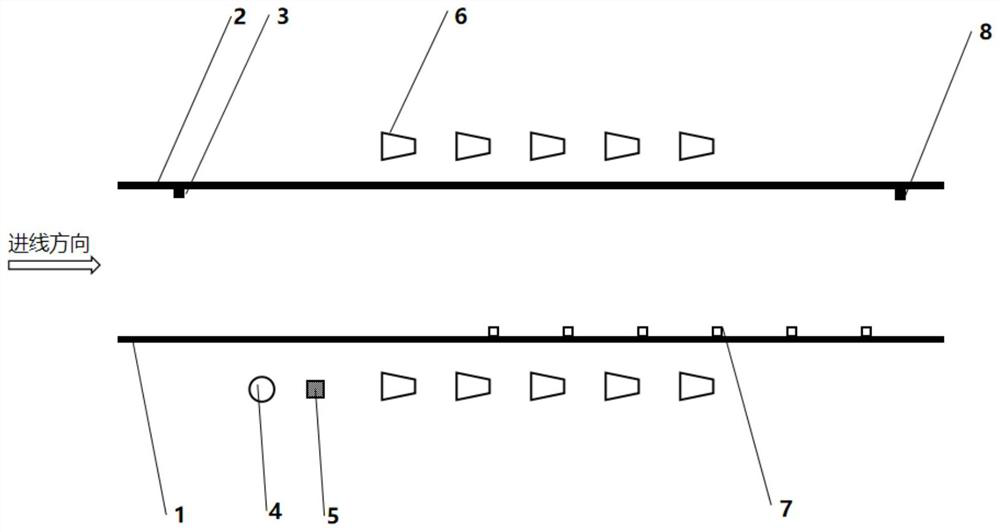

Railway vehicle wheel set tread 3D image detection method

The invention discloses a rail vehicle wheel set tread 3D image detection method, which comprises the following steps: (1) when a train approaches an incoming line sensor, acquiring a train incoming line signal, and entering a train receiving state; the speed measurement radar obtains the real-time passing speed of the train, the train number recognition mechanism obtains the number of the passing train, and the positioning device obtains the position of each wheel and starts the corresponding tread image acquisition equipment to acquire a wheel tread image; acquiring and combining each wheel on a single side through a plurality of pairs of tread image acquisition devices so as to obtain a wheel tread image covering a complete tread, and matching the acquired wheel tread image information with a vehicle number; and (2) processing the acquired image to form a 2D image of the wheel tread and a 3D image of a corresponding area, and analyzing and calculating the 3D image data to obtain the rim thickness, the Qr value and tread wear information. According to the invention, through coordination work of multiple groups of tread image acquisition devices, non-stop on-line real-time detection of the full-circumference tread of the wheel is realized.

Owner:NANJING TYCHO INFORMATION TECH

High impact polystyrene cup

ActiveCN103253461AGuaranteed low temperature resistanceGuaranteed impact performanceSynthetic resin layered productsPackaging ice-creamMechanical engineeringHigh impact polystyrene

The invention relates to a high impact polystyrene cup which comprises a cup body. A low-temperature-resistant layer is arranged on the outer side of the cup body. An anti-cracking layer is arranged on the inner side of the cup body. The low-temperature-resistant layer and the anti-cracking layer form the cup wall and the cup bottom of the cup body in a composite mode. The percentage of the thickness of the low-temperature-resistant layer and the thickness of the anti-cracking layer is 1:20-1:10. The cup wall forms a placing cavity in a surrounding mode along the side wall of the cup bottom. The low-temperature-resistant layer is made of GPPS. The anti-cracking layer is made of HIPS and SBS. The percentage of the mass of the HIPS and the mass of the SBS is 9:1-8:1. The high impact polystyrene cup has the advantages that the anti-cracking layer is made of the HIPS and the SBS by reasonable matching, the low-temperature-resistant layer is arranged on the outer side of the anti-cracking layer in a composite mode, so that the fact that the cup body has low-temperature-resistant performance is guaranteed, the cup body has anti-impact performance, the fact that the cup body is not broken under impact of external force is guaranteed, breaking rate is lowered, and service life is prolonged.

Owner:JIAXING YANDANG PACKAGING

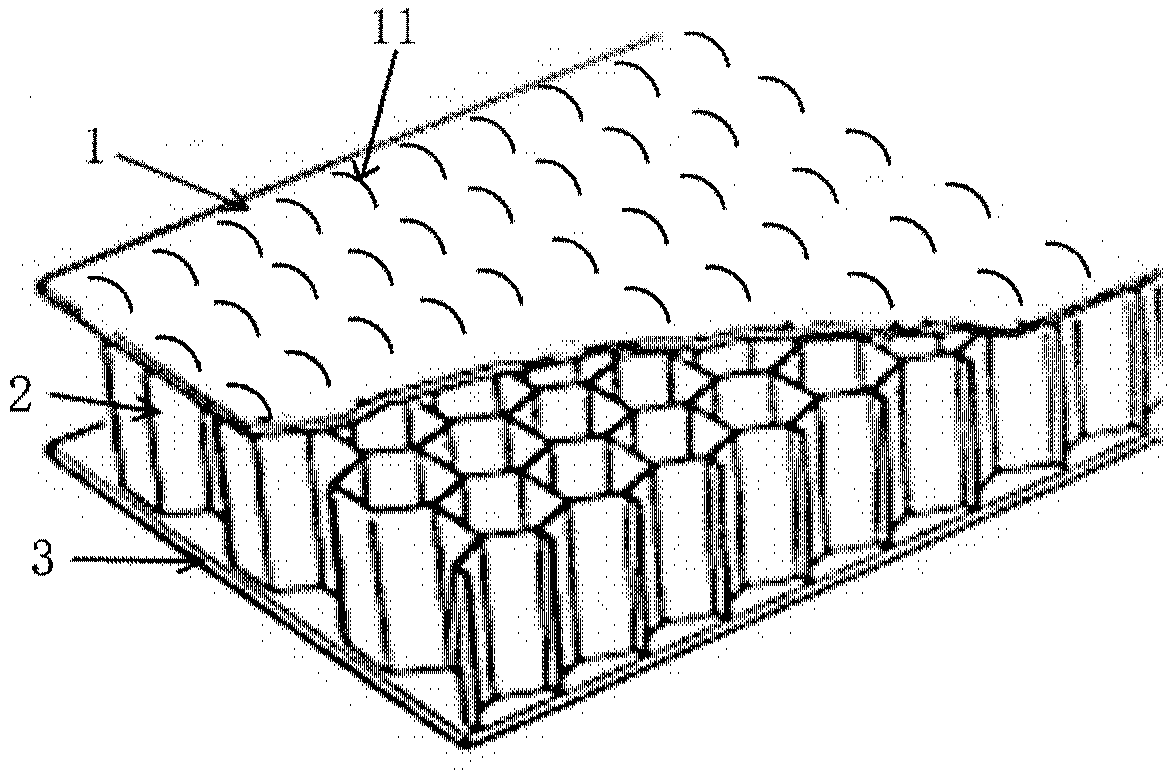

Brazed honeycomb sound absorbing structure with micro-seam

PendingCN109272980AMeet the needs of useImprove sound absorptionSound producing devicesMetal layered productsHoneycombUltimate tensile strength

A brazed microseam honeycomb sound absorbing structure is disclosed, which comprises a first panel, a second panel, and a core layer positioned between the first panel and the second panel. The firstpanel is a micro-slit plate and the core layer is a honeycomb core layer; the first panel, the second panel and the honeycomb core layer are brazed. The braze type micro-seam honeycomb sound absorbingstructure is arranged through the micro-seam plate and the core layer, the structural strength is improved, the sound absorbing effect is improved, and the use requirements of different environmentsare met.

Owner:中国船舶重工集团公司第七一四研究所 +1

Technique for producing small-size complex inner cavity titanium alloy casting by utilizing metal core

PendingCN112676534AGood effectGuaranteed dimensional accuracyMolten spray coatingFoundry mouldsComposite ceramicSlurry coating

The invention discloses a technique for producing a small-size complex inner cavity titanium alloy casting by utilizing a metal core, and belongs to the technical field of titanium alloy investment precision casting processes. The technique solves technical problems that in an existing investment precision casting composite water-soluble core technique, when inner cavity size is small to a certain extent, slurry coating and drying cannot be achieved, and an existing technological method for investment precision casting composite ceramic core is not suitable for small-size complex flow channel structures and other products with a high sealing degree. According to the technique, a metal core is adopted to replace an existing water-soluble core and an existing ceramic core, core removal is achieved through a chemical method by means of the property difference between metal core material and titanium alloy, development and production of small-size complex inner cavity products are completed, and the product size precision and the product quality are guaranteed.

Owner:AEROSPACE HIWING HARBIN TITANIUM IND

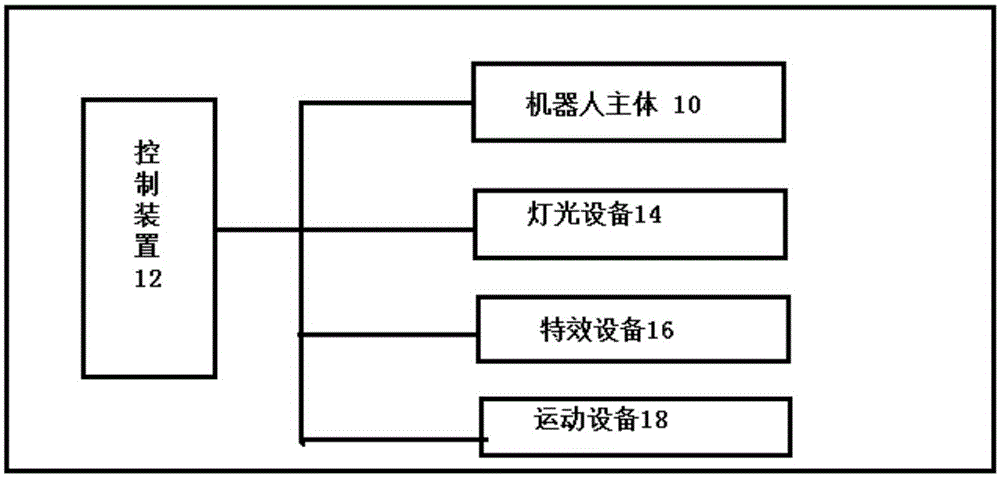

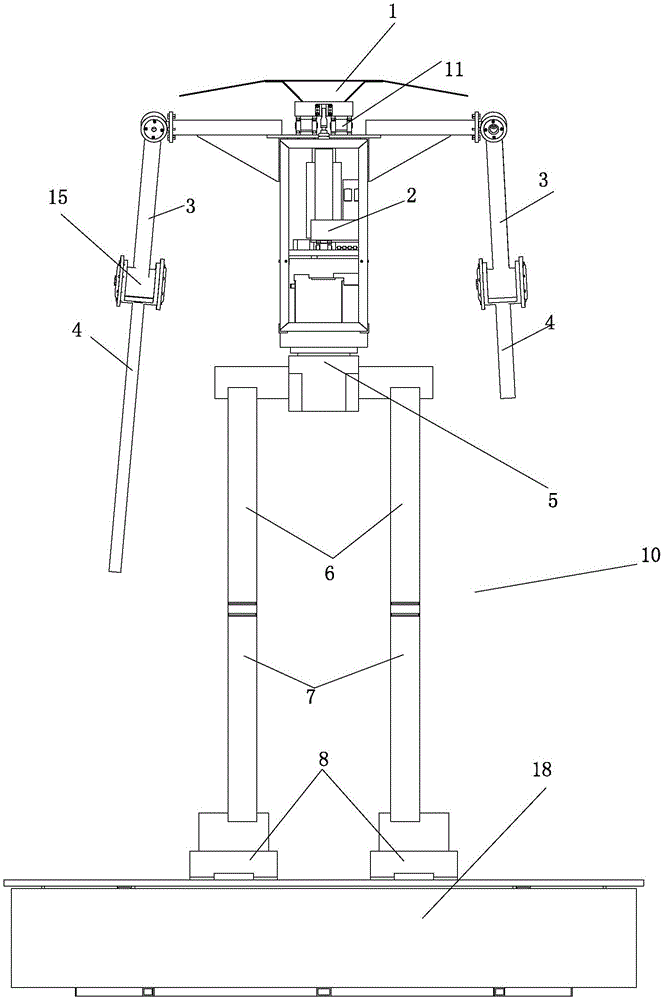

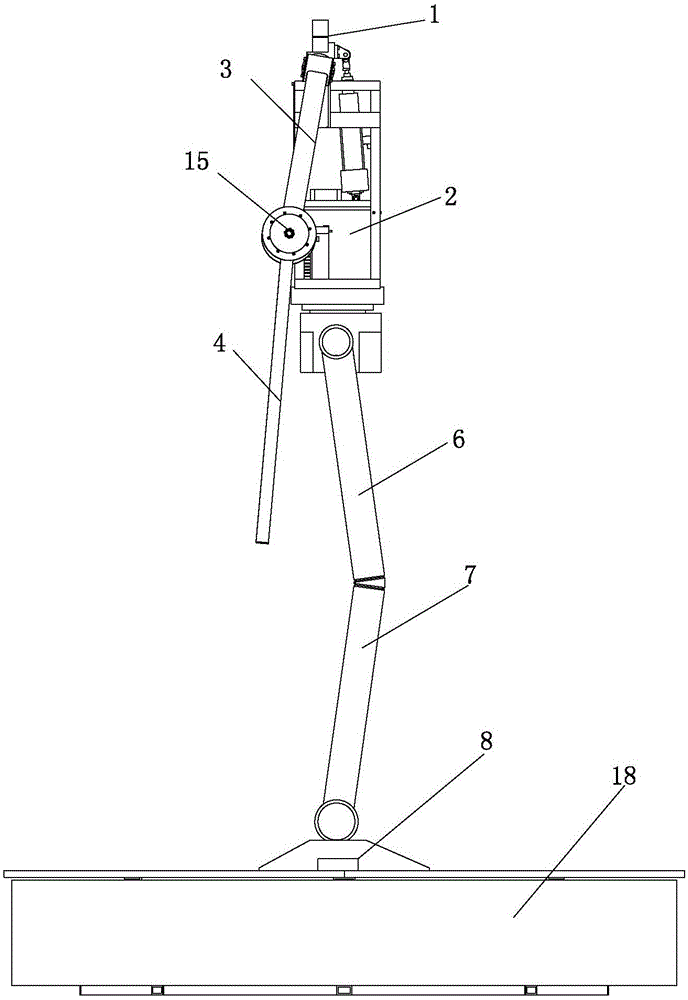

Novel stage performance robot

The invention discloses a novel stage performance robot, which comprises a robot main body, a control device, a lamp light device, a special effect device and a moving device, wherein the control device, a lamp light device and the special effect device are all arranged in the robot main body, and the moving device is arranged on the bottom end of the robot main body, and can drive the robot main body to displace and rotate in the horizontal direction and go up and down in the vertical direction by being controlled by the control device. The novel stage performance robot can combine actions, lamp light of a stage and special effects, thereby forming richer performance effect, perfectly meeting performance demands, and improving performance shock power.

Owner:WANDA CULTURAL TOURISM PLANNING & RES INST

Power coating formula

The invention discloses a powder coating formula. The powder coating formula comprises, by weight, 24-34% of polyester fibers, 14-15% of waterborne acrylic emulsion, 17-18% of curing agents, 3% of additives, 3% of flattening agents, 7-9% of barium sulfate, 5-6% of titanium dioxide, 2% of masterbatch, 3% of electricity increasing agents, 5-6% of antioxidants, and 6-12% of mould inhibitors, wherein the sum of the weight percentages of all the components is equal to 100%. The powder coating formula has the advantages of good covering performance and low cost.

Owner:袁传江

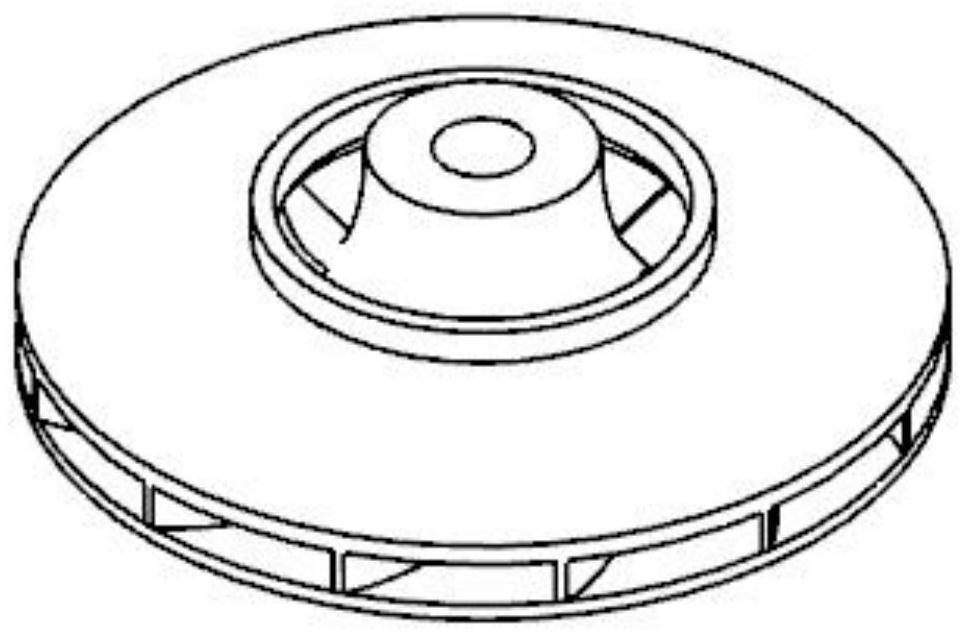

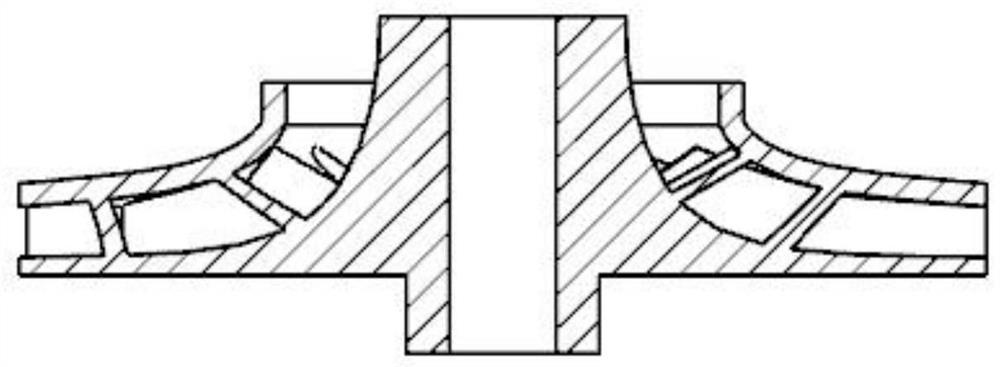

Ventilated round clutch rubber airbag and preparation method thereof

PendingCN109971155AHas super tear resistanceWith super wear resistanceHollow articlesVulcanizationLiquid water

The invention discloses a ventilated round clutch rubber airbag, which comprises the following raw materials in parts by weight: 15-25 parts of cis-butadiene rubber, 35-55 parts of urethane rubber, 15-25 parts of chloroprene rubber, 8-12 parts of zinc oxide, 2-3 parts of stearic acid, 3-5 parts of paraffin, 25-30 parts of carbon black N774, 1.5-2.5 parts of anti-aging agent A, 1.5-2.5 parts of anti-aging agent D, 0.5-1.5 parts of anti-aging agent 4010NA, 2.5-3.5 parts of graphene, 3-5 parts of petroleum pitch, 0.5-1.5 parts of accelerator M, 1.5-2.5 parts of accelerator TMTD, and 1.5-2.5 partsof sulfur. The preparation method comprises six process steps of rubber mixing, calender cutting, extrusion, molding, vulcanization and packaging. The vulcanization temperature, time and pressure areadjusted in the vulcanization process, thereby fundamentally solving the problem of labor consumption and time consumption. In addition, because liquid water is low in cost and can be recycled, the production cost of an enterprise can be significantly reduced.

Owner:HENAN DALIN RUBBER & TELECOMM APP

Automobile coating formula

The invention discloses an automobile coating formula. The coating comprises following components in parts by weight: 250-290 parts of methanol, 230-280 parts of paraformaldehyde, 3-6 parts of 20% caustic potash, 130-150 parts of a material named as Chinese characters 'Jiajiguaxuan' by the inventors, 5-7 parts of maleic acid, 70-80 parts of amino resin, 120-130 parts of titanium dioxide, 27-30 parts of water and 7-8 parts of a mixed solvent. The mixed solvent is formed by mixing a Solvay 100 solvent and a Solvay 150 solvent according to the ratio of 1:1. The automobile coating formula which isgood in physical property, good in covering effect and not liable to generate fine bubbles is provided.

Owner:江门市新会区创富香业有限公司

Formula of coating used for surface layer of refrigerator

The invention discloses a formula of a coating used for a surface layer of a refrigerator. The coating formula comprises the following components in percentage by weight: 10-15% of epoxy resin, 32-40% of polyester fiber, 11-18% of a thickening agent, 3-5% of an auxiliary, 5-6% of a leveling agent, 10-15% of barium sulfate, 4% of a luster-enhancing agent, 1% of color master batch, 3-5% of an electric power increasing agent, 4% of an anti-settling agent and 2% of silicon carbide. The coating disclosed by the invention has the advantages of good coverage performance and low cost.

Owner:袁传江

Micro-foam elastic polyurethane waterproof coating material

InactiveCN108300249AWith abrasion resistanceShockingPolyurea/polyurethane coatingsSpray coatingHigh activity

The invention discloses a micro-foam elastic polyurethane waterproof coating material, which comprises, by weight, 90-110 parts of high-activity mixed polyether, 20-30 parts of polyisocyanate, 2-4 parts of an antioxidant, 0.8-1.2 parts of a foam stabilizer, 75-110 parts of a filler, and 1-5 parts of water. According to the present invention, the cost of the micro-foam elastic polyurethane waterproof coating material prepared according to the formula is reduced compared to the existing coating material, the whole film layer is stable after the product is subjected to spray coating molding, andthe micro-foam elastic polyurethane waterproof coating material has good use prospect.

Owner:唐咸俊

Miniature ceramic shell

InactiveCN111613482AImprove insulation performanceImprove reliabilityElectromagnetic relay detailsAuxiliary electrodeComposite material

The invention discloses a miniature ceramic shell which comprises a ceramic base and a ceramic cap in airtight sealing fit with the ceramic base. The ceramic base and the ceramic cap are sealed to form a hollow structure, a first main electrode, a second main electrode, a first inner electrode area, a second inner electrode area, a base insulating cavity and a base sealing ring are arranged on theceramic base, and the ceramic cap is provided with a first auxiliary electrode, a second auxiliary electrode, a third inner electrode area, a cap insulation cavity and a cap sealing ring. According to the ceramic shell, the ceramic base and the ceramic cap form the hollow structure, and an upper-lower layer physical isolation structure is formed between the ceramic base and the ceramic cap, so that the insulation resistance and reliability of the shell are improved.

Owner:贵州振华群英电器有限公司(国营第八九一厂)

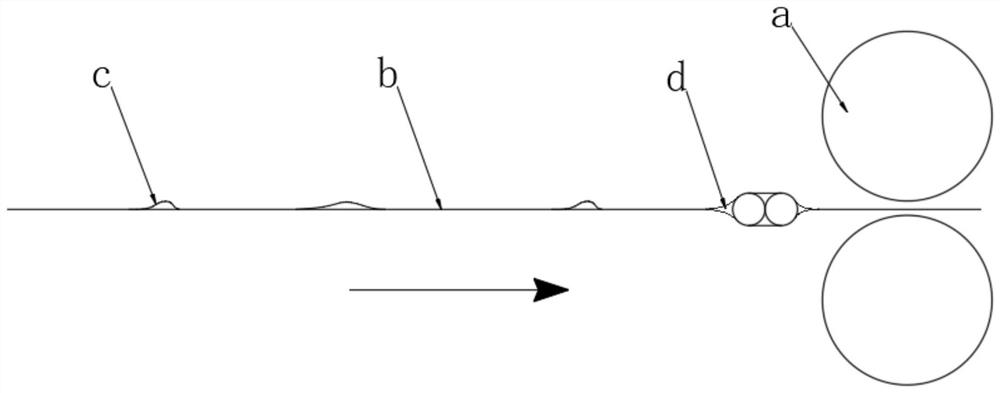

Double-layer composite aluminum film gas release type preparation process

InactiveCN113442546AImprove stabilityReduce bulgeLamination ancillary operationsLaminationGas releaseStatic electricity

The invention discloses a double-layer composite aluminum film gas release type preparation process, and belongs to the field of aluminum films. According to the double-layer composite aluminum film gas release type preparation process, through the arrangement of a two-way air cylinder, before a double-layer film is extruded, on one hand, gas is blown into the double-layer film, a gas release layer can be formed in the double-layer film, blowing force is generated on the overlapped double-layer films to force the double-layer films to be separated when the double-layer films are close to the blowing cylinder, so that the bulging part containing bubbles is integrated with other parts, the condition of individual bubble bulging is effectively reduced, then the double-layer films are integrated again in cooperation with air suction operation, the bubble amount in the double-layer films is remarkably reduced, the situation of being scraped because of bulging can be effectively avoided, and the quality of the finished products is significantly improved in comparison with the prior art. On one hand, the air blowing cylinder is bulged during air inflation, so that the fluff layer above the air blowing cylinder is in frictional contact with the upper-layer film to generate static electricity, the stability of the double-layer film which is overlapped again is effectively improved, and the quality of the composite aluminum film finished product is further improved.

Owner:律寅鹏

Vehicle coating material formula

The invention discloses a vehicle coating material formula, wherein the components comprise, by weight, 300-350 parts of methanol, 270-310 parts of paraformaldehyde, 1-3 parts of 20% caustic potash, 160-210 parts of Jiajiguaxuan, 1-4 parts of maleic acid, 40-60 parts of an amino resin, 90-110 parts of titanium dioxide, 10-26 parts of water, and 4-6 parts of a mixed solvent, wherein the mixed solvent is formed by mixing a Solvay 100 solvent and a Solvay 150 solvent according to a ratio of 1:1. According to the present invention, the vehicle coating material has advantages of extremely excellentadhesion, excellent impact resistance, excellent surface hardness, excellent toughness, excellent adhesion and other excellent mechanical properties, and can meet the vehicle production standard requirements.

Owner:唐咸俊

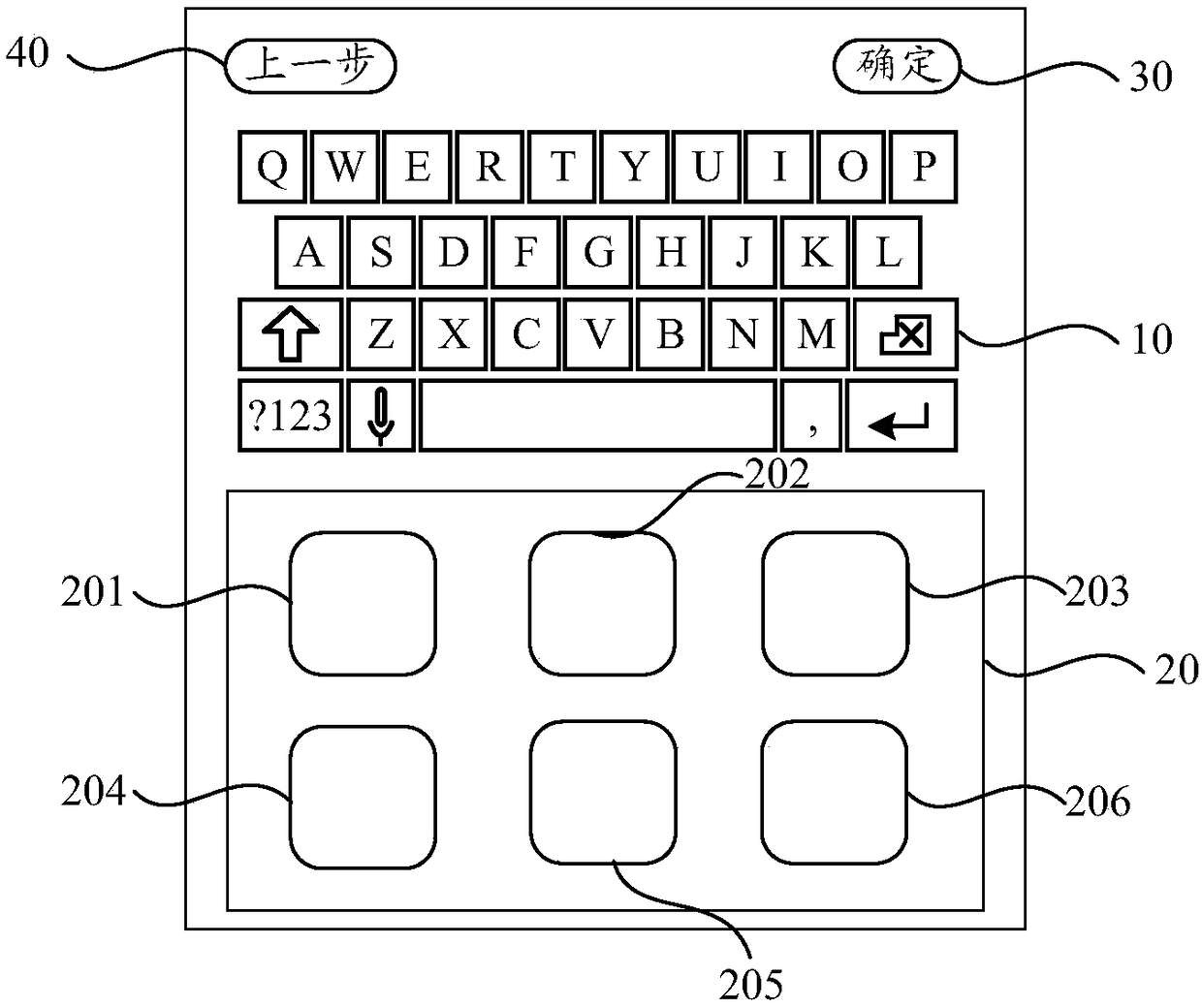

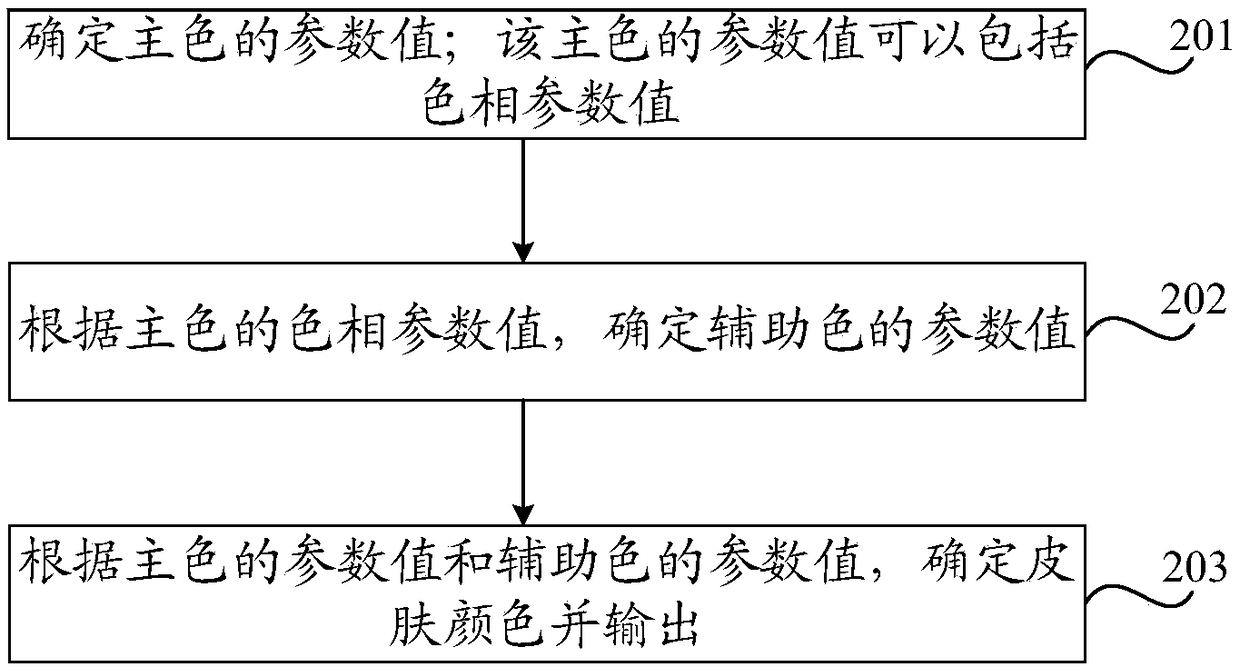

Method and device for treating skin color

ActiveCN109427036AImprove color qualityHarmonious color matchingImage analysisGeometric image transformationSkin colorHue

Embodiments of the present invention provide a skin color processing method and device, wherein the method specifically comprises the following steps: determining a parameter value of a main color. The parameter value of the main color comprises a hue parameter value, the parameter value of the auxiliary color is determined according to the hue parameter value of the main color, and the skin coloris determined and output according to the parameter value of the main color and the parameter value of the auxiliary color. The embodiment of the invention can improve the color matching quality of the skin color, and can improve the treatment efficiency of the skin.

Owner:BEIJING SOGOU TECHNOLOGY DEVELOPMENT CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com