Double-layer composite aluminum film gas release type preparation process

A double-layer composite and preparation process technology, applied in the direction of lamination, lamination device, layered products, etc., can solve the problems of surface damage of composite layer and poor quality of composite aluminum film finished products, so as to improve the quality, improve the quality of finished products, The effect of improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

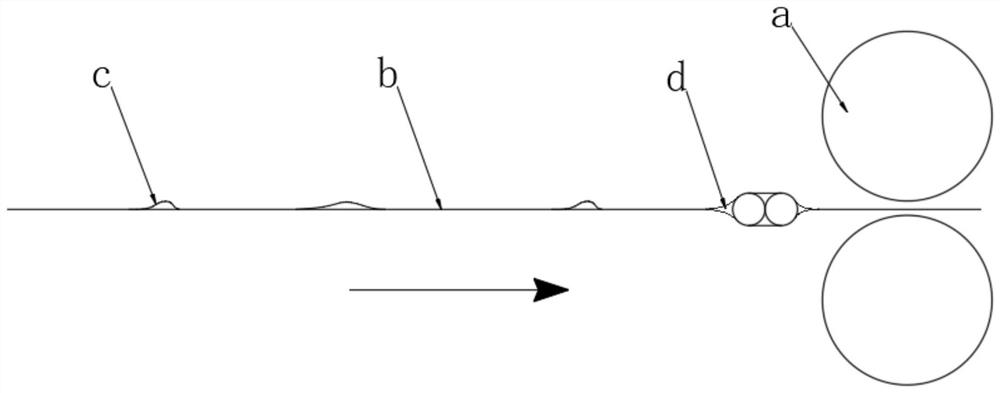

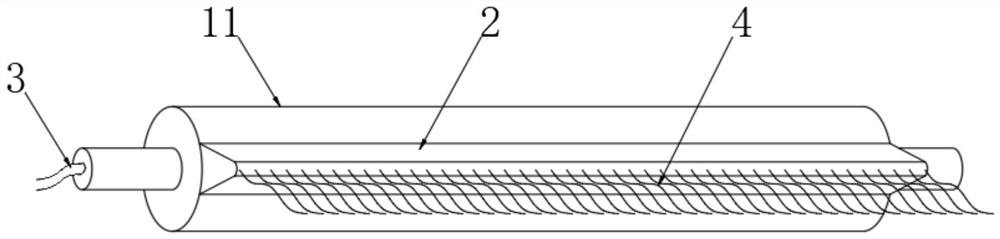

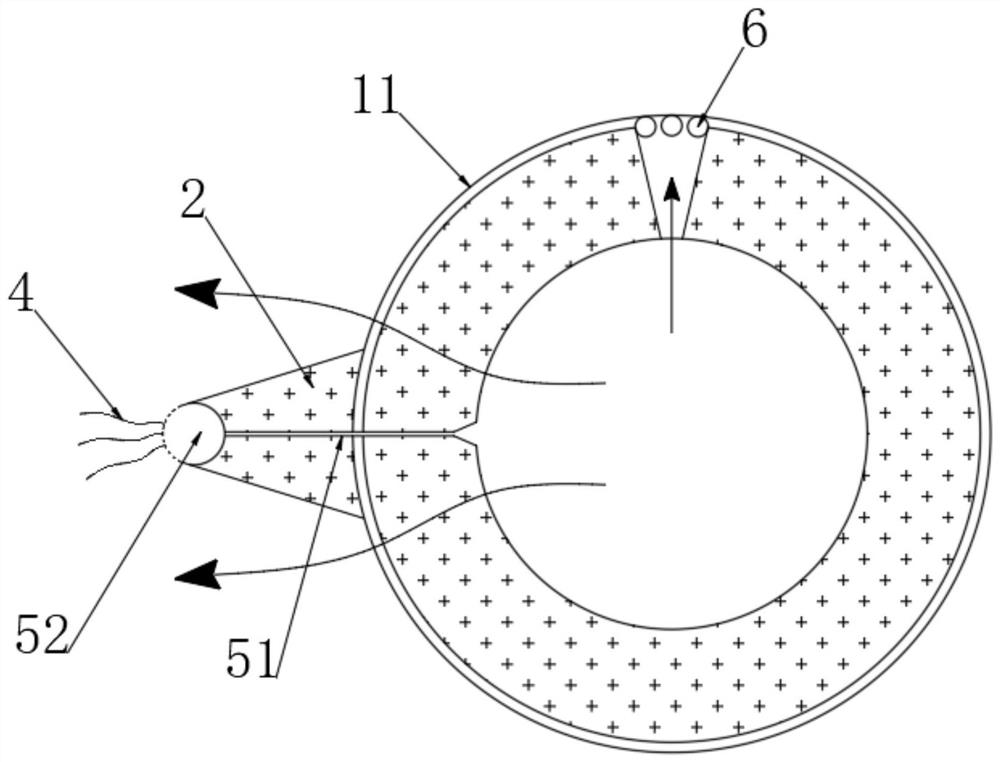

[0046] see figure 1 , the arrow in the figure indicates the moving direction of the double-layer film along with the assembly line, a indicates the roller of the composite equipment, b indicates the double-layer film, c indicates the bulge, and d indicates the area where the air ion layer is formed. A double-layer composite aluminum film air ionizer Type preparation process, comprises the following steps:

[0047] S1. First, the aluminum film and the plastic film are laminated, and then the laminated double-layer film is passed through the roller-type lamination equipment to align the edges of the double-layer film;

[0048] S2. Wrap the double-layer film on the two-way air cylinder respectively, control the pretreatment of the double-layer film to be continuously separated and bonded by the two-way air cylinder, and eliminate the air bubbles in the double-layer film;

[0049] The specific operations of preprocessing are:

[0050] S21. Along the moving direction of the doubl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com