Automatic height detecting device

An automatic detection and height detection technology, applied in measuring devices, instruments, manipulators, etc., can solve the problems of easy missed detection, low detection accuracy, low detection efficiency, etc., to ensure accurate positioning and accurate detection, avoid manual operation, The effect of high detection accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

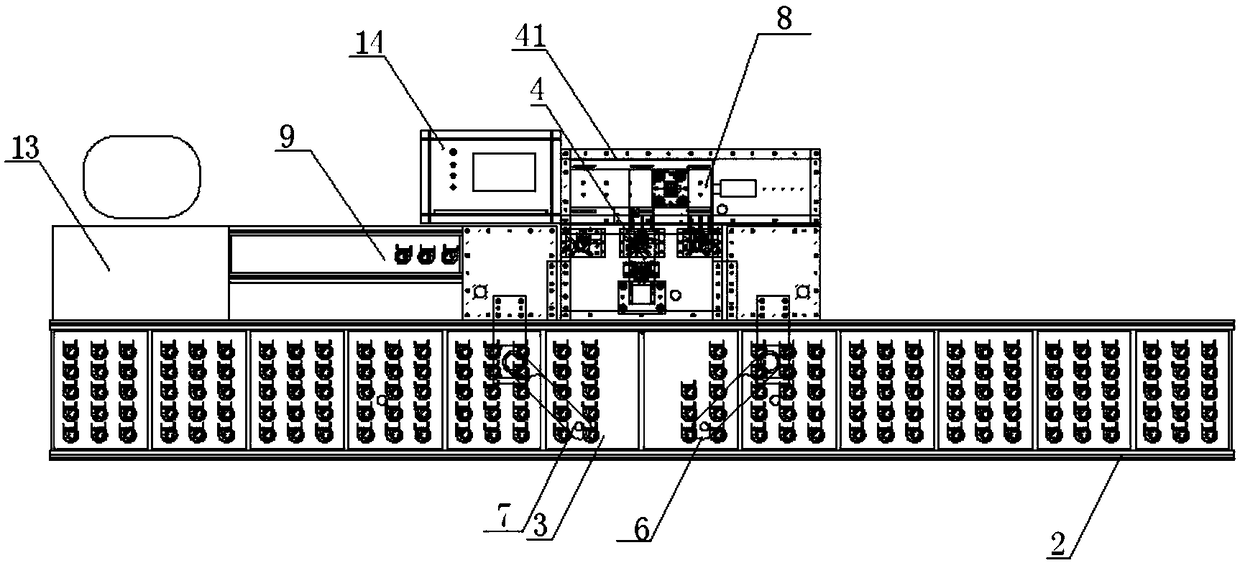

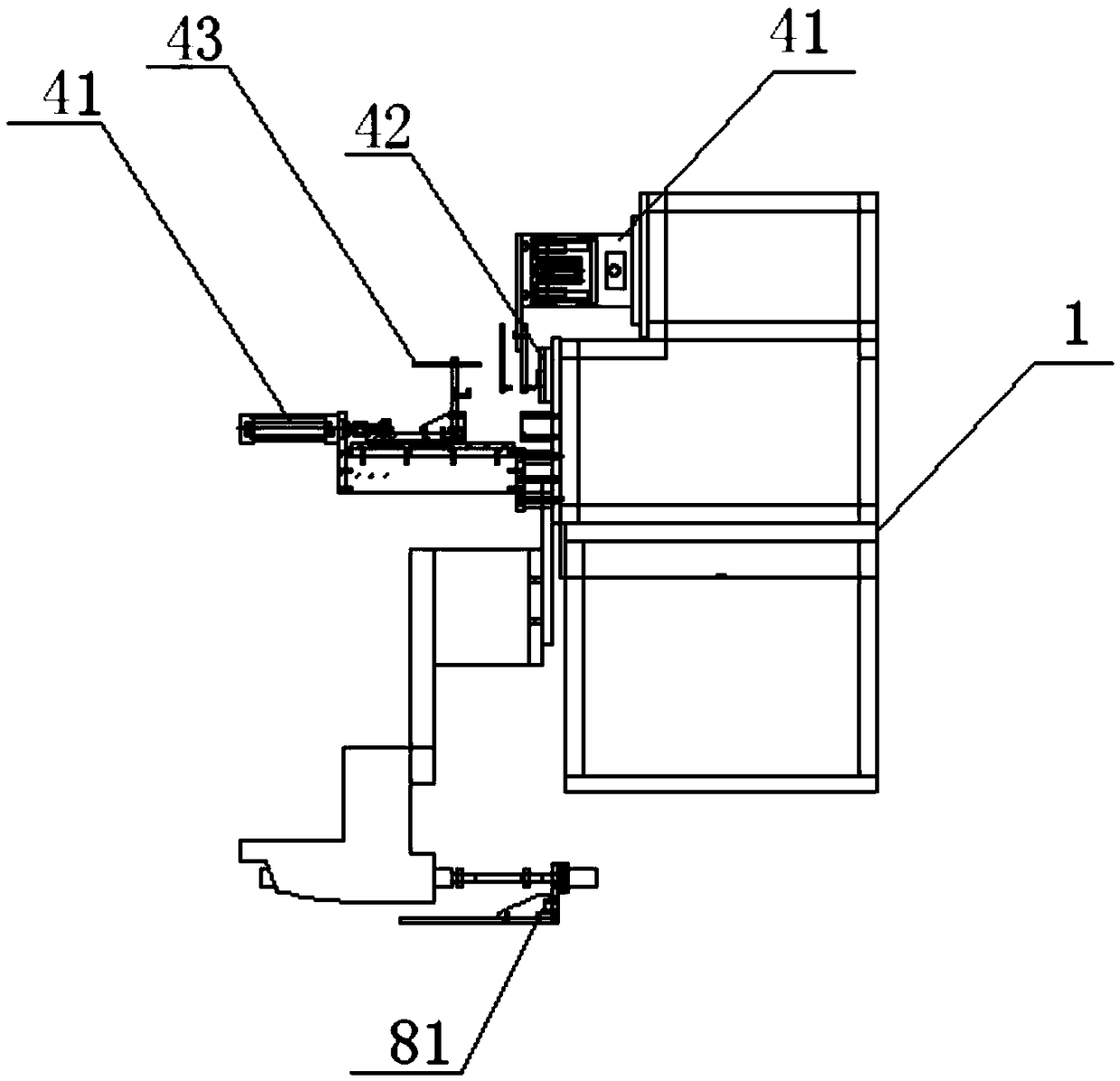

[0027] Embodiment: A kind of automatic detection equipment of height dimension, comprises frame 1, feeding conveying mechanism 2, qualified product conveying mechanism 3, unqualified product conveying mechanism 9, product height detection mechanism 4, product handling mechanism, product position sensing device and control system, where:

[0028] The feed conveying mechanism 2, the qualified product conveying mechanism 3 and the unqualified product conveying mechanism 9 are respectively arranged at different positions on the frame 1 and can realize the conveying of products;

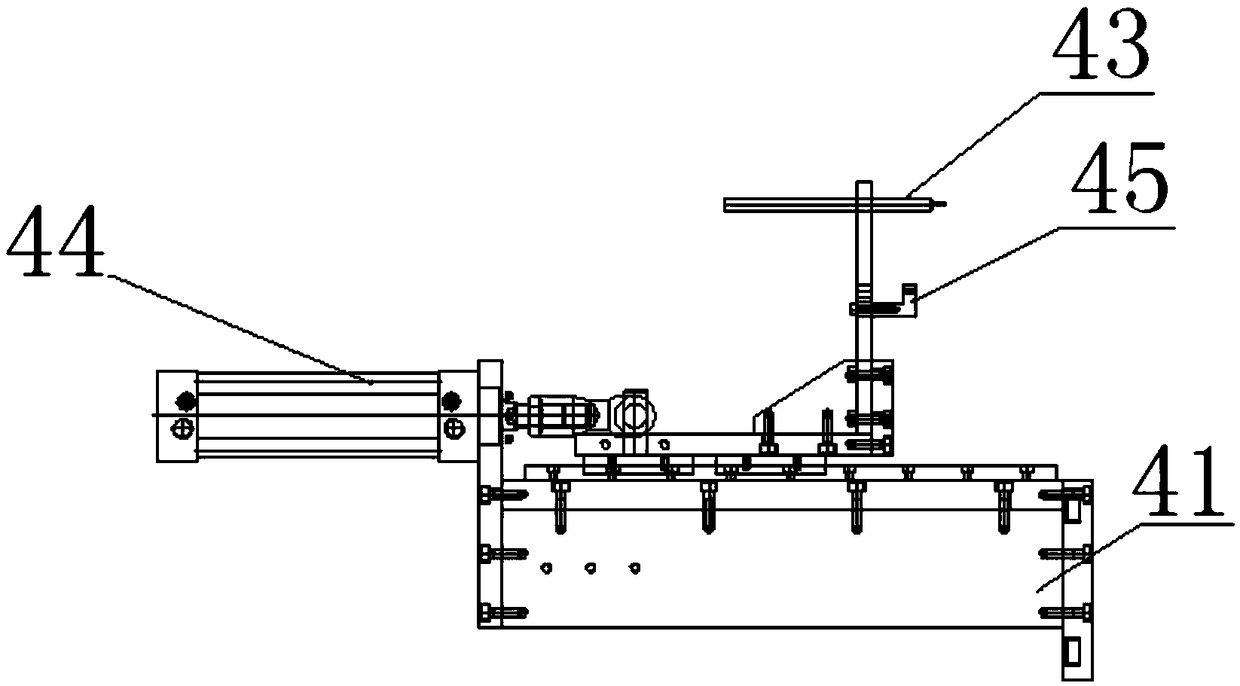

[0029] The product height detection mechanism 4 includes a detection bracket 41, a positioning platform 42, a detection probe 43 and a probe lifting drive device 44. The detection bracket 41 is fixedly installed on the frame 1, and the positioning platform 42 is fixedly installed on the detection bracket 41. The positioning platform 42 is provided with a positioning device for the positioning of the produ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com