Patents

Literature

82results about How to "Guaranteed low temperature resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Austenitic precipitation hardening stainless steel forge piece and machining method thereof

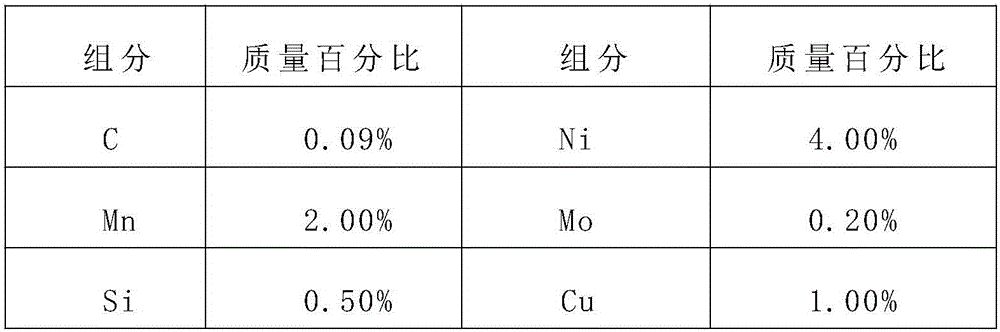

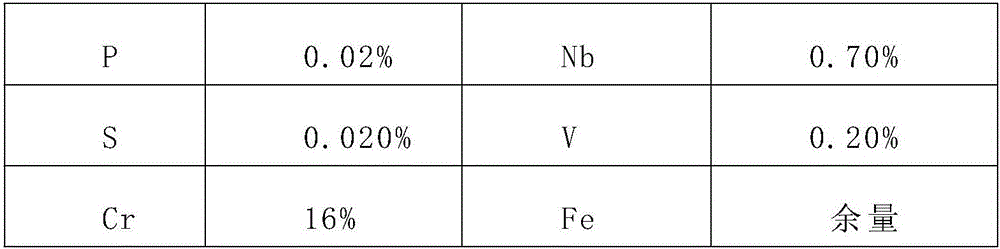

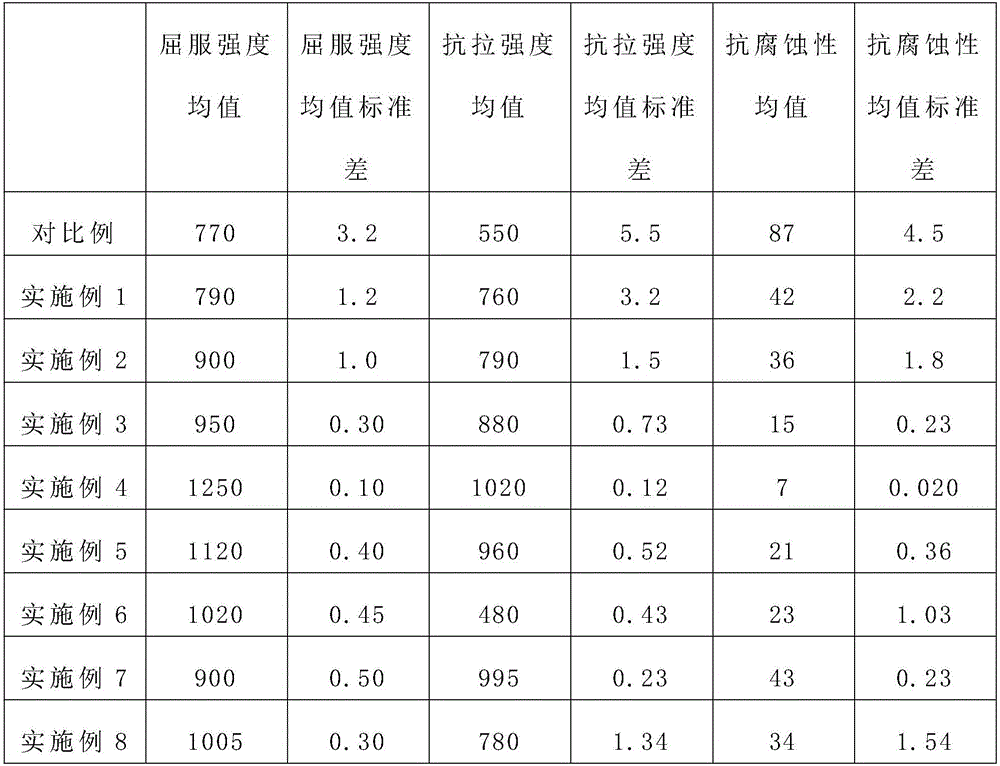

The invention discloses an austenitic precipitation hardening stainless steel forge piece and a machining method thereof. The problem that according to an existing machining method, a manufactured austenitic stainless steel forge piece is low in comprehensive performance is solved. According to the technical scheme, the austenitic precipitation hardening stainless steel forge piece comprises chemical components including, by mass percent, not larger than 0.09% of C, not larger than 2.00% of Mn, not larger than 1.00% of Si, not larger than 0.025% of P, 4.00% to 8.00% of Ni, 0.20% to 0.80% of Mo, 1.00% to 4.00% of Cu, not larger than 0.70% of Nb, not larger than 0.20% of V and the balance Fe. The manufactured forge piece has the beneficial effects of being high in strength, high in toughness, resistant to corrosion and wear, high in weather resistance, resistant to high temperature and low temperature, high in stability and the like.

Owner:陆照福

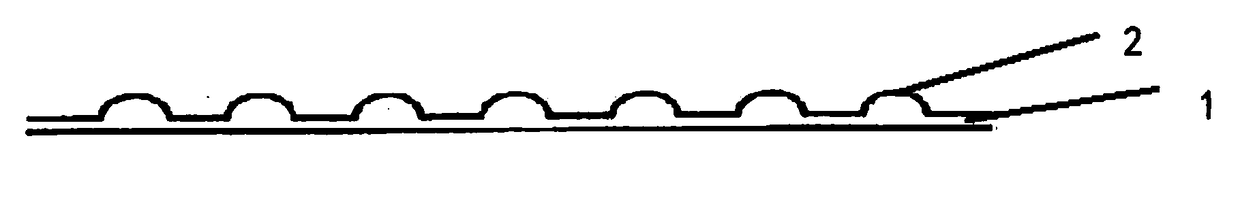

Protuberant hot-melt road marking coating, and preparation method and construction method thereof

ActiveCN109021830AGood formabilityImprove deformation resistanceRosin coatingsTraffic signalsHot meltRosin

The invention discloses a protuberant hot-melt road marking coating, and a preparation method and a construction method thereof, and relates to the technical field of road marking construction. The protuberant hot-melt road marking coating is mainly prepared from the following raw materials by the weight percentage: 3-8% of petroleum resin, 3-8% of rosin resin, 2-6% of polyamide resin, 0.5-1.5% ofalkyd resin, 20-50% of a reflective material, 1-10% of a pigment, 0-1.5% of an anti-sedimentation agent, and the balance a filler. The defects of poor formability, poor cohesion, poor low temperatureresistance, easy cracking when being used in winter and poor deformation resistance at high temperature of a traditional road marking coating are alleviated. The formula of the protuberant hot-melt road marking coating improves the performance of the coating through the cooperative use of petroleum resin, rosin resin, polyamide resin and alkyd resin; pigments and fillers, the reflective materialand the optional anti-sedimentation agent are added for compounding, so the product has the advantages of good performance, improved high temperature anti-compressive performance, no cracking in winter and no collapse when being pressed in summer.

Owner:河北新思维创业空间服务有限公司 +1

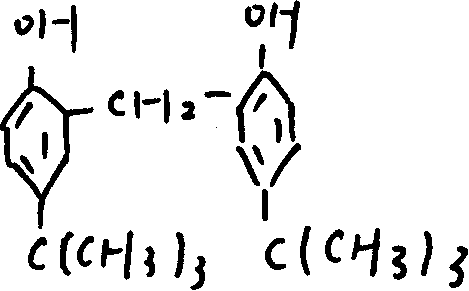

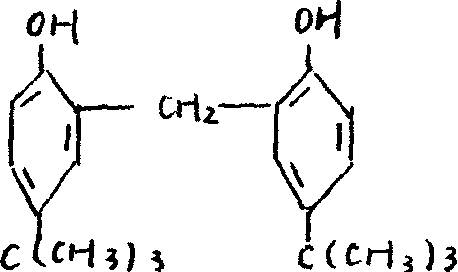

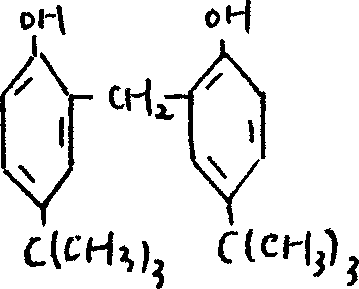

High temperature steam and oil resistant fluororubber pad

ActiveCN1702112AGuaranteed low temperature resistanceMeet the use requirementsHeating oilEngineering

The invention relates to a thermostable viton gasket, which is mainly used as sealing element in plate exchanger using high temperature steam and heating oil. The viton gasket comprises 70-75 wt% of F26 ready-mixed glue and 25-30 wt% of HNBR ready-mixed glue. Said F26 ready-mixed glue comprises 100 wt% of 26-style rubber, 2-2.2 wt% of hexaflurate bisphenol A and so on. HNBR ready-mixed glue comprises 100 wt% of hydrogenated rubber, 48-52 wt% of black pigment and so on. The invention can resist high temperature steam and oil.

Owner:蒋惠成

Alloy steel seamless steel tube for geological drilling and machining method thereof

InactiveCN102953019AImprove performanceImprove low temperature impact toughnessFurnace typesHeat treatment furnacesRotational deformationWear resistance

The invention relates to an alloy steel seamless steel tube for geological drilling and a machining method of the alloy steel seamless steel tube. The alloy steel seamless steel tube manufactured by the method disclosed by the invention is good in comprehensive properties, good in low-temperature impact toughness, and higher in rotational deformation resistance and abrasive resistance, wherein the yield strength of the alloy steel seamless steel tube is more than 1000MPa. After the cold-drawing technology, the thermal treatment technology and the straightening technology are adopted, the mechanical property, the rotational deformation resistance, the low-temperature impact toughness and the abrasive resistance of the seamless steel tube body can reach the standard.

Owner:无锡润丰特种钢管有限公司

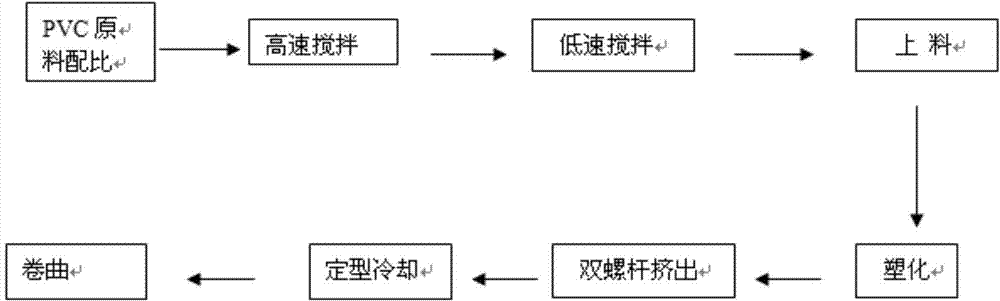

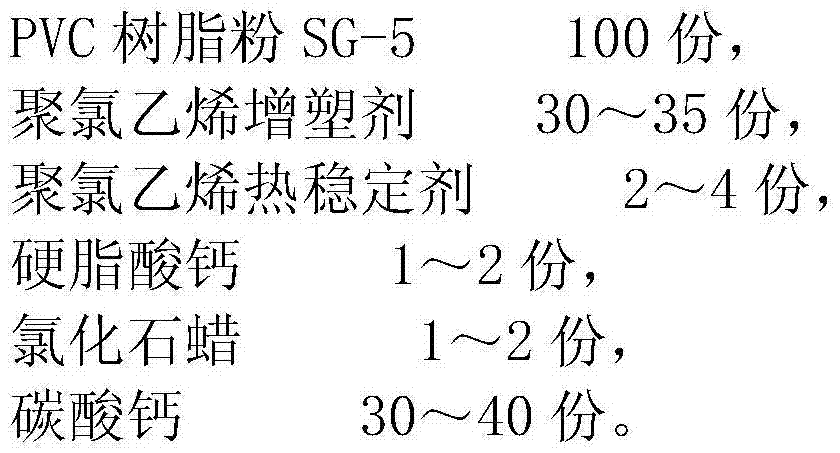

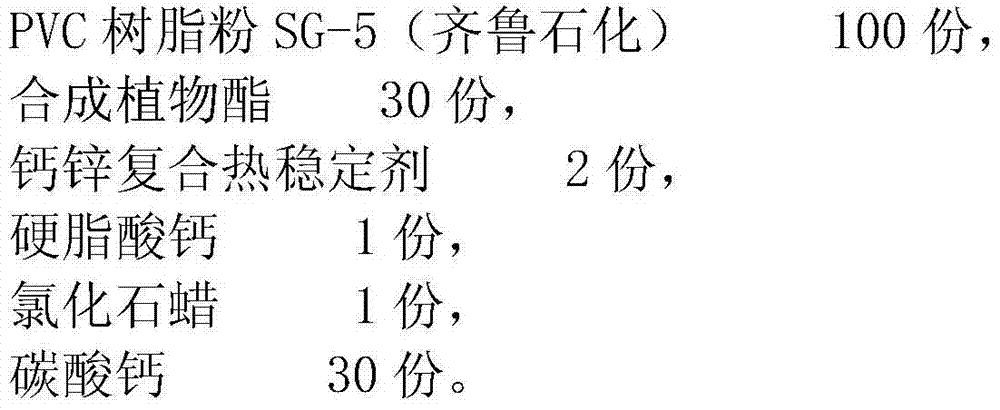

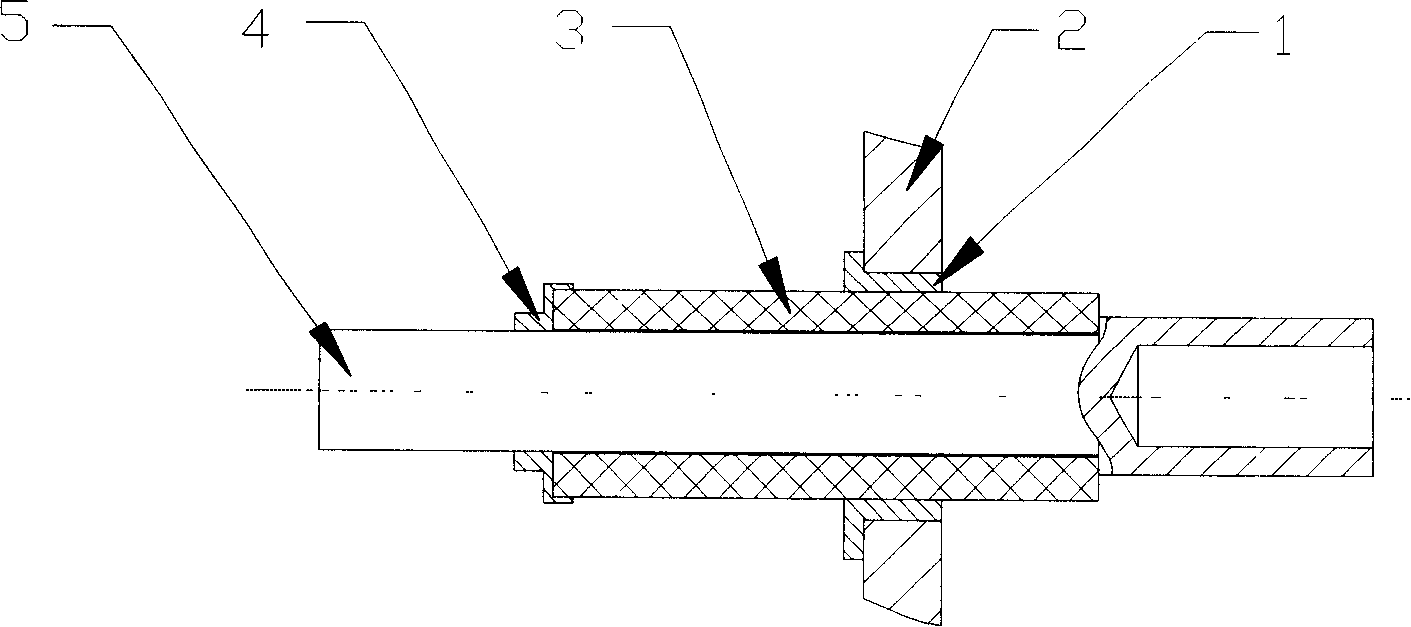

Environment-friendly cold-resistant polyvinyl chloride (PVC) waterproof coil and manufacturing technique thereof

ActiveCN103589092AGuaranteed to be environmentally friendlyGuaranteed low temperature resistanceParaffin waxPlasticizer

The invention provides an environment-friendly cold-resistant polyvinyl chloride (PVC) waterproof coil and a manufacturing technique thereof. The waterproof coil comprises the following components in parts by mass: 100 parts of PVC resin powder SG-5, 30-35 parts of synthetic plant ester, 2-4 parts of PVC heat stabilizer, 1-2 parts of calcium stearate, 1-2 parts of chlorinated paraffin wax and 30-40 parts of calcium carbonate. The synthetic plant ester, ethylene terpolymer or polyalcohol benzoate has the advantages of no toxicity and favorable low-temperature resistance, and thus, is used as a PVC plasticizer; and the environment-friendly heat stabilizer is added in the formula, thereby ensuring the environment-friendly performance and low-temperature resistance of the PVC waterproof coil. The coil adopts environment-friendly materials, does not have the problem of plasticizer volatilization, and prolongs the service life of the product (up to more than 15 years).

Owner:天津市禹红建筑防水材料有限公司

Organic-silicon-modified polyurethane sealant and processing technology thereof

InactiveCN101864165AImprove performanceIncrease elasticityNon-macromolecular adhesive additivesOther chemical processesSilanesTemperature resistance

The invention relates to organic-silicon-modified polyurethane sealant and processing technology thereof. The organic-silicon-modified polyurethane sealant is prepared by mixing the following components: polyether glycol, hydroxyl-terminated polymethyl siloxane with 6 to 18 degrees of polymerization, isocyanate, a catalyst, namely benzoyl chloride, an active hydrogen compound, a catalyst, namely dibutyltin dilaurate and filler. The process comprises the following steps of: 1, preparing a component A, wherein the step is divided into the following steps of: firstly, adding the polyether glycol and the isocyanate into a flask provided with a thermometer, a condenser, a stirring device and a vent pipe; secondly, heating the materials slowly; and thirdly, slowly adding silane into a reaction system dropwise, measuring the NCO group content by a titration method and storing tightly; and 2, preparing a component B, wherein the step is divided into the following steps of: mixing the materials, stirring and dispersing the materials, and grinding the materials by using a grinding machine for later use; and pouring the dispersed component B into another reactor, stirring the component to dehydrate, and storing tightly to obtain the component B. The organic-silicon-modified polyurethane sealant has the advantages of high elasticity, low-temperature flexibility, wear resistance, temperature resistance, water resistance and aging resistance.

Owner:陕西浩瀚新宇科技发展有限公司

Method of making electric heater socket connector plug

ActiveCN101202404AReduce corrosionGuaranteed low temperature resistanceContact member manufacturingElectricityHeat resistance

The invention relates to a manufacture method of a plug of a connector of an electric heater. The method comprises the following process steps: (1) preparation of metallising slurry; (2) coating of slurry; (3) metallising sintering; (4) glazing and glost firing; (5) plating and (6) brazing. Compared with traditional technologies, the invention adopts ceramic metallising and sealing process, improves the sintering method and sealing method by adjusting the slurry formulation of metal molybdenum and manganese, and utilizes the characteristics of ceramic material of good corrosion resistance and electric insulation performance, thus leading the connector to be characterized by anti-corrosion performance, heat resistance, radiation resistance, good sealing performance, good electric insulation performance, prolonging the service life of the electric heater, and reducing the cost of products.

Owner:SHANGHAI MUNICIPAL ELECTRIC POWER CO +1

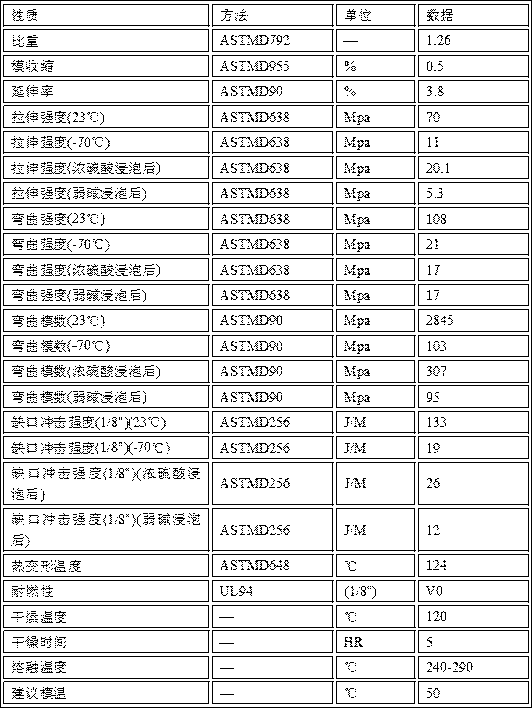

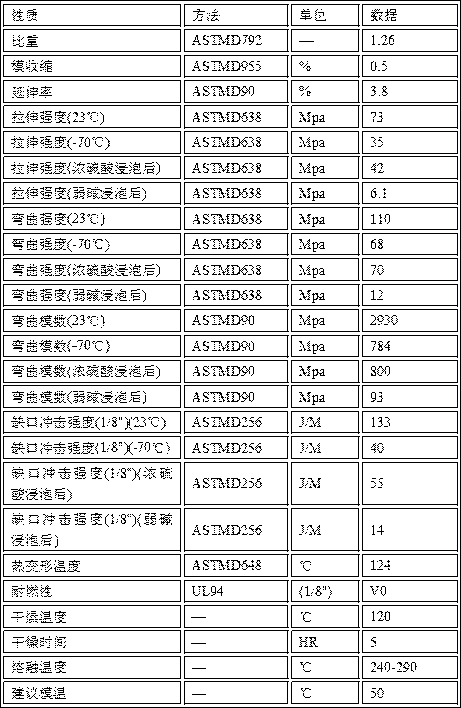

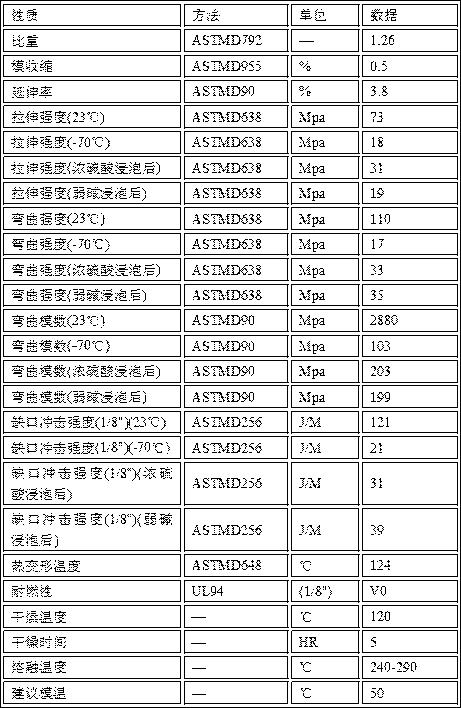

Cold-resistant anti-corrosion glass fiber reinforced polycarbonate composite material as well as preparation method and applications thereof

ActiveCN103265801ALow temperature resistanceHigh mechanical strength and impact resistancePolycarbonateAntioxidant

The invention discloses a cold-resistant anti-corrosion glass fiber reinforced polycarbonate composite material as well as a preparation method and applications thereof. According to the formula, the polycarbonate composite material comprises raw materials: polycarbonate, glass fiber, an antioxidant, a flexibilizer, an anti-ultraviolet agent, a lubricant, and an anti-corrosion agent. The composite material has the characteristics of high performance, high cold resistance, hihg corrosion resistance, high stability, electrostatic resistance and the like, is applicable to preparation of anti-impact and high-strength parts, protective covers, precise instrument parts, plugging elements, high-frequency tuners, printed circuit sockets, intelligent electric meter shells and terminal boards in mechanical industry.

Owner:广州仕天材料科技有限公司

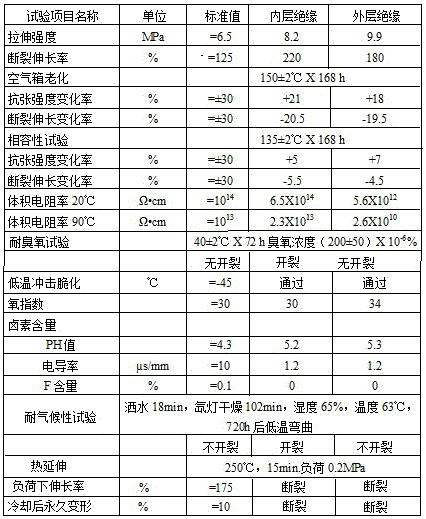

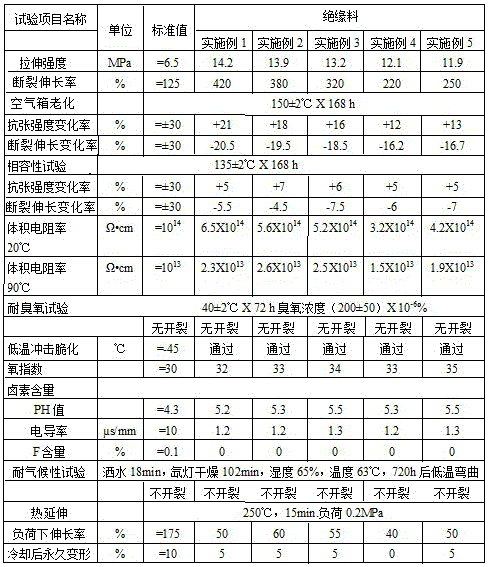

Low-smoke halogen-free anti-flaming and insulating material used for manufacturing photovoltaic cable and manufacturing method of low-smoke halogen-free anti-flaming and insulating material

InactiveCN106279961AReduce volumeGood dispersionPlastic/resin/waxes insulatorsPolyolefinUltraviolet lights

The invention discloses a low-smoke halogen-free anti-flaming and insulating material used for manufacturing a photovoltaic cable and a manufacturing method of the low-smoke halogen-free anti-flaming and insulating material. The low-smoke halogen-free anti-flaming and insulating material is prepared by the following steps according to weight ratio: 30-40 parts of ethylene-EVA(Ethylene vinyl-acetate copolymer) with the content of VA of 28 percent or above, 10-20 parts of HDPE (high density polyethylene), 20-30 parts of a halogen-free flame retardant, 10-20 parts of a polyphosphazene fire retardant, 1-5 parts of functional polyolefin resin, 1-2 parts of an antioxygen, 1-2 parts of a light stabilizer, 1-2 parts of an ultraviolet light absorber, 0.1 to 0.3 part of an Ir 1024 anticopper agent, 1-2 parts of a lubricant and 1-2 parts of a crosslinking sensitizer are mediated through a high speed kneader or internally mixed through an internal mixer, and then plasticized and extruded through a double-screw extruder, and then squeezing granulation is performed through a single screw extruder. Single layer insulation of a cable made of the anti-flaming and insulating material provided by the invention can meet the requirements of heat, damp and chemical attack resistance, weather proofing, ozone resistance, wear resistance, direct voltage resistance, 250 DEG C thermal extension and low-smoke halogen-free flaming resistance in the EN50618 standard of EU photovoltaic cable standards.

Owner:河北中联银杉新材料有限公司

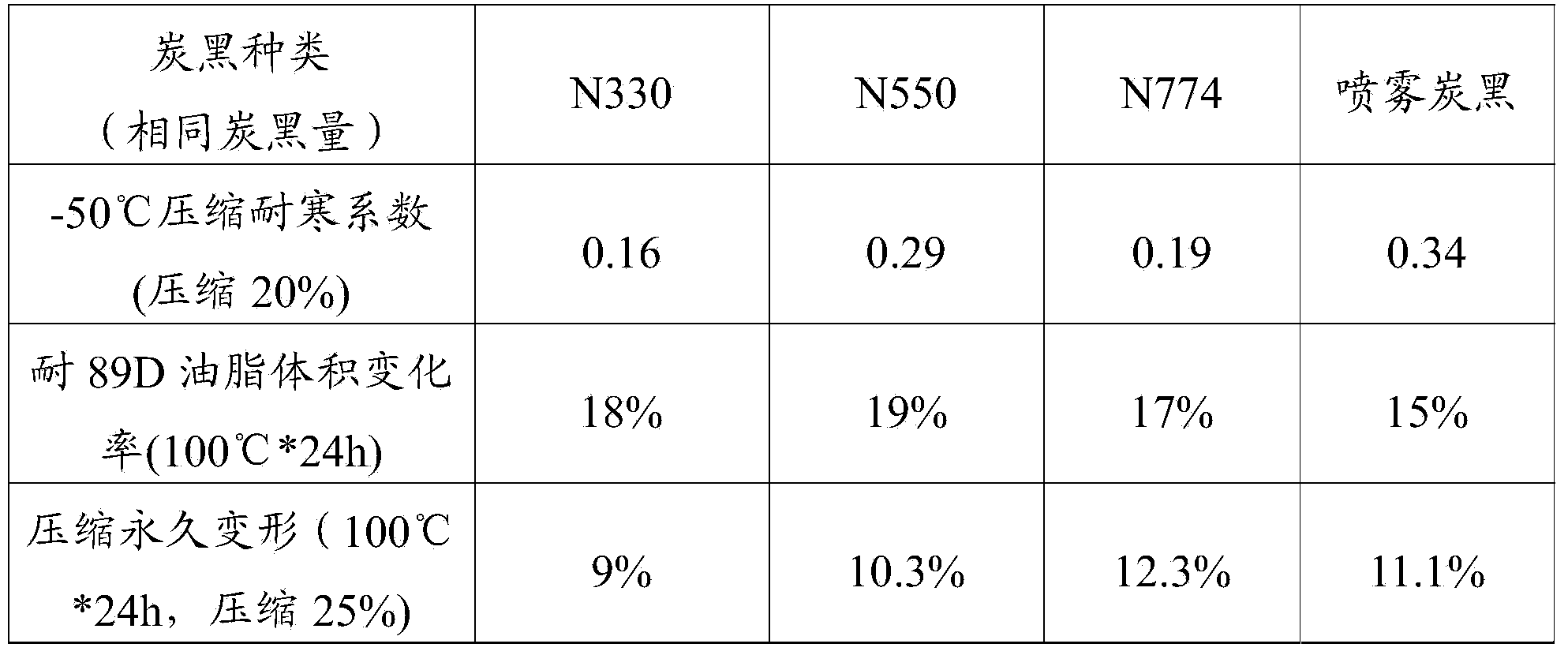

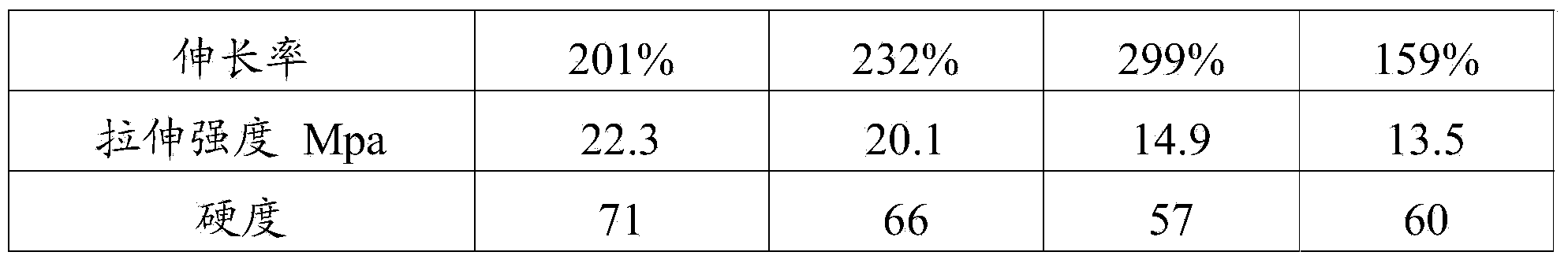

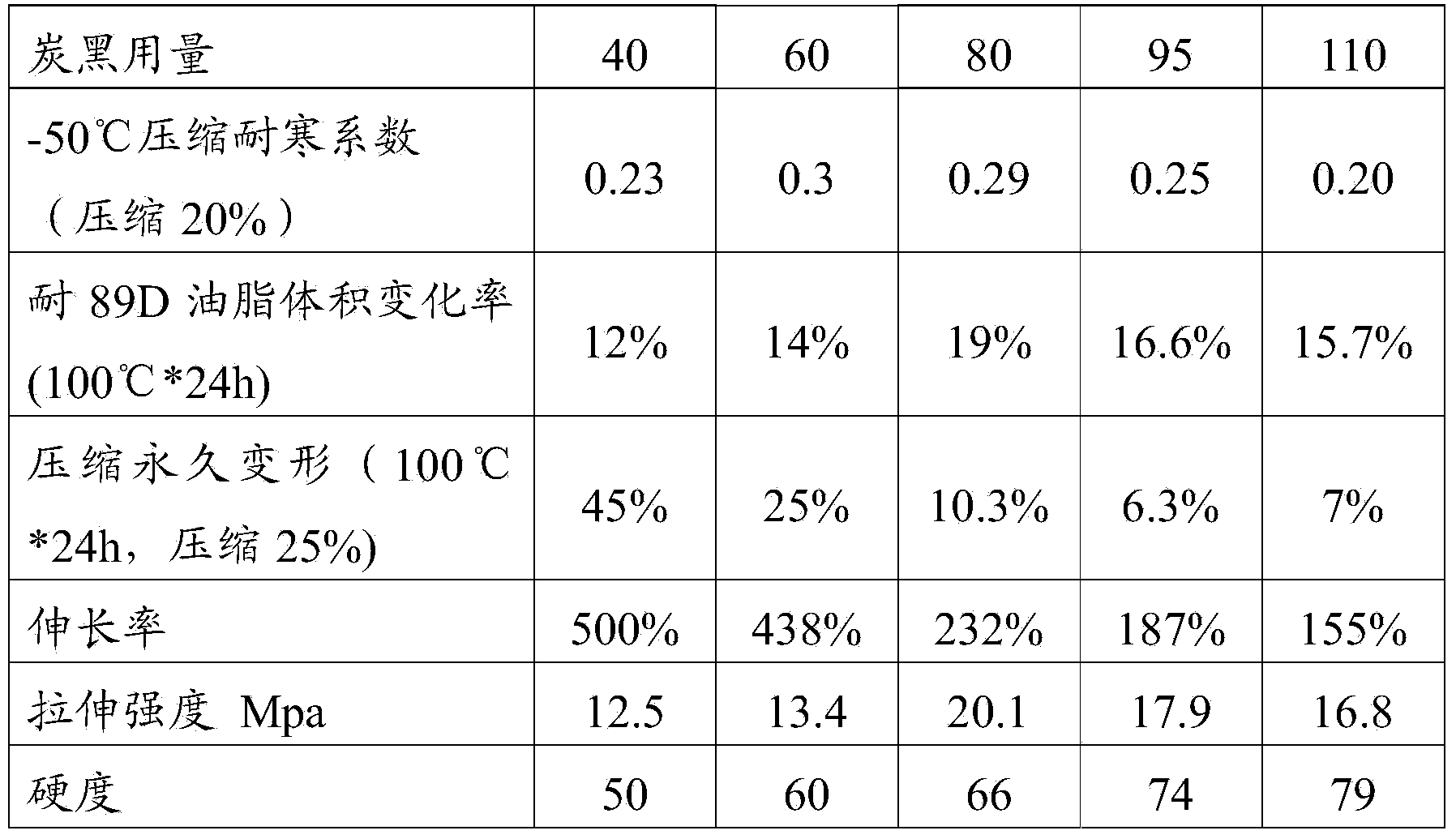

Oil-resisting and cold-resisting nitrile butadiene rubber composition and preparation method thereof

The invention relates to oil-resisting and cold-resisting nitrile butadiene rubber composition and a preparation method thereof. The oil-resisting and cold-resisting nitrile butadiene rubber composition comprises components in parts as follows: nitrile butadiene rubber, a reinforcing system, a vulcanization system and a plastification system. The nitrile butadiene rubber composition uses single nitrile butadiene rubber and has good oil resistance and oil resistance.

Owner:CHINA ACADEMY OF RAILWAY SCI CORP LTD +1

Super-hard material and preparation method thereof

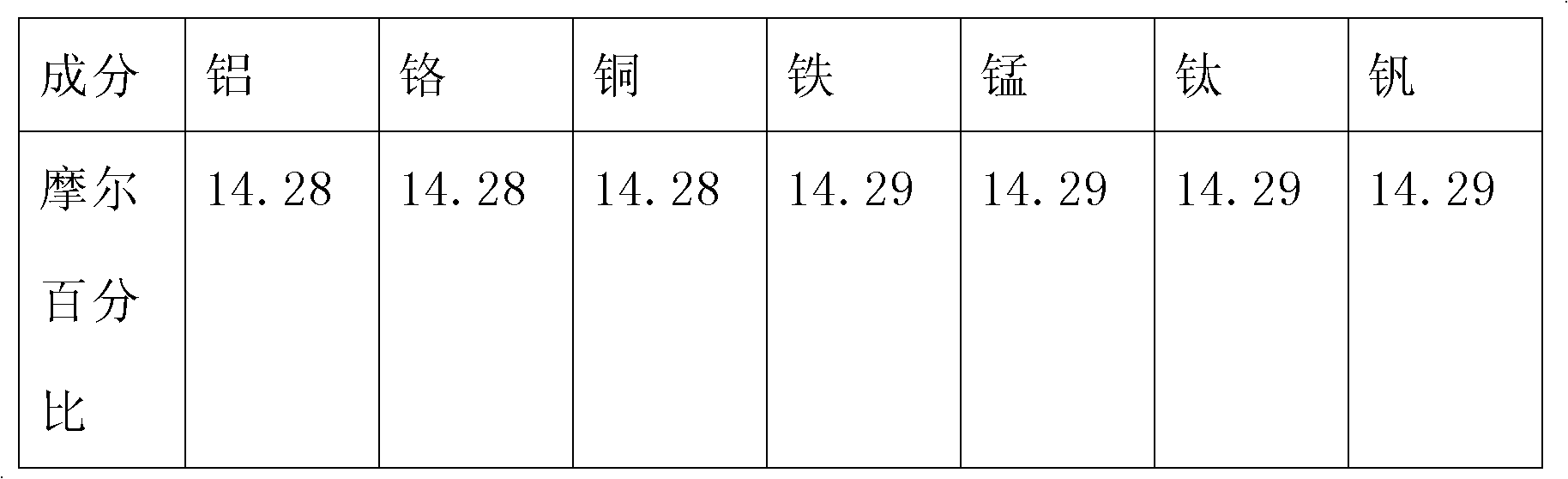

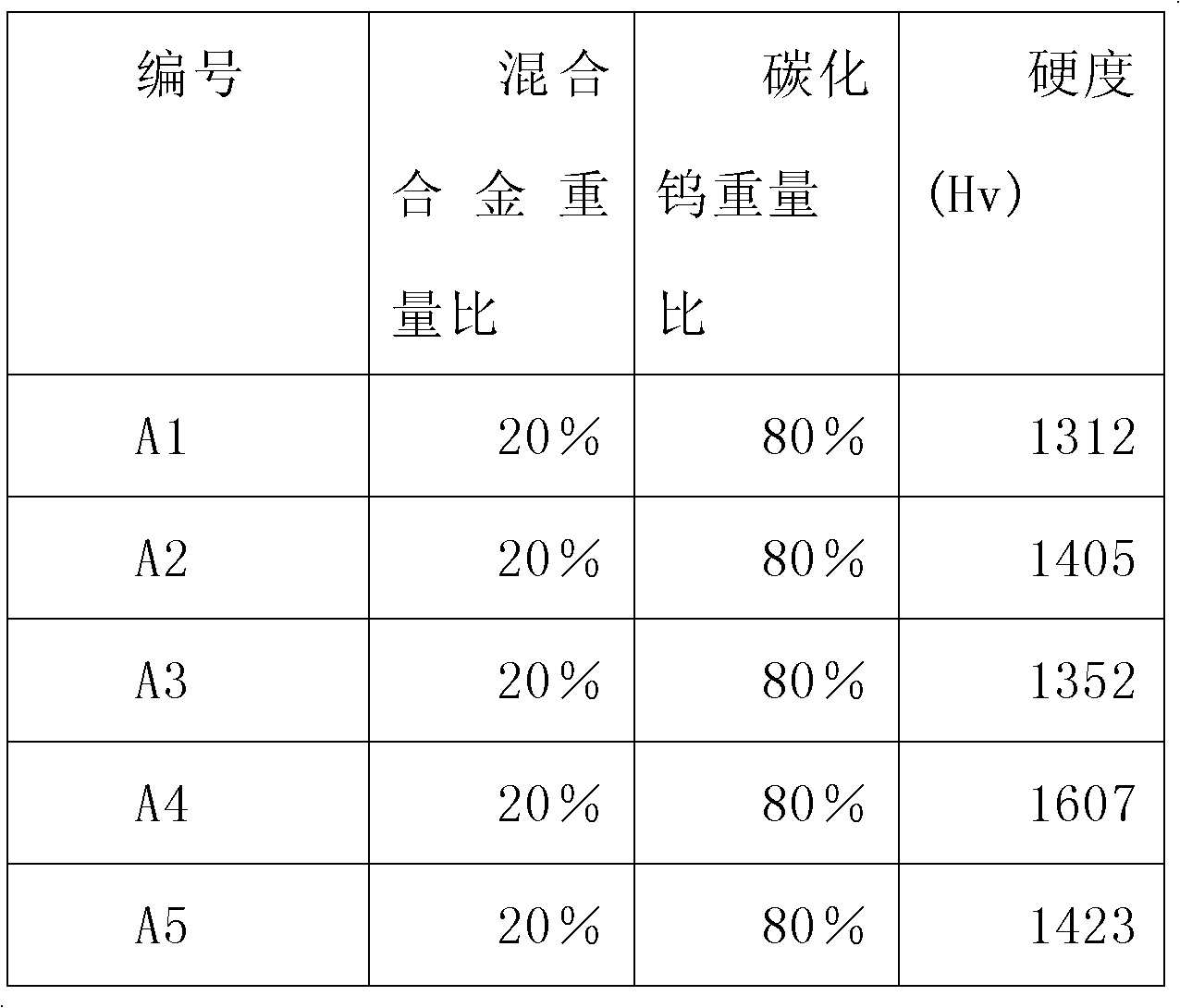

The invention discloses a super-hard material and a preparation method thereof. The super-hard material comprises at least one kind of ceramic phase powder and mixed alloy; the mixed alloy consists of at least five of aluminum, chromium, copper, iron, manganese, titanium, vanadium, cobalt, nickel and carbon, and each element accounts for 5 to 35 percent of the mixed alloy; the super-hard material comprises the following components in percentage by weight: 80 to 85 percent of ceramic phase powder, and 15 to 20 percent of mixed alloy; and because the multi-element alloy is used as a bonding phase of the super-hard material, the bonded metals can obtain temperature-resistant micro structure and hardness, and the hardness and the temperature and abrasion resistance of the whole ceramic phase composite material are improved. In addition, by using the slow diffusion effect, when the bonded metals are sintered into liquid phases, atoms are not easily transmitted and diffused, growth of ceramic phase grains such as tungsten carbide, titanium carbide and the like can be inhibited, and decrease of hardness, toughness, temperature resistance and abrasion resistance of a sintered body is further avoided.

Owner:四川欧曼机械有限公司

Graphene natural rubber polymer anti-slip mixed foaming material on ice and preparation method of mixed foaming material

ActiveCN110698733AHigh anti-slip coefficientImprove the anti-slip effectSolesCross linkerStearic acid

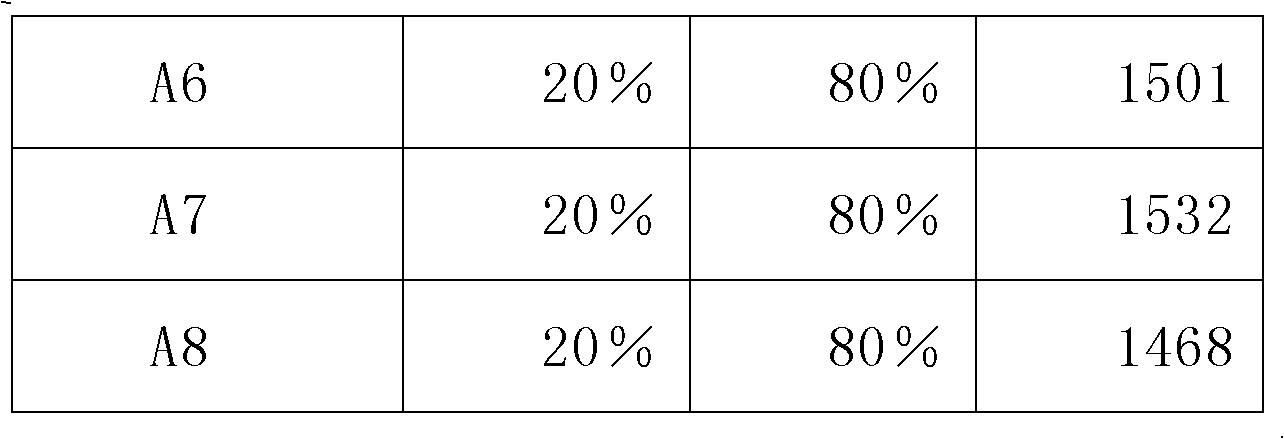

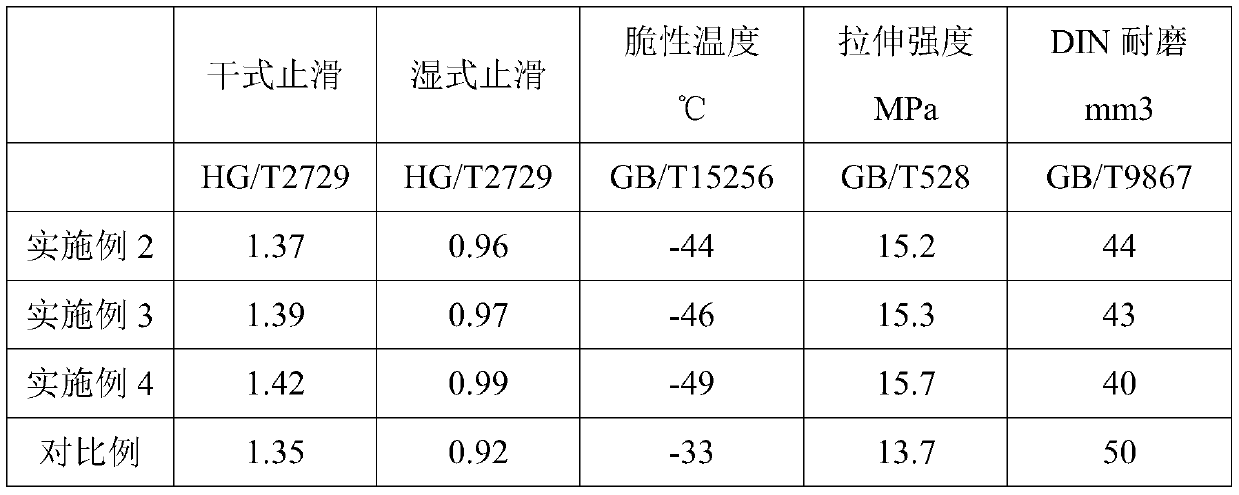

The invention discloses a graphene natural rubber polymer anti-slip mixed foaming material on ice and a preparation method of the mixed foaming material. The mixed foaming material is prepared from the following raw materials in parts by weight: 50-60 parts of natural rubber, 32-37 parts of butyl rubber, 8-12 parts of cis-polybutadiene, 4-6 parts of white carbon black, 2.4-2.8 parts of basalt fibers, 2-3 parts of nano silicon dioxide, 2.2-2.6 parts of graphene, 1.4-1.7 parts of silicone oil, 1.2-1.5 parts of zinc oxide, 1.5-2.0 parts of zinc stearate, 1.8-2.4 parts of stearic acid, 1.6-1.9 parts of a cross-linking agent, 4.5-5.5 parts of a flow promoting agent, and 1.5-2.0 parts of a foaming agent. The graphene natural rubber polymer anti-slip mixed foaming material on the ice provided bythe invention has a high anti-slip coefficient, a good anti-slip effect, good low-temperature resistance, a good low-temperature anti-slip effect, high tensile strength, good mechanical properties, low abrasion, good wear resistance and long service life.

Owner:FUJIAN WUCHIHENG TECH DEV CO LTD

Water-proof sealing grease for optical instrument and preparation method thereof

The invention relates to the field of optical auxiliary materials, in particular to a water-proof sealing grease for an optical instrument and a preparation method thereof. The grease, actually a mixture, is characterized by comprising the raw materials in part by weight ratio: two kinds of silicone oils with kinematic viscosities of 0.65-3000 cst and 3000-500000 cst at 25 DEG C, a lipid solubility additive, a plasticizer, and an inorganic gelling agent. The method comprises the following steps: adding the two kinds of silicone oils with kinematic viscosities of 0.65-3000 cst and 3000-500000 cst at 25 DEG C, the lipid solubility additive and the plasticizer in a mixing tank for mixing for 0.5-3 h at the speed of 30-1000 r / min, adding the inorganic gelling agent after the mixture is uniformly mixed for further uniformly mixing, pouring into a plate for spreading, placing in a vacuum drying box for heating 3-8 h, taking out for cooling to an ambient temperature, grinding 3-5 times, and packing if passing the detection. The grease is used for the sealing and lubricating of the optical instruments, has good water resistance, does not dissolve in the water environment, dose not disperse, is strong in air tightness, small in volatility and good in lubricity, has the advantages of no corrosion to metal and glass and has high and low temperature resistance.

Owner:云南光电辅料有限公司

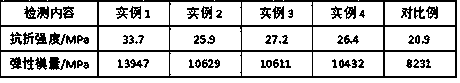

Production method of composite fiber cement board

The invention discloses a production method of a composite fiber cement board, and belongs to the technical field of building materials. The production method comprises the following steps: mixing microcrystalline cellulose with a sodium hydroxide solution, cooling the obtained solution, adding a precooled urea solution, stirring and mixing the obtained solution, centrifuging the obtained solutionto obtain a microcrystalline cellulose solution, dropwise adding an etherifying agent to the microcrystalline cellulose solution, performing constant-temperature stirring and reacting, cooling the obtained solution, adding urease and a calcium nitrate solution, continuing a reaction, concentrating the obtained reaction solution, drying the concentrated reaction solution to obtain etherified microcrystalline cellulose, performing a constant-temperature and constant-pressure reaction on the etherified microcrystalline cellulose and a sodium methoxide solution, cooling the obtained reaction solution, adding chloromethane, performing a constant-temperature and constant-pressure reaction, carrying out reduced pressure concentrating, drying the obtained concentrate to obtain modified microcrystalline cellulose, mixing cement, the modified microcrystalline cellulose, a water reducer and a defoamer, carrying out injection molding, and curing the molded mixture to obtain the composite fiber cement board. The composite fiber cement board obtained in the invention has excellent mechanical properties.

Owner:赣州大业金属纤维有限公司

Breeding method of pepper

InactiveCN104813917AStrong low light abilityExcellent agronomic traitsHorticulture methodsPlant tissue culturePolyethylene glycolPollination

The invention discloses a breeding method of pepper. According to the method, artificial pollination is performed after artificial emasculation of the pepper, a first-filial generation is obtained firstly and then three generations are back-crossed, and then the breeding of the pepper is quickened through a tissue culture technology; a drought-resistant strain is induced through stress treatment of polyethylene glycol. The obtained pepper new product has good stress resistance, can resist the diseases such as diseases, virus diseases and anthracnose of the pepper, is low-temperature-resistant, has high weak light capacity, and organically combines the advantages of different pepper resources. The method has the advantages of superior agronomic characters, good plant growth, increased plant height, difficulty in lodging and high yield.

Owner:CHANGZHOU KEHONG ELECTRONICS DEVICES

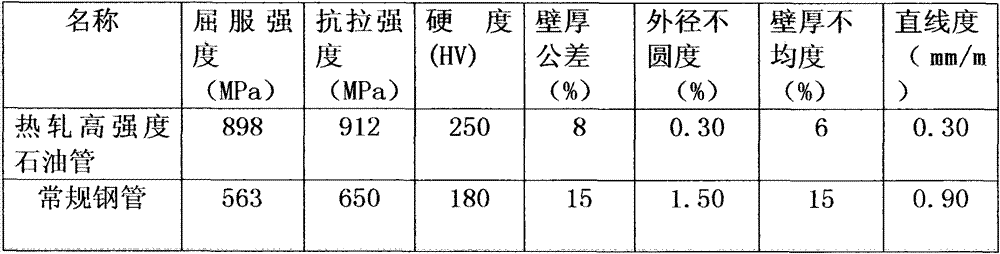

Hot-rolled high-strength oil pipe manufacturing method

The invention relates to a hot-rolled high-strength oil pipe manufacturing method, which comprises the following steps: heating: heating a pipe blank in an annular furnace; punching: punching holes in the heated pipe blank through a puncher; annealing: annealing the pipe blank; spraying borax; removing oxide skin; hot-rolling: feeding the annealed pipe into a pipe mill for hot-rolling; separating the pipe: separating the rolled pipe from a core rod; removing stress and annealing: feeding the rolled pipe into the heating furnace for heating, so as to obtain the annealed pipe blank; pickling: removing rust scale on the surface; phosphating: forming a zinc phosphate chemically-generated covering membrane on the surface; saponifying: forming metal soap and lubrication covering membranes: cold-drawing: cold-drawing the pipe blank to be cold-drawn, so as to obtain a cold-drawn pipe; performing heat treatment: reducing residual stress; honing; and performing hot straightening treatment, so as to obtain a cold-drawn precise inner-hole honed pipe, wherein a numerically-controlled honing machine is adopted in honing. The cold-drawn precise inner hole-honed pipe obtained through the method is good in comprehensive performance, good in low-temperature impact toughness, precise in dimension, smooth in surface, and excellent oil storage property.

Owner:WUXI OULONG SPECIAL STEEL PIPE

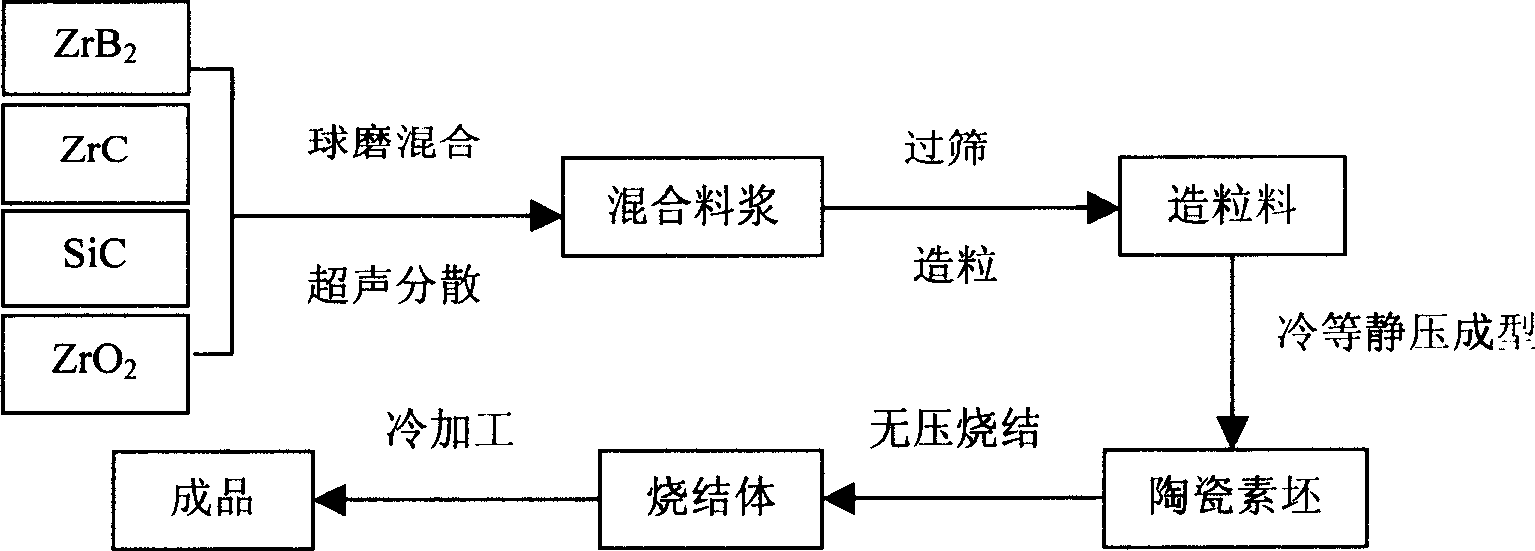

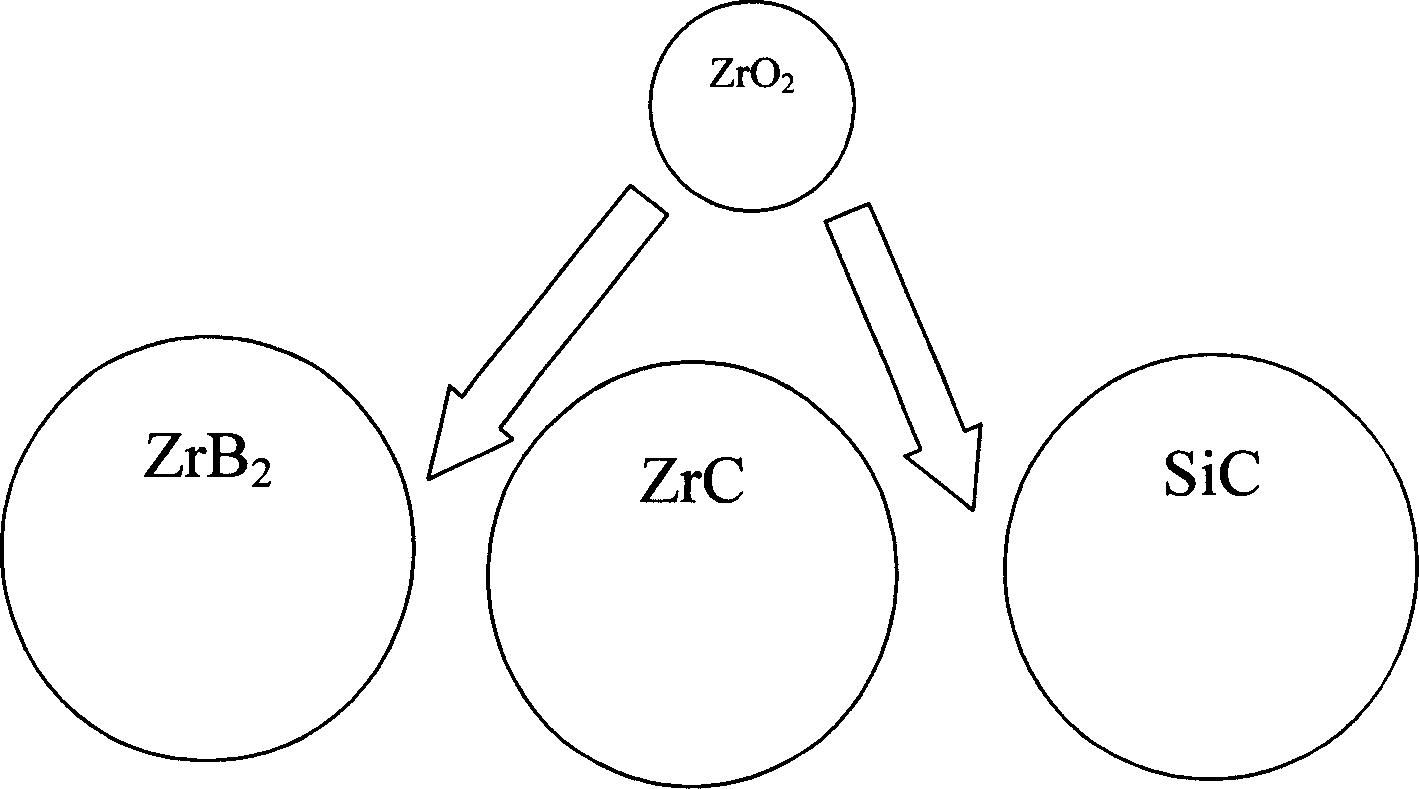

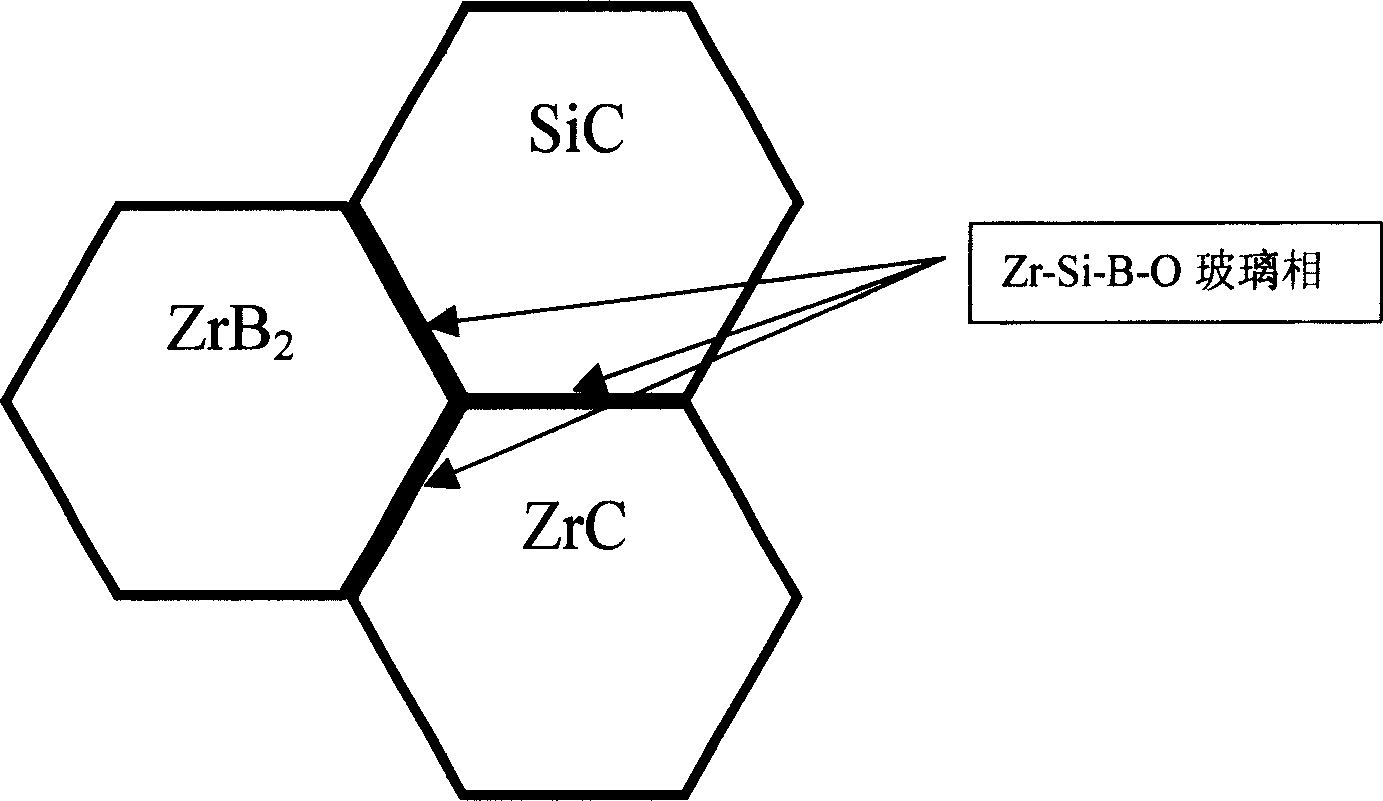

Method for preparing super high temperature complex phase ceramic ZrB2-ZrC-SiC near to zero ablation

ActiveCN1915906AGood high temperature performanceHigh oxidation resistance and anti-ablation performanceLinear ablationSingle phase

This invention relates to a method for preparing ZrB2-ZrC-SiC multiphase ceramic at ultrahigh temperatures with near-zero ablation. The ZrB2-ZrC-SiC multiphase ceramic is prepared from: ZrB2 50-75 wt.%, ZrC 15-40 wt.%, SiC 10-20 wt.%, and ZrO2 as the combustion aid 6-16 wt.%. The ZrB2-ZrC-SiC multiphase ceramic has synergistic effects at high temperatures, which can result in good high-temperature properties. The ZrB2-ZrC-SiC multiphase ceramic has a room-temperature bending strength of 300-400 MPa, a Rockwell hardness of 88-92, and a linear ablation of 0.0003-0.001 mm / s. The ZrB2-ZrC-SiC multiphase ceramic has better oxidation resistance, better ablation resistance and lower sintering temperature compared with single phase ceramics, and has such advantages as good applicability, even distribution, no limit to product shapes and little shape change after 2400 s oxygen-ethylene combustion at 2800-3200 deg.C.

Owner:ZHONGCAI HIGH NEW MATERIAL +1

Alloy for casting space shuttle liquid hydrogen fuel tank

InactiveCN107400812AImprove purityGuaranteed low temperature resistanceFuel systems for specific fuelsTransportation hydrogen technologyFuel tankSolvent free

The invention discloses alloy for casting a space shuttle liquid hydrogen fuel tank. The alloy is prepared from the following raw materials in parts by weight: 85-90 parts of Al, 2.0-3.0 parts of Li, 2.0-3.0 parts of Cu, 0.1-0.25 parts of Zr and 0.1-0.2 parts of Sr. The alloy has the advantages as follows: with adoption of electron beams for smelting the alloy, harmful impurity elements such as O, N, S and the like can be greatly reduced in the alloy smelting process, purity and content of Al, Ni and Cu in the alloy are increased, low temperature resistance of the alloy is guaranteed, and as the temperature decreases, strength, ductility and toughness of the alloy are greatly improved; the aluminum ingot with the grade of Al99.85 is used as a raw material, purity of Al in the alloy is further improved; an ultra-low-temperature-resistant pressure-sensitive adhesive is solvent-free, the curing temperature is low, curing time is short, the ultra-low-temperature-resistant pressure-sensitive adhesive is used for bonding flexible foam plastic and a pipe rapidly, the on-site construction process is good, the ultra-low-temperature-resistant pressure-sensitive adhesive still realizes a better adhesion effect under the condition of ultra-low temperature; and transmission of low temperature can be better insulated by the soft foam plastic layer.

Owner:NANJING LVZHICHENG PATENT TECH DEV CO LTD

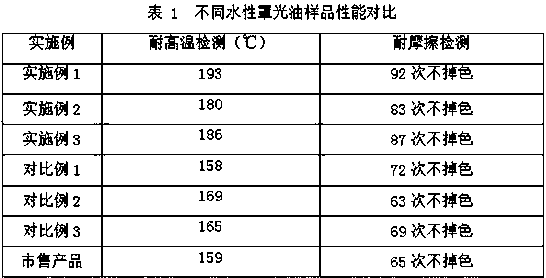

High temperature-resistant anti-adhesion over-printing varnish

ActiveCN108774915AStrong weather resistanceGood weather resistanceCoatingsCoatings without pigmentsWaxEmulsion

The invention discloses a high temperature-resistant anti-adhesion over-printing varnish, The over-printing varnish is prepared from the following components in parts by mass: 60-80 parts of styrene-acrylic acid copolymerized emulsion, 5-10 parts of waterborne self-crosslinking acrylic emulsion, 8-10 parts of waterborne wax emulsion, and 6-10 parts of solvent. Through using high temperature-resistant components of styrene-acrylic acid copolymerized emulsion, waterborne self-crosslinking acrylic emulsion and waterborne wax emulsion, a waterborne over-printing varnish, which can be dried under high temperature and has a high abrasion performance, can be obtained; meanwhile, as the varnish is waterborne over-printing varnish, therefore having environment-friendly characteristic.

Owner:HUBEI DANYAXIANG BIOLOGICAL TECH

Novel rubber seal ring for explosion-proof motor and production technology for rubber seal ring for

InactiveCN104592603AExcellent ozone resistanceImprove low temperature resistanceSulfidationEngineering

The invention discloses a novel rubber seal ring for an explosion-proof motor, and belongs to the technical field of sealing rings. The rubber seal ring is characterized by comprising the following raw materials in parts by weight: 45-55 parts of neoprene, 10-20 parts of EPDM rubber, 4-6 parts of sulfidation system, 5-10 parts of a coldproof soften flux, 12-18 parts of a reinforcing agent, 5-10 parts of a coldproof assistant, and 2-5 parts of an ozone proof assistant. The rubber seal ring has the advantages that the rubber seal ring is high in ozone resistance, good in low temperature resistant performance, and reliable in sealing; the abrasion resistant capability is reinforced greatly; the product quality is more stable; the service life is prolonged by 200% to rubber seal rings for explosion-proof motors in the prior art.

Owner:南阳天一密封股份有限公司

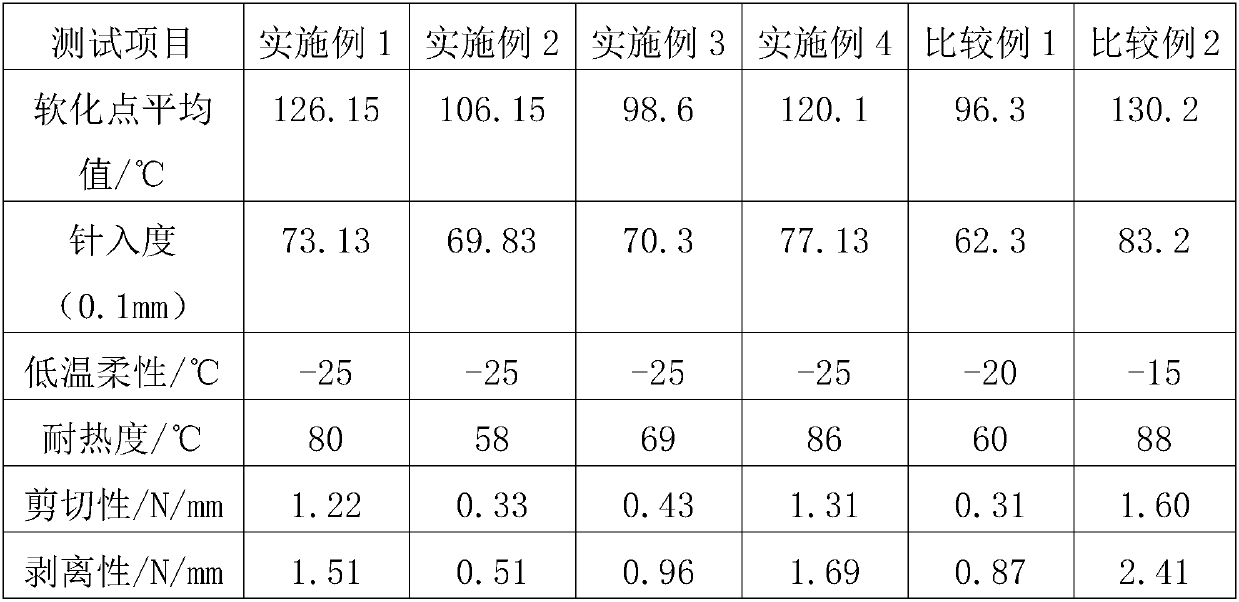

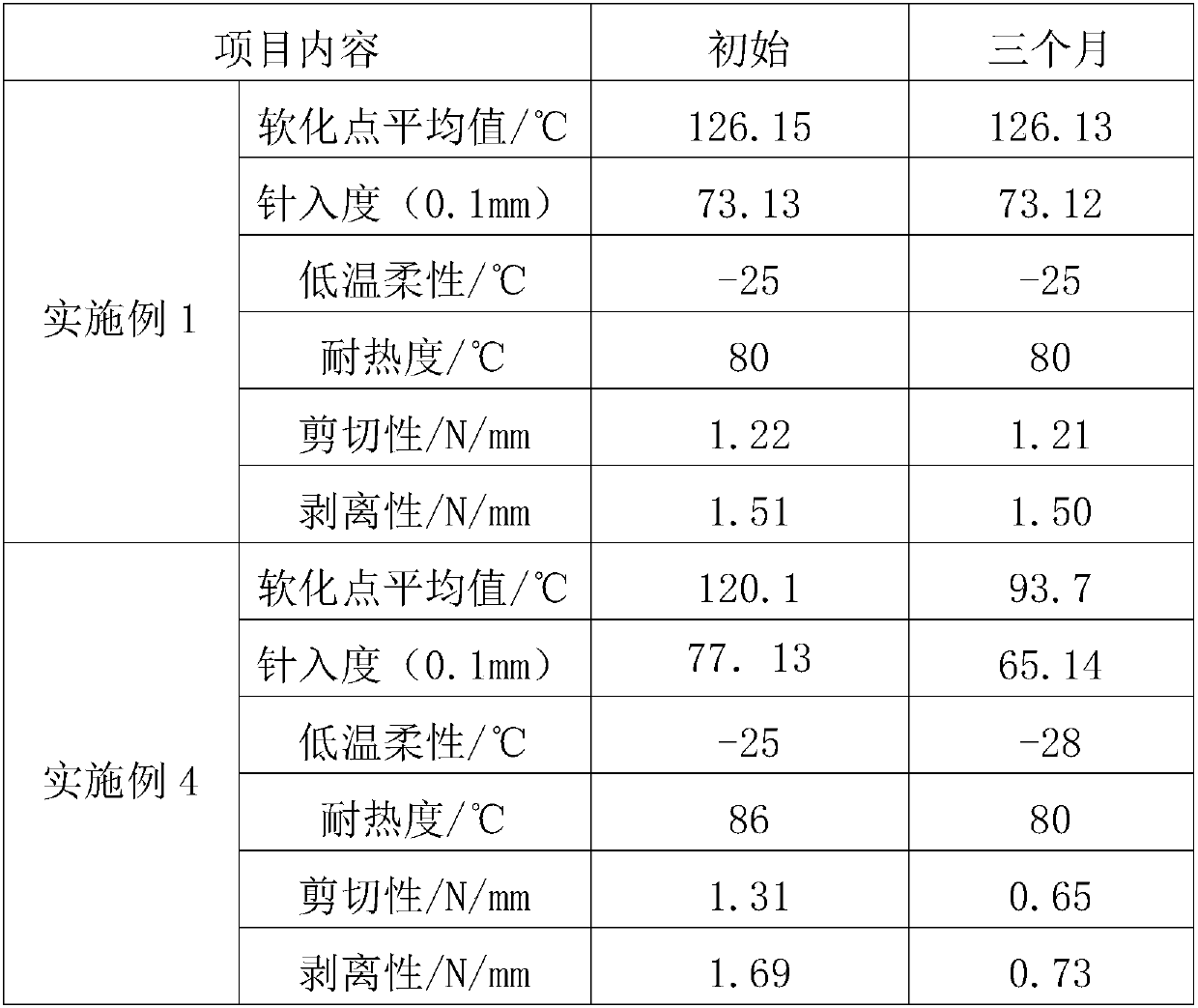

Butyl rubber modified asphalt waterproof material as well as preparation method and application thereof

InactiveCN107815130AImprove aging resistance and stabilitySmall rate of changeBuilding insulationsEmbrittlementBituminous waterproofing

The invention relates to the technical field of waterproof materials, in particular to a butyl rubber modified asphalt waterproof material as well as a preparation method and application thereof. Thebutyl rubber modified asphalt waterproof material is mainly prepared from the following components in percentage by weight: 40-60% of asphalt, 8-20% of butyl rubber, 2-4% of butadiene styrene rubber,6-25% of softening oil and 10-36% of talcum powder. According to the butyl rubber modified asphalt waterproof material disclosed by the invention, butyl rubber is added for modifying, so that ageing resistance and stable performance of asphalt are effectively improved, and embrittlement of the asphalt is improved; a little butadiene styrene rubber is added, so that strength of the waterproof material is improved; and butyl rubber and butadiene styrene rubber are good in compatibility, can form a homogenized mixed system with asphalt, and effectively improves performances of the asphalt, so that the waterproof material has the advantages of being resistant to a high temperature, a low temperature, ageing, corrosion and water; and meanwhile, low-temperature elasticity and plasticity as wellas high-temperature strength and stability are met.

Owner:北京市住房和城乡建设科学技术研究所

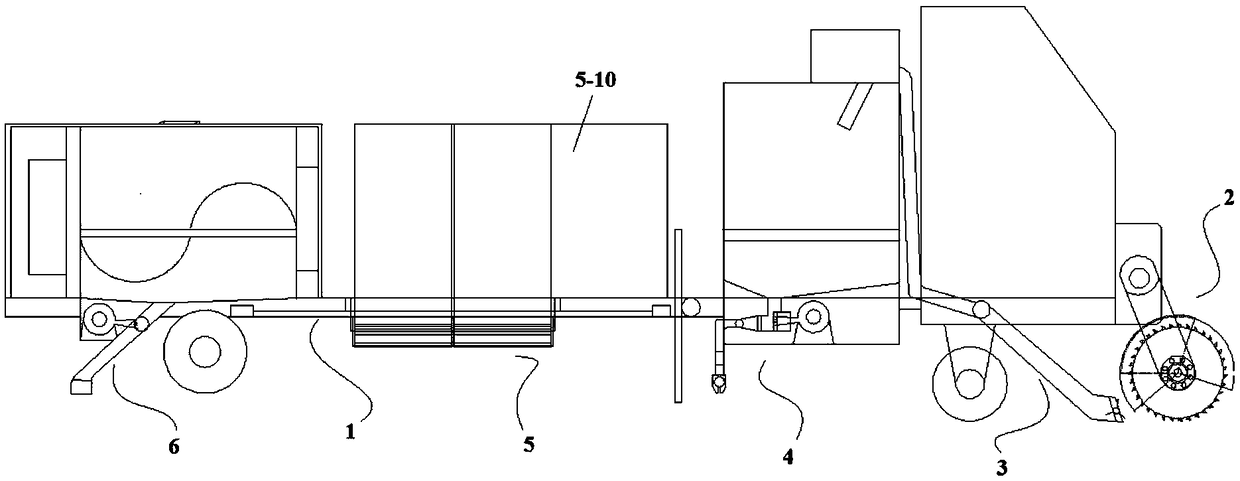

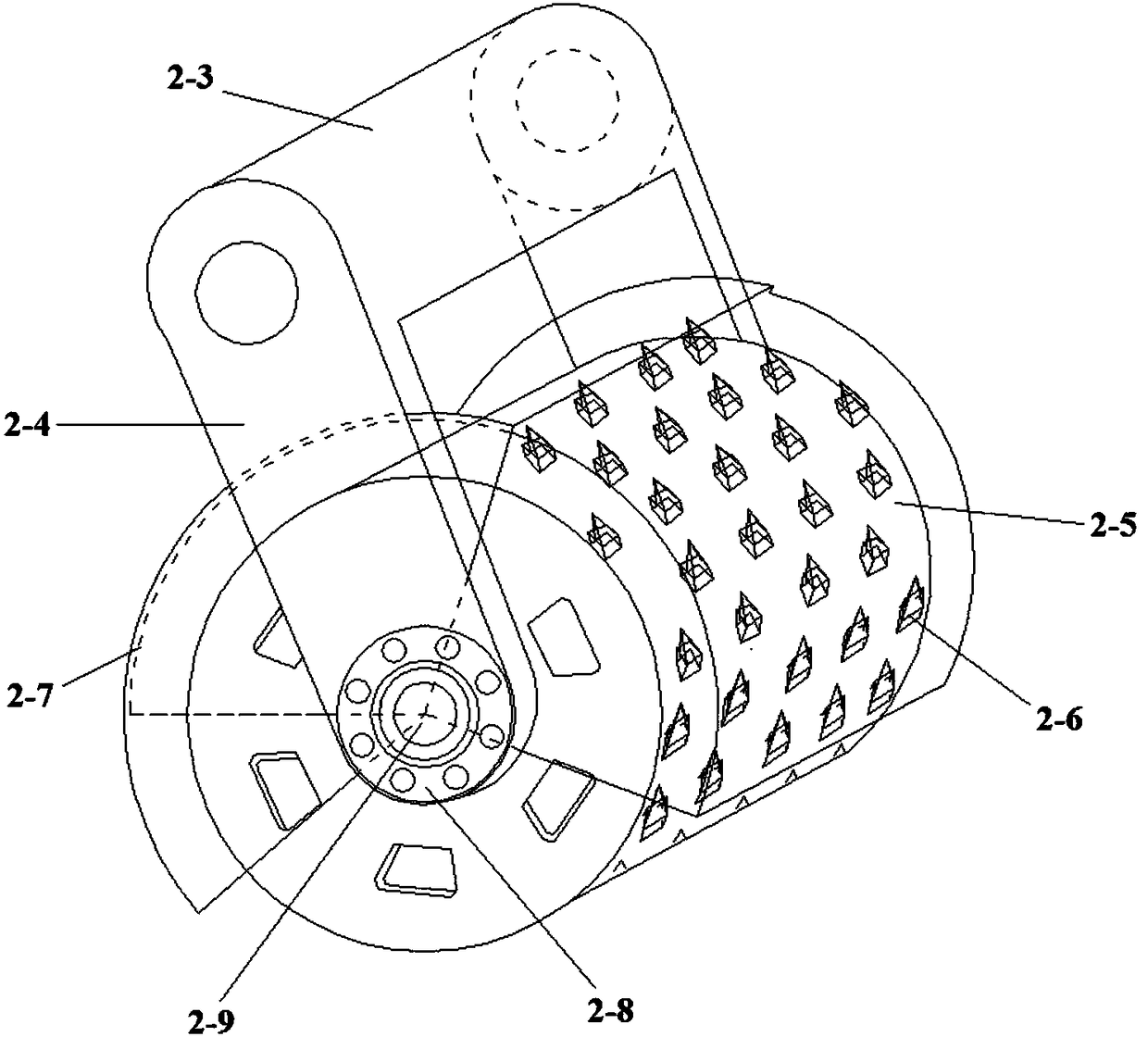

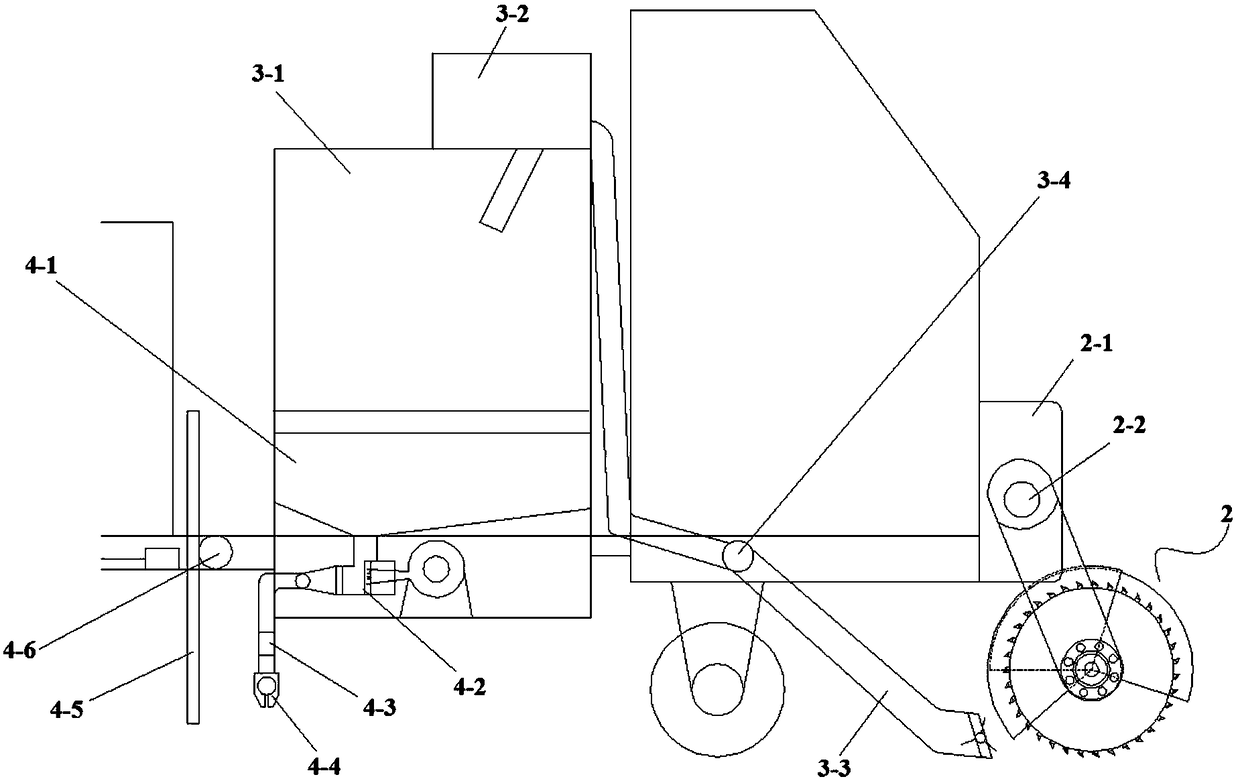

Road surface embedding device and method of piezoelectric substrate

ActiveCN108221609AImprove buried survival rateImprove adhesionRoad cleaningRoads maintainenceWaste collectionEngineering

The invention provides a road surface embedding device and method of a piezoelectric substrate. The road surface embedding device comprises a vehicle body, wherein a milling mechanism, a waste collection mechanism, a bonding layer spraying mechanism, a piezoelectric substrate mounting and embedding mechanism and an asphalt structure layer paving mechanism are mounted on the vehicle body in sequence from a vehicle head to a vehicle tail, wherein the milling mechanism can be used for milling a road surface to form an embedding groove; the waste collection mechanism is used for collecting wasteswhich are generated in a process of milling the road surface through the milling mechanism; the bonding layer spraying mechanism is used for spraying a bonding layer into the embedding groove; by adopting the piezoelectric substrate mounting and embedding mechanism, the piezoelectric substrate is conveyed into a hanging basket through the conveyor belt and is mounted in the embedding groove through the hanging basket; the asphalt structure layer paving mechanism is used for paving an asphalt structure layer and restoring a road surface. The road surface embedding device provided by the invention can realize more functions. The invention provides a novel engineering machinery product which is rare in a piezoelectric substrate embedding construction process, so that mechanical construction of piezoelectric substrate embedding of an existing road surface and a newly-built road surface can be realized.

Owner:CHANGAN UNIV +1

Butadiene acrylonitrile rubber sheath formula

InactiveCN104327329AImprove working conditionLow costInsulated cablesInsulated conductorsPolymer sciencePolystyrene

The invention relates to a butadiene acrylonitrile rubber sheath formula. The formula comprises the following components: 100 parts of butadiene acrylonitrile rubber, 3 parts of polystyrene, 5 parts of ultralow density polyethylene, 6 parts of chlorinated paraffin, 6 parts of polyurethane, 2 parts of butyl acetate, 6 parts of calcined clay, 3 parts of talcum powder, 4 parts of ethylene glycol, 7 parts of phthalo blue, 3 parts of ethylene-vinyl acetate and 10 parts of dicyclopentadiene. The rubber sheath formula has the advantages of low cost, reasonable proportion, excellent performance, use stability and the like, improves the production benefits of factories and reduces the consumption of rubber, and the physical and mechanical properties of rubber sheaths are not reduced.

Owner:QINGDAO DTCN NEW MATERIAL TECH DEV

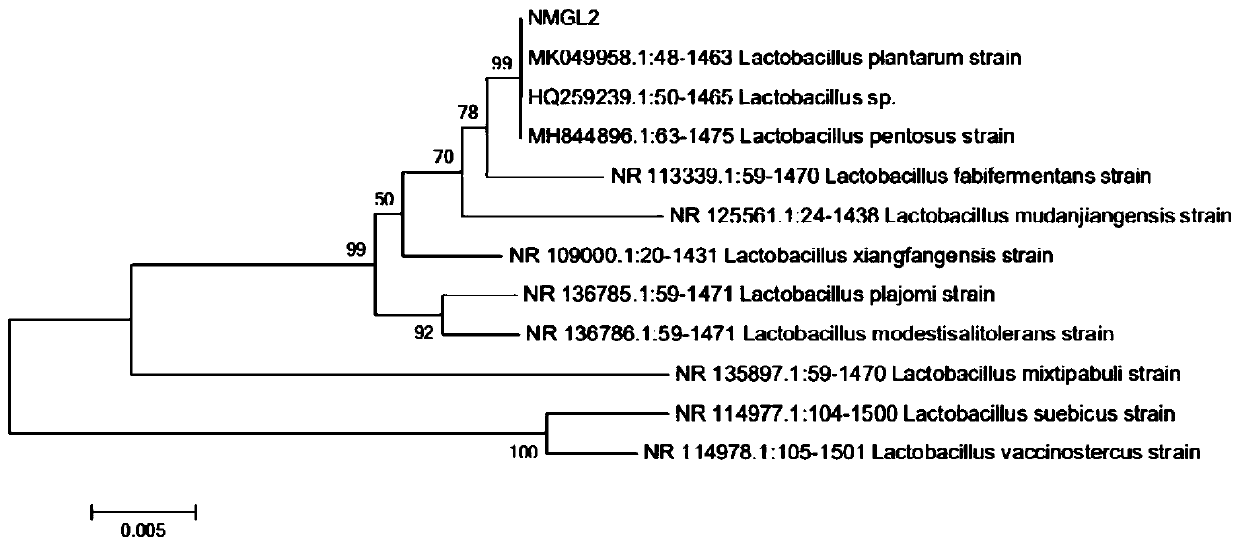

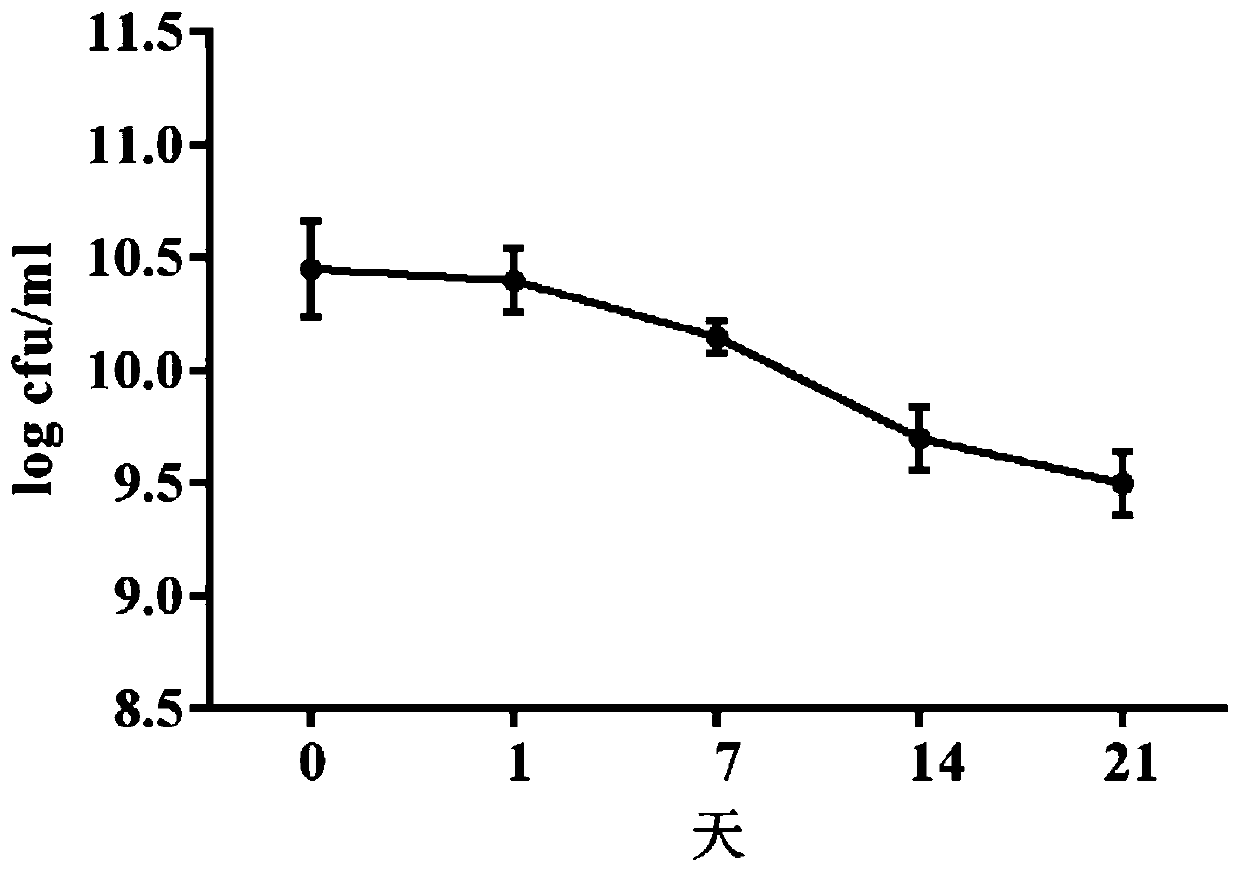

Lactobacillus plantarum resistant to low temperature and acidity dual coercion and application of lactobacillus plantarum

ActiveCN110591955AKeep aliveGuaranteed functionMilk preparationBacteriaChemistryLactobacillus plantarum

The invention discloses lactobacillus plantarum resistant to low temperature and acidity dual coercion and an application of the lactobacillus plantarum. For the lactobacillus plantarum (lactobacillusplantarum) NMGL2 provided by the invention, the preservation number is CGMCC No.18495. The application of the lactobacillus plantarum NMGL2 to preparation of fermented milk also belongs to the protection range of the invention. The application of the lactobacillus plantarum NMGL2 to preparation of a bacterial inhibitor also belongs to the protection range of the invention. The invention further claims for protection of a preparation method of the fermented milk. The preparation method comprises the following steps of inoculating the lactobacillus plantarum NMGL2 in liquid milk, and performingfermentation to obtain the fermented milk. The invention finds lactobacillus plantarum, and the lactobacillus plantarum has high low temperature, acid and cholate resistance and broad-spectrum bacterial inhibition.

Owner:BEIJING TECHNOLOGY AND BUSINESS UNIVERSITY

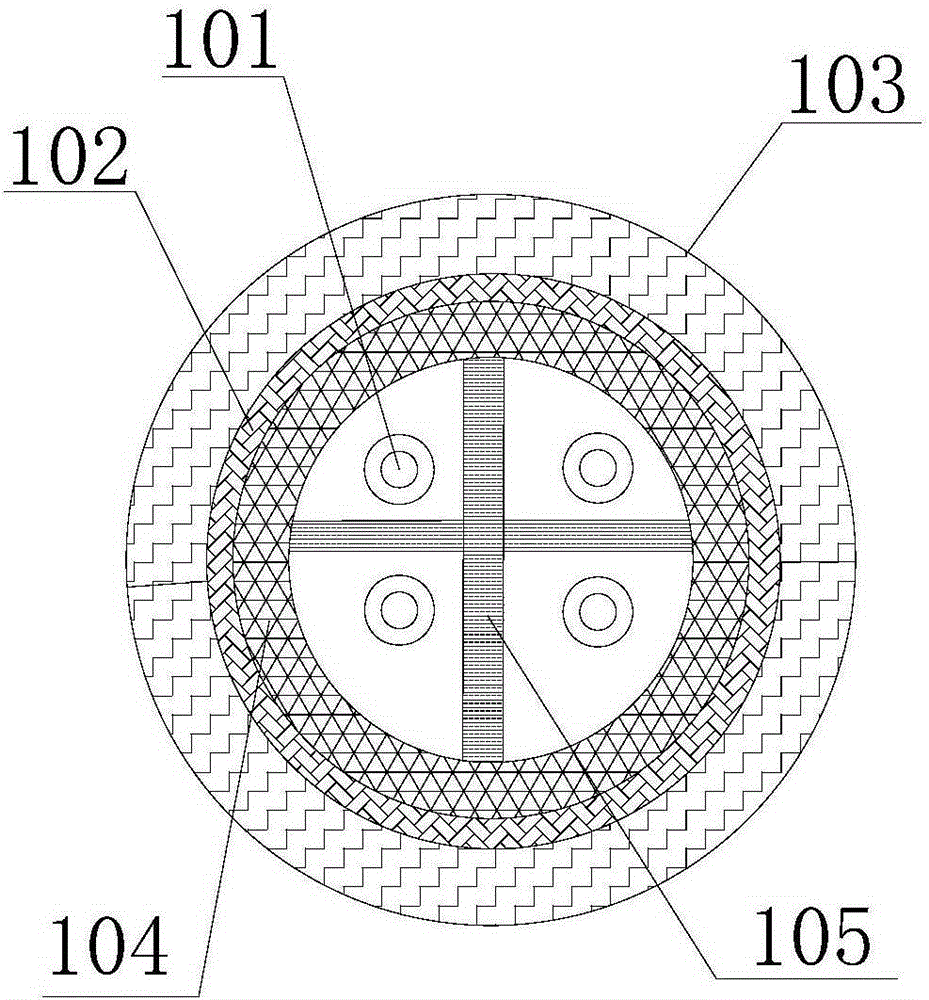

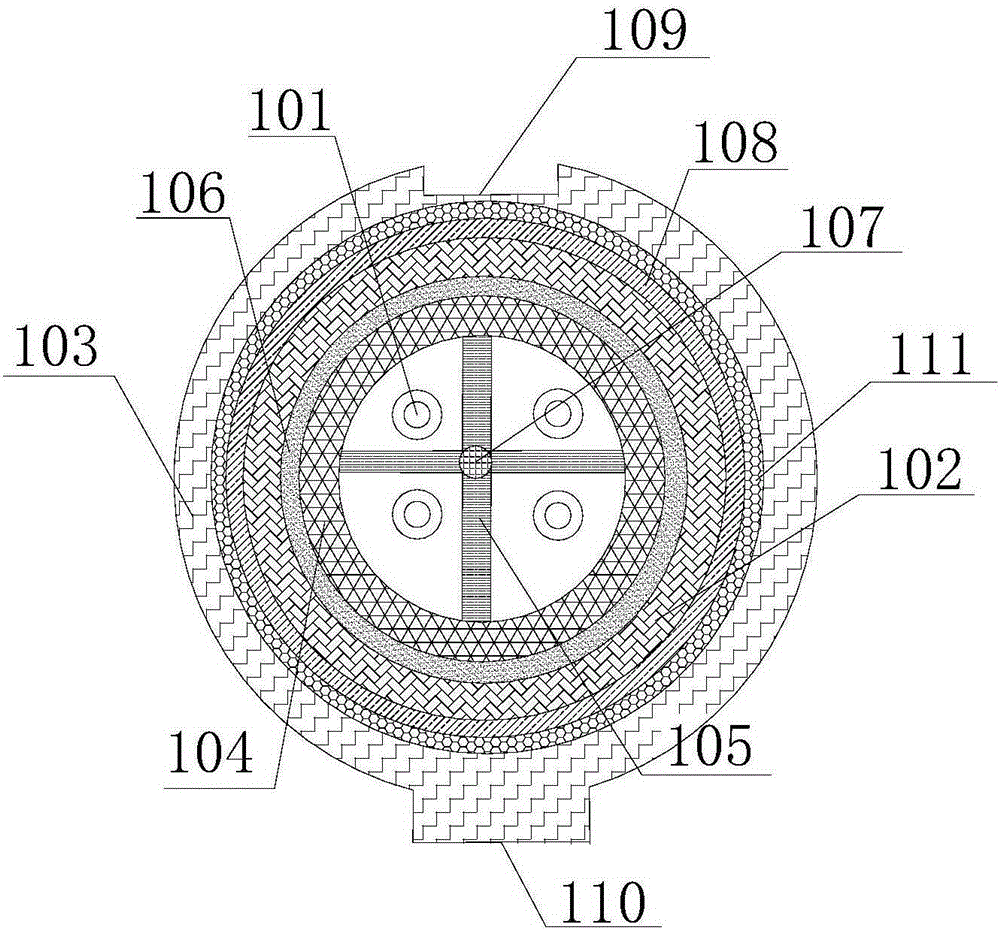

Shielded cable

InactiveCN105280300AImprove anti-interference abilityImprove shielding effectPower cables with screens/conductive layersInsulated cablesShielded cablePower cable

The invention provides a shielded cable, and relates to the field of power cables. The shielded cable comprises a plurality of insulation cable cores, a braid layer, a sheathing layer, a copper-plastic composite shield layer and a plurality of interval shield plates. The shielded cable provided by the embodiment of the present invention has excellent anti-interference performance. By use of the shielded cable, signal transmission is more stable and images transmitted are clearer.

Owner:TIANJIN LANGXING WIRE & CABLE

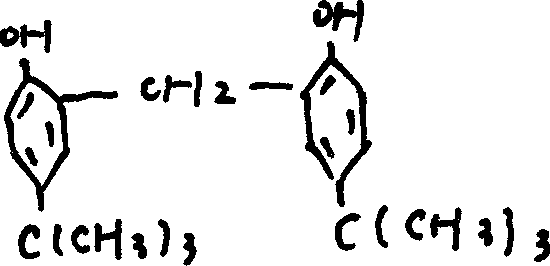

High temperature steam and oil resistant fluororubber pad

ActiveCN1288204CGuaranteed low temperature resistanceMeet the use requirementsHeating oilEngineering

The invention relates to a thermostable viton gasket, which is mainly used as sealing element in plate exchanger using high temperature steam and heating oil. The viton gasket comprises 70-75 wt% of F26 ready-mixed glue and 25-30 wt% of HNBR ready-mixed glue. Said F26 ready-mixed glue comprises 100 wt% of 26-style rubber, 2-2.2 wt% of hexaflurate bisphenol A and so on. HNBR ready-mixed glue comprises 100 wt% of hydrogenated rubber, 48-52 wt% of black pigment and so on. The invention can resist high temperature steam and oil.

Owner:蒋惠成

Foaming thermoplastic polyurethane elastomer, preparation method and application

The invention provides a foaming thermoplastic polyurethane elastomer which can solve the technical problems that the hardness, density, wear resistance, rebound rate and compression permanent deformation indicators of existing foaming thermoplastic polyurethane elastomers cannot meet requirements. The foaming thermoplastic polyurethane elastomer is characterized by being prepared from the following raw materials in parts by weight: 100 parts of a thermoplastic polyurethane elastomer, 3 to 10 parts of phenylene terephthamide fibers, 0.5 to 2.0 parts of polyimide, 1 to 3 parts of polytetrafluoroethylene fibers, 4 to 10 parts of ethylene-bis-stearamide and 0.3 to 2.5 parts of zinc borate. The foaming thermoplastic polyurethane elastomer disclosed by the invention improves the physical properties of the foaming thermoplastic polyurethane elastomer sneaker soles, and particularly shows that the density is further reduced, wear resistance is improved and rebound resilience is improved on the basis of maintaining relatively high hardness of the foaming thermoplastic polyurethane elastomer sneaker soles.

Owner:JIANGNAN UNIV

Low-temperature-resistant and anti-corrosion forging press bearing and preparation method of same

InactiveCN108443324AImprove mechanical propertiesImprove fatigue resistanceShaftsBearing componentsHardnessWear resistance

The invention relates to the technical field of production of bearings, and particularly relates to a low-temperature-resistant and anti-corrosion forging press bearing and a preparation method of same. The bearing includes, by weight, 56-65 parts of Fe, 15.2-17.5 parts of Ni, 5.8-7.6 parts of Cr, 4.6-6.1 parts of Mo, 4.3-5.1 parts of Si, 3.9-4.7 parts of Al, 0.7-1.3 parts of Mn, 0.4-0.9 parts ofCu, 0.9-1.4 parts of C, 1.1-1.6 parts of S and 1.6-2.3 parts of P. Through comprehensive effects of the raw materials and two times of sintering of a green body of a bearing bush at different temperature increasing speeds, the steel has fine grains and clean crystal boundary, thus improving the mechanical performance and anti-fatigue performance of the steel. The bearing has high hardness and strong low-temperature-resistant and anti-corrosion performances. By means of quenching treatment, the bearing has better anti-oxidizing performance and is smoother in surface. By means of tempering treatment, wearing resistance of the bearing is enhanced. The bearing can be applied to large machinery and can bear intensive impact, thus ensuring service life of the bearing.

Owner:宁国市顺鑫金属制品有限公司

Process for processing organic-silicone modified polyurethane sealant

InactiveCN103122235AImprove performanceIncrease elasticityOther chemical processesPolyureas/polyurethane adhesivesPolymer sciencePolyol

The invention relates to a process for processing an organic-silicone modified polyurethane sealant. The process comprises the following steps of: preparing a component A and preparing a component B. The steps of preparing the component A are as follows: (1) adding polyether polyol which is dehydrated in vacuum and isocyanate into a four-necked flask which is provided with a thermometer, a condenser, a stirring device and a vent tube; (2) heating the materials slowly; and (3) dropwise adding silicane into a reaction system slowly while stirring at a constant speed, measuring the content of NCO groups, sealing and storing if the content of the NCO groups meets the requirement. The steps of preparing the component B are as follows: (1) mixing talcum powder, light calcium carbonate, calcium oxide, a plasticizer, an antioxidant 1010, an UV (ultraviolet) absorber UV-327, a carbide-imine hydrolytic stabilizer, MOCA, polyether polyol and a pigment, stirring fully to disperse and grinding; and (2) pouring the dispersed component B into another reactor, dehydrating in vacuum under the condition of stirring, and sealing and storing in a plastic or iron container to obtain the component B. The organic-silicone modified polyurethane sealant has the advantages of high elasticity, low temperature flexibility, water resistance and ageing resistance.

Owner:XIAN HUIKE GEOLOGICAL TECH SERVICES

Tempeerature-constant air exchanger

InactiveCN1609525ARealize two-way equal ventilationAchieve variable ventilationTubular elementsVentilation systemsAir volumeFresh air

The present invention is constant temperature air exchanging machine and belongs to the field of air conditioning technology. The efficient heat exchange equipment comprising copper-aluminum finned pipes has small volume, light weight, no crossed infection, no maintenance, long service life and low power consumption, and may be combined with available central air conditioner system, ventilating system and refrigerating system to lower power consumption and provide sufficient fresh air. It has efficient heat exchanging copper-aluminum finned pipes as key part, and is one box structure with 2 independent channels and 4 ventilation ports. It has increased air exchange function on the basis of regulating air temperature and has lowered power consumption.

Owner:DALIAN SHANGLIDE HEAT CONDUCTION TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com