Foaming thermoplastic polyurethane elastomer, preparation method and application

A thermoplastic polyurethane, plastic polyurethane technology, used in applications, shoe soles, clothing, etc., can solve the problems of inability to meet high hardness and low density performance requirements, reduced wear resistance, increased density, etc., to achieve good melt strength and melt strength. Viscosity, density reduction, good compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Below in conjunction with specific embodiments, the present invention is further clarified, and the physical properties of the sports shoe soles made of the foamed thermoplastic polyurethane elastomer particles of the present invention are tested.

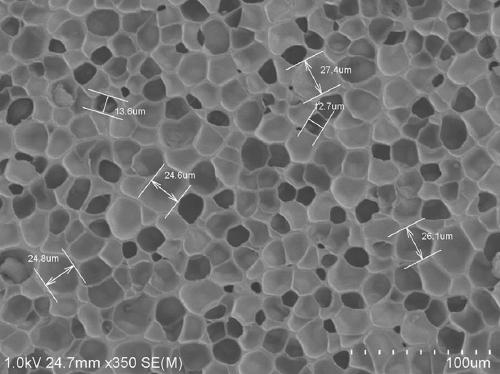

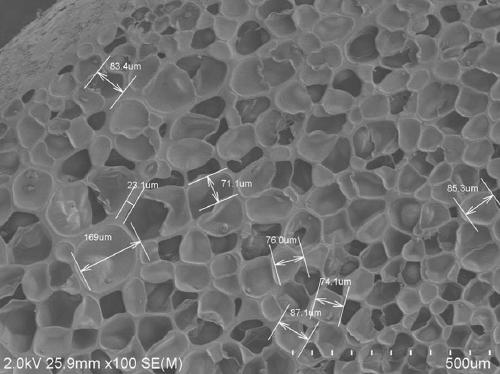

[0030] The specific embodiment of the present invention is: weigh each raw material component as shown in Table 1 by mass fraction, stir and mix each weighed raw material component evenly, extrude through twin-screw, and cool and cut under water To obtain thermoplastic polyurethane elastomer composite particles, soak the thermoplastic polyurethane elastomer composite particles with water, and then use supercritical carbon dioxide to foam. The foaming temperature is 90-160°C, the foaming pressure is 2-6MPa, and the pressure release rate is 5- 20MPa / min, then after drying, sieving and aging to obtain foamed thermoplastic polyurethane elastomer particles, such as figure 1 shown. Among them, sieving is used to screen out unexpa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com