Patents

Literature

39results about How to "Low acid and alkali resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

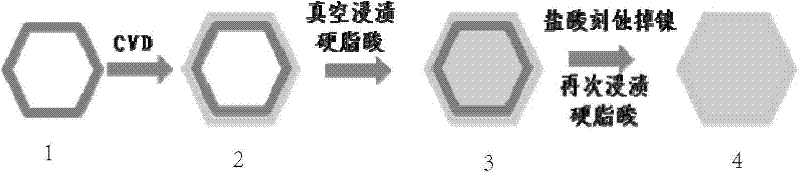

Three-dimensional graphene/phase change energy storage composite material and preparation method thereof

InactiveCN102585776AImprove thermal conductivityLow densityHeat-exchange elementsPorous grapheneLiquid state

The invention provides a three-dimensional graphene / phase change energy storage composite material and a preparation method thereof. The technical scheme is as follows: graphene and a phase change energy storage material are in situ compounded, wherein porous graphene with a three-dimensional structure is used as a heat conductor and a compound die, and a solid-liquid phase change organic material is used as the energy storage material and filler. The three-dimensional porous graphene is compounded with the phase change material, the phase change energy storage material is partitioned in a plurality of pore spaces and is in tight joint with the graphene wall so as to greatly increase the effective heat contact area, and the highly linked graphene three-dimensional heat conduction network channels can realize rapid system heat exchange. In addition, due to the capillary adsorption capacity of porous graphene, the liquid-state phase change energy storage material is localized, so as to effectively prevent seepage. Therefore, the three-dimensional graphene foam has good designability, and becomes a lighter and more effective heat dissipation material for electronic devices.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

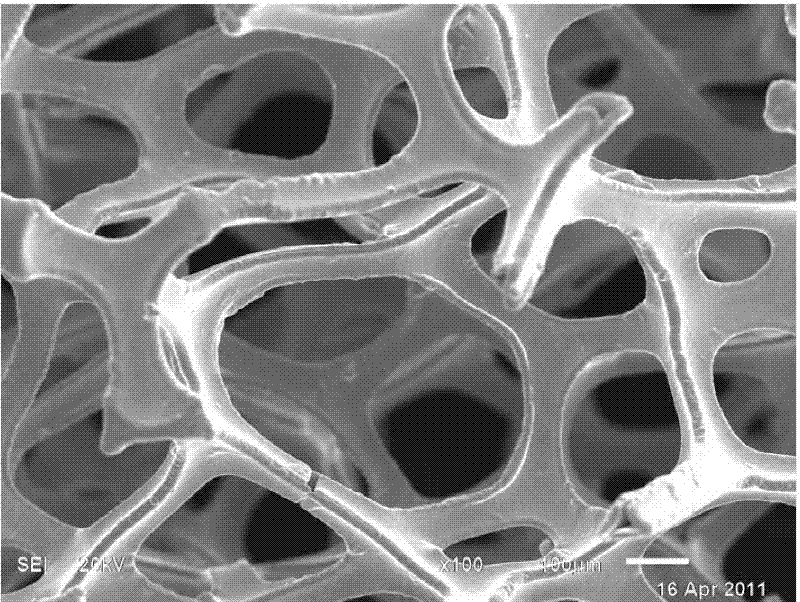

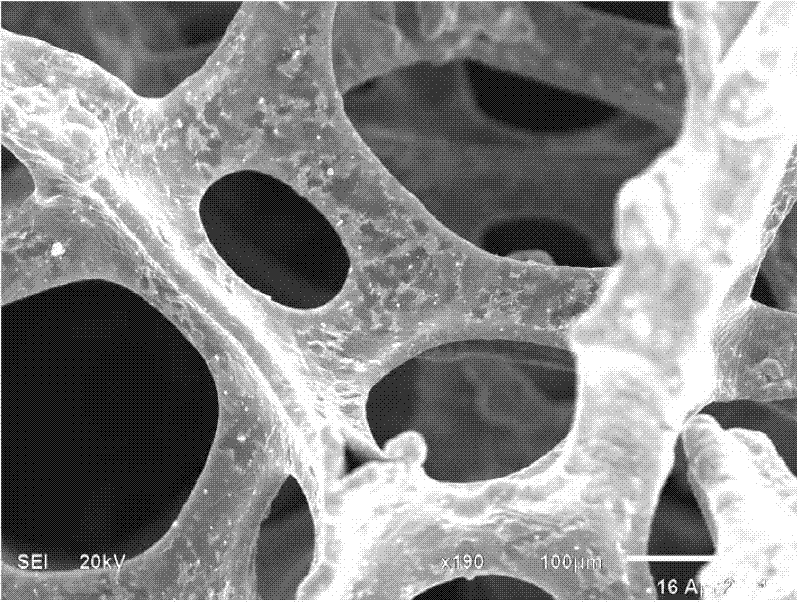

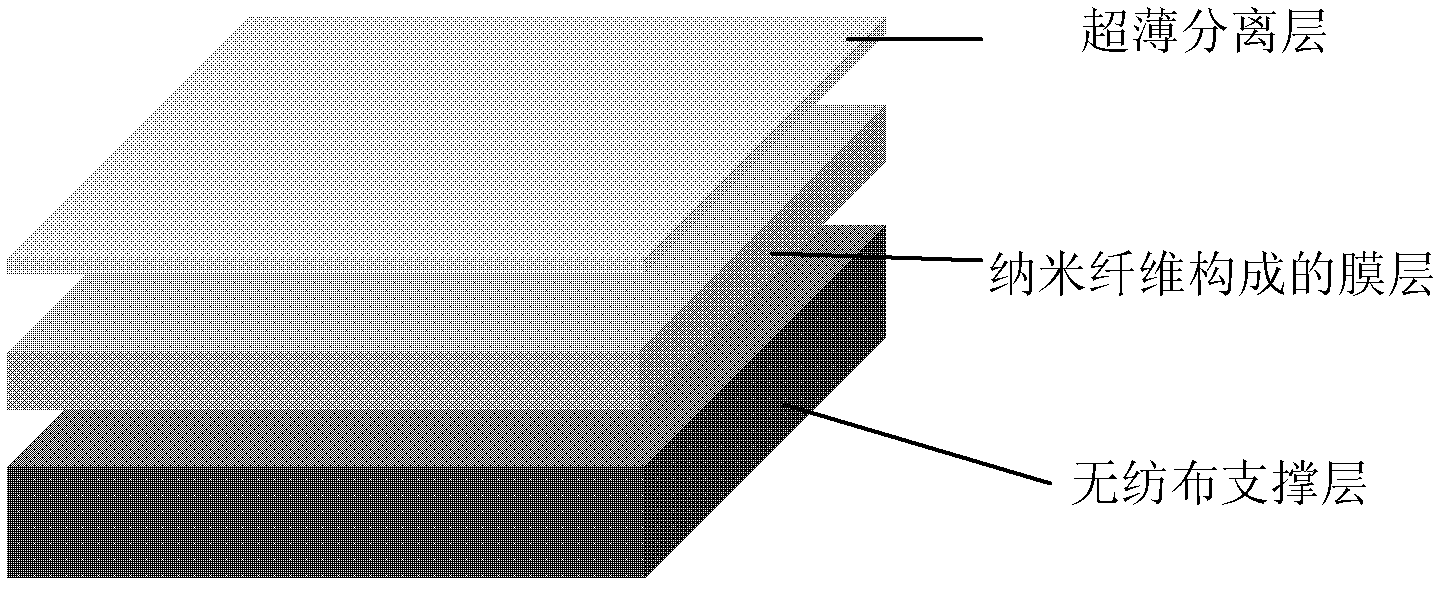

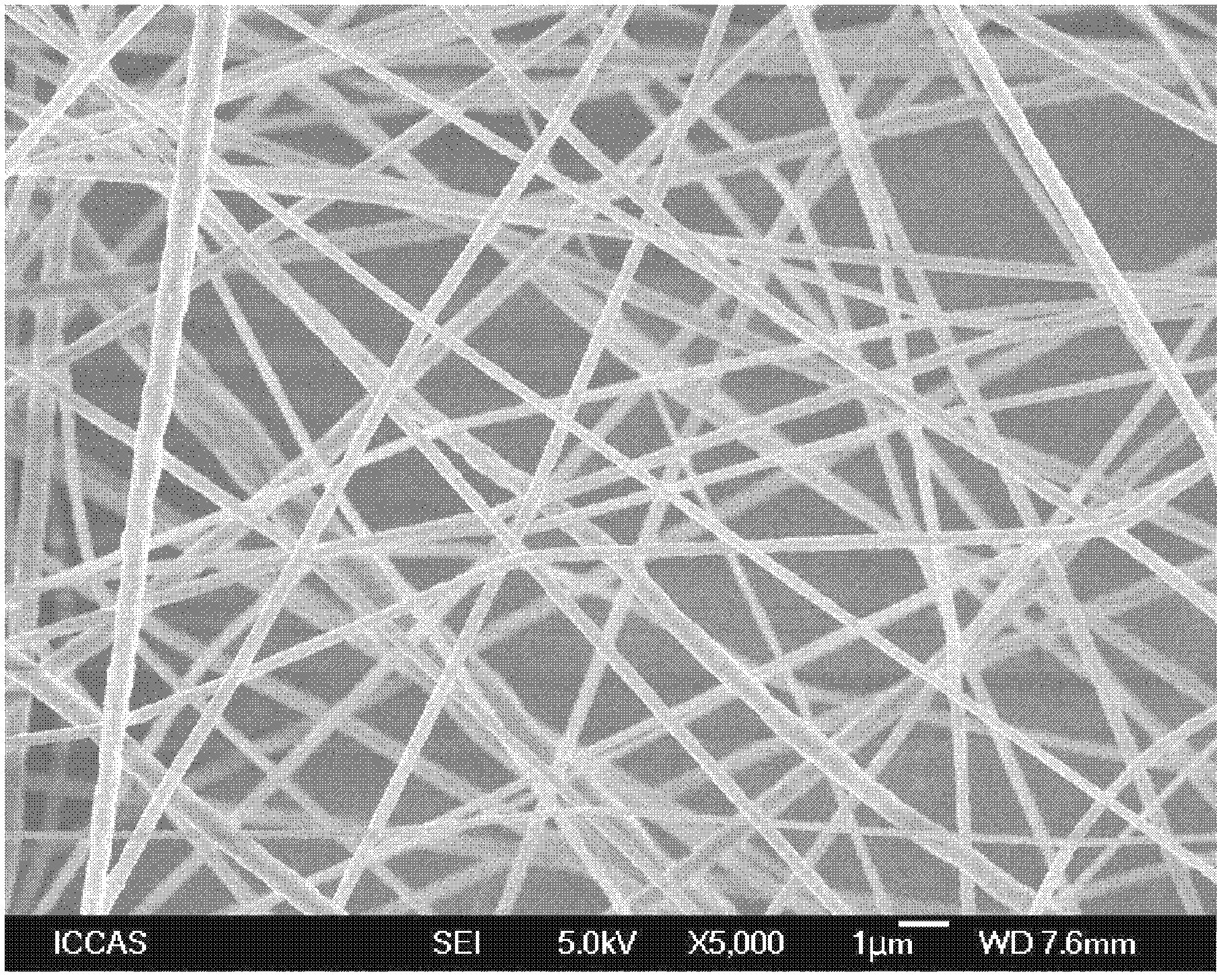

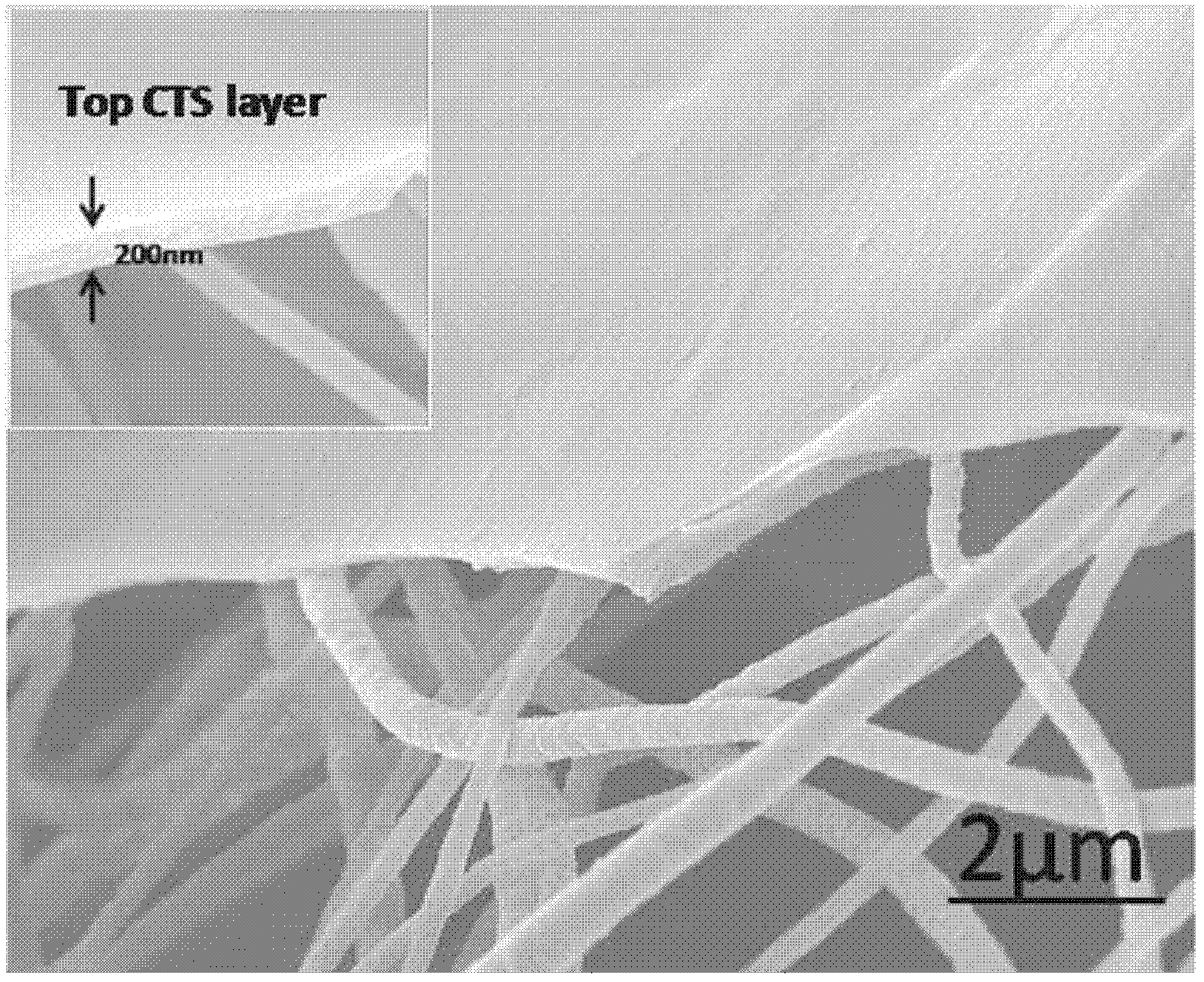

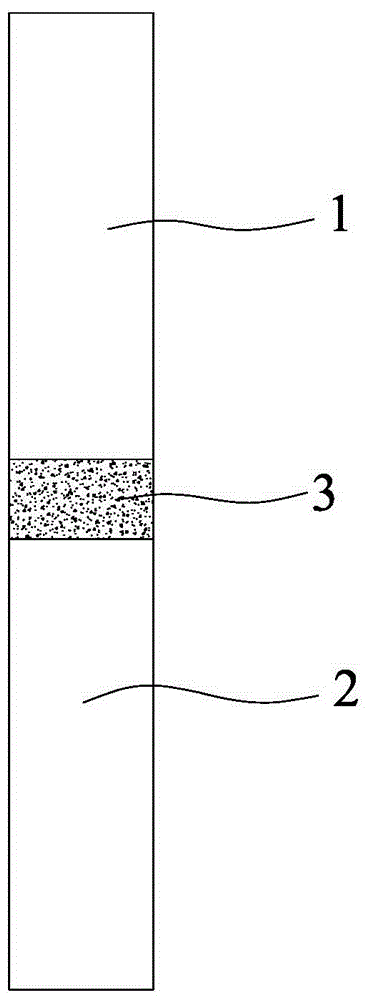

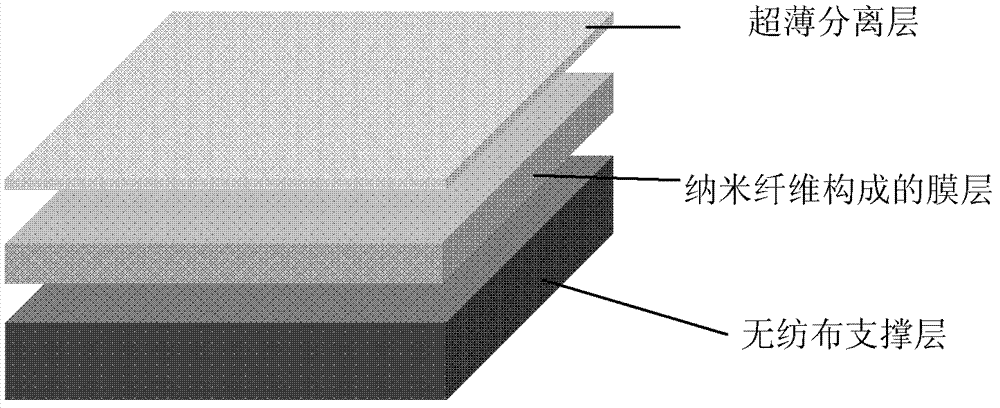

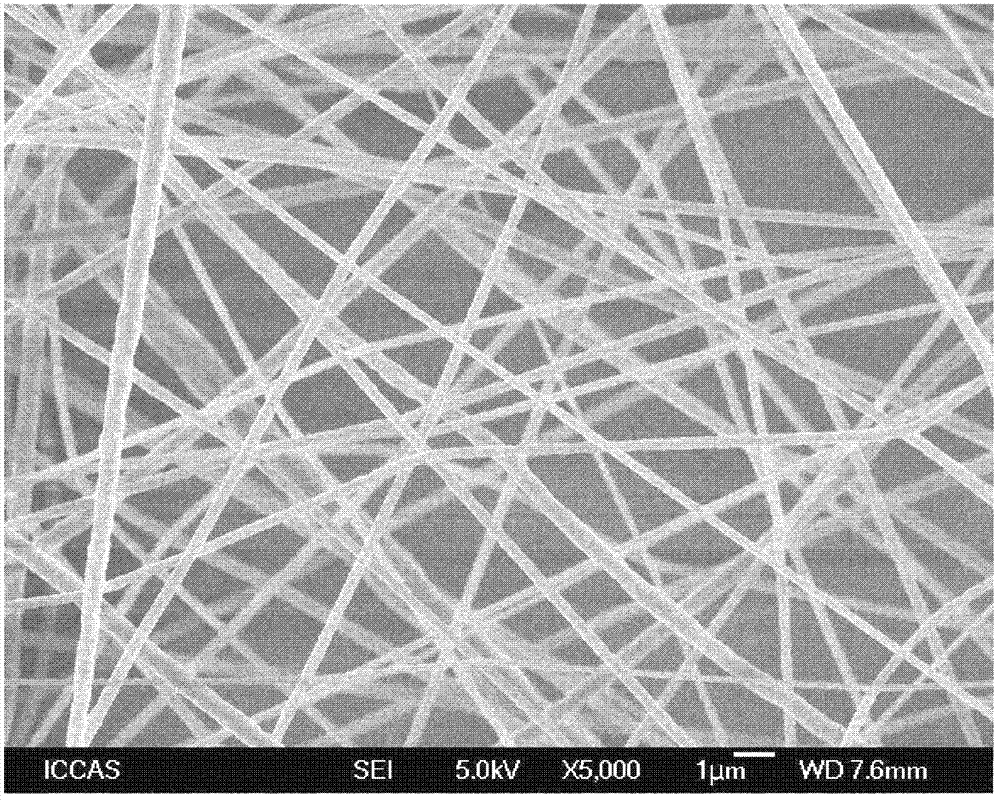

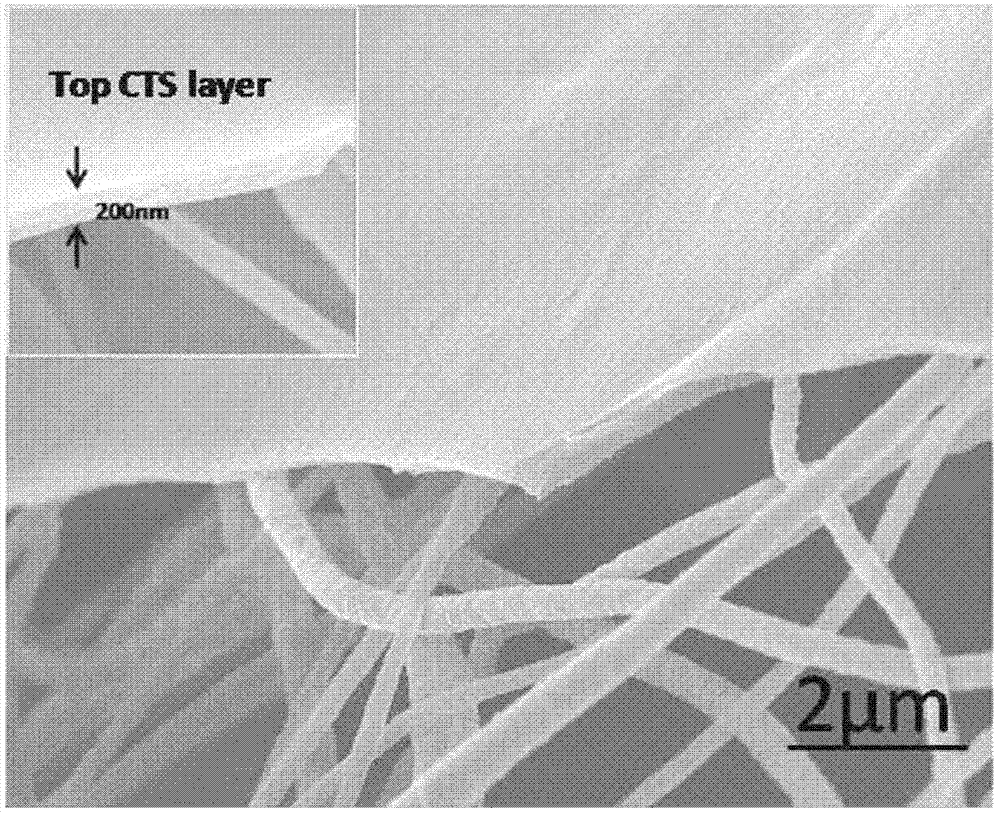

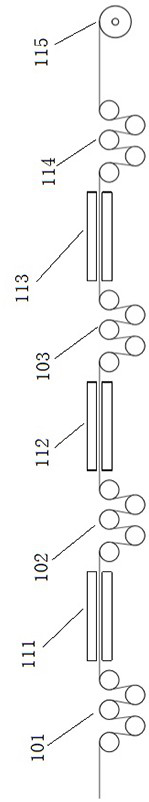

Composite ultrafiltration membrane of modified chitosan composite electrostatic spinning nanofiber and preparation method of composite ultrafiltration membrane

InactiveCN103041714AIncrease water fluxHigh retention rateSemi-permeable membranesUltrafiltrationElectrospinning

The invention relates to a composite ultrafiltration membrane of a modified chitosan composite electrostatic spinning nanofiber. The composite ultrafiltration membrane is structurally characterized in that a non-woven fabric supporting layer substrate is sequentially provided with a membrane layer which has excellent chemical resistance and ageing resistance, and is composed of polymer electrostatic spinning nanofiber and prepared by using an electrostatic spinning method; and the surface of the membrane layer is an ultrathin modified chitosan separation layer which has high water permeability and stable chemical property, and is formed after a high-hydrophilcity ultrathin chitosan layer coated on the surface of the membrane layer composed of the polymer electrostatic spinning nanofiber by using aldehyde and acyl chloride modifiers is subjected to crosslinking modification. The multi-layer composite ultrafiltration membrane provided by the invention has the characteristics of high water flux, high interception efficiency, low pollution, resistance to acid and base and the like. The filtration membrane can be used for producing domestic water, drinking water and water used under special conditions and is suitable for the fields such as medicines, bioengineering, foods, environment friendliness and the like.

Owner:INST OF CHEM CHINESE ACAD OF SCI

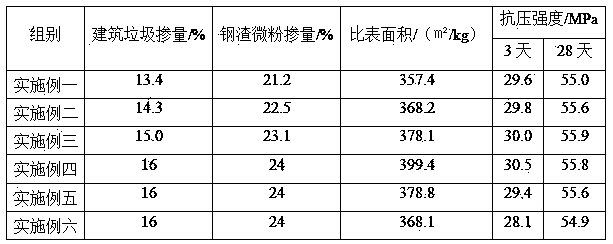

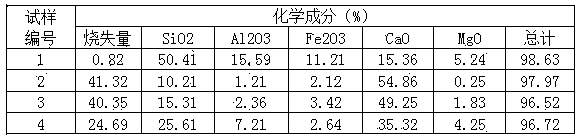

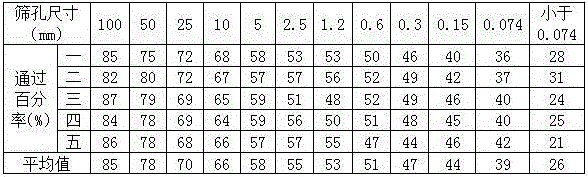

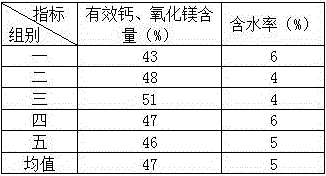

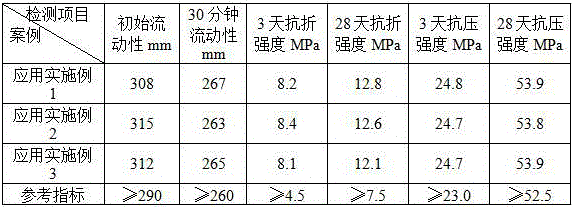

Method for producing green ecological cement resistant to seawater corrosion by using construction wastes

The invention discloses a method for producing green ecological cement resistant to seawater corrosion by using construction wastes. The cement comprises the following raw materials in parts by weight: 40-50 parts of sulphoaluminate cement clinkers, 5-20 parts of construction wastes, 20-25 parts of steel slag powder, 0.06-0.08 part of compound activating agent, 2-5 parts of early strength agent, 0.3-0.5 part of water reducing agent, 0.005-0.007 part of air entraining agent and 0.3-0.5 part of retarder. The production method is characterized by breaking, grinding and homogenizing the construction wastes, the sulphoaluminate cement clinkers, the compound activating agent and the early strength agent respectively, preparing the materials in proportion, mixing the materials, homogenizing the mixture, then adding the water reducing agent, the air entraining agent and the retarder, mixing the materials and homogenizing the mixture, thus preparing the product. The green ecological cement resistant to seawater corrosion has the excellent characteristics of high strength, resistance to seawater corrosion and seawater scouring, and the like besides the properties of ordinary cement, and is especially suitable for underground engineering, ports, wharfs and other engineering suffering corrosion of erosion media.

Owner:广西云燕特种水泥建材有限公司

Method for producing seawater corrosion-resistant green ecological cement from stone waste

ActiveCN104291717AReduce stone dust pollutionWide variety of sourcesCement productionScrapCorrosion resistant

The invention discloses a method for producing seawater corrosion-resistant green ecological cement from stone waste. The seawater corrosion-resistant green ecological cement comprises the following raw materials in parts by weight: 30-40 parts of stone waste, 40-50 parts of sulphate aluminum cement clinker, 0.03-0.05 part of a complex activator, 2-4 parts of an early-strength agent, 0.3-0.5 part of a water-reducing agent, 0.005-0.007 part of an air entraining agent, and 0.3-0.5 part of a retarder; and the production method comprises the following steps: respectively crushing the stone waste, sulphate aluminum cement clinker, complex activator and early-strength agent, grinding, homogenizing, then mixing and homogenizing according to a proportion, then adding the water-reducing agent, air entraining agent and the retarder, mixing and homogenizing to obtain the seawater corrosion-resistant green ecological cement. The seawater corrosion-resistant green ecological cement has the excellent properties of being high-strength, seawater corrosion-resistant, seawater scouring-resistant and the like besides the performances of common cement, and is especially applicable to underground engineering, ports, wharfs and other engineering corroded by erosion media.

Owner:广西云燕特种水泥建材有限公司

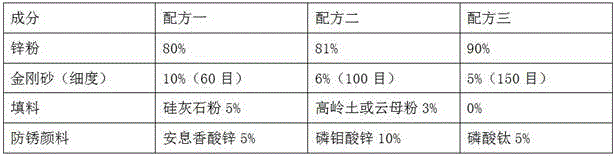

Water-based epoxy anticorrosive paint and preparation method thereof

ActiveCN105713487AStrong adhesionEmission reductionAnti-corrosive paintsEpoxy resin coatingsWater basedEpoxy

The invention provides a water-based epoxy anticorrosive paint and a preparation method thereof. The water-based epoxy anticorrosive paint comprises a component A and a component B in a weight ratio of 1:(2-3), wherein the component A and component B are mixed only when in use. The component A comprises the following ingredients in percentage by mass: 30-40% of water-based epoxy resin emulsion, 18-25% of potassium silicate, 18-25% of lithium silicate, 1-3% of water-based wetting and dispersing agent and 15-25% of deionized water. The component B comprises the following ingredients in percentage by mass: 80-90% of zinc powder, 5-10% of corundum, 0-5% of filler and 5-10% of antirust pigment. By adopting the two-component system composed of the component A and component B, the component B is added into the component A, evenly stirred and filtered, and can be subjected to spray construction. The production technique and use operation are very simple and convenient, have the advantages of environment friendliness and energy saving, and are safe to use. The water-based epoxy anticorrosive paint can be widely used in various hardware materials, and has higher decorative performance.

Owner:SHENZHEN ZHONGKE HONGYE TECH CO LTD

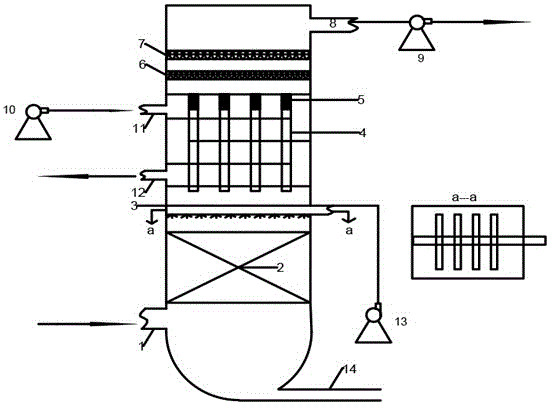

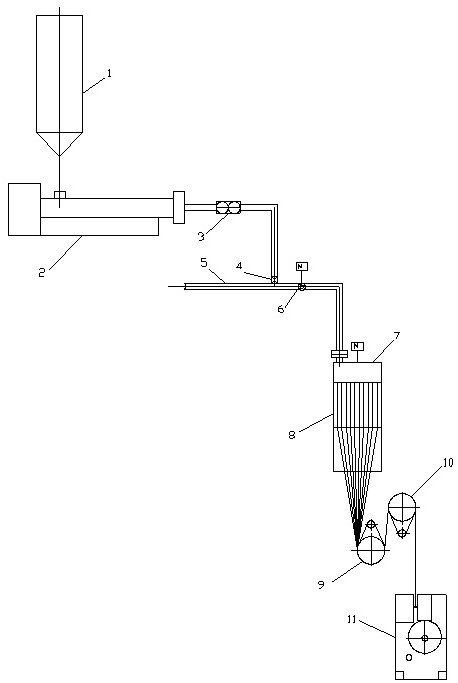

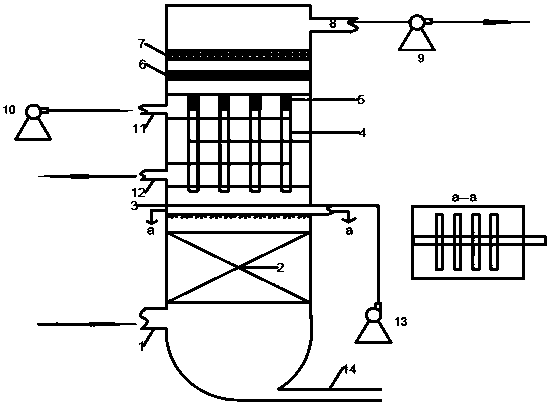

Integrated dust-fog removing device and dust-fog removing method for wet desulphurization system

The invention relates to the field of flue gas treatment, in particular to an integrated dust-fog removing device and a dust-fog removing method for a wet desulphurization system. According to the device, the principle of glass tube condensation, the principle of screen filtration and the characteristic of different porosities of polytetrafluoroethylene (PTFE) monofilament fibers are utilized to realize the simultaneous efficient purification of original micron-grade solid smoke dust fine particles with different particle sizes and micron-grade fogdrop particles with different particle sizes in flue gas of the wet desulfurization system. After the device is adopted, the micron-grade solid dust and the micron-grade fogdrops in the flue gas can be efficiently removed in an integrated way; furthermore, the device is compact in structure, is easily installed in the wet desulphurization system of the flue gas, and is simple and convenient to operate, thus having wide market prospect and higher promotional value. The device and the method which are provided by the invention are suitable for large-load and high-power wet flue gas desulphurization treatment systems of coal in a power plant, the coal chemical industry, and the like.

Owner:LIAONING TECHNICAL UNIVERSITY

High-strength concrete

InactiveCN107151115AImprove mechanical propertiesHigh strengthSolid waste managementHigh strength concreteCrack resistance

The invention discloses high-strength concrete. The high-strength concrete is prepared from, by weight, 10-12 parts of cement, 35-45 parts of sand, 60-75 parts of coarse aggregate, 13-17 parts of silicon powder, 7-12 parts of rubber powder, 3-5 parts of modified bamboo fibers, 1-4 parts of polyvinyl alcohol fibers and 3-7 parts of polypropylene fibers. By addition of a certain quantity of silicon powder into cement and sand, pressure resistance of the concrete is greatly improved; due to addition of the modified bamboo fibers, the polyvinyl alcohol fibers and the polypropylene fibers, cracking resistance of the concrete is improved while concrete strength is improved as well, and concrete density is reduced to some extent.

Owner:成都市德容建筑劳务有限公司

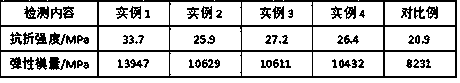

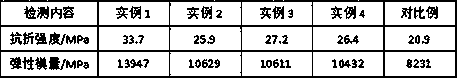

Production method of composite fiber cement board

The invention discloses a production method of a composite fiber cement board, and belongs to the technical field of building materials. The production method comprises the following steps: mixing microcrystalline cellulose with a sodium hydroxide solution, cooling the obtained solution, adding a precooled urea solution, stirring and mixing the obtained solution, centrifuging the obtained solutionto obtain a microcrystalline cellulose solution, dropwise adding an etherifying agent to the microcrystalline cellulose solution, performing constant-temperature stirring and reacting, cooling the obtained solution, adding urease and a calcium nitrate solution, continuing a reaction, concentrating the obtained reaction solution, drying the concentrated reaction solution to obtain etherified microcrystalline cellulose, performing a constant-temperature and constant-pressure reaction on the etherified microcrystalline cellulose and a sodium methoxide solution, cooling the obtained reaction solution, adding chloromethane, performing a constant-temperature and constant-pressure reaction, carrying out reduced pressure concentrating, drying the obtained concentrate to obtain modified microcrystalline cellulose, mixing cement, the modified microcrystalline cellulose, a water reducer and a defoamer, carrying out injection molding, and curing the molded mixture to obtain the composite fiber cement board. The composite fiber cement board obtained in the invention has excellent mechanical properties.

Owner:赣州大业金属纤维有限公司

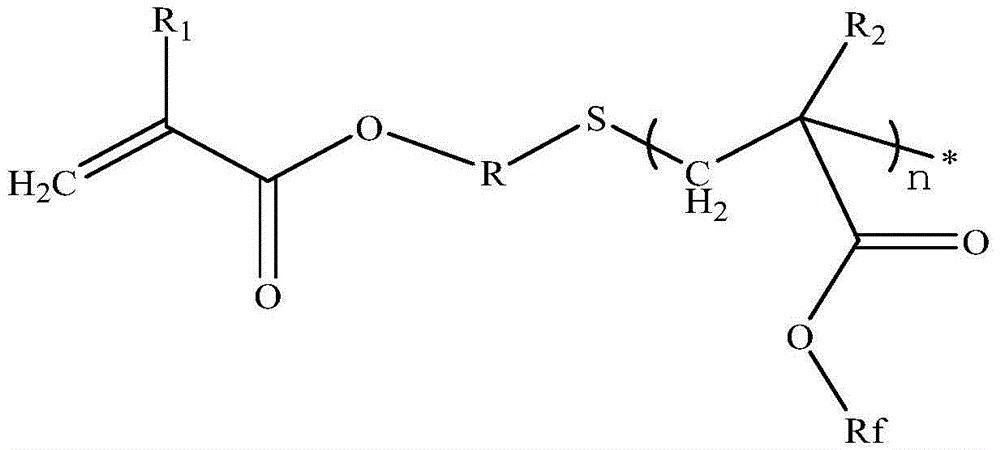

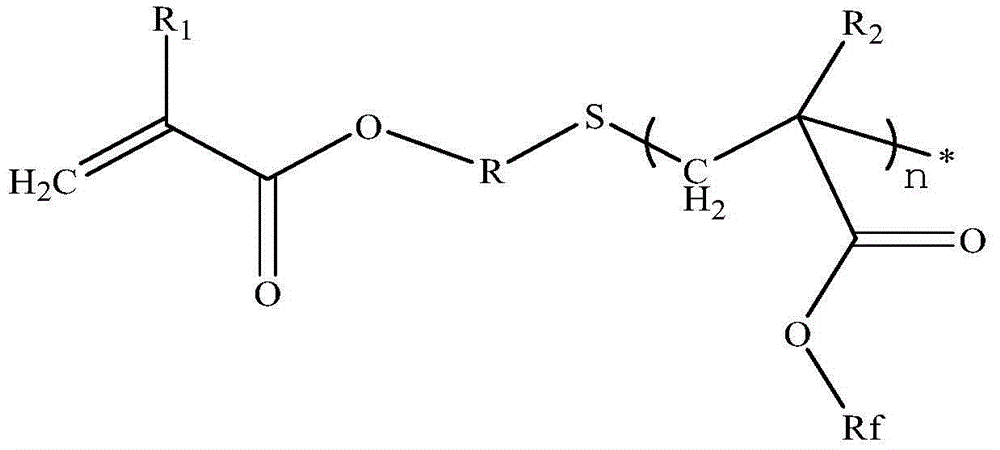

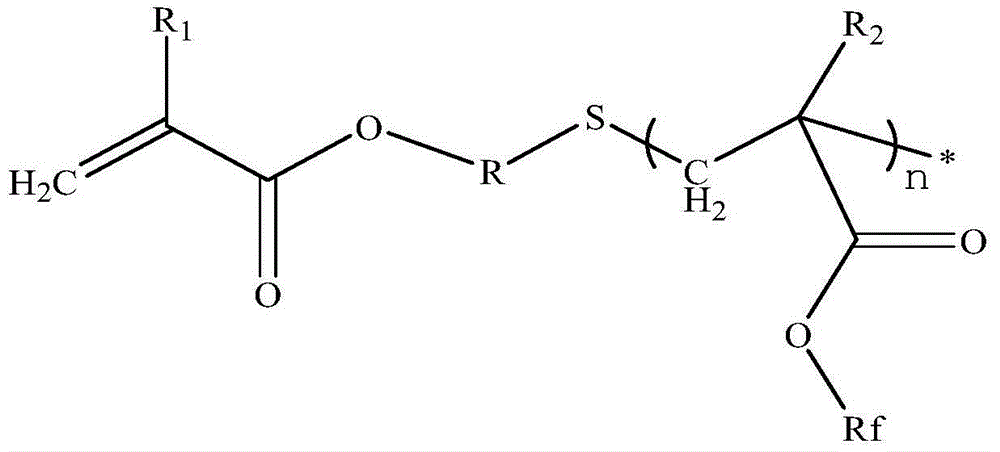

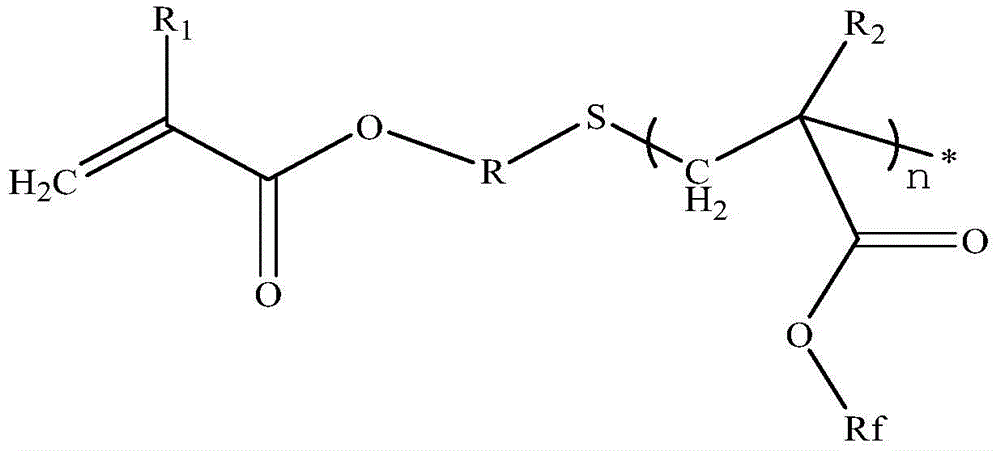

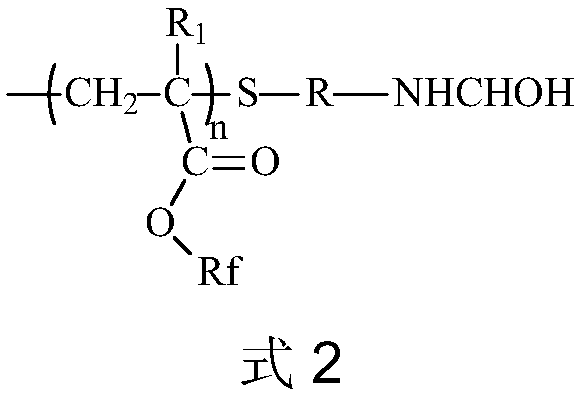

Monovinyl-terminated fluorine-containing prepolymer/epoxy (methyl) acrylate composite UV-cured paint, preparation and applications thereof

The invention discloses a monovinyl-terminated fluorine-containing prepolymer / epoxy (methyl) acrylate composite UV-cured paint, preparation and applications thereof, and belongs to the field of polymer materials. The composite UV-cured paint comprises the following components in parts by weight: 0.01 to 50 parts of monovinyl terminated fluorine-containing prepolymer, 100 parts of epoxy (methyl) acrylate resin, 2 to 20 parts of active diluting monomers, 0.5 to 8 parts of photoinitiator, 0.5 to 5 parts of dispersant, and 0.1 to 4 parts of antifoaming agent. In the composite UV-cured paint, the monovinyl-terminated fluorine-containing prepolymer and epoxy (methyl) acrylate are taken as the main resins, and at the same time, active diluting monomers, dispersant, and antifoaming agent are added to prepare the paint, which has the advantages of low surface energy, alkali / acid resistant property, and good transparency and can be applied to the fields such as electronic encapsulation, construction paint, metal paint, and the like.

Owner:国科广化(南雄)新材料研究院有限公司

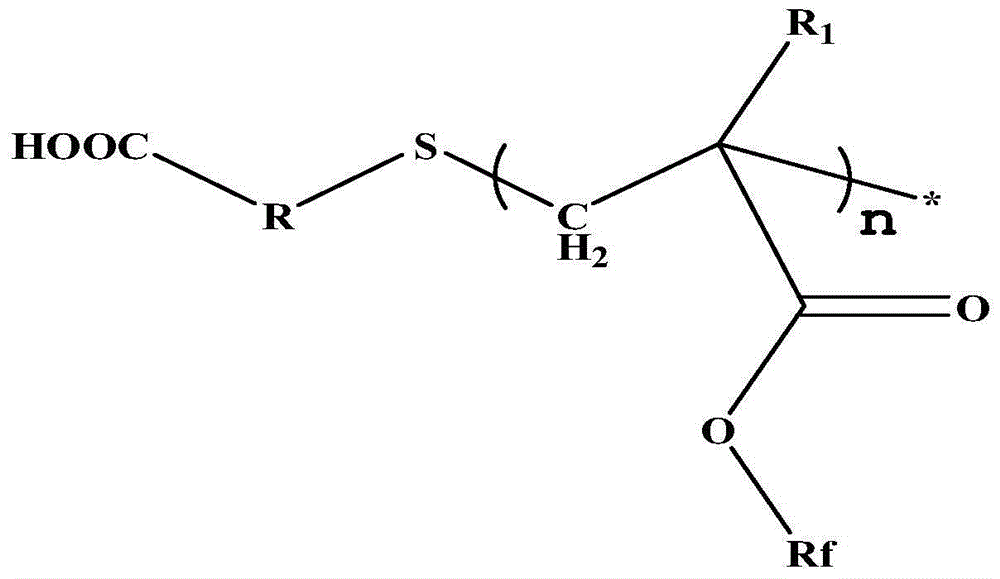

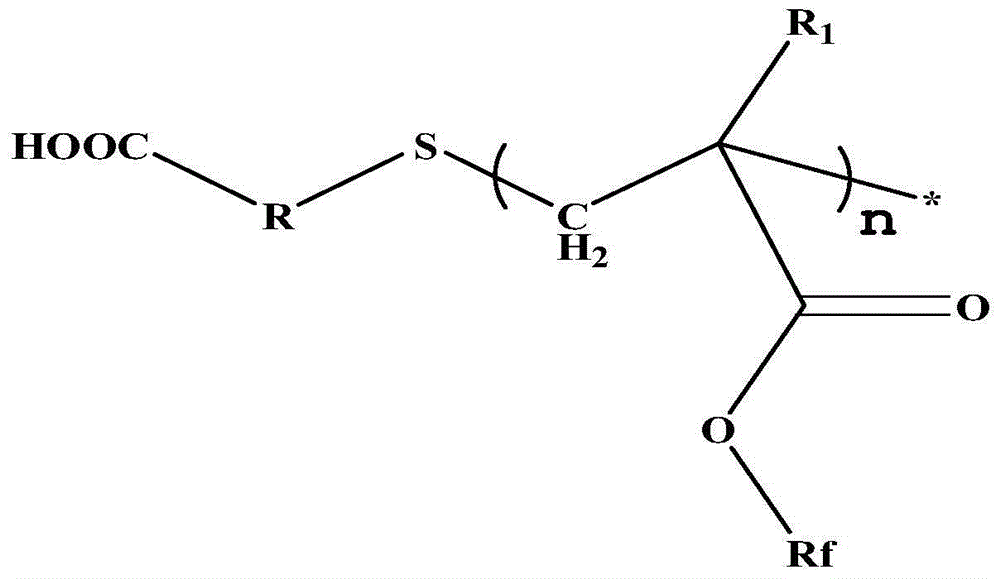

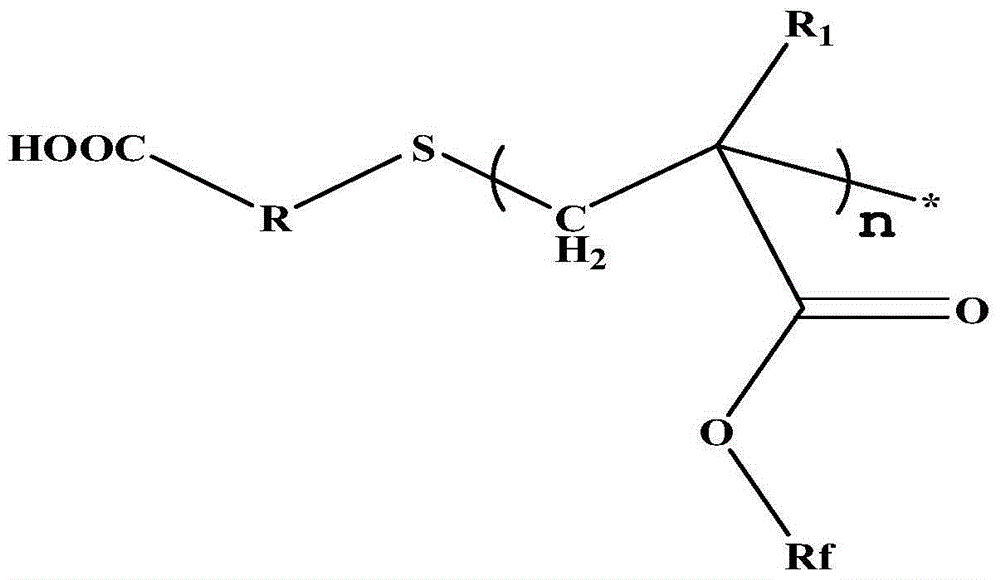

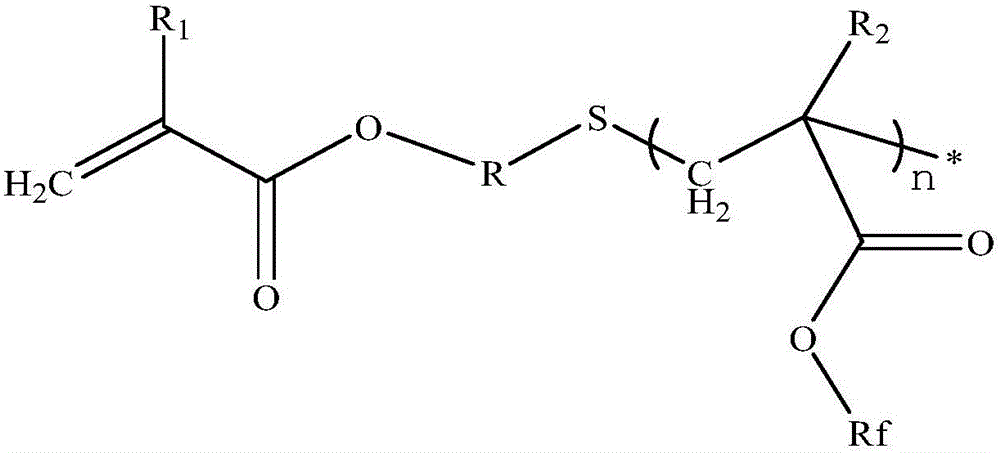

Carboxyl-terminated fluorine-containing prepolymer modified epoxy coating and preparation method and application thereof

ActiveCN104789094AHigh molecular weightHigh fluorine contentAnti-corrosive paintsEpoxy resin coatingsSurface energyPrepolymer

The invention discloses a carboxyl-terminated fluorine-containing prepolymer modified epoxy coating and a preparation method and application thereof and belongs to the field of polymer coatings. The modified epoxy coating contains the following components in parts by weight: 0.1-30 parts by mass of a carboxyl-terminated fluorine-containing prepolymer, 100 parts by mass of epoxy resin, 80-100 parts by mass of a curing agent, 0.5-2.5 parts by mass of an accelerant and 0.5-1 part by mass of a leveling agent. The modified epoxy coating is prepared by compounding the carboxyl-terminated fluorine-containing polymer and epoxy (methyl) acrylate, has the advantages of low surface energy, good adhesion, high hardness, acid-alkali resistance and the like, and can be applied in coating of metal parts and coating of electric parts.

Owner:国科广化(南雄)新材料研究院有限公司 +1

Silicon carbide-based composite circuit board and preparation method thereof

The invention discloses a silicon carbide-based composite circuit board and a preparation method thereof and belongs to the technical field of circuit boards. The silicon carbide-based composite circuit board comprises a silicon carbide-based composite base board and a circuit printed on the silicon carbide-based composite base board, wherein the silicon carbide-based composite circuit board is prepared from raw materials of, by weight part, 50-60 parts of silicon carbide, 20-28 parts of glass powder, 5-10 parts of filler, 3-7 parts of adhesives and 7-12 parts of additives. The silicon carbide-based composite circuit board is prepared by taking the silicon carbide and the glass powder as the main component and matching with the filler, the adhesives and the additives through ball milling,ultrasonic treatment, spray granulation and three sintering processes. Through dispersion and adhesion of the raw materials, the prepared silicon carbide-based composite base board can be low in thermal expansion coefficient, high in mechanical strength, good in stability and capable of effectively improving the qualification rate, thereby being high in promotional significance.

Owner:国网河南省电力公司社旗县供电公司

High-temperature-resistant and low-expansion adhesive sealant for filter cartridge

InactiveCN106675502AReduce bloatExtended service lifeNon-macromolecular adhesive additivesCross-linkPolymer science

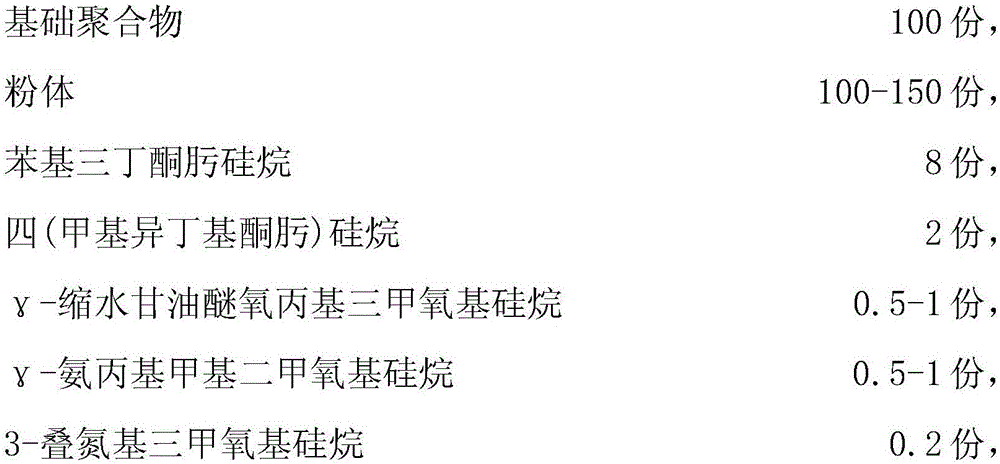

The invention discloses a high-temperature-resistant and low-expansion adhesive sealant for a filter cartridge. The adhesive sealant is prepared from the following components of a basic polymer, powder, a cross-linking agent, a coupling agent and a catalyst. The invention provides the high-temperature-resistant and low-expansion adhesive sealant for the filter cartridge according to characteristics of the making mode, the service environment, the working condition and the like of the filter cartridge; the made adhesive sealant has the features of being resistant to high temperature, resisting heat shock, being low in expansion, being resistant to acid and alkali, resisting aging and being long in service life, and is applicable to the filter cartridge which is used in severe and complicated working conditions of a coal-fired power plant, garbage incineration and the like for a long term.

Owner:XIAMEN ZHONGCHUANG ENVIRONMENTAL TECH CO LTD

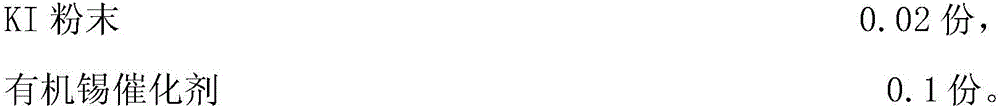

Ecological rock and method for preparing same

The invention discloses ecological rock. The ecological rock is prepared from surface materials and base materials. The surface materials are prepared from raw materials including, by weight, 8-10% ofball clay, 8-10% of super-white ball clay, 25-30% of transparent powder, 40-60% of mixed sand and 1-3% of bentonite; the sum of the weight percentage contents of the raw materials is 100%. The invention further discloses a method for preparing the ecological rock. The method includes steps of proportioning, ball-milling and ageing, spray-drying, compression molding, drying, green brick printing and permeating, burning and polishing. The ecological rock and the method have the advantages that the method is low in energy consumption and pollution, the ecological rock can be prepared by the aidof the method, good decoration effects can be realized by the ecological rock, and the ecological rock is low in water absorption, good in acid and alkali resistance, abrasion resistance and pollutionresistance and high in mechanical strength and Mohs hardness.

Owner:GUANGDONG BODE FINE IND CONSTR MATERIAL

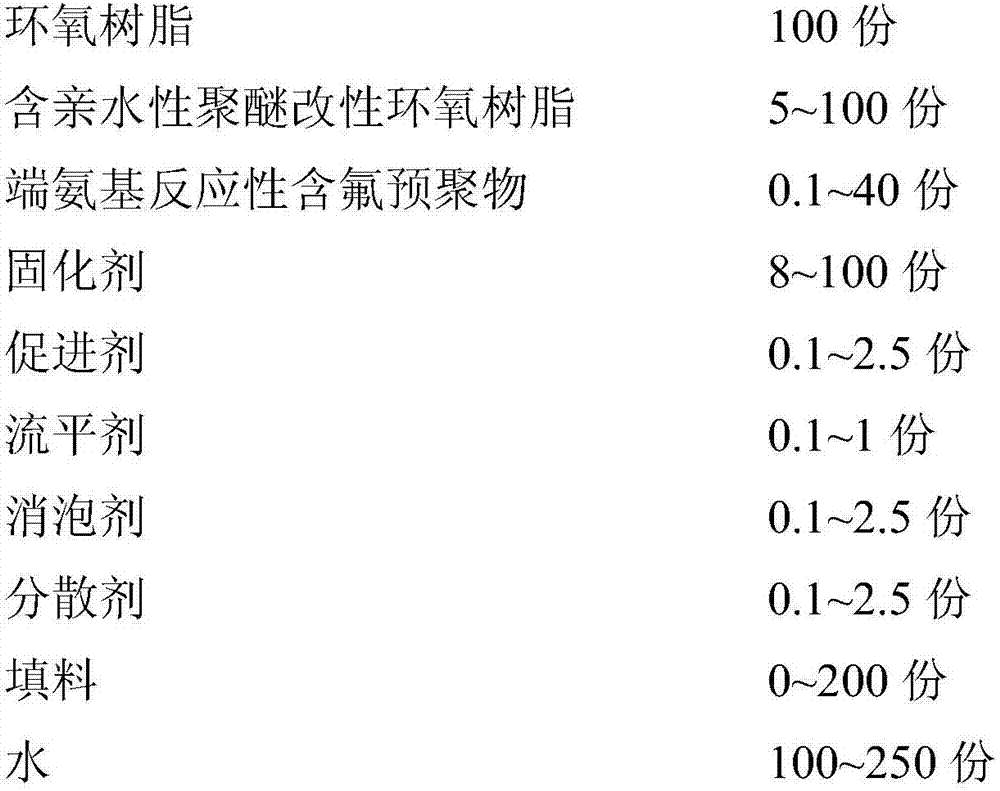

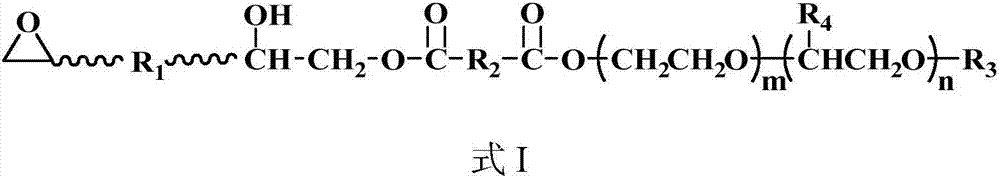

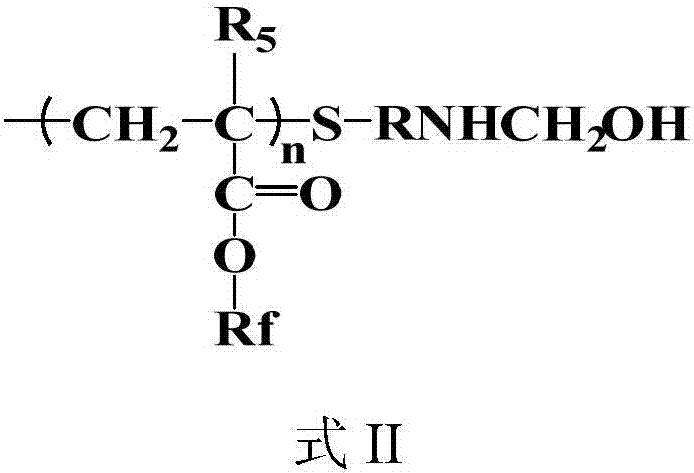

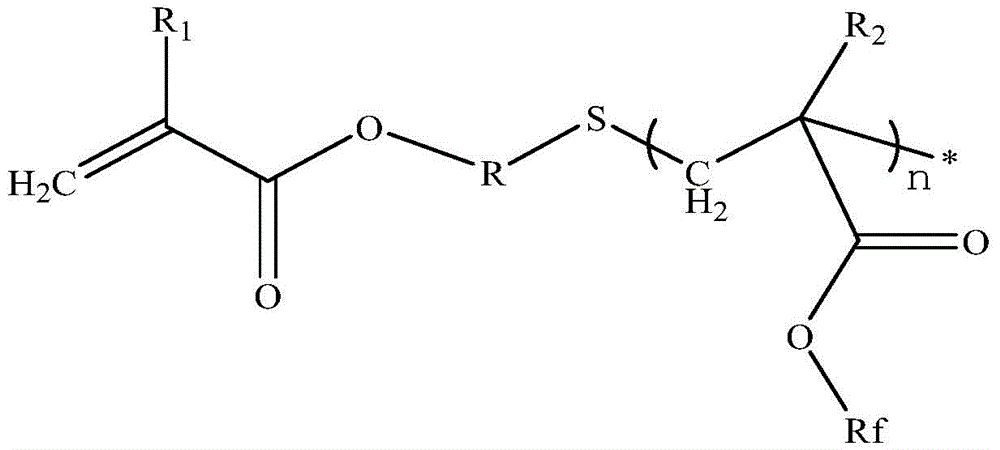

Amine-terminated reactive fluorine-containing polymer modified waterborne epoxy coating, and preparation and application of amine-terminated reactive fluorine-containing polymer modified waterborne epoxy coating

The invention belongs to the technical field of polymer coating, and discloses amine-terminated reactive fluorine-containing polymer modified waterborne epoxy coating, and preparation and applicationof the amine-terminated reactive fluorine-containing polymer modified waterborne epoxy coating. The amine-terminated reactive fluorine-containing polymer modified waterborne epoxy coating comprises, by weight, 100 parts of epoxy resin, 5-100 parts of modified epoxy resin with hydrophilic polyether, 0.1-40 parts of amine-terminated reactive fluorine-containing prepolymers, 8-100 parts of curing agents, 0.1-2.5 parts of accelerators, 0.1-1 part of leveling agents, 0.1-2.5 parts of defoaming agents, 0.1-2.5 parts of dispersing agents, 0-200 parts of fillers and 100-250 parts of water. The amine-terminated reactive fluorine-containing polymer modified waterborne epoxy coating, the preparation and the application have the advantages that films formed by the amine-terminated reactive fluorine-containing polymer modified waterborne epoxy coating are high in adhesion and hardness and good in acid and alkali resistance; components in the amine-terminated reactive fluorine-containing polymer modified waterborne epoxy coating are good in compatibility; the amine-terminated reactive fluorine-containing polymer modified waterborne epoxy coating can be used for coating metal components and electric components.

Owner:GUANGZHOU CHEM CO LTD CHINESE ACADEMY OF SCI +2

A kind of monovinyl-terminated fluorine-containing prepolymer/epoxy (meth)acrylate composite UV curing coating and its preparation and application

The invention discloses a monovinyl-terminated fluorine-containing prepolymer / epoxy (methyl) acrylate composite UV-cured paint, preparation and applications thereof, and belongs to the field of polymer materials. The composite UV-cured paint comprises the following components in parts by weight: 0.01 to 50 parts of monovinyl terminated fluorine-containing prepolymer, 100 parts of epoxy (methyl) acrylate resin, 2 to 20 parts of active diluting monomers, 0.5 to 8 parts of photoinitiator, 0.5 to 5 parts of dispersant, and 0.1 to 4 parts of antifoaming agent. In the composite UV-cured paint, the monovinyl-terminated fluorine-containing prepolymer and epoxy (methyl) acrylate are taken as the main resins, and at the same time, active diluting monomers, dispersant, and antifoaming agent are added to prepare the paint, which has the advantages of low surface energy, alkali / acid resistant property, and good transparency and can be applied to the fields such as electronic encapsulation, construction paint, metal paint, and the like.

Owner:国科广化(南雄)新材料研究院有限公司

Composite ultrafiltration membrane of modified chitosan composite electrostatic spinning nanofiber and preparation method of composite ultrafiltration membrane

InactiveCN103041714BIncrease water fluxImprove retention efficiencySemi-permeable membranesFiberWater use

The invention relates to a composite ultrafiltration membrane of a modified chitosan composite electrostatic spinning nanofiber. The composite ultrafiltration membrane is structurally characterized in that a non-woven fabric supporting layer substrate is sequentially provided with a membrane layer which has excellent chemical resistance and ageing resistance, and is composed of polymer electrostatic spinning nanofiber and prepared by using an electrostatic spinning method; and the surface of the membrane layer is an ultrathin modified chitosan separation layer which has high water permeability and stable chemical property, and is formed after a high-hydrophilcity ultrathin chitosan layer coated on the surface of the membrane layer composed of the polymer electrostatic spinning nanofiber by using aldehyde and acyl chloride modifiers is subjected to crosslinking modification. The multi-layer composite ultrafiltration membrane provided by the invention has the characteristics of high water flux, high interception efficiency, low pollution, resistance to acid and base and the like. The filtration membrane can be used for producing domestic water, drinking water and water used under special conditions and is suitable for the fields such as medicines, bioengineering, foods, environment friendliness and the like.

Owner:INST OF CHEM CHINESE ACAD OF SCI

Preparation method of cracking-resistant and waterproof concrete admixture

The invention discloses a cracking-resistant and waterproof concrete admixture. The cracking-resistant and waterproof concrete admixture comprises, by weight, 40-50 parts of marble powder, 10-20 partsof granite powder, 0.6-0.8 part of a composite activator, 4-6 parts of an early strength agent, 1-3 parts of a water reducing agent, 6-8 parts of an assistant, 1-3 parts of a set retarder, 3-5 partsof a flame retardant mixture and 12-14 parts of modified nanometer calcium carbonate. The cracking-resistant and waterproof concrete admixture has the advantages of low alkalinity, good acid and alkali resistance, early strength, fastness in hardening, continuous increase of the later strength, facilitation of the improvement of the safety and the durability of reinforced concrete, and suitableness for constructing ports, seawalls, coastal protection, cross-sea bridges, refueling-at-sea stations and other offshore engineering .

Owner:邱海亮 +1

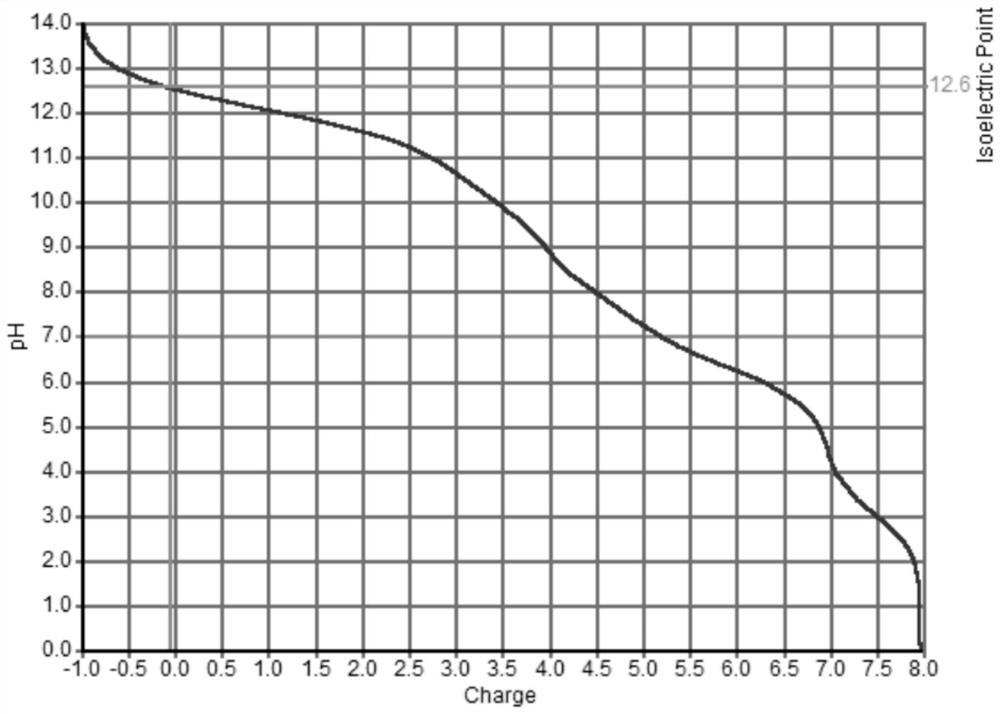

Antibacterial peptide LJ-2 and application thereof

ActiveCN111848739AHigh antibacterial activityLow hemolyticAntibacterial agentsAntimycoticsArginineValine

The invention discloses an antibacterial peptide LJ-2 and an application thereof. The amino acid sequence of the antibacterial peptide LJ-2 is as follows: the amino acid sequence of the antibacterialpeptide LJ-2 is shown in the specification: arginine, arginine, valine, leucine, arginine, isoleucine, leucine, lysine, histidine, histidine, glutamine, glycine, leucine, isoleucine, arginine, asparagine, leucine and leucine; the antibacterial peptide LJ-2 has good antibacterial activity on gram-positive bacteria, gram-negative bacteria and fungi, and has the advantages of low hemolysis, heat resistance, salt resistance, acid and alkali resistance and repeated freeze thawing resistance. Therefore, the antibacterial peptide LJ-2 disclosed by the invention has a wide application prospect in thefields of anti-infective drug preparation, animal husbandry development, human disease prevention and treatment, food preservation, detergents, cosmetics and the like.

Owner:HENAN INST OF SCI & TECH +1

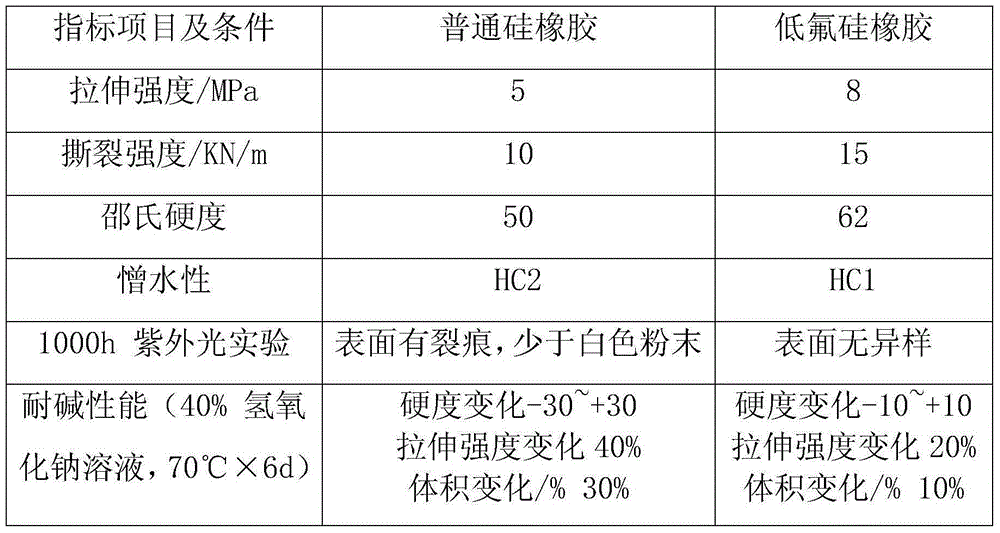

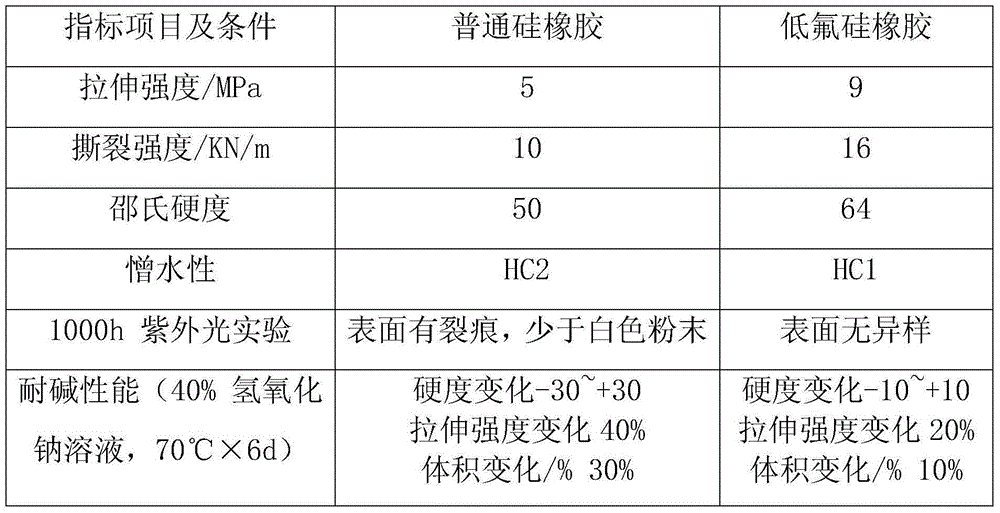

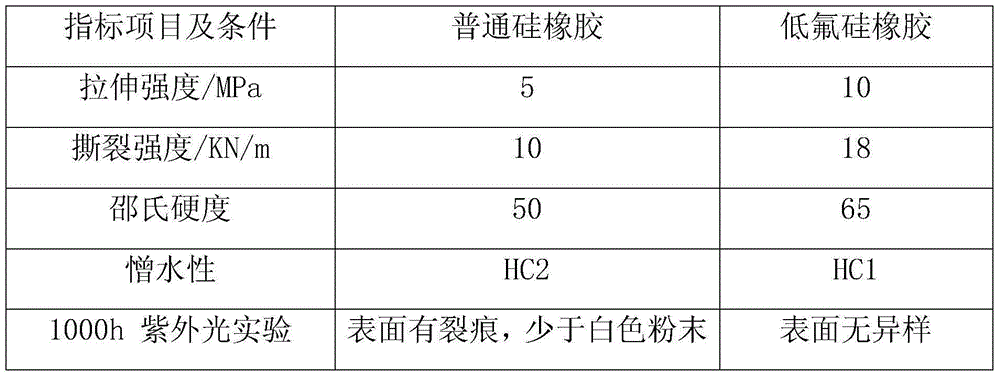

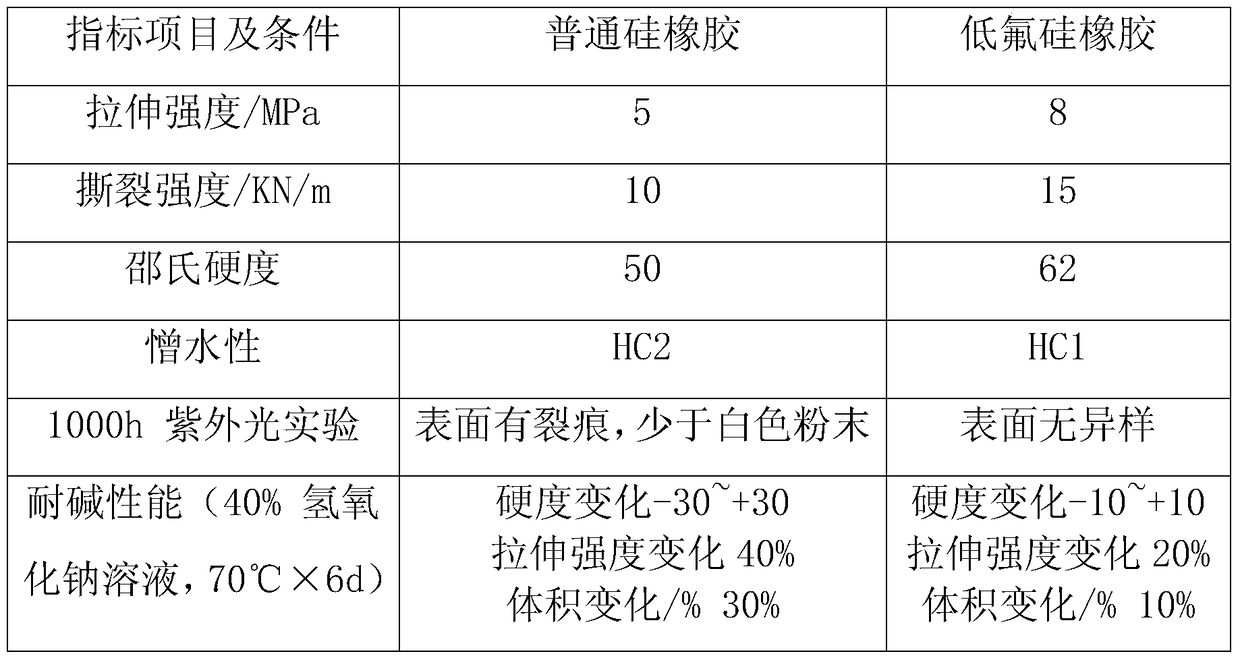

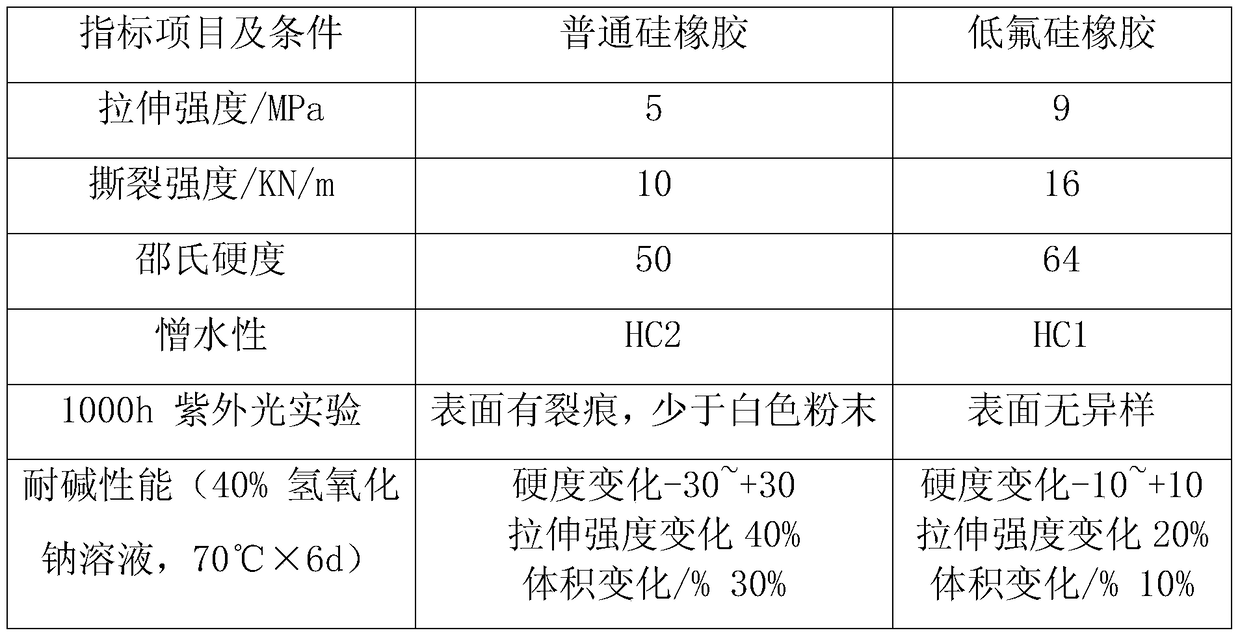

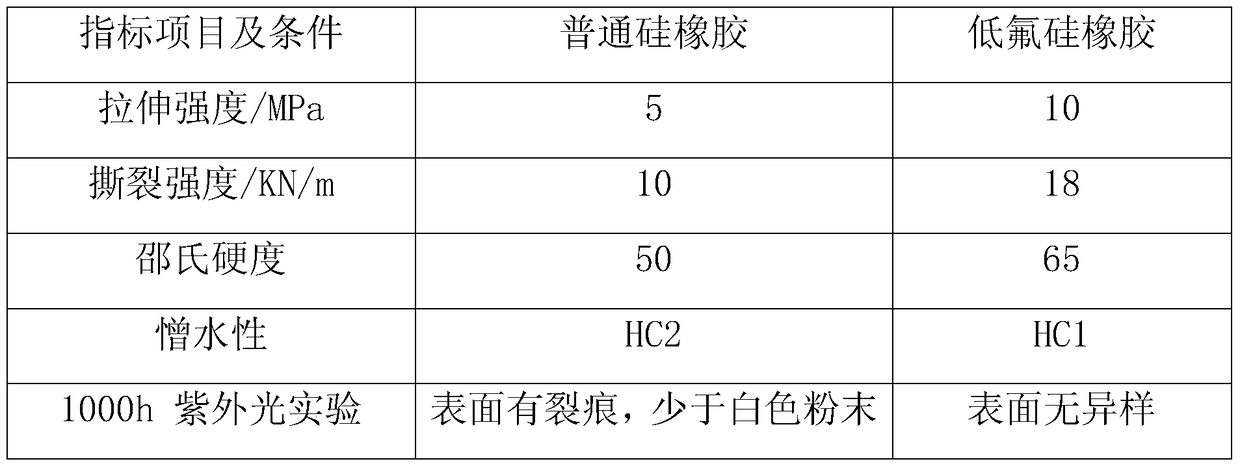

Preparation method of low-fluorine silicone rubber used for ceramic composite insulator

ActiveCN105017778ALow surface energy performanceGood for anti-agingPrecipitated silicaDicumyl peroxide

The invention discloses a preparation method of low-fluorine silicone rubber used for a ceramic composite insulator. The preparation method comprises weighing 100 parts of methyl vinyl fluorosilicone rubber, 6-9 parts of precipitated silica, 18-25 parts of a fire retardant, 3-7 parts of zinc stearate, 2-6 parts of activated magnesium oxide and 2-5 parts of ferric oxide powder according to a ratio, and uniformly mixing in a double-roller mixing mill so as to prepare a uniform master batch, performing banburying on the master batch in a kneader at 170 DEG C at a vacuum degree of -0.09 MPa for 10-20 min, then adding 0.1-0.3 part of dicumyl peroxide, again performing banburying at 200 DEG C for 3-5 h, and leaving overnight, so as to prepare the low-fluorine silicone rubber. The prepared low-fluorine silicone rubber possesses excellent performances of fluorosilicone rubber, overcomes problems of silicon rubber, is resistant to ageing, possesses excellent acid and alkali resistance, is strong in hydrophobicity, is affordable, and helps to effectively save cost.

Owner:JIANGSU SOUTH PORCELAIN INSULATOR CO LTD

A kind of preparation method of composite fiber cement board

The invention discloses a production method of a composite fiber cement board, and belongs to the technical field of building materials. The production method comprises the following steps: mixing microcrystalline cellulose with a sodium hydroxide solution, cooling the obtained solution, adding a precooled urea solution, stirring and mixing the obtained solution, centrifuging the obtained solutionto obtain a microcrystalline cellulose solution, dropwise adding an etherifying agent to the microcrystalline cellulose solution, performing constant-temperature stirring and reacting, cooling the obtained solution, adding urease and a calcium nitrate solution, continuing a reaction, concentrating the obtained reaction solution, drying the concentrated reaction solution to obtain etherified microcrystalline cellulose, performing a constant-temperature and constant-pressure reaction on the etherified microcrystalline cellulose and a sodium methoxide solution, cooling the obtained reaction solution, adding chloromethane, performing a constant-temperature and constant-pressure reaction, carrying out reduced pressure concentrating, drying the obtained concentrate to obtain modified microcrystalline cellulose, mixing cement, the modified microcrystalline cellulose, a water reducer and a defoamer, carrying out injection molding, and curing the molded mixture to obtain the composite fiber cement board. The composite fiber cement board obtained in the invention has excellent mechanical properties.

Owner:赣州大业金属纤维有限公司

Method for producing green ecological cement resistant to seawater corrosion with stone waste

The invention discloses a method for producing seawater corrosion-resistant green ecological cement from stone waste, which comprises the following raw materials in parts by weight: 30-40 parts of stone waste; 40-50 parts of sulphoaluminate cement clinker; 0.03-0.05 parts of activator; 2-4 parts of early strength agent; 0.3-0.5 parts of water reducing agent; 0.005-0.007 parts of air-entraining agent; The salt cement clinker, composite activator and early strength agent are crushed separately, pulverized, homogenized, then mixed and homogenized according to the proportion, and then added with water reducer, air-entraining agent and retarder, mixed and homogenized to obtain the product. The seawater corrosion-resistant green ecological cement of the present invention, in addition to the performance of ordinary cement, also has excellent characteristics such as high strength, seawater erosion resistance, seawater erosion resistance, etc., and is especially suitable for underground projects, ports, wharves and other erosive media. project.

Owner:广西云燕特种水泥建材有限公司

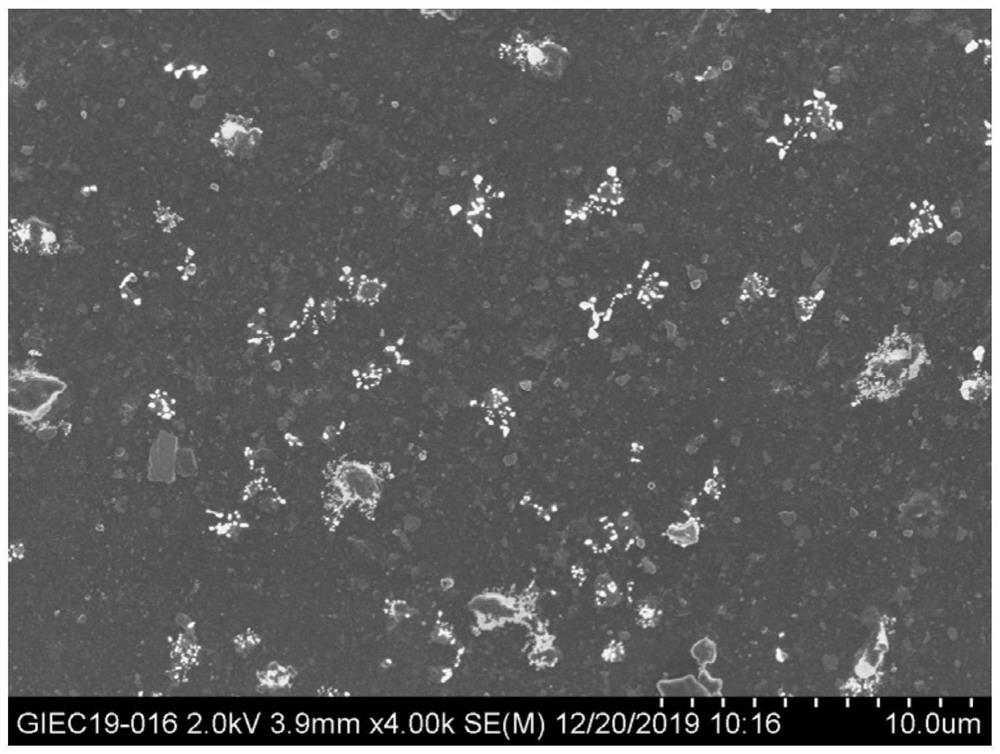

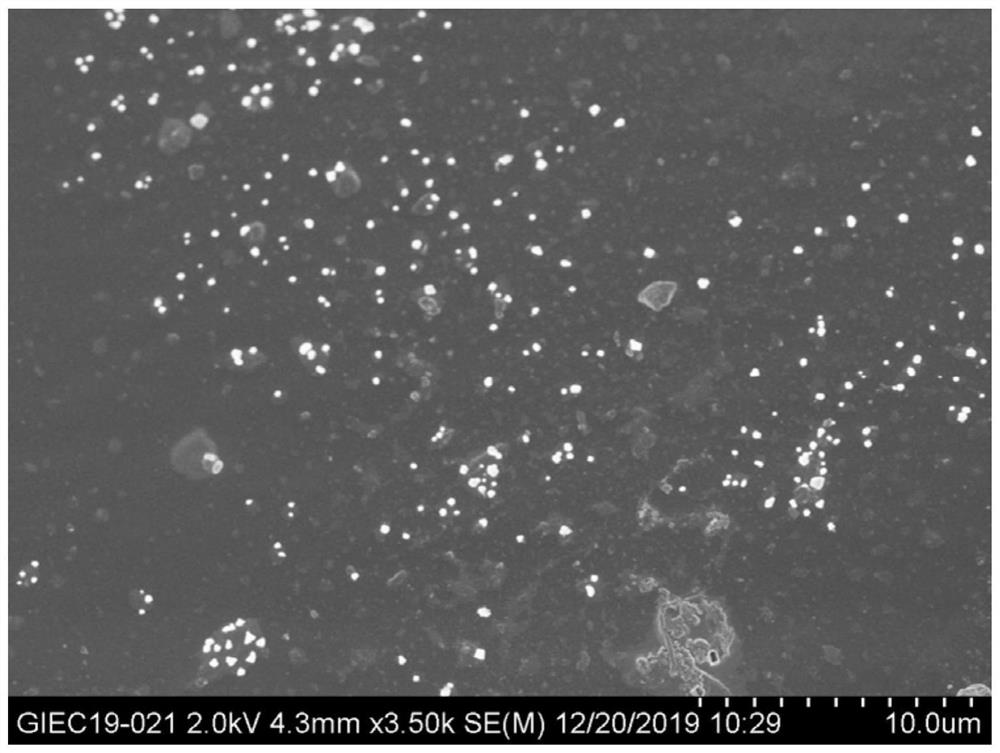

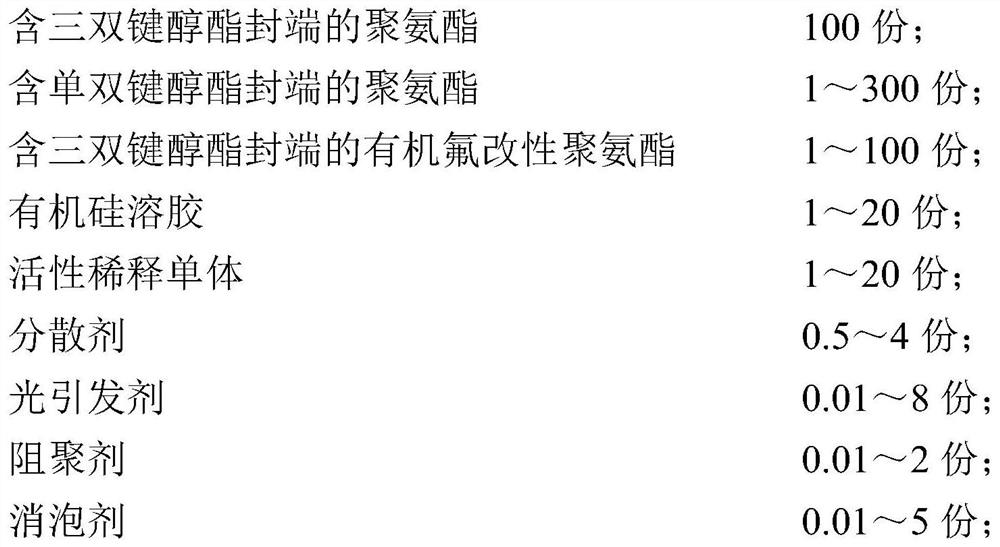

Organic silicon/organic fluorine dual-modified polyurethane composite UV photocureable coating as well as preparation and application thereof

ActiveCN111748275ALow costReduce volatilityPolyurea/polyurethane coatingsMetal coatingWeather resistance

The invention discloses an organic silicon / organic fluorine dual-modified polyurethane composite UV photocureable coating as well as preparation and application thereof. The composite UV photocureablecoating provided by the invention has relatively high molecular weight and silicon / fluorine content; by introducing organic silicon into the polyurethane coating, the hydrophobicity, weather resistance, wear resistance, cold resistance, biocompatibility, aging resistance and other properties of the modified polyurethane coating can be obviously enhanced, and the polyurethane coating has the advantages of low cost, low VOC, favorable coating adaptability, no toxicity, no irritation and the like, and is easy to clean. In addition, the composite UV photocureable coating is prepared by adding anorganic fluorine polymer with photosensitivity for compounding, so that the composite UV photocureable coating has the properties of low surface energy, acid and alkali resistance, good transparency and the like by virtue of a small amount of fluorine-containing prepolymer modified coating; in addition, organic fluorine and waterborne polyurethane are compounded at the molecular level, the modification effect of the fluorine-containing prepolymer on polyurethane is exerted to the maximum extent, and the fluorine-containing prepolymer can be applied to the fields of electronic packaging, building coatings, metal coatings and the like.

Owner:GUANGZHOU CHEM CO LTD CHINESE ACADEMY OF SCI +2

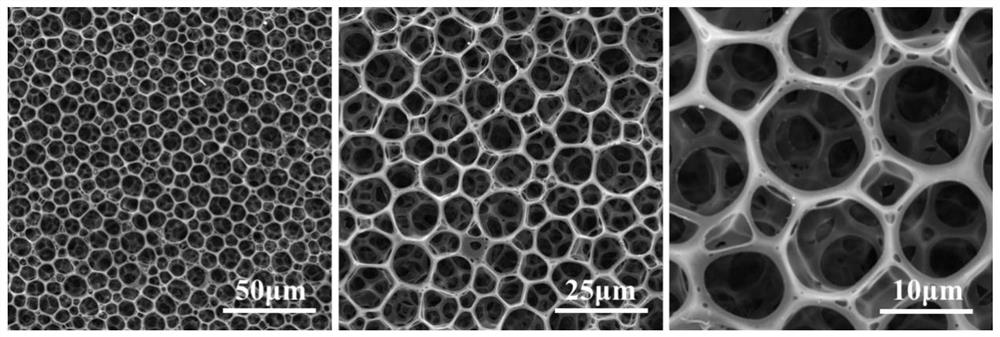

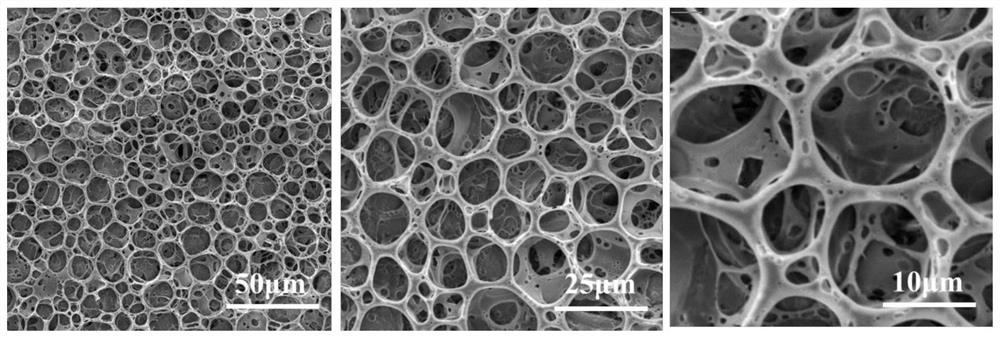

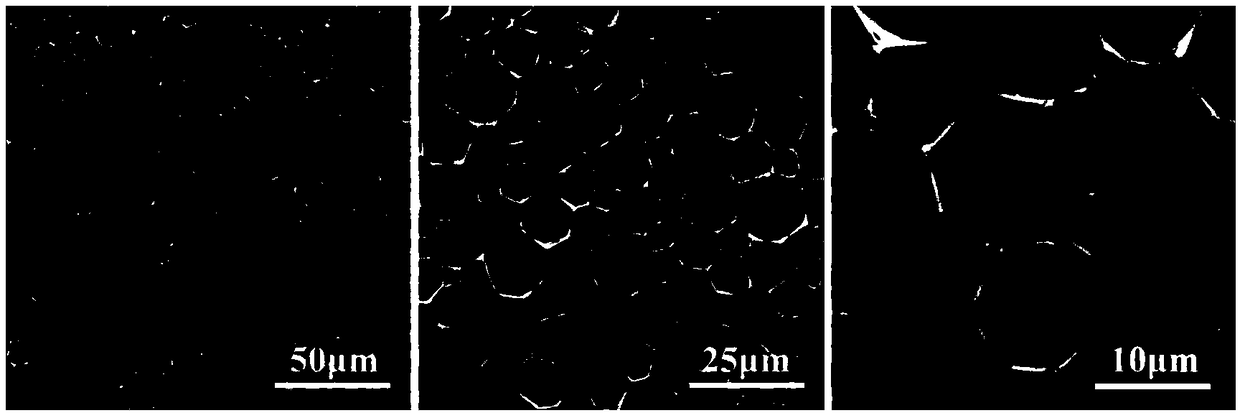

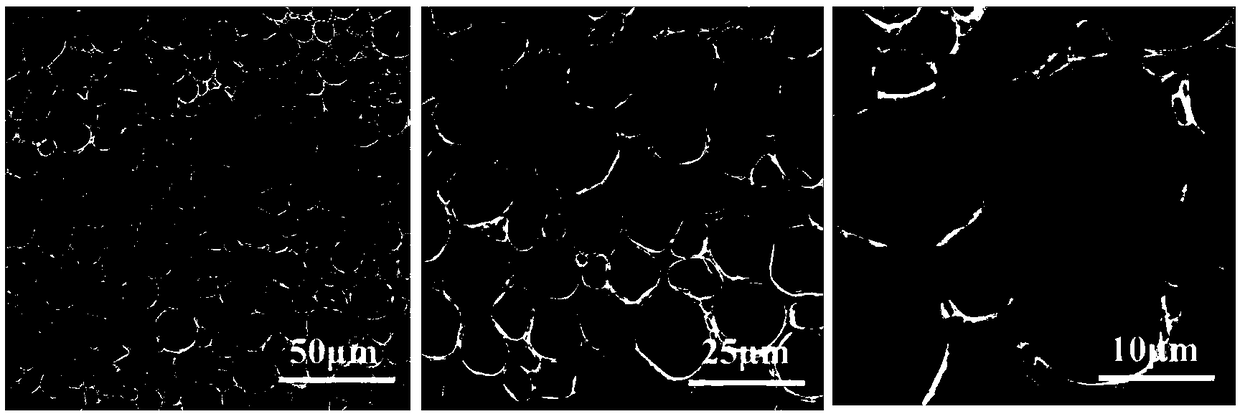

Preparation method of hydrophobic and lipophilic self-supporting membrane polymer porous membrane and composite hydrophobic and lipophilic separation material

ActiveCN109289559BReduce adhesionGood adhesionMembranesSemi-permeable membranesPolymer scienceEmulsion

The invention relates to a method for preparing a hydrophobic-lipophilic self-supporting polymer porous membrane and a composite hydrophobic-lipophilic separation material. The emulsion obtained after stabilizing high-speed stirring is stabilized by adding a stabilizer to the polymer solution, and is prepared by volatilization of a solvent. Hydrophobic-oleophilic self-supporting membrane polymer porous membrane. The composite hydrophobic-lipophilic separation material can be obtained by casting the emulsion onto different substrates. The micron-scale pore structure in the film increases the roughness of the surface, and the nano-scale and / or micron or sub-micron-scale pores make the film hydrophobic, thereby enabling efficient separation of emulsified oil and water. The invention solves the problems of poor thermal stability, acid and alkali resistance, poor anti-pollution ability and poor mechanical strength of ordinary polymer separation membranes, has high separation efficiency and flux, and its preparation process is simple and easy to operate, and can be applied It is used to prepare a large-area separation membrane with controllable thickness, uniform flatness and high mechanical strength.

Owner:江苏艾合复合材料有限公司

Glass fiber compound surface skin and production method

The invention discloses a glass fiber compound surface skin which is prepared from glass fabric, spunlace nonwoven fabric, polypropylene randon copolymer and a binding agent. The binding agent is prepared from liquid resin, quartz sand, dicyandiamide, dimethyl formamide, polyacrylic ester, dipropylene glycol monomethyl ether, dimethicone, fumaric acid, fumaric acid anhydride, trimesic acid, trimesic acid anhydride and a negative ion surface active agent. The invention further discloses a production method of the glass fiber compound surface skin. The method includes the following steps of preparing the raw materials, preparing solidification liquid, conducting rolling and thermocuring, conducting quick cooling to form a semi-solidified plate, cutting the semi-solidified plate, and conducting natural cooling to the normal temperature to obtain the glass fiber compound surface skin. The glass fabric and the spunlace nonwoven fabric are used as base materials, polypropylene random copolymer and the binding agent are added, and the produced glass fiber compound surface skin has excellent performance on the aspects of appearance, high compactness, high strength, abrasion resistance, high temperature resistance, corrosion resistance, acid and base resistance and low expansion.

Owner:四川省中鑫威格节能科技股份有限公司

A kind of polyester high-strength fishing net with self-luminous function and preparation method thereof

ActiveCN110983482BIncrease brightnessGood priceFilament forming substance formingArtificial thread manufacturing machinesPolyesterYarn

The invention discloses a polyester high-strength fishing net thread with self-luminous function and a preparation method thereof, comprising: compounding alkaline earth aluminate luminescent materials and alkaline earth silicate luminescent materials to obtain mixed luminescent powder; The powder self-luminous polyester masterbatch melt and ordinary polyester melt are mixed dynamically and statically to obtain a mixed melt containing low-concentration luminescent powder; by adjusting the spinning parameters, a large amorphous area and low crystallinity are produced. It is more suitable for self-luminous polyester FDY filaments of multi-stage drafting, and then low-speed, multi-stage drafting treatment. The polyester high-strength fishing net yarn with self-luminous function prepared by the present invention has a breaking strength of >6.5cN / dtex, a boiling water shrinkage rate of <4%, and can continue to glow in the dark for more than 12 hours after being fully illuminated.

Owner:JIANGSU HENGKE ADVANCED MATERIALS CO LTD

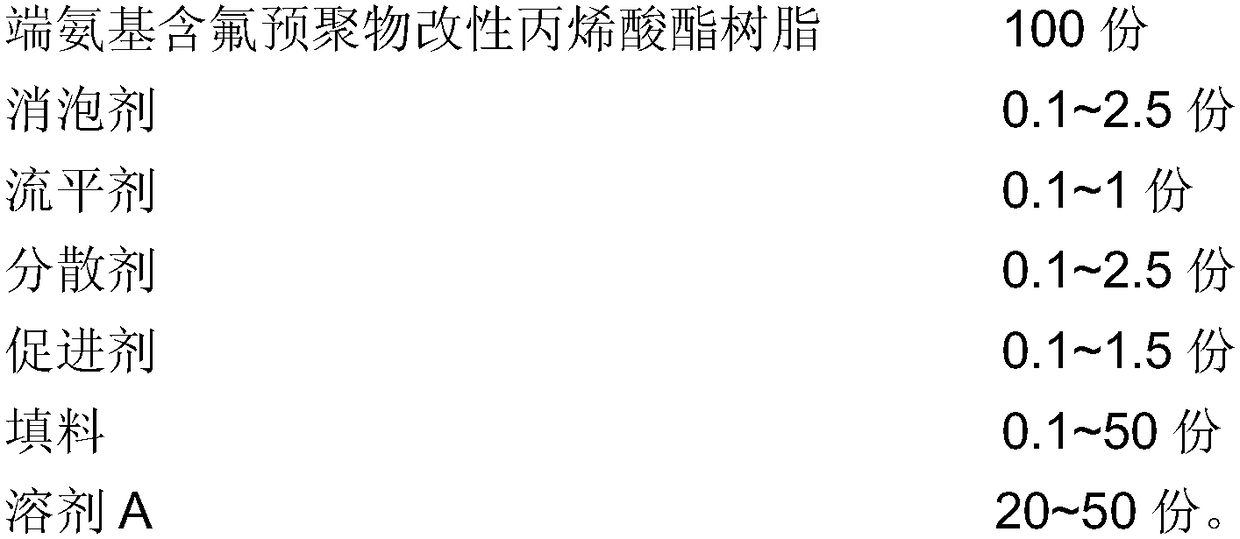

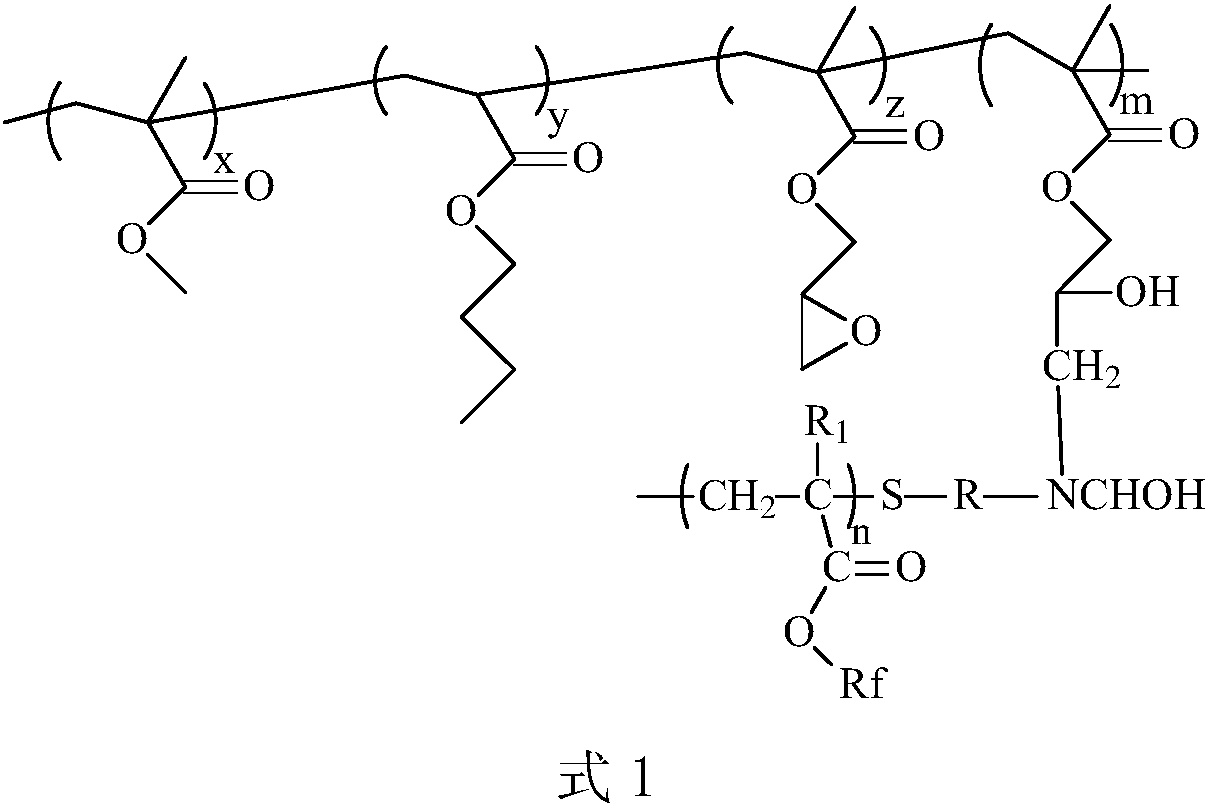

A kind of amino-terminated fluorine-containing prepolymer modified acrylate coating and preparation method thereof

Owner:国科广化(南雄)新材料研究院有限公司

Method for producing green ecological cement resistant to seawater corrosion with lime plant waste

The invention discloses a method for producing green ecological cement resistant to seawater corrosion by using wastes from lime factories. The cement comprises the following raw materials in parts by weight: 45-55 parts of wastes from lime factories, 40-50 parts of sulphoaluminate cement clinkers, 0.04-0.07 part of compound activating agent, 1-3 parts of early strength agent, 0.5-0.7 part of water reducing agent, 0.004-0.006 part of air entraining agent and 0.4-0.6 part of retarder. The production method is characterized by breaking, grinding and homogenizing the wastes from lime factories, the sulphoaluminate cement clinkers, the compound activating agent and the early strength agent respectively, then preparing the materials in proportion, mixing the materials, homogenizing the mixture, then adding the water reducing agent, the air entraining agent and the retarder, mixing the materials and homogenizing the mixture, thus preparing the product. The green ecological cement resistant to seawater corrosion has the excellent characteristics of high strength, resistance to seawater corrosion and seawater scouring, and the like besides the properties of ordinary cement, and is especially suitable for underground engineering, ports, wharfs and other engineering suffering corrosion of erosion media.

Owner:广西云燕特种水泥建材有限公司

Preparation methods of hydrophobic-oleophylic self-supporting film macromolecular porous film and composite hydrophobic-oleophylic separation material

The invention relates to preparation methods of a hydrophobic-oleophylic self-supporting film macromolecular porous film and a composite hydrophobic-oleophylic separation material. By addition of a stabilizer in a macromolecular solution, an emulsion obtained after stable high-speed stirring is made into the hydrophobic-oleophylic self-supporting film macromolecular porous film by volatilization of a solvent. The composite hydrophobic-oleophylic separation material can be obtained by casting the emulsion onto different substrates. The micron-scale pore structure in the thin film increases thesurface roughness, and nano-scale and / or micron or submicron-scale pore channels make the thin film hydrophobic, so emulsified oil and water can be efficiently separated. The problems of poor thermalstability, no acid and alkali resistance, poor pollution resistance ability and poor mechanical strength of common macromolecular separation films are solved, the macromolecular porous film has high separation efficiency and flux, and the preparation process is simple and feasible, and can be applied to preparation of large-area separation films with controllable thickness, uniformness and smoothness and high mechanical strength.

Owner:江苏艾合复合材料有限公司

A dedusting-mist integrated device and method for wet desulfurization system

ActiveCN106268178BReduce coefficient of frictionHigh tensile strengthCombination devicesGas treatmentFiberPorosity

The invention relates to the field of flue gas treatment, in particular to an integrated dust-fog removing device and a dust-fog removing method for a wet desulphurization system. According to the device, the principle of glass tube condensation, the principle of screen filtration and the characteristic of different porosities of polytetrafluoroethylene (PTFE) monofilament fibers are utilized to realize the simultaneous efficient purification of original micron-grade solid smoke dust fine particles with different particle sizes and micron-grade fogdrop particles with different particle sizes in flue gas of the wet desulfurization system. After the device is adopted, the micron-grade solid dust and the micron-grade fogdrops in the flue gas can be efficiently removed in an integrated way; furthermore, the device is compact in structure, is easily installed in the wet desulphurization system of the flue gas, and is simple and convenient to operate, thus having wide market prospect and higher promotional value. The device and the method which are provided by the invention are suitable for large-load and high-power wet flue gas desulphurization treatment systems of coal in a power plant, the coal chemical industry, and the like.

Owner:LIAONING TECHNICAL UNIVERSITY

A preparation method of low-fluorine silicone rubber for porcelain composite insulators

The invention discloses a preparation method of low-fluorine silicone rubber used for a ceramic composite insulator. The preparation method comprises weighing 100 parts of methyl vinyl fluorosilicone rubber, 6-9 parts of precipitated silica, 18-25 parts of a fire retardant, 3-7 parts of zinc stearate, 2-6 parts of activated magnesium oxide and 2-5 parts of ferric oxide powder according to a ratio, and uniformly mixing in a double-roller mixing mill so as to prepare a uniform master batch, performing banburying on the master batch in a kneader at 170 DEG C at a vacuum degree of -0.09 MPa for 10-20 min, then adding 0.1-0.3 part of dicumyl peroxide, again performing banburying at 200 DEG C for 3-5 h, and leaving overnight, so as to prepare the low-fluorine silicone rubber. The prepared low-fluorine silicone rubber possesses excellent performances of fluorosilicone rubber, overcomes problems of silicon rubber, is resistant to ageing, possesses excellent acid and alkali resistance, is strong in hydrophobicity, is affordable, and helps to effectively save cost.

Owner:JIANGSU SOUTH PORCELAIN INSULATOR CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com