Detection production line for full-automatic welding of loudspeaker based on fused tin soldering and AI visual detection

A fully automatic welding and visual inspection technology, applied in welding equipment, instruments, measuring devices, etc., can solve problems such as unguaranteed product quality, unstable quality, poor welding quality, etc., and achieve improved welding inspection efficiency and simple operation Controllable, fast welding results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

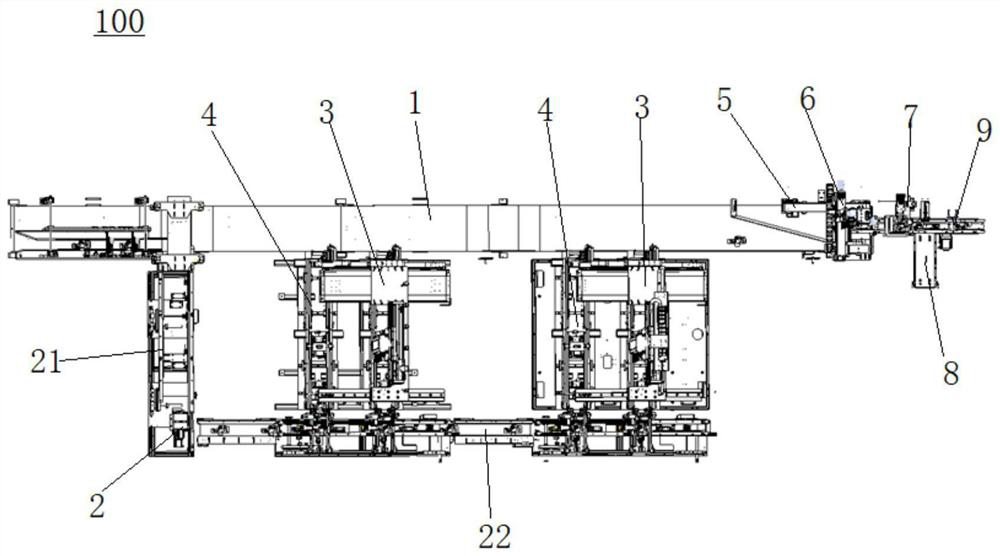

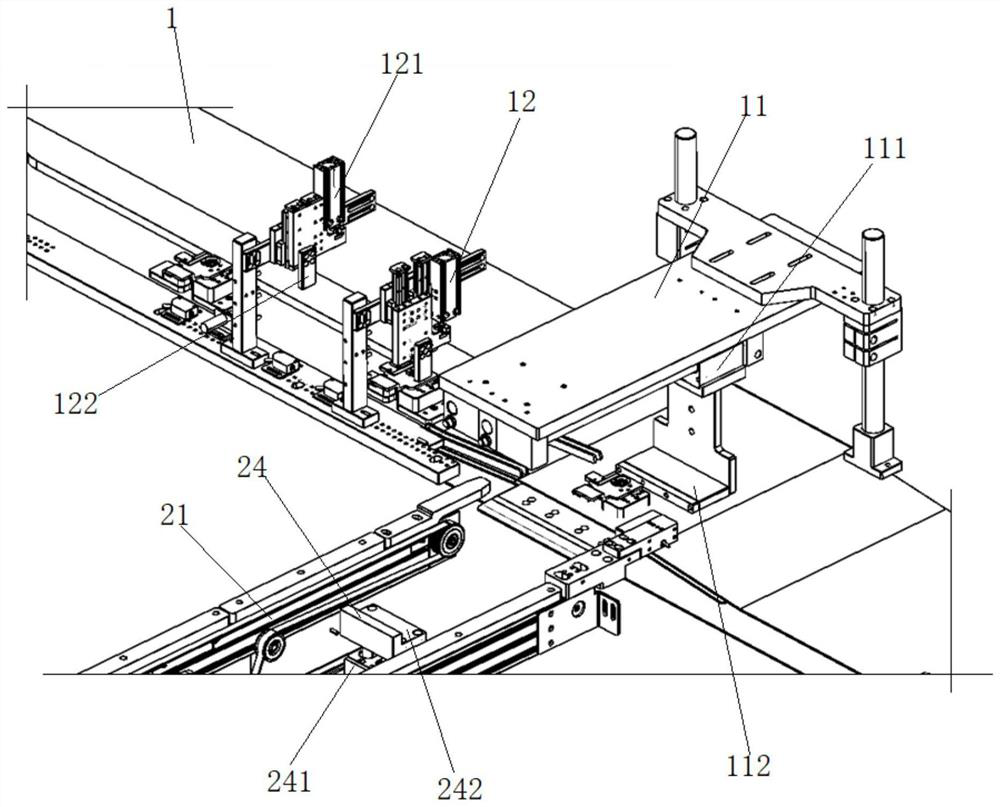

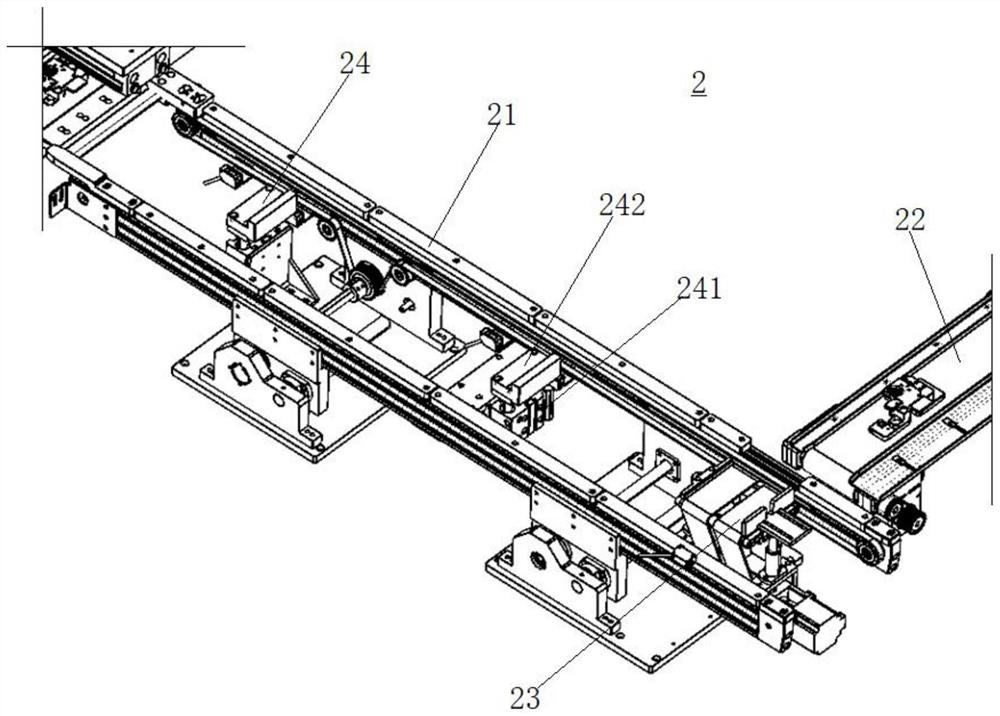

[0058] Please refer to Figure 1-Figure 14 , the present embodiment is a loudspeaker automatic welding inspection production line 100 based on molten tin soldering and AI visual inspection, which includes a main flow line 1, a welding feeding conveyor line 2 vertically connected to the main flow line 1 and distributed in an L shape as a whole, along Several welding units 3 provided on the main waterline 1, one end is vertically connected to the welding feeding conveying line 2, and the other end is vertically connected to the main waterline 1 and the welding in-out conveying line 4 that flows through the welding unit 3 is arranged above the end of the main waterline 1 and The welding cover plate on the product is removed and placed on a transport clamping mechanism 6 on the cover plate reflow conveying line 5, an AI visual inspection unit 7 and a waste discharge mechanism 8 for detecting solder joints on the product.

[0059] The main waterline 1 is provided with a first steer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com