A preparation method of low-fluorine silicone rubber for porcelain composite insulators

A ceramic composite insulator, fluorosilicone rubber technology, applied in the rubber field, achieves excellent high and low temperature resistance, is conducive to aging resistance, and has excellent performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

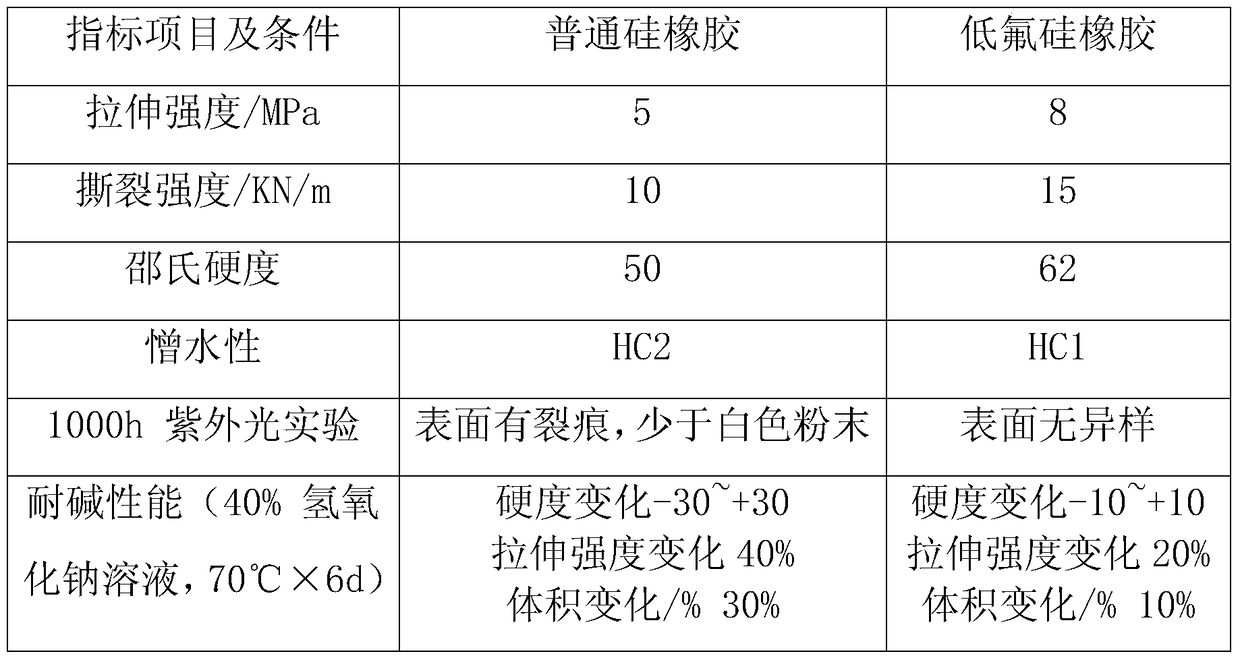

Embodiment 1

[0012] Weigh 100 parts of methyl vinyl fluorosilicone rubber, 6 parts of precipitated white carbon black, 18 parts of flame retardant, 3 parts of zinc stearate, 2 parts of activated magnesium oxide, and 2 parts of iron oxide powder in a double-roller Mix uniformly in the kneader to obtain a uniform masterbatch, wherein the linear speed of the front roller of the two-roll kneader is 25m / min, and the speed ratio of the front and rear rollers is 1:1.3; the flame retardant is aluminum hydroxide Compounding with antimony trioxide, the compounding molar ratio of aluminum hydroxide and antimony trioxide is 1:1, the masterbatch is kneaded in a kneader at 170°C and a vacuum of -0.09MPa for 10min, and then added 0.1 part of dicumyl peroxide was mixed again at 200° C. for 3 hours, and left overnight to prepare the low-fluorine silicone rubber.

[0013] The properties of the low-fluorine silicone rubber prepared according to the components and weight / number ratios of this embodiment are a...

Embodiment 2

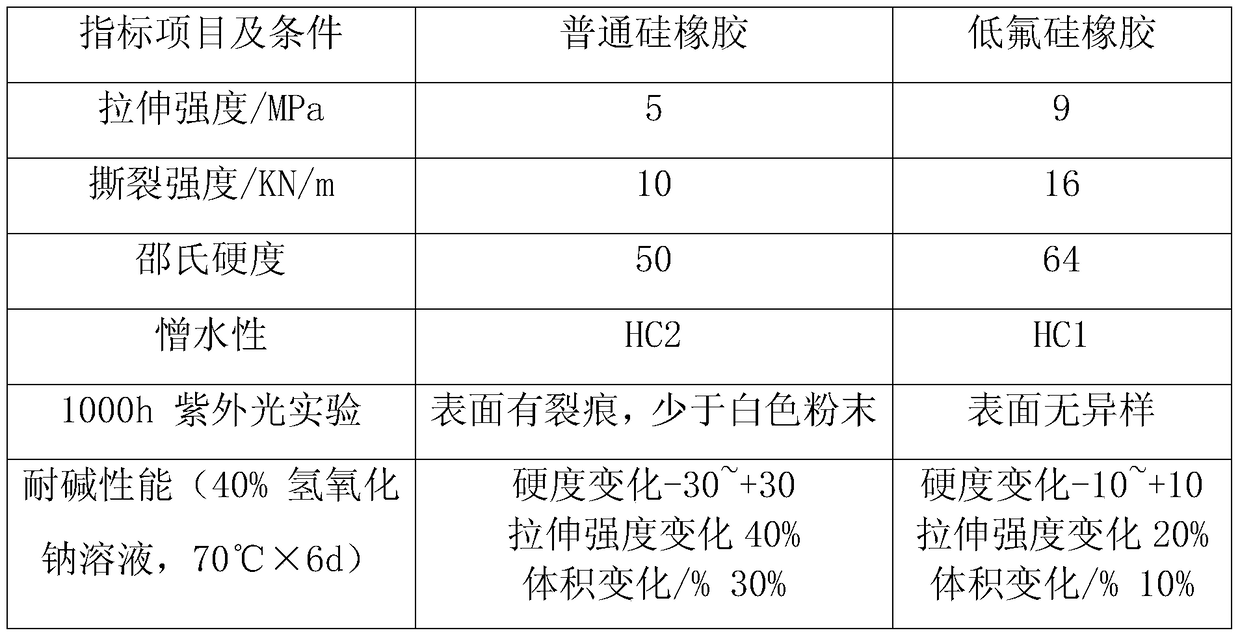

[0017] Weigh 100 parts of methyl vinyl fluorosilicone rubber, 9 parts of precipitated white carbon black, 25 parts of flame retardant, 7 parts of zinc stearate, 6 parts of activated magnesium oxide, and 5 parts of iron oxide powder in a double-roller Mixing uniformly in the kneader to obtain a uniform masterbatch, the flame retardant is a composite of aluminum hydroxide and antimony trioxide, the composite molar ratio of aluminum hydroxide and antimony trioxide is 3:1, and the The masterbatch was banburyed in a kneader at 170°C and a vacuum of -0.09MPa for 20min, then 0.3 parts of dicumyl peroxide was added, banburyed again at 200°C for 5h, and left overnight to obtain the low-fluorine Silicone Rubber.

[0018] The properties of the low-fluorine silicone rubber prepared according to the components and weight / number ratios of this embodiment are as follows:

[0019] Table 2 is the performance parameter of the low fluorine silicone rubber prepared by embodiment

[0020]

Embodiment 3

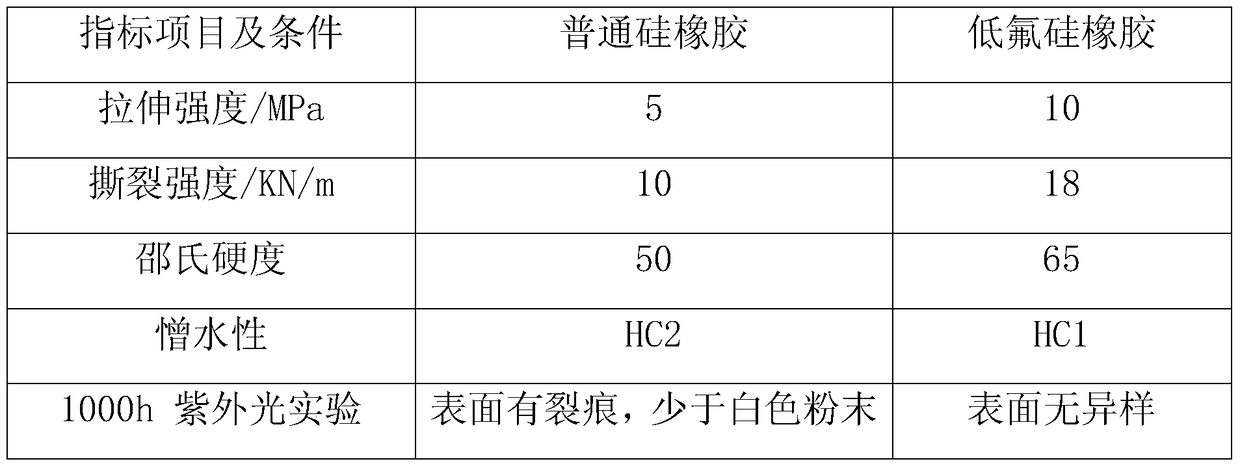

[0022] Weigh 100 parts of methyl vinyl fluorosilicone rubber, 8 parts of precipitated white carbon black, 20 parts of flame retardant, 5 parts of zinc stearate, 4 parts of activated magnesium oxide, and 3 parts of iron oxide powder in a double-roller Mixing uniformly in the kneader to obtain a uniform masterbatch, the flame retardant is a composite of aluminum hydroxide and antimony trioxide, the composite molar ratio of aluminum hydroxide and antimony trioxide is 2:1, and the The masterbatch was banburyed in a kneader at 170°C and a vacuum of -0.09MPa for 15min, then added 0.2 parts of dicumyl peroxide, banburyed again at 200°C for 4h, and left overnight to obtain the low-fluorine Silicone Rubber.

[0023] The properties of the low-fluorine silicone rubber prepared according to the components and weight / number ratios of this embodiment are as follows:

[0024] Table 3 is the performance parameter of the low fluorine silicone rubber prepared by embodiment

[0025]

[0026...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com