High temperature steam and oil resistant fluororubber pad

A technology of rubber gasket and high temperature resistance, applied in the field of sealing gasket, can solve the problems of poor steam resistance of F26 rubber compound, and achieve the effect of prolonging the service time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Step 1. Prepare F26 rubber compound:

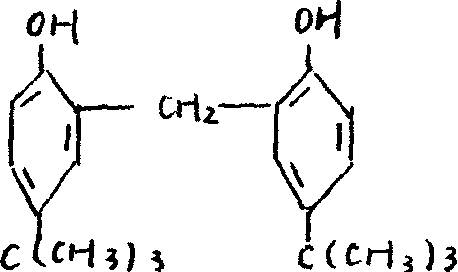

[0030] Take 100 parts of 26-type fluororubber, 2 parts of vulcanizing agent hexafluorobisphenol A, 0.7 parts of vulcanizing agent benzyl triphenyl phosphorus chloride, 30 parts of filler spray carbon black, 6 parts of vulcanization accelerator magnesium oxide, accelerator hydrogen 6 parts of calcium oxide, 2.2 parts of polyethylene wax, placed in a container, stirred and mixed evenly for later use;

[0031] Step 2. Preparation of HNBR rubber compound:

[0032] Take 100 parts of hydrogenated nitrile rubber, 48 parts of spray carbon black, 32 parts of 539 quick extruded carbon black, 2.6 parts of dicumyl peroxide, 1.5 parts of triallyl cyanurate, 0.2 parts of polyethylene wax, paraffin wax 3 parts of oil, put in a container, stir and mix evenly for later use;

[0033] Step 3. Prepare the mixed rubber gasket:

[0034] Take 70 parts of F26 compound rubber and 30 parts of HNBR compound rubber, put them in a container, stir and mix th...

Embodiment 2

[0036] Step 1. Prepare F26 rubber compound:

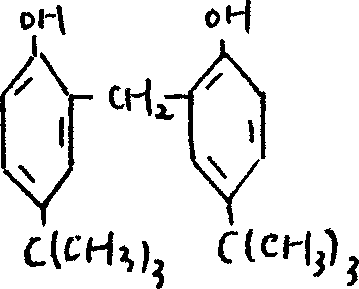

[0037] Take 100 parts of 26-type fluororubber, 2.2 parts of hexafluorobisphenol A, 0.5 parts of benzyl triphenylphosphorous chloride, 35 parts of spray carbon black, 5 parts of magnesium oxide, 7 parts of calcium hydroxide, and 2 parts of polyethylene wax , placed in a container and stirred evenly for later use;

[0038] Step 2. Preparation of HNBR rubber compound:

[0039] Take 100 parts of hydrogenated nitrile rubber, 52 parts of spray carbon black, 28 parts of 539 quick extruded carbon black, 2.8 parts of dicumyl peroxide, 1.3 parts of triallyl cyanurate, 0.3 parts of polyethylene wax, paraffin wax 2 parts of oil, put in a container, stir and mix evenly for later use;

[0040] Step 3. Prepare the mixed rubber gasket:

[0041] Take 75 parts of F26 compound rubber and 25 parts of HNBR compound rubber respectively, put them in a container, stir and mix them evenly, mold them into shape, and treat them with hot air twice to get h...

Embodiment 3

[0043] Step 1. Prepare F26 rubber compound:

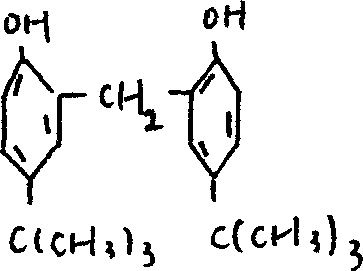

[0044] Take 100 parts of 26-type fluororubber, 2.1 parts of hexafluorobisphenol A, 0.6 parts of benzyltriphenylphosphorous chloride, 33 parts of spray carbon black, 5.5 parts of magnesium oxide, 6.5 parts of calcium hydroxide, and 2.1 parts of polyethylene wax , placed in a container and stirred evenly for later use;

[0045] Step 2. Preparation of HNBR rubber compound:

[0046] Take 100 parts of hydrogenated nitrile rubber, 50 parts of spray carbon black, 30 parts of 539 quick extruded carbon black, 2.7 parts of dicumyl peroxide, 1.4 parts of triallyl cyanurate, 0.25 parts of polyethylene wax, paraffin wax 2.5 parts of oil, put in a container, stir and mix evenly for later use;

[0047] Step 3. Prepare the mixed rubber gasket:

[0048] Take 72 parts of F26 rubber compound, 28 parts of HNBR rubber compound and 2 parts of thickening aid, put them in a container, stir and mix them evenly, mold them, and heat them for the second ti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com