Production method of composite fiber cement board

A composite fiber and cement board technology, which is applied in the field of building materials, can solve problems such as poor mechanical properties of cement boards, and achieve the effects of maintaining mechanical properties, prolonging service life, and improving chemical stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

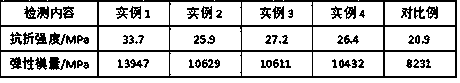

Examples

example 1

[0021]In parts by weight, 50 parts of microcrystalline cellulose are taken successively, 300 parts of mass fraction are 20% sodium hydroxide solution, 150 parts of mass fraction are 20% urea solution, first the urea solution is moved into the refrigerator, and Cool to 0°C to obtain a pre-cooled urea solution, then mix microcrystalline cellulose and sodium hydroxide solution into a three-necked flask, and cool to 0°C, then add the pre-cooled urea solution to the three-necked flask, and use a stirrer to After stirring and mixing at 1200r / min for 60min, transfer the materials in the three-neck flask to a centrifuge, and centrifuge at a speed of 10000r / min for 20min, then remove the sediment in the lower layer to obtain a microcrystalline cellulose solution; 150 parts of microcrystalline cellulose solution, 8 parts of etherification agent, 0.6 part of urease, 40 parts of calcium nitrate solution with a mass fraction of 10%, first add microcrystalline cellulose to a four-necked flas...

example 2

[0023] In parts by weight, 50 parts of microcrystalline cellulose are taken successively, 300 parts of mass fraction are 20% sodium hydroxide solution, 150 parts of mass fraction are 20% urea solution, first the urea solution is moved into the refrigerator, and Cool to 0°C to obtain a pre-cooled urea solution, then mix microcrystalline cellulose and sodium hydroxide solution into a three-necked flask, and cool to 0°C, then add the pre-cooled urea solution to the three-necked flask, and use a stirrer to After stirring and mixing at 1200r / min for 60min, transfer the materials in the three-neck flask to a centrifuge, and centrifuge at a speed of 10000r / min for 20min, then remove the sediment in the lower layer to obtain a microcrystalline cellulose solution; 150 parts of microcrystalline cellulose solution, 8 parts of etherification agent, 40 parts of calcium nitrate solution with a mass fraction of 10%, first add microcrystalline cellulose to a four-necked flask with a stirrer, a...

example 3

[0025] In parts by weight, 50 parts of microcrystalline cellulose are taken successively, 300 parts of mass fraction are 20% sodium hydroxide solution, 150 parts of mass fraction are 20% urea solution, first the urea solution is moved into the refrigerator, and Cool to 0°C to obtain a pre-cooled urea solution, then mix microcrystalline cellulose and sodium hydroxide solution into a three-necked flask, and cool to 0°C, then add the pre-cooled urea solution to the three-necked flask, and use a stirrer to After stirring and mixing at 1200r / min for 60min, transfer the materials in the three-neck flask to a centrifuge, and centrifuge at a speed of 10000r / min for 20min, then remove the sediment in the lower layer to obtain a microcrystalline cellulose solution; 150 parts of microcrystalline cellulose solution, 8 parts of etherification agent, 0.6 part of urease, 40 parts of calcium nitrate solution with a mass fraction of 10%, first add microcrystalline cellulose to a four-necked fla...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com