High impact polystyrene cup

A technology of polystyrene and high impact resistance, which is applied to the types of packaging items, special packaging items, and layered products. It can solve the problems of poor impact resistance, short service life of the cup body, and poor use effect, so as to reduce damage efficiency and increase the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

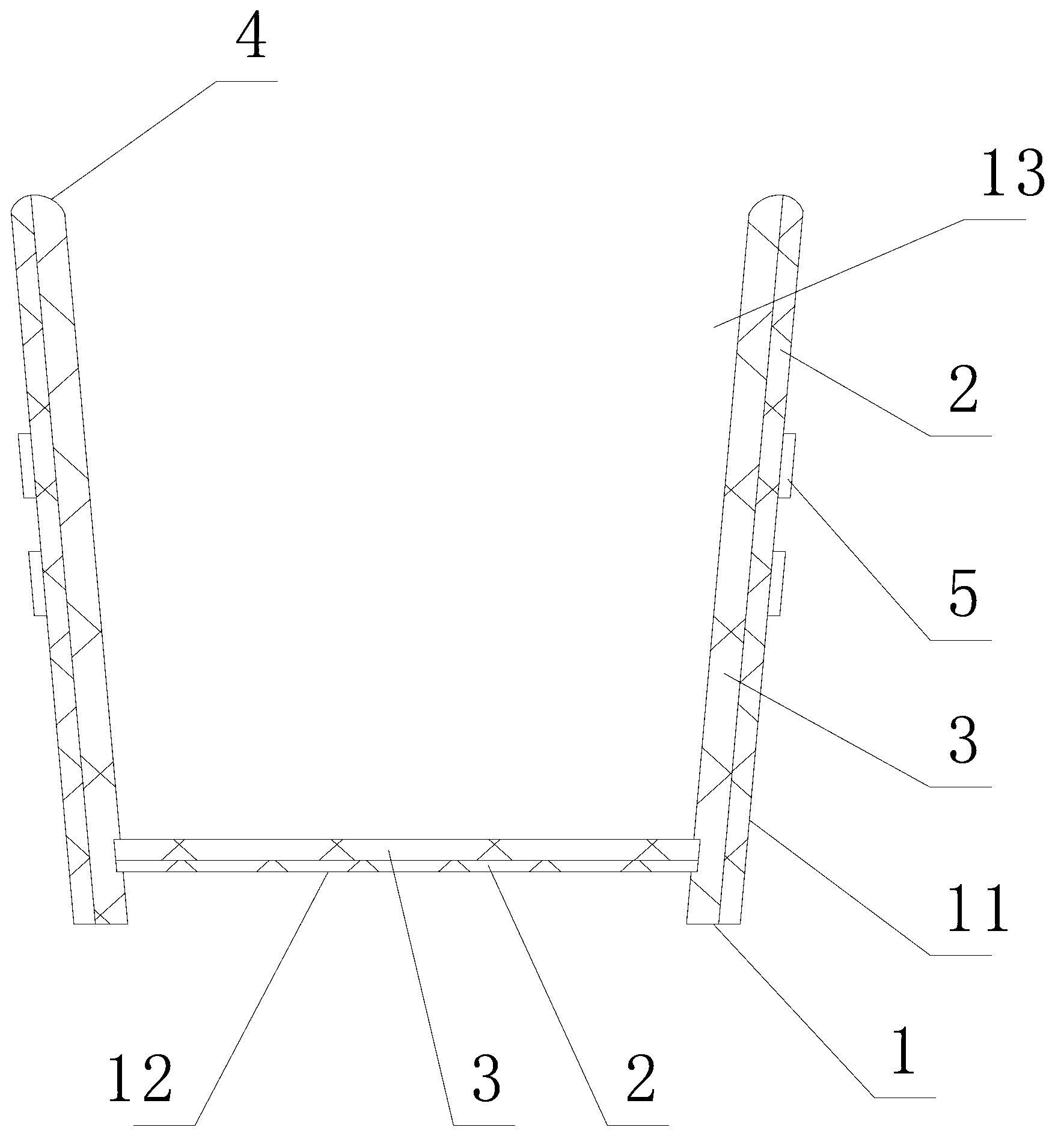

[0017] Such as figure 1 As shown, the high-impact polystyrene cup includes a cup body 1, the outer side of the cup body 1 is a low-temperature resistant layer 2, the inner side of the cup body 1 is a crack-resistant layer 3, and the low-temperature resistant layer 2 and the anti-crack layer The cracked layer 3 is composited into the cup wall 11 of the cup body 1 and the cup bottom 12 of the cup body 1, and the ratio of the thickness of the low temperature resistant layer 2 to the thickness of the crack resistant layer 3 is 1:10, and the cup wall 11 A cavity 13 is formed along the side wall of the cup bottom 12, the low temperature resistant layer 2 is GPPS, the crack resistant layer 3 is HIPS and SBS, and the mass ratio of HIPS to SBS is 8:1 , the thickness of the low-temperature-resistant layer 2 is 0.05mm, which has good low-temperature resistance and good practicability. The thickness of the crack-resistant layer 3 is 0.5mm, which ensures that the cup body 1 will not break ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com