Tempeerature-constant air exchanger

An air exchange and constant temperature technology, applied in heat exchange equipment, space heating and ventilation, household heating, etc., can solve the problems of difficult miniaturization, large equipment volume, short service life, etc., and achieve convenient installation and combination, small size , long service life effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

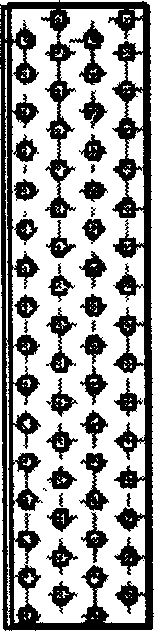

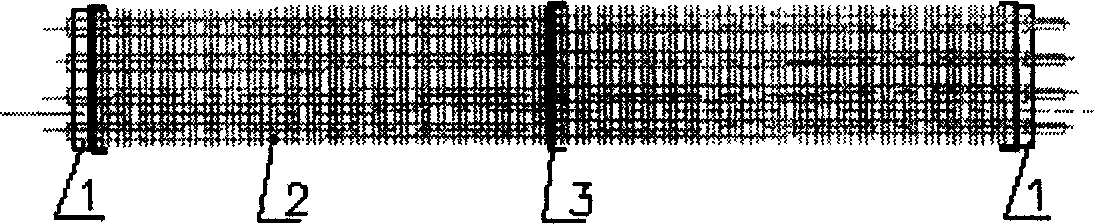

[0025] by figure 2 As shown in the example, press the figure 1 First arrange 10 rows of 25 sections of copper-aluminum finned heat pipes 2 filled with heat-transfer working medium in a matrix, expand them into 5 heat-exchanging tube core assemblies through the middle partition 3 and end plate 1, and then combine them into a A heat exchange tube row 7 is enclosed from the side by an outer panel to form a box body 6 with 2 channels and 4 air outlets, and the bottom of each channel is provided with a condensate nozzle 5; for single-season equipment, the tube row Fix the assembly with an installation inclination angle of 4°. When the equipment is used in both directions in winter and summer, a tilting mechanism 4 is installed at the bottom of the box.

[0026] by Figure 4 As shown in the example, press the figure 1 First arrange 10 rows of 25 sections of copper-aluminum finned heat pipes 2 filled with heat transfer fluid in a matrix, and expand them into 5 heat exchange tube...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com