Patents

Literature

35results about How to "Improve acid corrosion resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

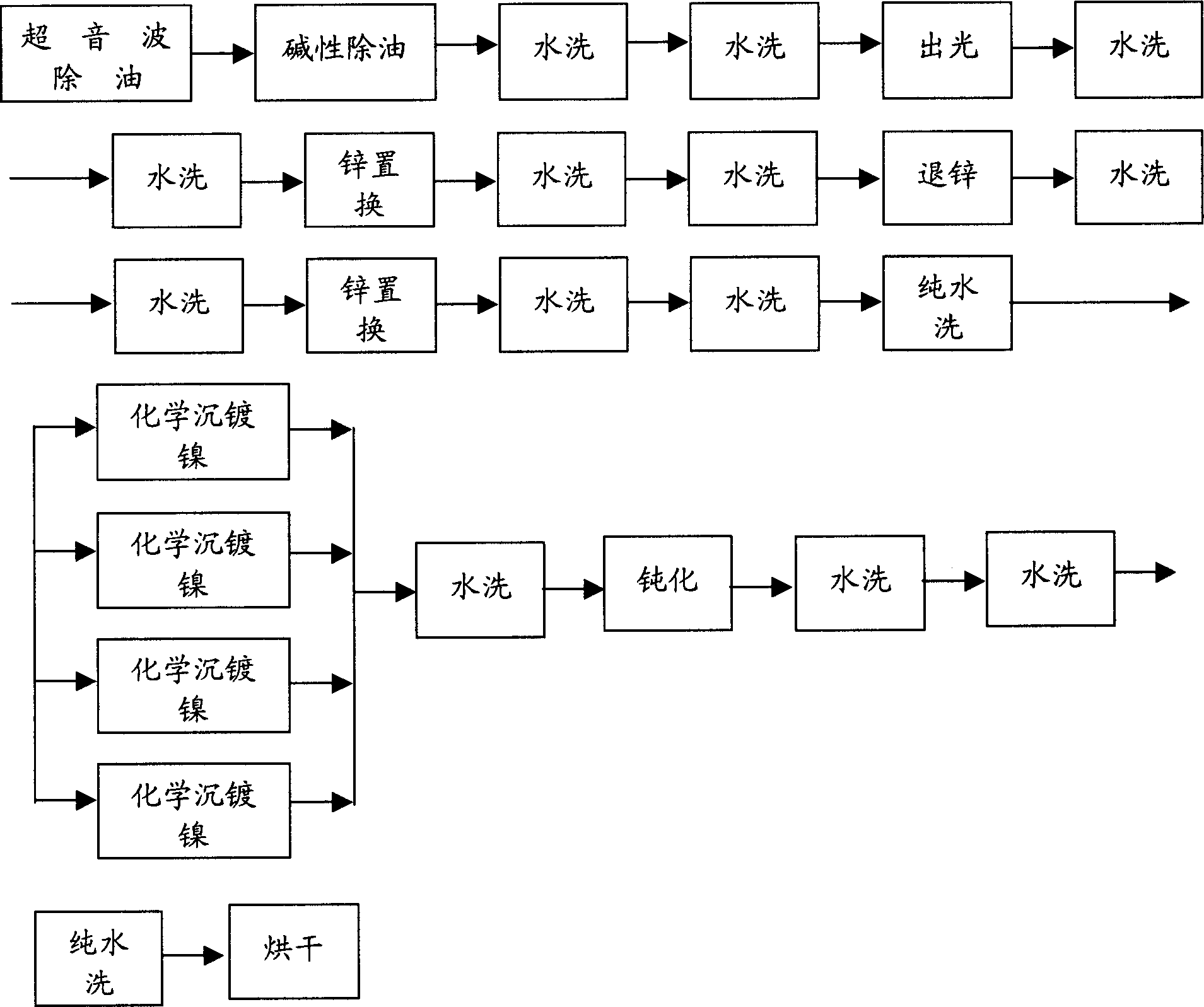

Chemical-deposition nickel-plating method

InactiveCN1814859AHigh Alkali Corrosion StrengthImprove acid corrosion resistanceLiquid/solution decomposition chemical coatingChemical platingZinc

This invention discloses a method for Ni plating by chemical deposition including: oil elimination, washing, Zn replacement, washing, Zn replacement, washing, Ni chemical-plating, washing and drying. This invention applies an advanced and simple Ni-chemical deposition method, combines a method of high and low NiP and Zn-dip to operate them independently so as to replace the traditional Ni-plating and the continous process method.

Owner:赖源清 +1

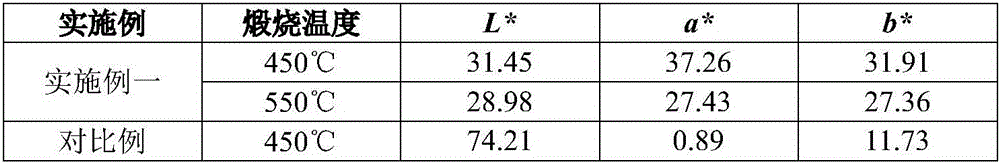

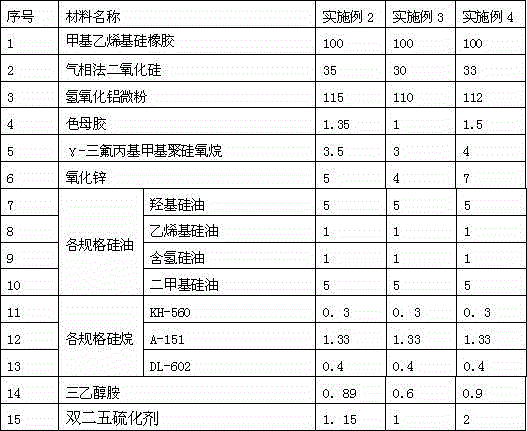

Preparation method of compound coated type cerium sulfide red pigment and product prepared through preparation method

ActiveCN106280551AHigh densityReaction is easy to controlPigment treatment with non-polymer organic compoundsCeriumSilicon oxide

The invention discloses a preparation method of a composite coated cerium sulfide red pigment. The preparation method comprises the steps that firstly, colorant suspension liquid containing gamma-Ce2S3 toner is hydrolyzed by a solution containing Zr<4+>, and after a hydrolysis product is dried, first-time coated precursor powder is prepared; secondly, first-time coated precursor powder suspension liquid is hydrolyzed by a solution containing Si<4+>, and after a hydrolysis product is dried, second-time coated precursor powder is prepared; finally, the second-time coated precursor powder is subjected to calcining treatment in a non-oxidation atmosphere, and then the composite coated cerium sulfide red pigment which has a zirconium oxide-silicon oxide composite coating layer and is densely coated is prepared. The invention further discloses a product prepared through the preparation method. According to the preparation method, by means of stepped hydrolysis-composite coating, reacting is easy to control, effective coating of the surface of cerium sulfide is improved, the preparation process is stable and reliable, and obtaining of the cerium sulfide red pigment with the dense and compact coating layer is promoted. The preparation technology is simple and easy to operate, and the prepared product is high in stability and suitable for industrial popularization.

Owner:JINGDEZHEN CERAMIC INSTITUTE

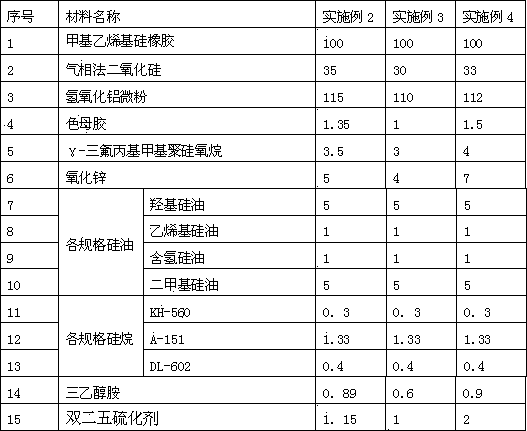

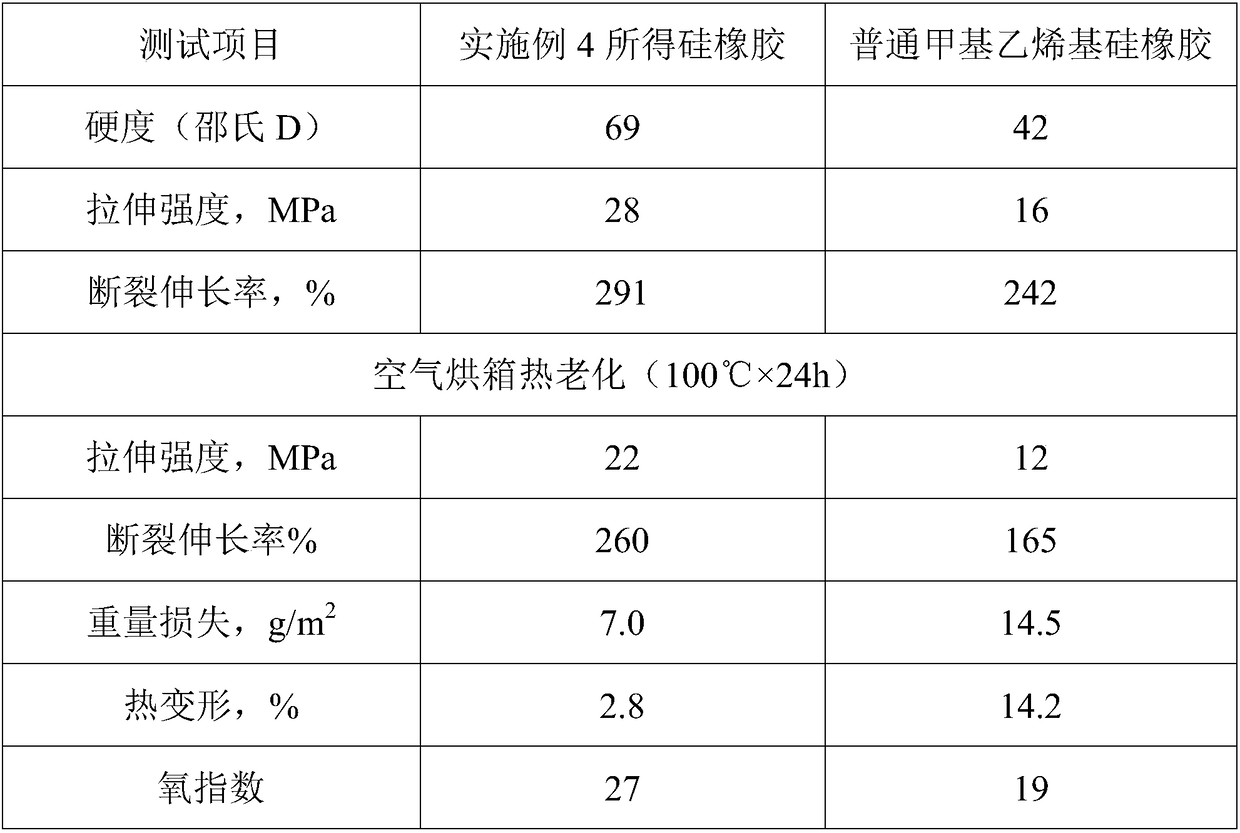

High-temperature vulcanized modified silicon rubber and production method thereof

ActiveCN103360770AImproves UV resistanceImprove acid corrosion resistanceAcid etchingPolymer science

The invention discloses high-temperature vulcanized modified silicon rubber which is mainly prepared from the following base materials: 110-1 methyl vinyl silicone rubber, 110-2 methyl vinyl silicone rubber and 110-3 methyl vinyl silicone rubber at the weight ratio of (1-2):(2-5):(1-3). The high-temperature vulcanized modified silicon rubber has the advantages of all excellent property of high-temperature vulcanized silicon rubber and better ultraviolet resistant property and acid etching resistant property. According to the IEC62217 standard, after the high-temperature vulcanized modified silicon rubber is aged through ultraviolet light (xenon-arc method) for 1500 hours, the material is intact; after the high-temperature vulcanized modified silicon rubber is soaked in a 65% nitric acid solution for 45 minutes, the material is intact.

Owner:JIANGSU SOUTH PORCELAIN INSULATOR CO LTD

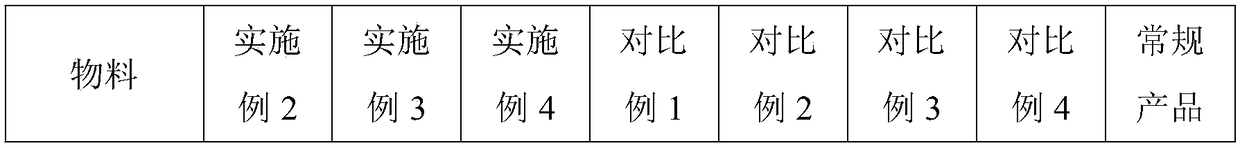

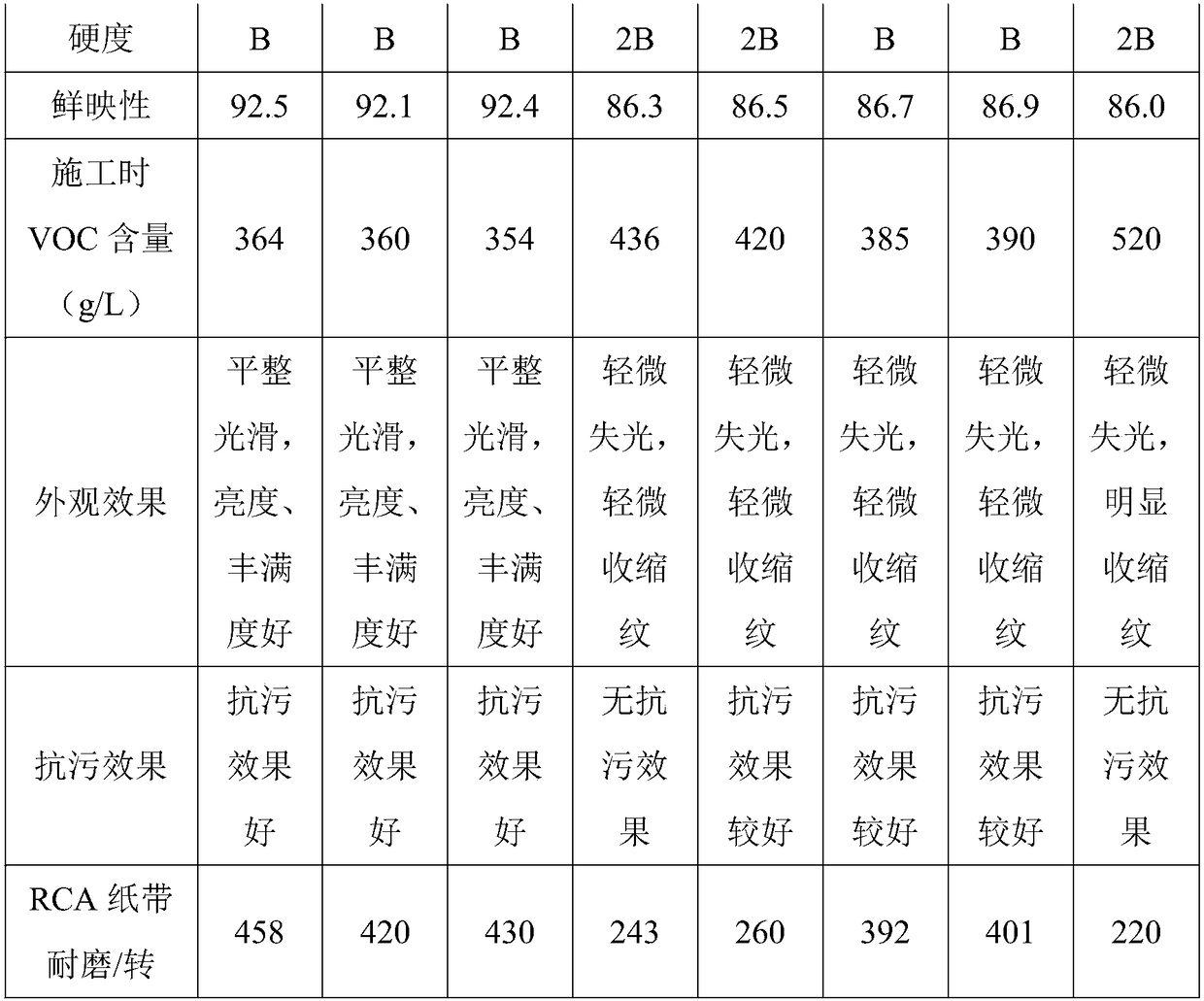

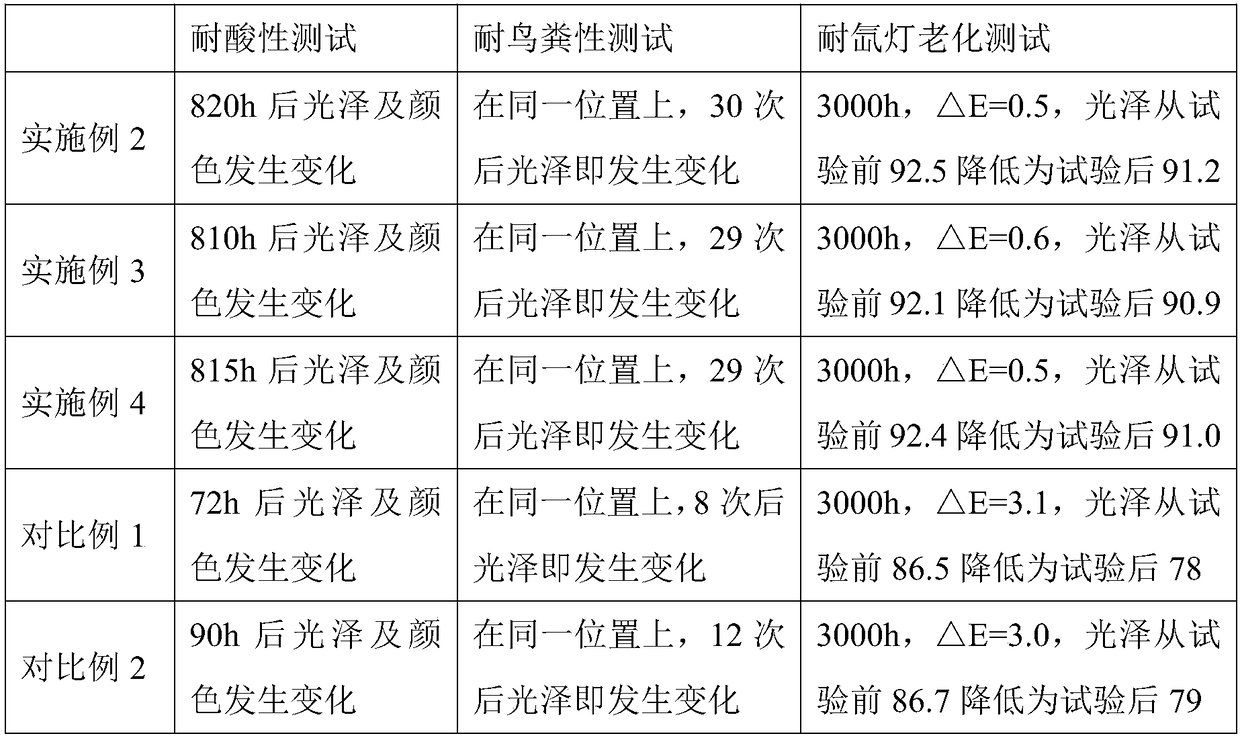

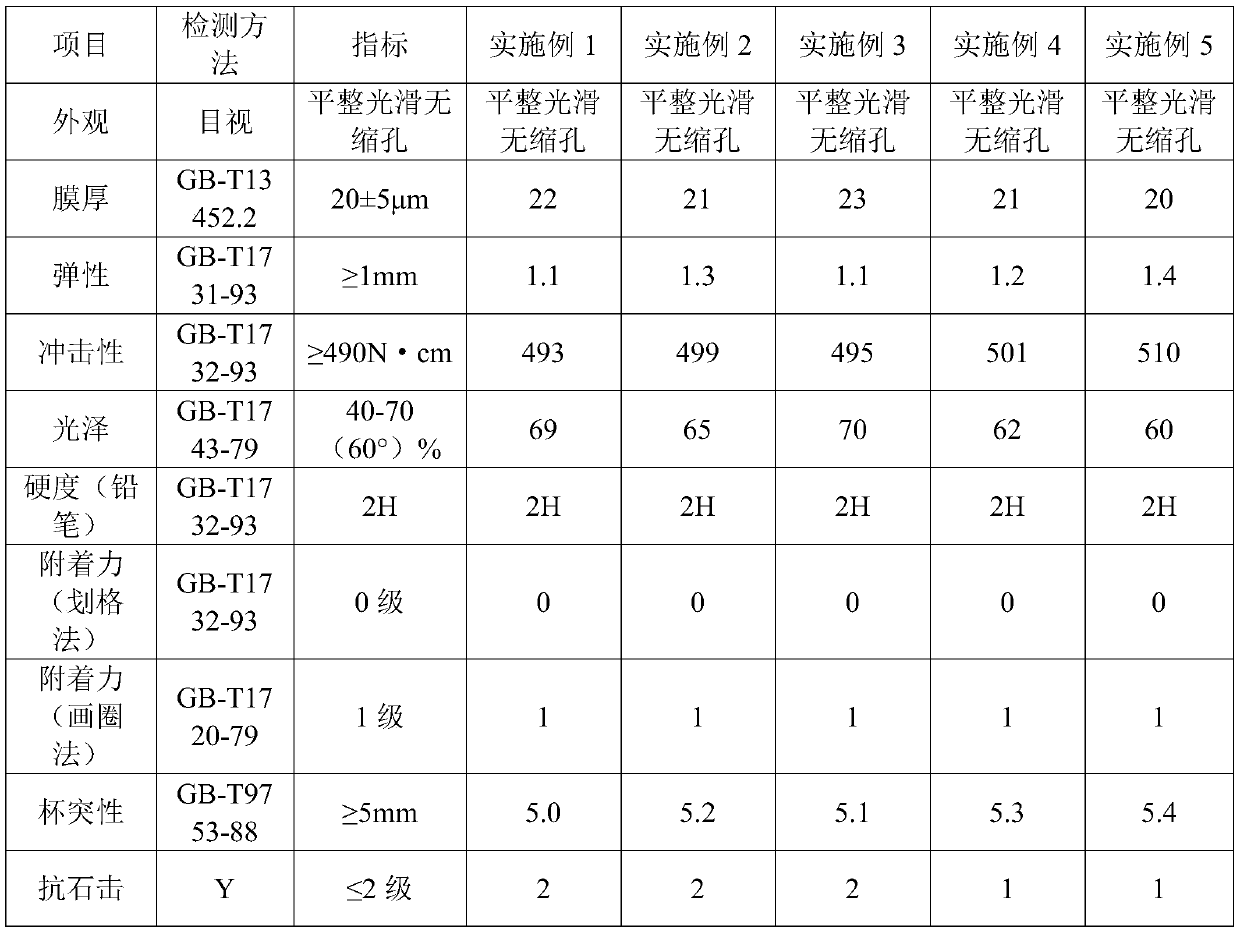

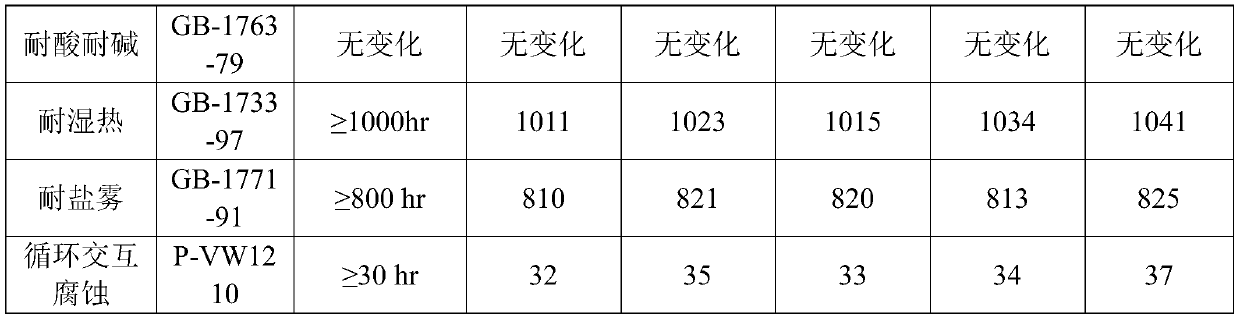

Low-VOC (volatile organic compound) super-curing repairing varnish and preparation method thereof

ActiveCN108276886AHigh hardnessReduce VOC contentAntifouling/underwater paintsPaints with biocidesSolventN-Butyl acetate

The invention belongs to the technical field of chemical coatings, and particularly relates to low-VOC (volatile organic compound) super-curing repairing varnish and a preparation method thereof. Thelow-VOC super-curing repairing varnish provided by the invention is mainly prepared from a component A and a component B; the component A is mainly prepared from polyol super-curing resin, fluoro-modified acrylic resin, overbranched polyester polyol resin, a solvent, a leveling agent and an organic tin dryer; the component B is mainly prepared from low-viscosity aliphatic polyisocyanate, xylene and n-butyl acetate. The low-VOC super-curing repairing varnish provided by the invention can reduce the VOC content using use of coating and relieve the environmental pollution; furthermore, the low-VOC super-curing repairing varnish also has the advantages of formation of a bright varnish film, high fullness, high hardness, scratching resistance, aging resistance, straining resistance and the likein a use process.

Owner:GUANGDONG YATU CHEM

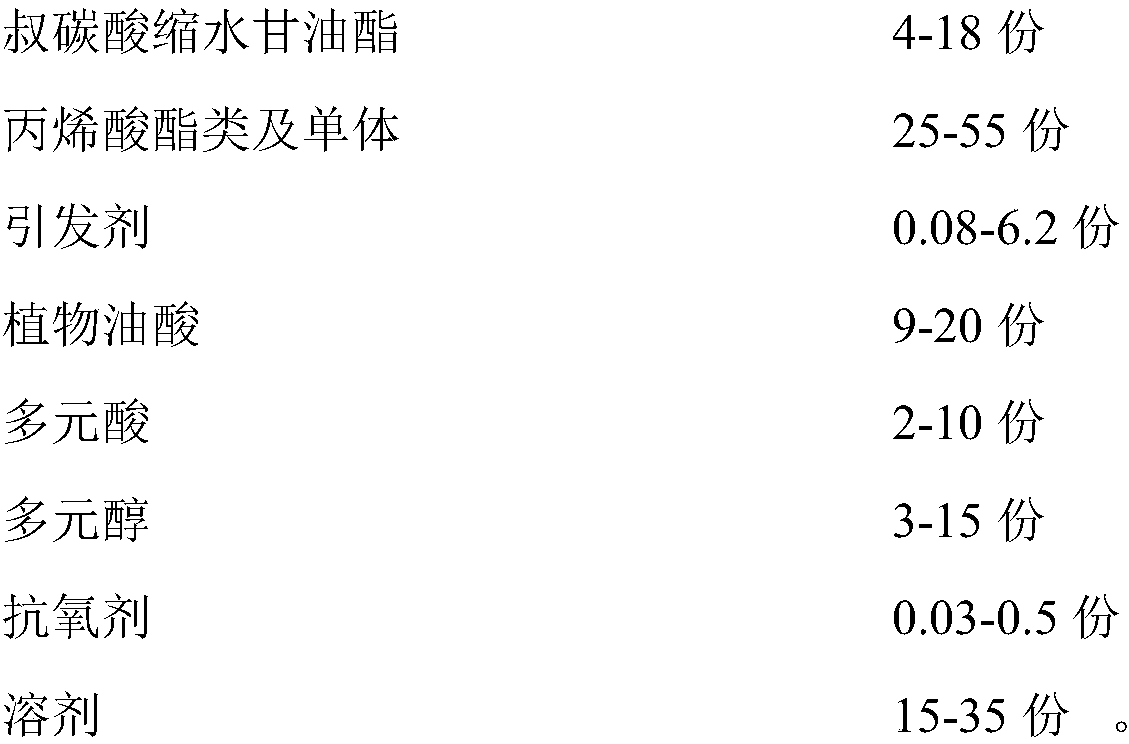

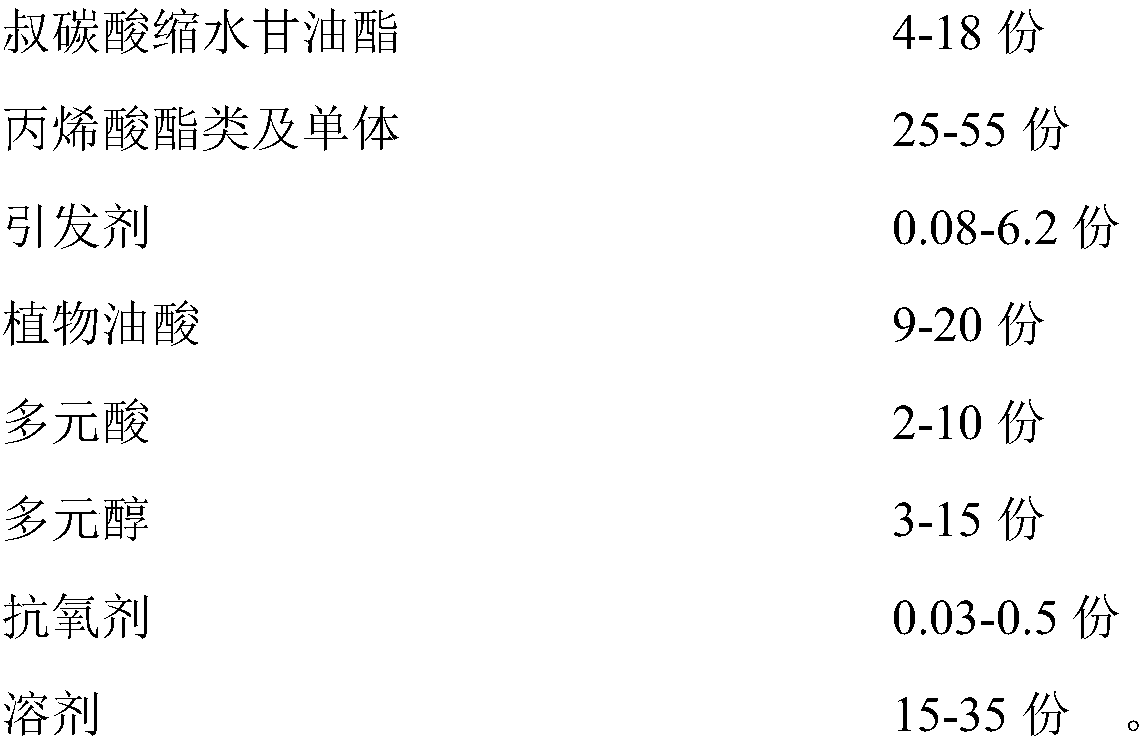

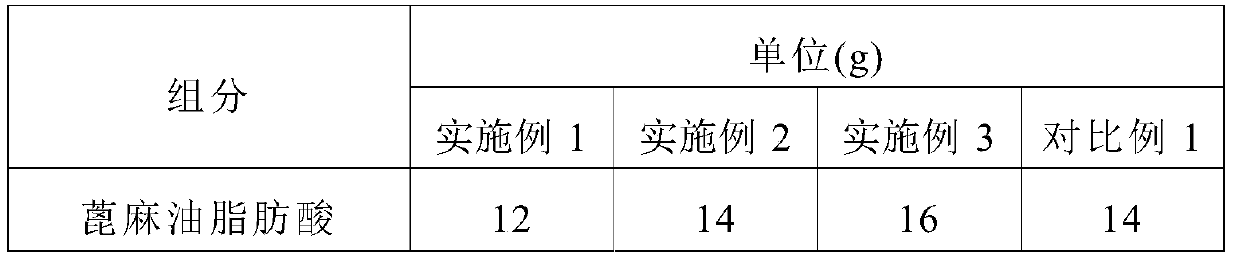

High-solid-content high-performance glycidyl tertiary carboxylic ester modified alkyd resin and preparation method thereof

ActiveCN111234126AImprove water resistanceImprove acid resistanceAnti-corrosive paintsPrepolymerComposite material

The invention discloses high-solid-content high-performance glycidyl tertiary carboxylic ester modified alkyd resin and a preparation method thereof, and belongs to the technical field of coatings. The resin is prepared from glycidyl tertiary carboxylic ester, acrylates and monomers, an initiator, vegetable oleic acid, polybasic acid, polyhydric alcohol, an antioxidant, a solvent and the like. Thepreparation method comprises the following steps: firstly, synthesizing an alkyd resin prepolymer through esterification polycondensation reaction and reflux dehydration, and then synthesizing the high-solid high-performance glycidyl tertiary carboxylic ester modified alkyd resin from the alkyd resin prepolymer, acrylates, monomers and glycidyl tertiary carboxylic ester according to a specific raw material ratio through a chemical synthesis modification method. By introducing glycidyl tertiary carboxylic ester, the water resistance, the acid resistance, the alkali resistance and the like areimproved. Compared with common acrylic acid modified alkyd resin, the high-solid-content high-performance glycidyl tertiary carboxylic ester modified alkyd resin has lower viscosity and a proper amount of reactive groups, and is better in miscibility with other resins, and a paint film formed after crosslinking is improved in weather resistance and has excellent water resistance and acid corrosionresistance.

Owner:NANJING CHANGJIANG PAINT

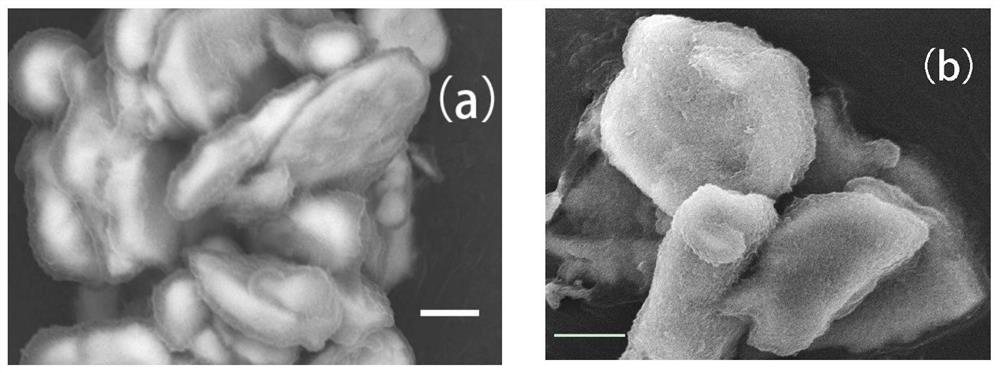

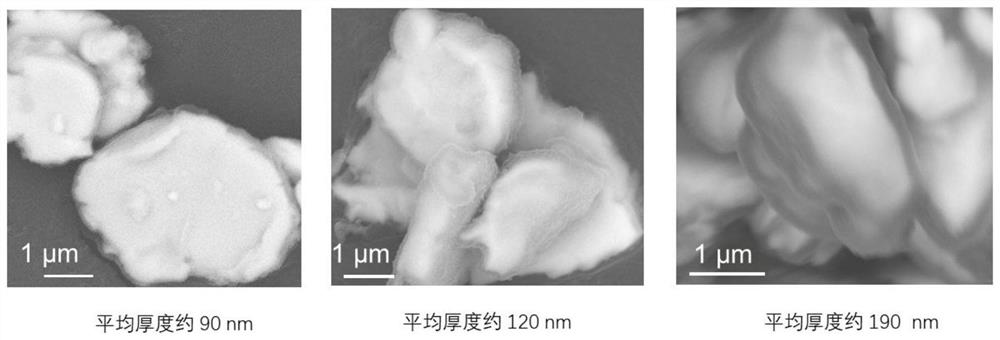

Preparation method of cross-linked resin coated flaky carbonyl iron powder

ActiveCN112863845AAddress process complexityAddressing inhomogeneityMagnetic/electric field screeningInorganic material magnetismIron powderAcid corrosion

The invention belongs to the technical field of electromagnetic wave absorbents, and particularly relates to a preparation method of cross-linked resin coated flaky carbonyl iron powder. According to the preparation method, the flaky carbonyl iron powder is coated with the resin in a cross-linked network structure, a coating layer cannot be dissolved and damaged by a solvent and an external environment, and the coating firmness is greatly improved; and firstly, good contact with the flaky carbonyl iron powder can be ensured by utilizing the flexibility of the resin, and secondly, the characteristics of heat resistance, oxidation resistance, electrochemical corrosion resistance and acid corrosion resistance are ensured by a cross-linked network structure. According to the preparation method, the corrosion resistance of the flaky carbonyl iron powder is effectively improved, the flaky carbonyl iron powder with excellent chemical and electrochemical stability is prepared so as to be better applied to an electromagnetic wave absorbent of a military target, and an effective technical path is provided for improving the corrosion resistance of the flaky carbonyl iron powder.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

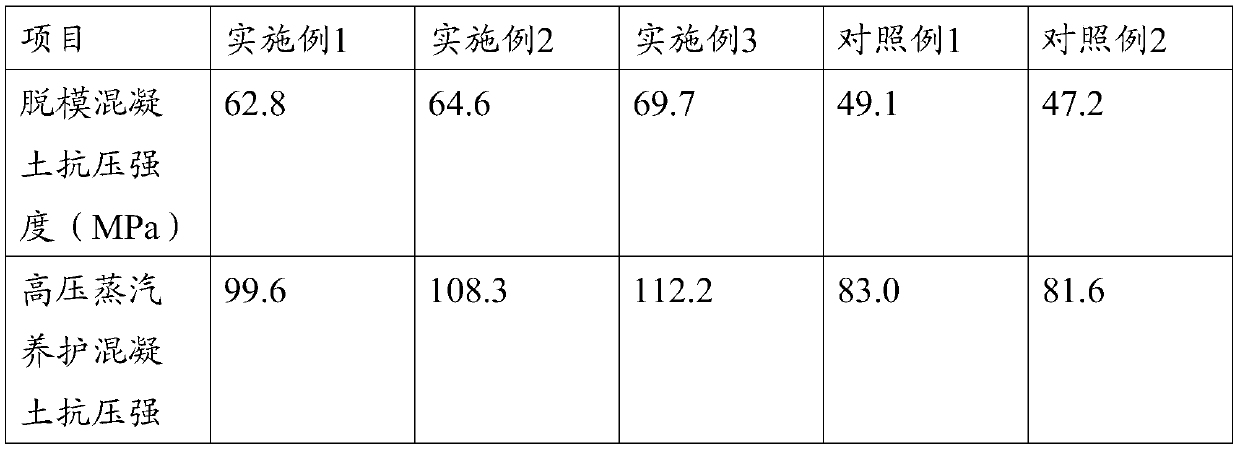

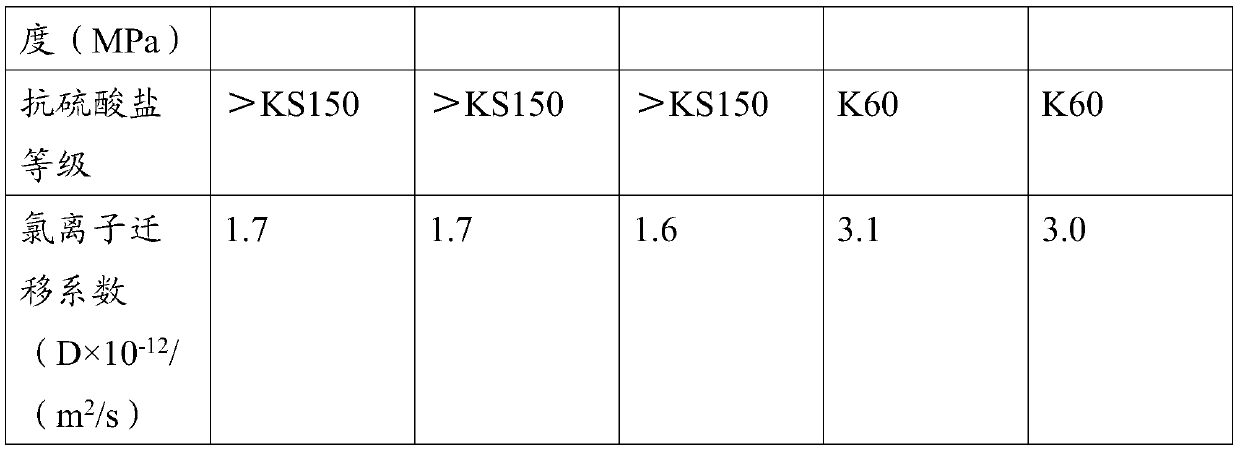

Concrete based on limestone powder supplementary cementing material

The invention discloses concrete based on a limestone powder supplementary cementing material, and belongs to the field of concrete. A water-binder ratio of the concrete is between 0.35 and 0.55; the concrete comprises the following components in percentage by weight: 12-24 percent of cementing materials, 20-34 percent of sand, 47-50 percent of stones, and 6.5-8.5 percent of water, wherein an addictive accounts for 1.5 percent of the cementing material; the cementing material having a cementing function in the concrete is formed by mixing limestone powder and silicate cement; based on the weight percentage, the common silicate cement accounts for 60-90 percent, the limestone powder accounts for 40-10 percent, and the specific surface area of the limestone powder is 350m<2> / kg. The concrete has the advantages that the concrete is prepared by the limestone powder used as a supplementary cementing material of the silicate cement, so that the acid resistance erosion ability of the fine limestone powder concrete is improved; the source of the material is rich, and stone crumbs generated during production of waste stone materials and machine-made sand are used as raw materials so as to solve the problems of deficiency of mineral admixtures and environment pollution of the waste stones in our country; and the preparation cost of compound cement and the concrete can be greatly reduced at the same time.

Owner:CHINA UNIV OF MINING & TECH

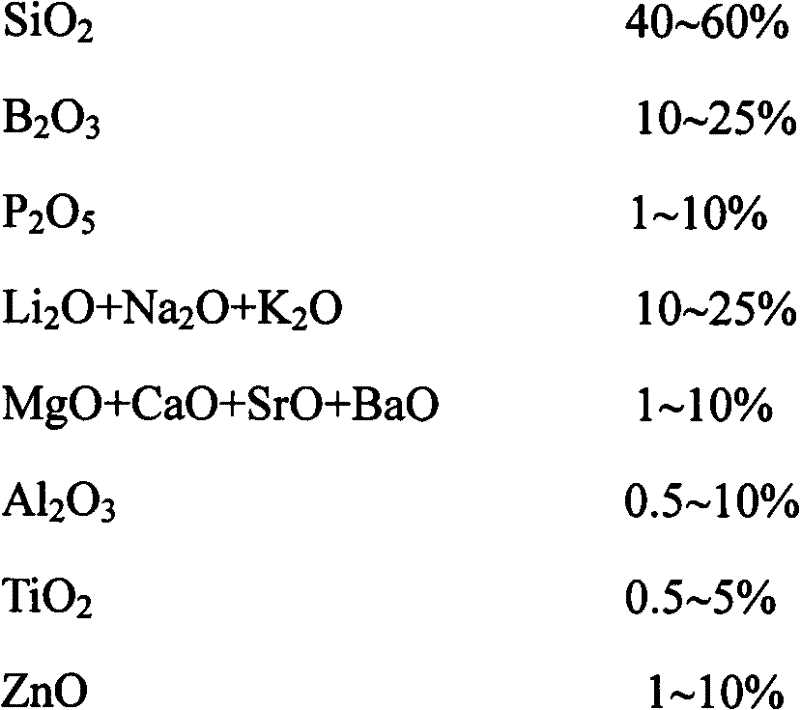

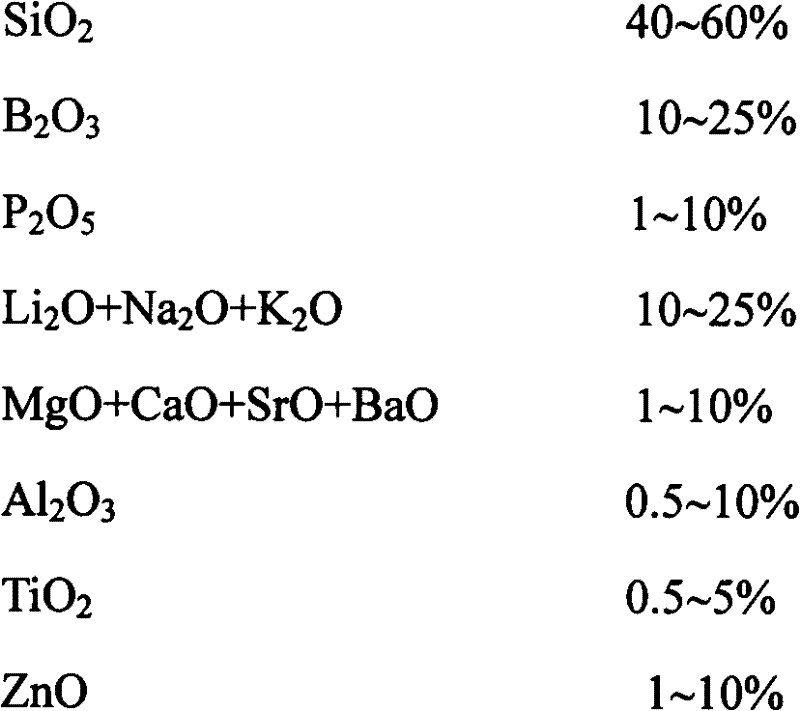

Lead-free low-temperature glass for manufacturing diode glass shell

The invention discloses lead-free low-temperature glass for manufacturing a diode glass shell. The glass mainly contains the following components in percentage by mass: 40 to 60 percent of SiO2, 10 to 25 percent of B2O3, 1 to 10 percent of P2O5, 10 to 25 percent of Li2O, Na2O and K2O, 1 to 10 percent of MgO, CaO, SrO and BaO, 0.5 to 10 percent of Al2O3, 0.5 to 5 percent of TiO2, 1 to 10 percent of ZnO, 0 to 5 percent of F2, and 0 to 2 percent of clarifying agent, wherein the clarifying agent can be one or more of Sb2O3, CeO2 and / or As2O3. The lead-free low-temperature glass has very excellent acid corrosion resistance, and meets the requirement of a diode planting process for acid resistance of the glass shell. In addition, the expansion coefficient of the lead-free glass is matched with that of a Dumet wire, the softening temperature does not exceed 630 DEG C, and the glass can be stably sealed with the Dumet wire at the temperature of below 700 DEG C.

Owner:金招娣

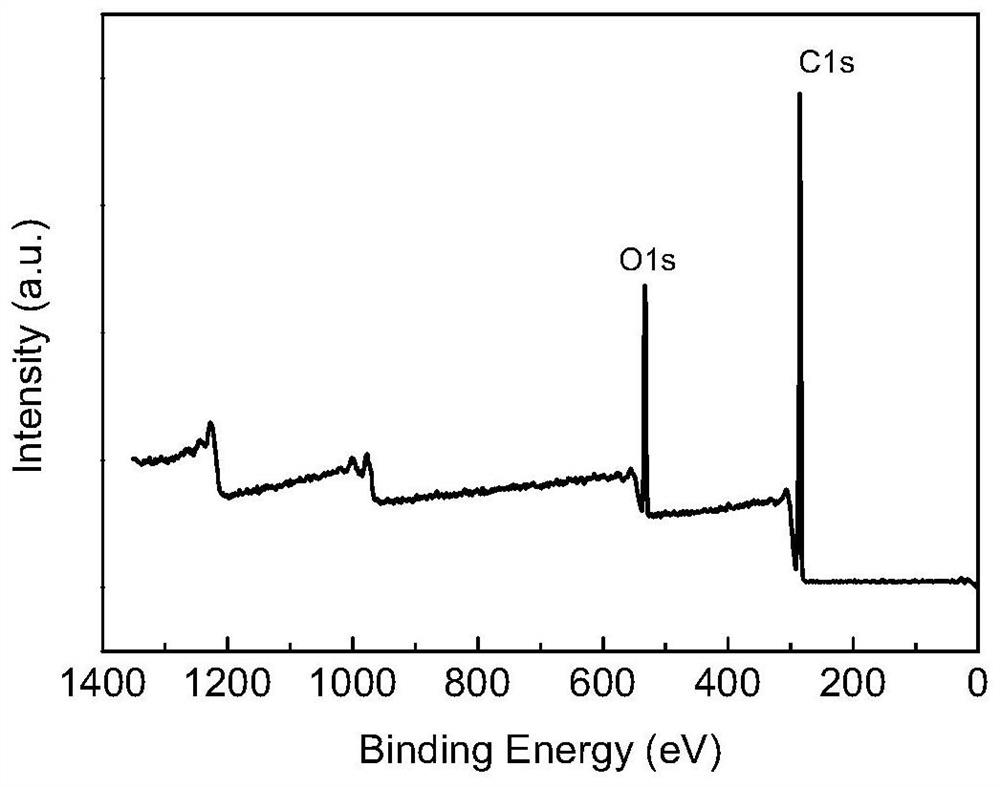

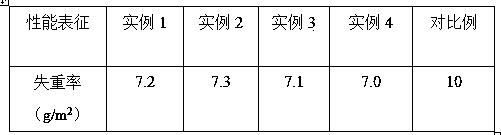

Preparation method of acid-corrosion-resistant enamel glass glaze

InactiveCN109851220AExcellent adhesionThe concentration gradient changes smoothlyNeutral phNano al2o3

The invention relates to a preparation method of an acid-corrosion-resistant enamel glass glaze, belonging to the technical field of materials. A technical scheme of that invention adopts the size effect, antimony oxide is compounded with alumina and nano alumina power is added into that an enamel ground glaze, the crystals in the transition zone between metal and enamel glaze are refined, and theconcentration gradient of elements in the transition zone changes gently, so that the adhesion of the two kinds of ground glaze can be improved effectively, the density strength of the material can be improved, thus the acid corrosion resistance of the material can be improved effectively. In a technical solution of the present invention, fluoride-containing gel is prepared by sol-gel method andadded to that glaze surface material as binder and compactor, fluoride can promote crystal growth and slow down the dissolution of minerals in the enamel, as a temporary barrier to acid attack, the acid is neutralized during acid attack, so that the enamel surface reaches neutral pH value. Meanwhile, the free material produced by fluoride dissolution forms coating film effectively, which improvesthe coating structure of the material and improves the compactness and acid corrosion resistance of the material.

Owner:雷春艳

Rust removing liquid capable of preventing steel surface from being damaged by excessive acid etching

InactiveCN111850575AAcid etch stopAvoid hydrogen embrittlementMetallic material coating processesAcid etchingLanthanum

The invention discloses a rust removing liquid capable of preventing a steel surface from being damaged by excessive acid etching, and relates to the technical field of metal surface treatment. A specific method comprises the following steps of 1) preparing PSSA modified ferroferric oxide nanoparticles; 2) preparing lanthanum doped nano titanium dioxide; 3) preparing silver-lanthanum doped nanometer titanium dioxide nanometer particles; 4) carrying out modification treatment by adopting polyethyleneimine silver-lanthanum doped nanometer titanium dioxide nanoparticles; and 5) uniformly mixing raw materials to obtain a component A and a component B, and putting the components into a container bottle with a middle interlayer to obtain the required rust removing liquid. According to the provided rust removing liquid, rust on the steel surface can be efficiently removed, and depositing can be carried out on a base steel surface to form a acid-corrosion-resistant nanoparticle layer which issmooth, uniform and compact on the whole so that organic acid can be effectively prevented from carrying out acid corrosion on base steel, the hydrogen embrittlement phenomenon of the steel can be avoided, and then the damage of the rust removing liquid to the steel in the rust removing process is reduced.

Owner:ANHUI SHUNBANG FINE CHEM

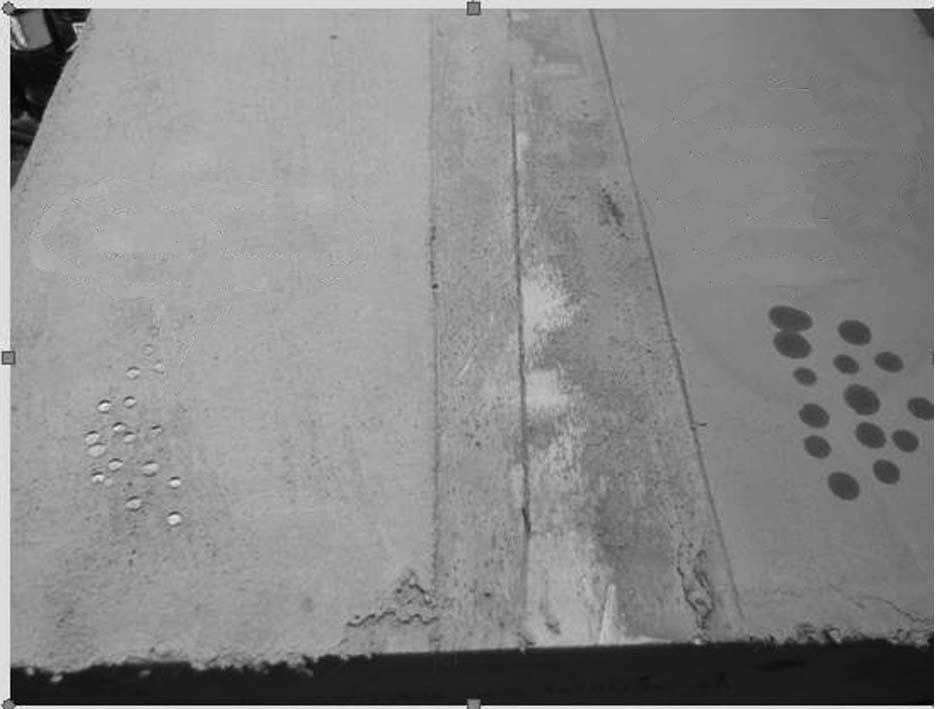

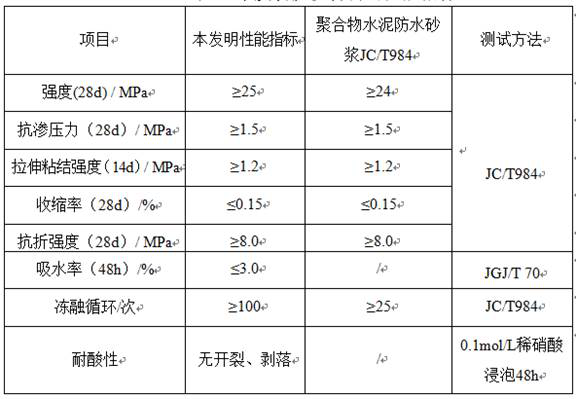

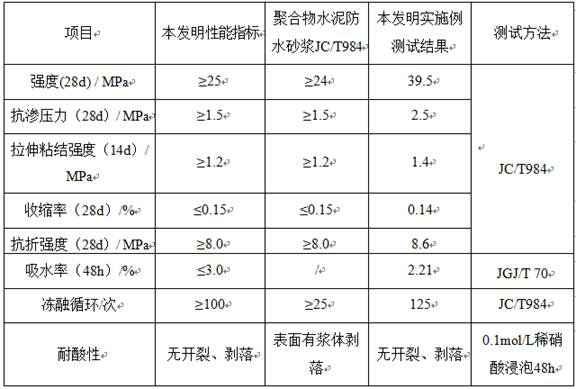

Protective material and application thereof as protective layer for building surfaces and in repair of corroded parts of buildings

ActiveCN108569872AReduce typesThe ratio is scientific and reasonableBuilding repairsBuilding insulationsFiberPortland cement

The invention discloses a protective material, which is prepared by mixing 100 parts of Portland cement, 100 to 250 parts of natural fine sand, 0.15 to 0.20 part of dura fiber, 5 parts of moisture migration inhibitor and 3 to 8 parts of metakaolin. The invention further discloses application of the protective material as a protective layer for building surfaces and in the repair of corroded partsof buildings. The raw material varieties of the protective material disclosed by the invention is few, raw material proportioning and grain size gradation are scientific and reasonable, the waterproofeffect is outstanding, and the corrosion of concrete buildings caused by water quality can be effectively prevented; moreover, when the protective material is used as a repairing material, construction is convenient, and the difficulty of construction is greatly decreased.

Owner:YELLOW RIVER ENG CONSULTING

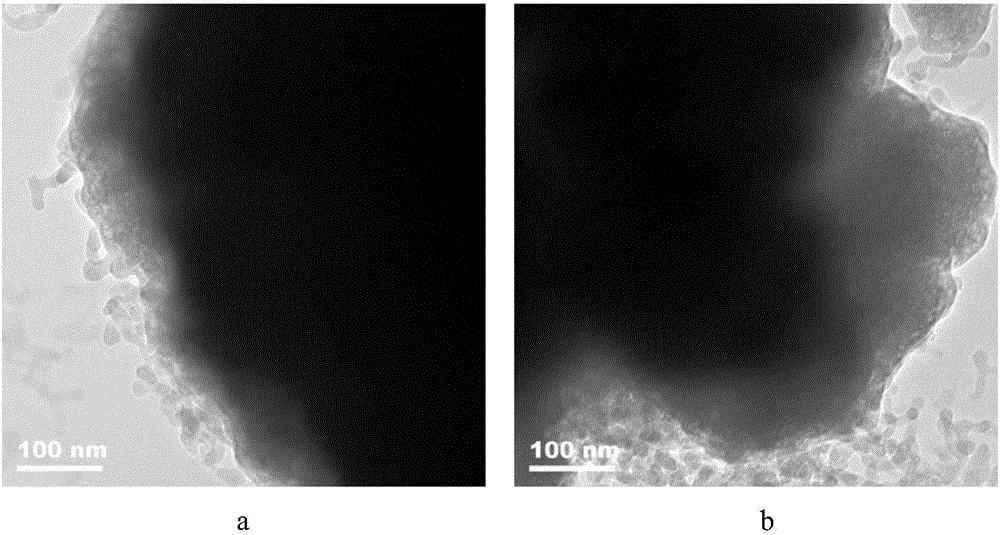

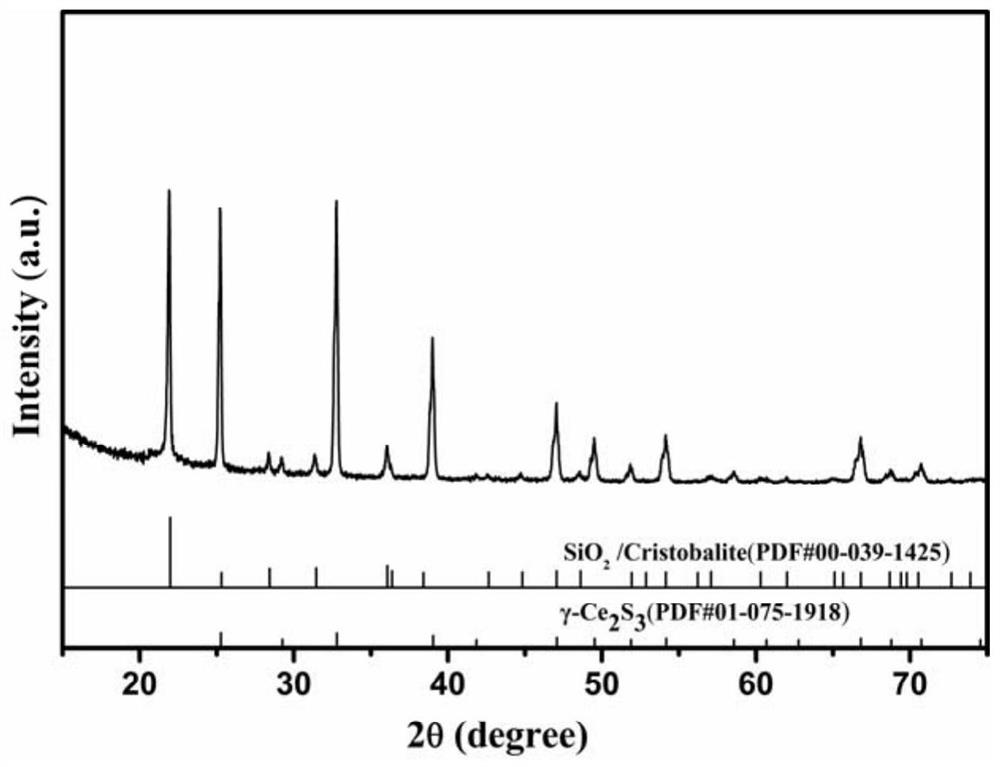

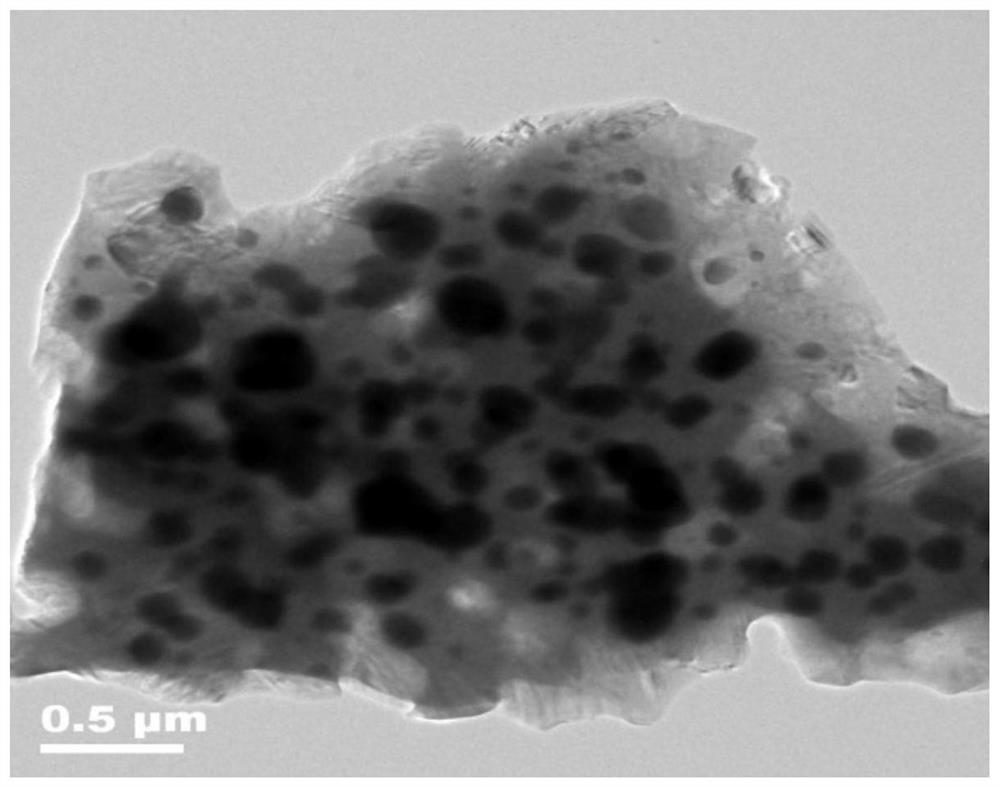

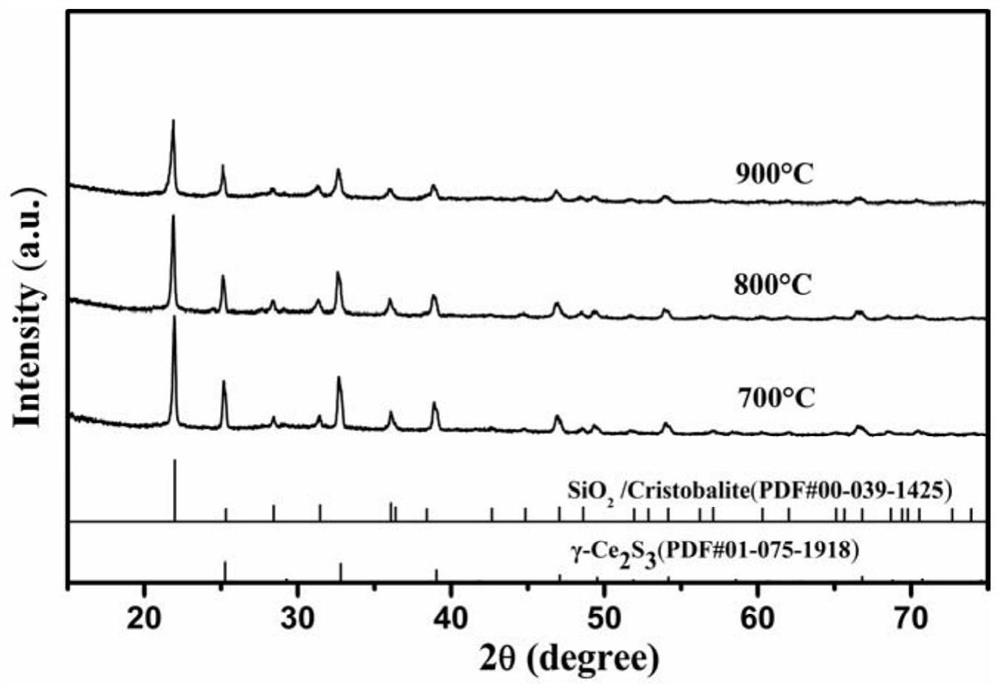

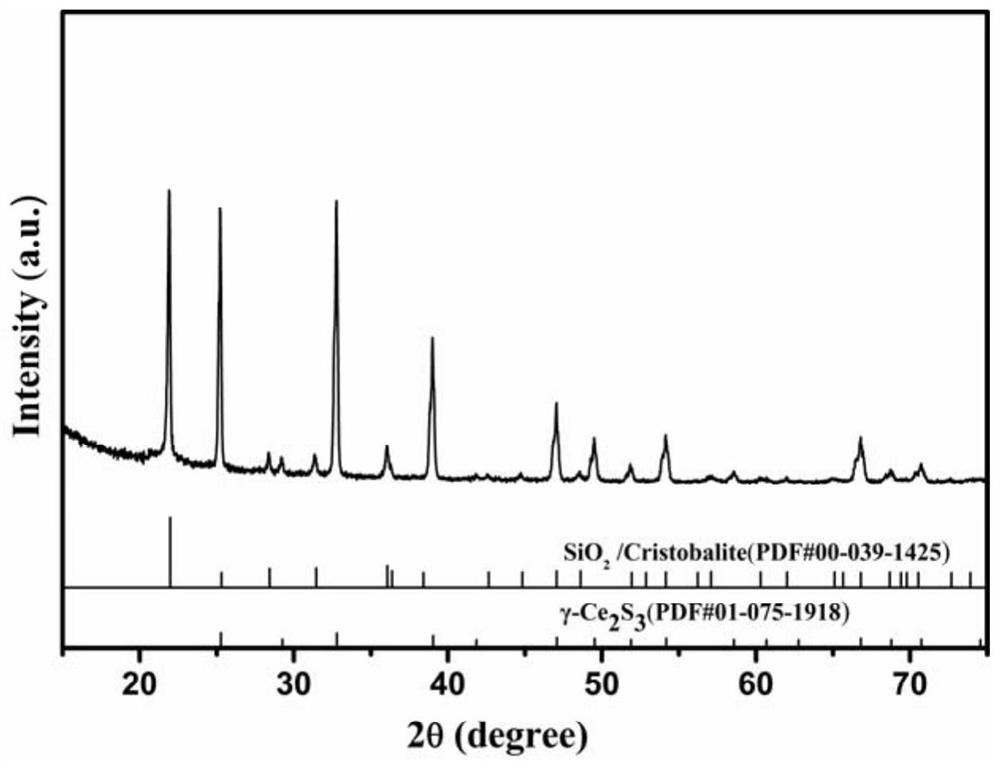

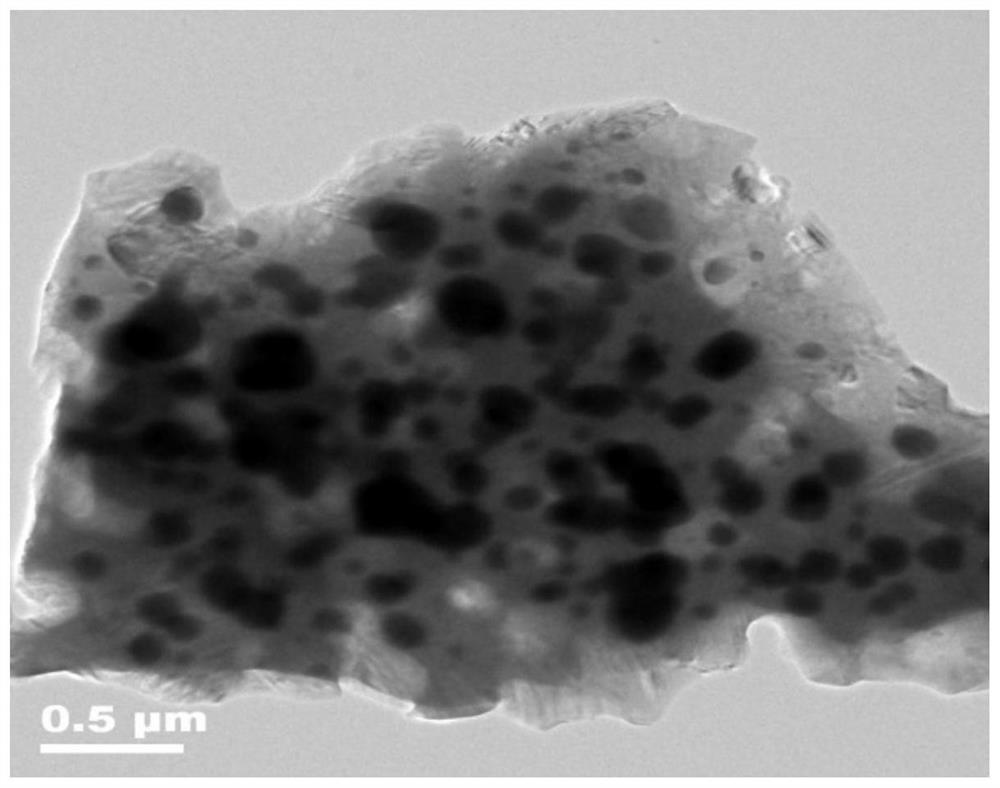

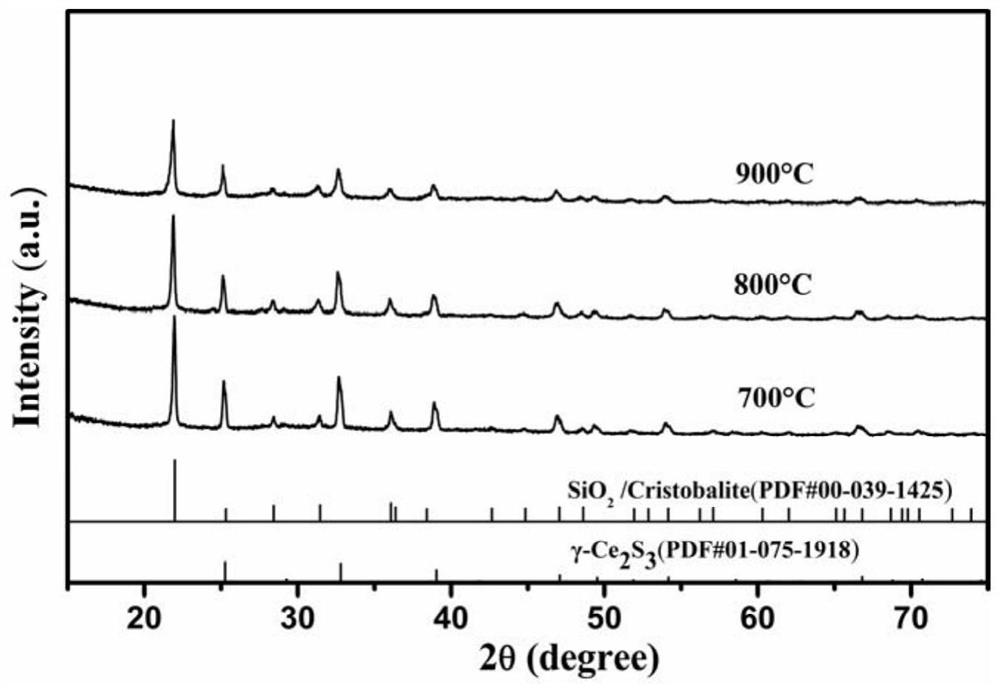

Preparation method of ultrafine cristobalite in-situ coated gamma-Ce2S3 bright red pigment and product prepared by preparation method

ActiveCN112175416AFine granularityImprove hair colorRare earth metal sulfidesNanotechnologyColourantCalcination

The invention discloses a preparation method of an ultrafine cristobalite in-situ coated gamma-Ce2S3 scarlet pigment. The preparation method comprises the following steps: introducing a cerium sourceand a silicon source into a microemulsion system, carrying out precipitation reaction, centrifuging, washing, drying to obtain pigment-coated precursor powder, carrying out vulcanization treatment, and carrying out high-temperature calcination to obtain the ultrafine cristobalite in-situ coated gamma-Ce2S3 bright red pigment. In addition, the invention also discloses a product prepared by the preparation method. According to the invention, the inner core color agent gamma-Ce2S3 pigment particles and cristobalite coating layer crystals are synchronously synthesized through a simple and controllable preparation process, and are coated in situ to form a pomegranate seed-like coating structure in which the inner core color agent gamma-Ce2S3 pigment particles are uniformly stacked and embeddedin the cristobalite coating layer so that the high-temperature stability and acid corrosion resistance of the pigment are greatly improved; and the application field is greatly expanded.

Owner:JINGDEZHEN CERAMIC INSTITUTE

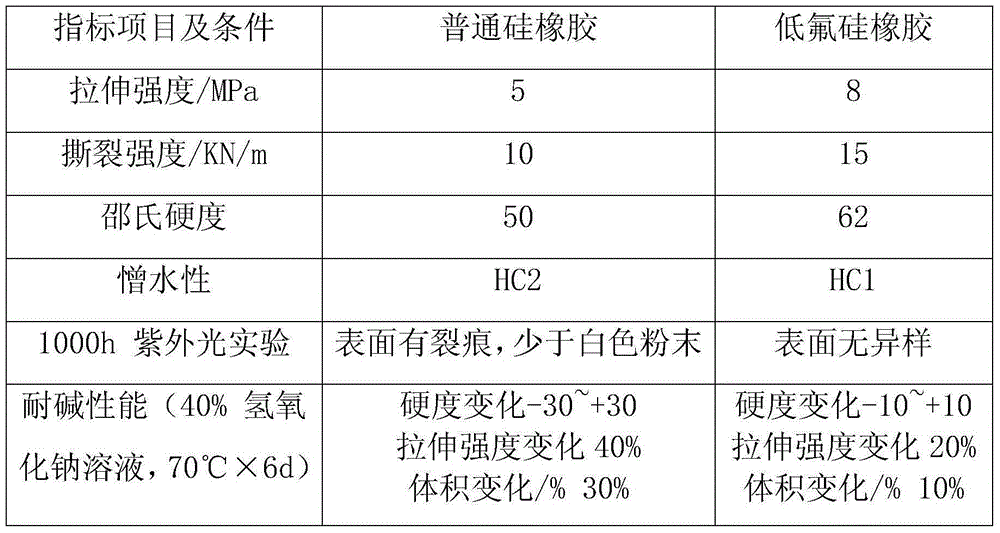

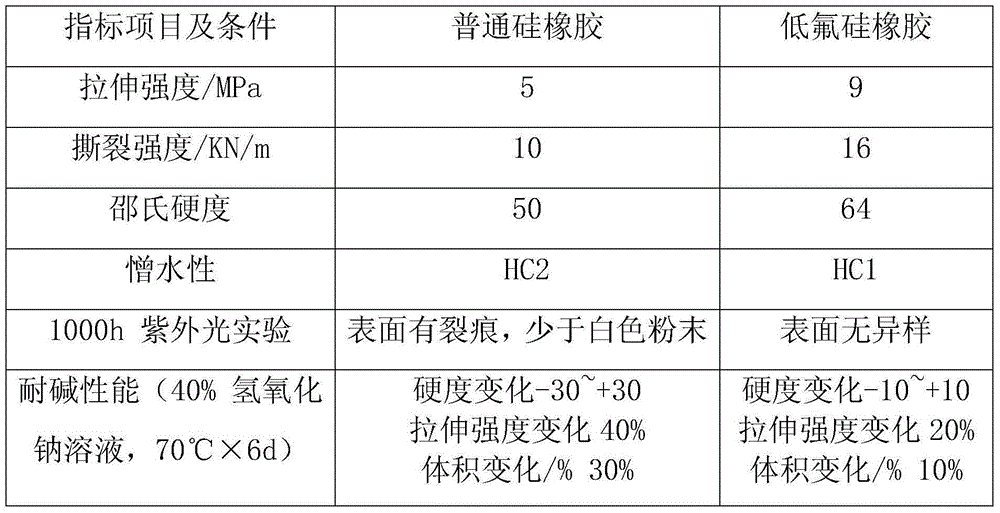

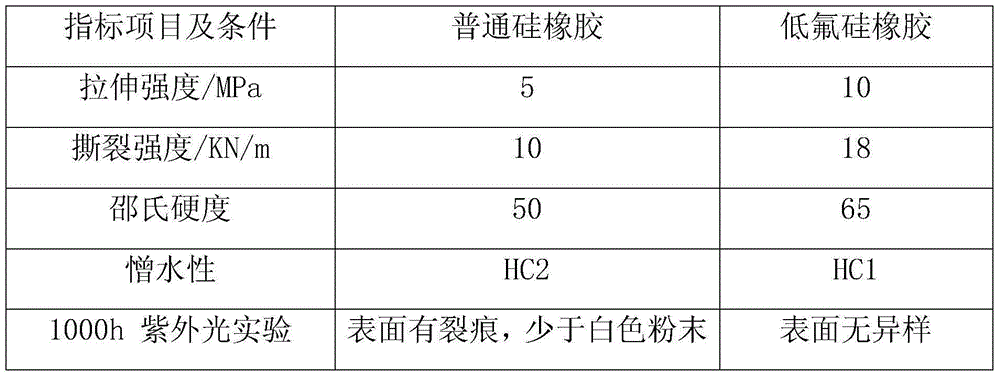

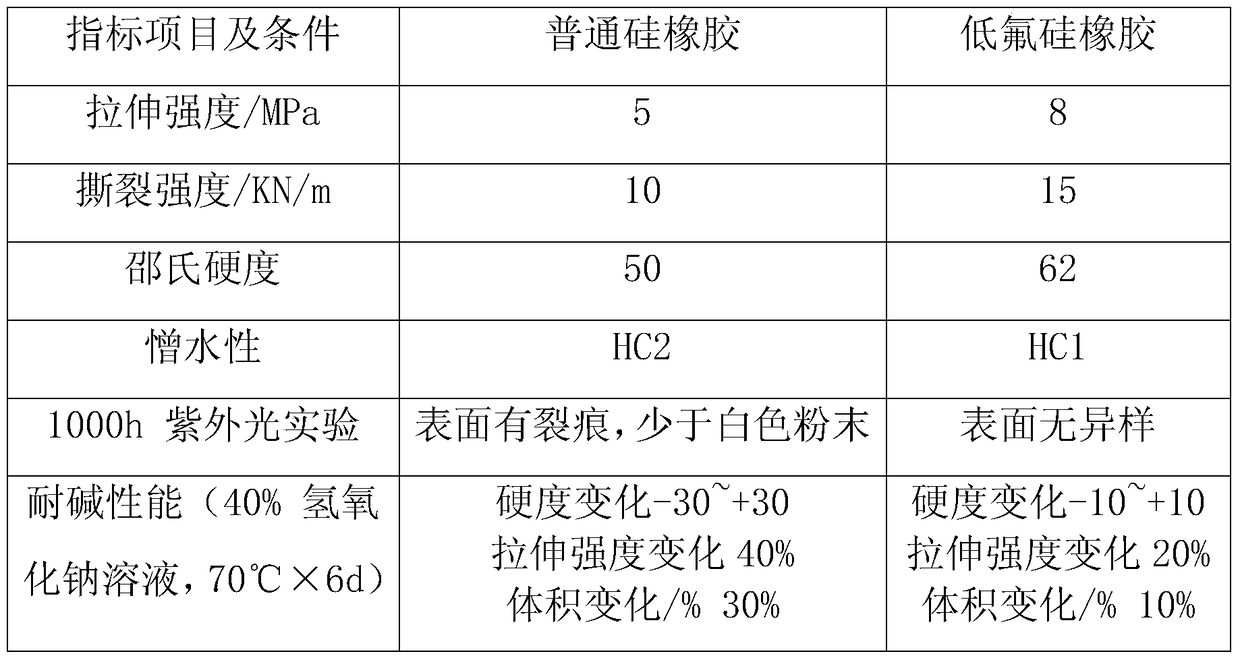

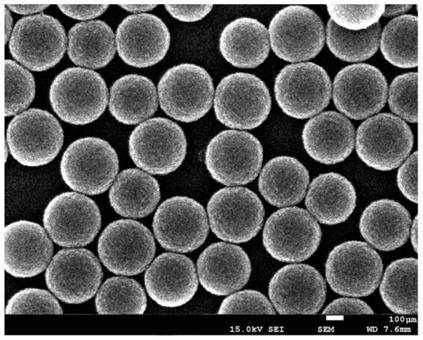

Preparation method for anti-aging silicone rubber used for compression seal products

InactiveCN108102379AImprove mechanical propertiesGood electrical propertiesHeat-exchange elementsPolymer scienceVulcanization

The invention discloses a preparation method for anti-aging silicone rubber used for compression seal products. The method comprises the following steps: stirring spherical aluminum oxide particles, monomethoxypolyethylene glycol and dichloromethane, adding hydroxypropyl methacrylate and ethylene oxide, continuing stirring, adding hydrochloric acid and a polymerization inhibitor, sending the obtained material to a seal reaction kettle, performing heating and performing stirring under the protection of nitrogen gas, allowing the stirred material to stand, performing cooling, and performing washing to obtain a first material; stirring methyl vinyl silicone rubber, nitrile silicone rubber, heavy calcium carbonate, the first material and a structure controlling agent, adjusting the temperature, and allowing the material to stand under vacuum, so as to obtain a second material; and heating the second material, allowing the heated second material to stand, adding cyclohexane peroxide, performing mill run, performing primary vulcanization, and performing secondary vulcanization to obtain the anti-aging silicone rubber used for the compression seal products. The obtained silicone rubber provided by the invention has excellent mechanical properties and electrical properties, excellent ultraviolet resistance and acid corrosion resistance, and good heat resistance, wherein the thermal conductivity can reach 5.8W / (m*K).

Owner:天长市荣盛有机硅科技有限公司

Acid-corrosion-resistant concrete pipe pile and preparation method thereof

The invention provides an acid-corrosion-resistant concrete pipe pile and a preparation method thereof. The acid-corrosion-resistant concrete pipe pile comprises the following components in parts by weight: 280-380 parts of cement, 130-160 parts of quartz ultrafine powder, 980-1230 parts of granite macadam, 520-780 parts of quartz sand, 110-160 parts of water, 10-22 parts of a water reducing agent, 28-48 parts of potash water glass and 3-9.6 parts of aluminum tripolyphosphate. The SiO2 content of the quartz ultrafine powder is greater than or equal to 90%, and the specific surface area is greater than or equal to 500m < 2 > / kg. According to the formula component concrete, the corrosion resistance of the pipe pile is improved, corrosion of an acid medium to pile body concrete is avoided, steel bars in the pipe pile can be protected against corrosion, the structural strength of the pipe pile is improved and the service life is prolonged.

Owner:FUJIAN DADI CONCRETE PILE

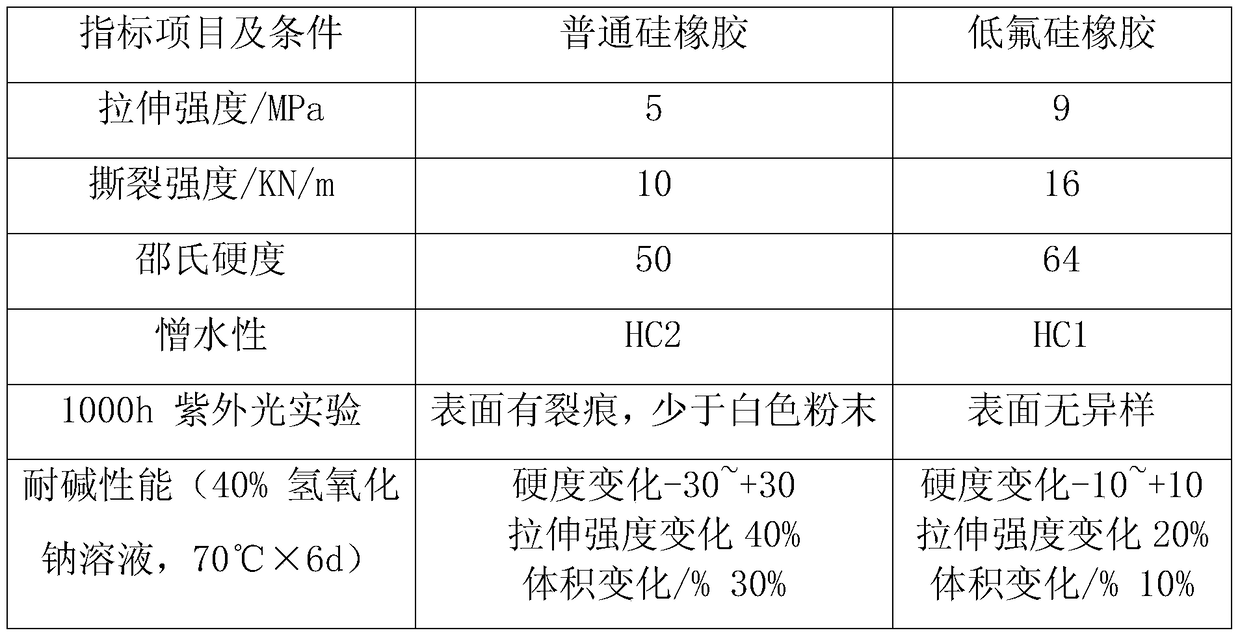

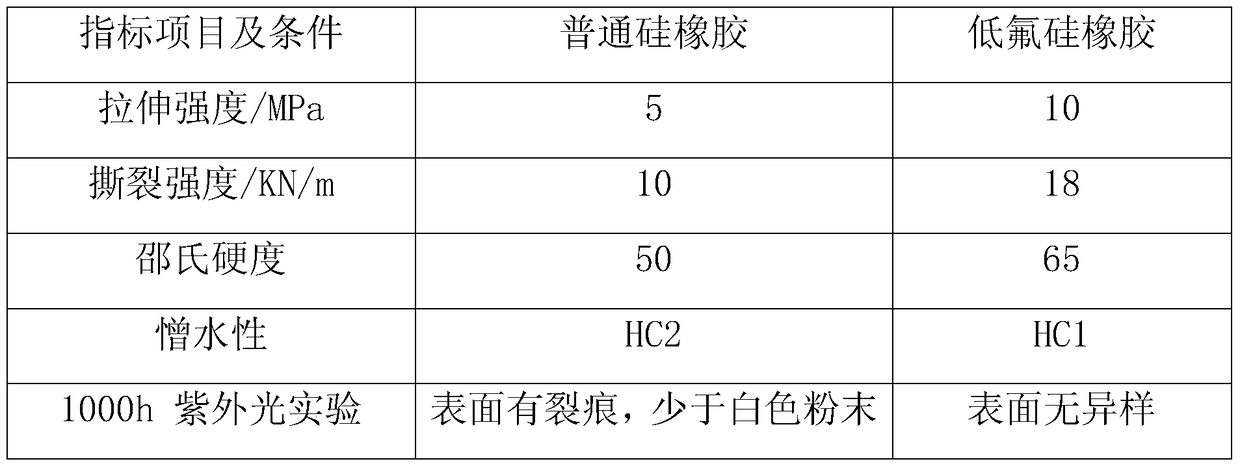

Preparation method of low-fluorine silicone rubber used for ceramic composite insulator

ActiveCN105017778ALow surface energy performanceGood for anti-agingPrecipitated silicaDicumyl peroxide

The invention discloses a preparation method of low-fluorine silicone rubber used for a ceramic composite insulator. The preparation method comprises weighing 100 parts of methyl vinyl fluorosilicone rubber, 6-9 parts of precipitated silica, 18-25 parts of a fire retardant, 3-7 parts of zinc stearate, 2-6 parts of activated magnesium oxide and 2-5 parts of ferric oxide powder according to a ratio, and uniformly mixing in a double-roller mixing mill so as to prepare a uniform master batch, performing banburying on the master batch in a kneader at 170 DEG C at a vacuum degree of -0.09 MPa for 10-20 min, then adding 0.1-0.3 part of dicumyl peroxide, again performing banburying at 200 DEG C for 3-5 h, and leaving overnight, so as to prepare the low-fluorine silicone rubber. The prepared low-fluorine silicone rubber possesses excellent performances of fluorosilicone rubber, overcomes problems of silicon rubber, is resistant to ageing, possesses excellent acid and alkali resistance, is strong in hydrophobicity, is affordable, and helps to effectively save cost.

Owner:JIANGSU SOUTH PORCELAIN INSULATOR CO LTD

A kind of imitation jade Longquan celadon, glaze, billet and preparation method of Longquan celadon

The invention relates to a blank material and glaze material of a jade-imitated Longquan celadon and a preparation method of the product. The jade-imitated Longquan celadon comprises a glaze and a blank; the glaze material is composed of a component A and a component B; the component A comprises, by weight, 35-45% of potassium feldspar, 15-21% of quartz, 20-28% of talc, 6-10% of calcium borate, 2-6% of bone ash, and 3-7% of bentonite; the component B is a color glaze material and comprises, by weight, 40-60% of feldspar, 7-13% of quartz , 7-13% of glaze paste, 5-10% of dolomite, 10-20% of limestone, 4-12% of strontium carbonate, and 0.5-1.5% of CuO. The blank of the jade-imitated Longquan celadon is prepared from the following blank material by weight: 30-50% of Longquan porcelain clay, 40-60% of Longyan kaolin, and 5-15% of limestone. The product is a Longquan celadon product which is sintered in a 1200 DEG C oxidation atmosphere, presents calm and steady color and luster and greasy texture and is similar to jades but superior to jades.

Owner:龙泉市土圭垚文化创意有限公司

A kind of low-temperature low-alkali metal lead-free glaze and its preparation process

ActiveCN109851224BImprove acid corrosion resistanceSmall coefficient of thermal expansionThermal dilatationAlkali metal oxide

The invention relates to a low-temperature low-alkali metal lead-free glaze and a preparation process thereof, mainly comprising the following components and parts by weight: 20-24 parts of potassium feldspar, 7-9 parts of quartz, and 45-54 parts of low-temperature lead-free glass powder , 9‑10 parts of talc, 10‑12 parts of limestone; the low-temperature lead-free glass powder is ZnO–B 2 o 3 – SiO 2 Glass, including ZnO 30-55%, B 2 o 3 18-22%, SiO 2 17~30%, Al 2 o 3 5~10%, BaO 4~6%, TiO 2 0~3%. The present invention adds ZnO-B in the glaze 2 o 3 – SiO 2 Glass is used to replace lead-containing flux and alkali metal oxides. When the content of alkali metals is less than 3%, the acid corrosion resistance of the glaze is greatly improved, and the strength and wear resistance of the glaze are better. It can ensure that the sintering temperature is below 800°C, and it can also reduce the thermal expansion coefficient of the glaze, and at the same time, it will not precipitate heavy metals such as lead and cadmium, which meets the requirements of health and environmental protection. In addition, the invention also effectively reduces the viscosity of the glaze by adding talc and limestone, and improves the fluidity and gloss of the glaze.

Owner:潮州市广嘉陶瓷制作有限公司 +1

Preparation method of high-strength anti-fracture concrete

InactiveCN112500060AEnsure dynamic balanceImprove crack resistanceComposite materialStructural engineering

The invention discloses a preparation method of high-strength anti-fracture concrete. The preparation method sequentially comprises the following steps: treating cement paste; mixing the cement mortar; mixing coal ash and the cement mortar; prefabricating and mixing an expanding agent and a water reducing agent; pretreating phenolic resin; mixing sodium alginate and sodium monofluorophosphate; andfinished product synthesis. According to the preparation method of the high-strength anti-fracture concrete, the expanding agent is doped into the concrete, a special expansion source is generated bythe expansion component, the fracture reason of the concrete after pouring is air humidity, and the proportion of the concrete during blending; The problem of cracking caused by shrinkage of concretein each setting period in the prior art can be solved, the net shrinkage value of the concrete in each age is ensured to be always less than the ultimate tensile value of the concrete, and the crackresistance of the concrete is effectively enhanced. The modified phenolic resin is added, the modified phenolic resin solves the problem of poor deformability with a concrete cured product, and can make the concrete resistant to aging.

Owner:宿迁市京成建材有限公司

Low-cost waterproof anti-aging construction brick

The invention discloses a low-cost waterproof anti-aging construction brick which comprises the following raw materials by weight part: 0.5-1.5 parts of ethylene-vinyl acetate copolymer, 1.5-2.5 parts of cellulose hydroxypropyl methyl, 0.4-0.8 part of polysiloxane powder, 8-16 parts of modified montmorillonite, 10-20 parts of coal ash, 8-16 parts of calcium hydroxide, 20-30 parts of clay, 8-16 parts of stone wastes, 3-7 parts of silicon nitride, 3-9 parts of kieselguhr, 3-7 parts of magnesium oxide, 25-35 parts of cement and 10-20 parts of argil. A preparation method for the modified montmorillonite comprises the following steps: stirring montmorillonite powder, oxalic acid and sodium dihydrogen phosphate; standing by; extracting upper-layer turbid liquid; adding sodium hydroxide into the turbid liquid and stirring; adding oxalic acid and stirring; adding monopotassium phosphate and stirring; adding ethylene diamine tetraacetic acid disodium and stirring; centrifuging, drying and crushing; adding silane coupling agent and water; adjusting pH value, stirring and filtering; washing; adding glutaraldehyde aqueous solution and stirring; filtering, washing and drying, thereby acquiring the modified montmorillonite.

Owner:蚌埠市淮上区昊天新型建材厂

A kind of anti-blue light sulfonated organic membrane and manufacturing method thereof

InactiveCN108059805BImprove mechanical propertiesStrong absorption capacityCoatingsOrganic filmPolyester

Owner:ZHEJIANG COLLEGE OF ZHEJIANG UNIV OF TECHOLOGY

A preparation method of low-fluorine silicone rubber for porcelain composite insulators

The invention discloses a preparation method of low-fluorine silicone rubber used for a ceramic composite insulator. The preparation method comprises weighing 100 parts of methyl vinyl fluorosilicone rubber, 6-9 parts of precipitated silica, 18-25 parts of a fire retardant, 3-7 parts of zinc stearate, 2-6 parts of activated magnesium oxide and 2-5 parts of ferric oxide powder according to a ratio, and uniformly mixing in a double-roller mixing mill so as to prepare a uniform master batch, performing banburying on the master batch in a kneader at 170 DEG C at a vacuum degree of -0.09 MPa for 10-20 min, then adding 0.1-0.3 part of dicumyl peroxide, again performing banburying at 200 DEG C for 3-5 h, and leaving overnight, so as to prepare the low-fluorine silicone rubber. The prepared low-fluorine silicone rubber possesses excellent performances of fluorosilicone rubber, overcomes problems of silicon rubber, is resistant to ageing, possesses excellent acid and alkali resistance, is strong in hydrophobicity, is affordable, and helps to effectively save cost.

Owner:JIANGSU SOUTH PORCELAIN INSULATOR CO LTD

A protective material and its application as a protective layer on the surface of a building and repairing the corroded part of a building

ActiveCN108569872BGood filling effectImprove acid corrosion resistanceBuilding repairsBuilding insulationsFiberPortland cement

The invention discloses a protective material, which is prepared by mixing 100 parts of Portland cement, 100-250 parts of natural fine sand, 0.15-0.20 parts of durafiber, 5 parts of moisture migration inhibitor, and 3-8 parts of metakaolin The present invention also discloses the application of the protective material as a protective layer on the surface of a building and repairing a corroded part of a building. The protection material of the present invention has few types of raw materials, scientific and reasonable raw material ratio and particle size distribution, outstanding waterproof effect, and can effectively prevent corrosion of concrete buildings caused by water quality. At the same time, when used as a repair material, the construction is convenient. The difficulty of construction is greatly reduced.

Owner:YELLOW RIVER ENG CONSULTING

Molding powder for LOC box

InactiveCN110903736AGood dispersionPrevent saggingFireproof paintsAnti-corrosive paintsEpoxyPolymer science

The invention discloses molding powder for electrostatic spraying of an LOC box. The molding powder comprises the following components in parts by weight: 30-35 parts of epoxy resin, 25-30 parts of polyester resin, 10-15 parts of hydroxyl-containing fluorocarbon resin, 4-8 parts of tri-beta-methyl glycidyl isocyanurate, 1-3 parts of triglycidyl isocyanurate, 0.5-1 part of a pigment, 25-30 parts ofa filler, 2-3 parts of a leveling agent, 0.5-1 part of a moisture-proof agent, 0.5-1 part of a corner modifier, 0.5-1 part of benzoin and 1-1.5 parts of a coupling agent. The molding powder has goodcorrosion resistance and high temperature resistance.

Owner:ANHUI TIAN CHANG INSTR FACTORY

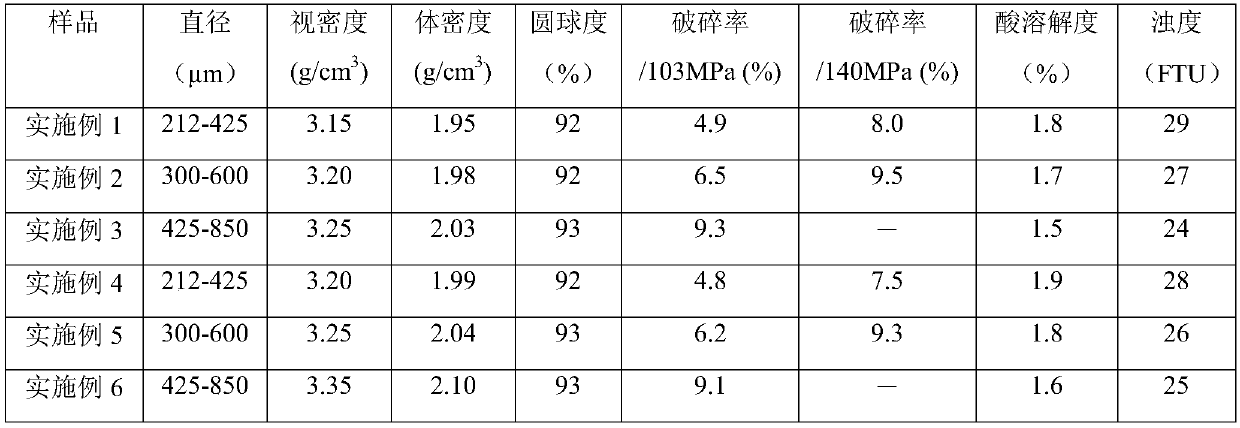

Ultrahigh strength corrosion resistant composite ceramic fracturing propping agent

InactiveCN109652056AImprove corrosion resistanceReduce turbidityFluid removalDrilling compositionComposite ceramicUltimate tensile strength

The invention belongs to the field of oil exploitation aids, and especially relates to an ultrahigh strength corrosion resistant composite ceramic fracturing propping agent. The propping agent comprises following components in percentage by weight: 80 to 85 wt.% of high pure ultrafine Al2O3; 1 to 3 wt.% of ultrafine kaolin, 10 to 15 wt.% of ultrafine ZrO3, 0.5 to 1.0 wt.% of CaO, 0.3 to 0.5 wt.% of SiO2, 0.3 to 0.8 wt.% of MgO, and 2.0 to 3.5 wt.% of lignin. The raw materials are mixed, blended, aged, and granulated, and then the particles are moulded, compacted, screened and sintered to prepare the fracturing propping agent with a controllable diameter of 100 to 900 [mu]m. The prepared fracturing propping agent has the advantages of high strength, good corrosion resistant property, and high roundness, and can be widely used in fields of deep mining, super deep mining, and deep sea oil and gas exploitation, and the preparation method is innovative.

Owner:郑州可塑金新材料有限公司

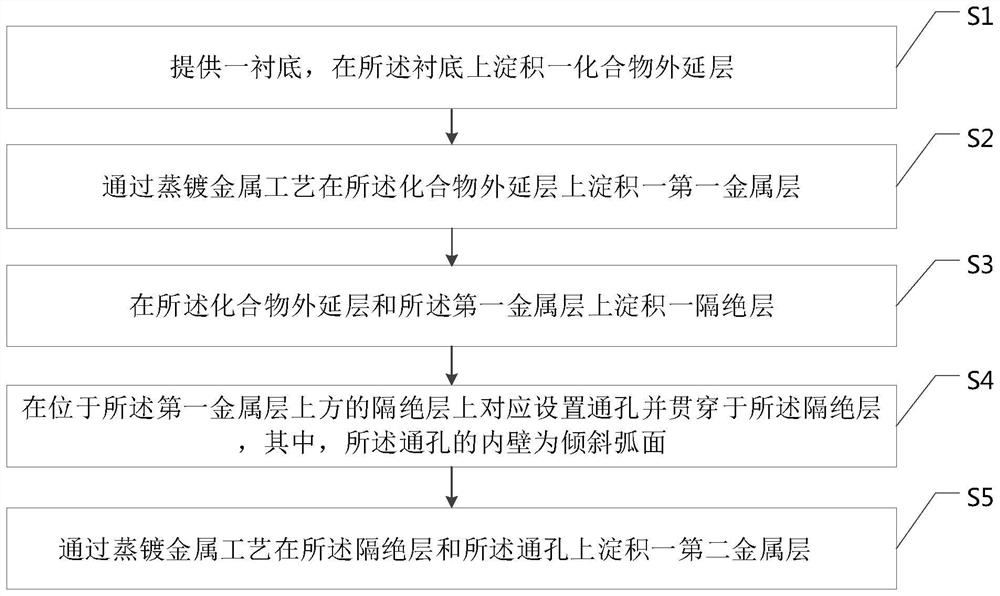

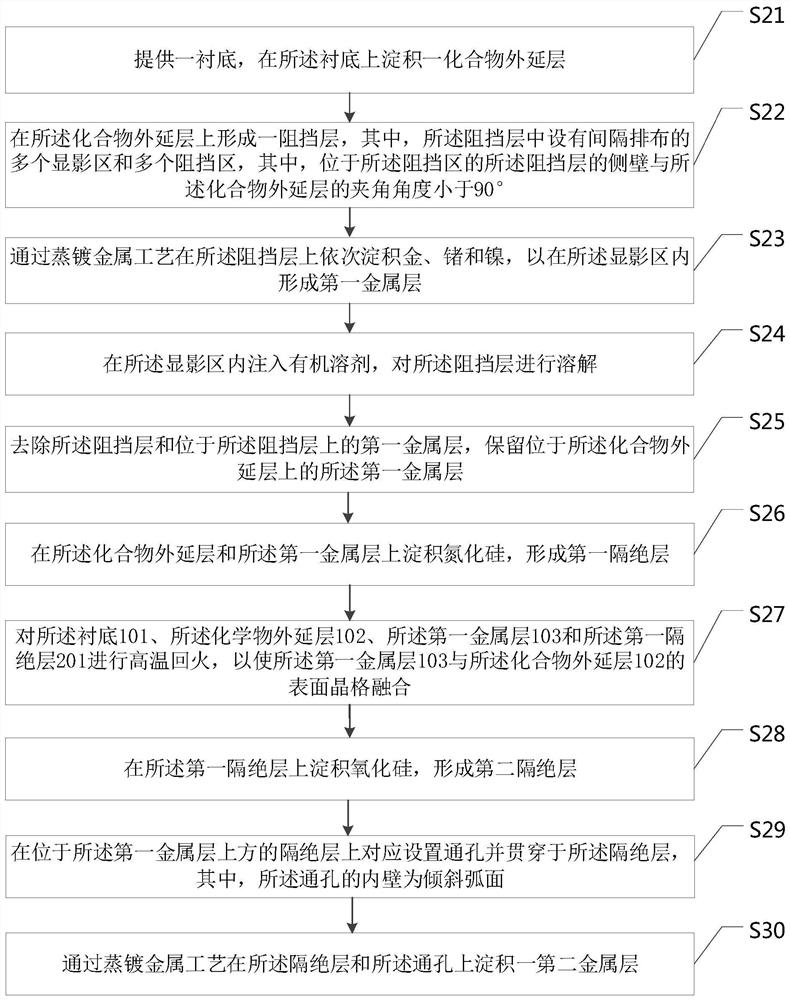

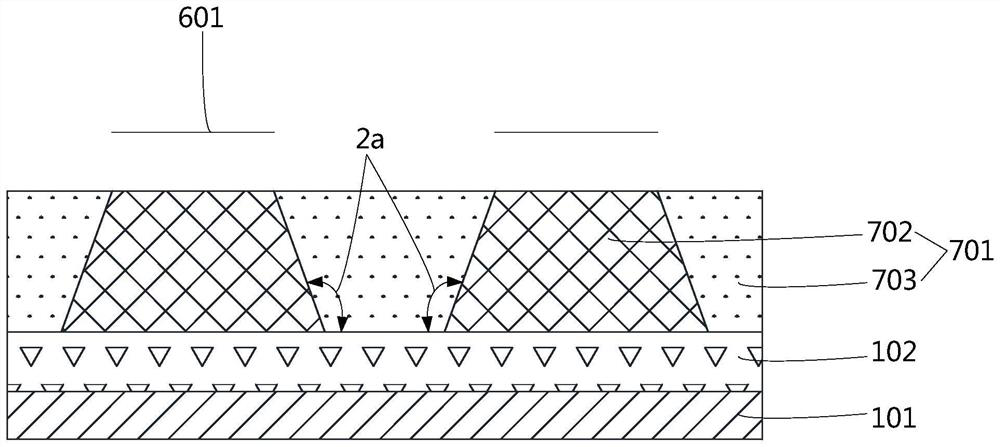

Third-generation semiconductor contact window structure and manufacturing method thereof

PendingCN114551340AMaintain electronic physical propertiesAvoid pollutionFinal product manufactureSemiconductor/solid-state device detailsIsolation layerImpurity ions

The invention relates to the technical field of semiconductor manufacturing, and discloses a third-generation semiconductor contact window structure and a manufacturing method thereof. The manufacturing method comprises the following steps: providing a substrate, and depositing a compound epitaxial layer on the substrate; depositing a first metal layer on the compound epitaxial layer through a metal evaporation process; depositing an isolation layer on the compound epitaxial layer and the first metal layer; a through hole is correspondingly formed in the portion, located above the first metal layer, of the isolation layer and penetrates through the isolation layer, and the inner wall of the through hole is an inclined cambered surface; and depositing a second metal layer on the isolation layer and the through hole through a metal evaporation process. Damage and impurity ion pollution to a lattice structure on the surface of a compound epitaxial layer by a metal sputtering process are effectively prevented, and the contact impedance of a third-generation semiconductor contact window structure is reduced.

Owner:GALLIUM ADVANCE SEMICON TECH CO

A kind of anti-blue light high-definition polyester film and its manufacturing method

The invention discloses an anti-blue light high-definition polyester film and a manufacturing method thereof. The anti-blue light high-definition polyester film is based on a blue light softening material, and the blue light softening material is specifically 0.03mm-0.05mm thick and has been stabilized and modified. After hydrogen hardening the polyester optical film, the surface of the substrate is compounded with a rosin-based polyester acrylate film layer with a thickness of 0.01mm-0.02mm, cured by ultraviolet light and stabilized and modified. The anti-blue light high-definition polyester film of the present invention uses polyester optical film as the base material, which is processed and formed at one time, has stable chemical properties, strong anti-aging performance, scratch resistance on the surface, and long service life, and can reduce the impact of high-energy blue light on human eyes. s damage.

Owner:ZHEJIANG COLLEGE OF ZHEJIANG UNIV OF TECHOLOGY

Gas-shielded welding stainless steel welding wire with high hardness and strong corrosion resistance as well as preparation method thereof and application

ActiveCN112122824AHigh hardnessImprove acid corrosion resistanceWelding/cutting media/materialsSoldering mediaStainless steel weldingMetal

The invention discloses a gas-shielded welding stainless steel welding wire with high hardness and strong corrosion resistance as well as a preparation method thereof and application. The welding wireconsists of the following elements in percentage by mass: less than or equal to 0.03% of C, 0.6-1.5% of Mn, 0.5-1.2% of Si, 14.0-19.0% of Cr, 4.0-8.0% of Ni, 2.0-3.0% of Mo, 2.0-5.0% of Cu, 0.5-2.5%of B, 0.2-0.7% of Nb, 0.2-0.5% of V, less than or equal to 0.03% of S, less than or equal to 0.03% of P and the balance of Fe. Steel billets of the welding wire are precisely smelted under vacuum andinert gas atmospheres. The welding wire disclosed by the invention aims to solve the technical problems of high hardness and strong acid corrosion resistance of clad layer metal.

Owner:郑州凯博焊割设备有限公司

Gas-shielded welding stainless steel wire with high hardness and strong acid corrosion resistance and its preparation method and application

ActiveCN112122824BHigh hardnessImprove acid corrosion resistanceWelding/cutting media/materialsSoldering mediaSS - Stainless steelStainless steel wire

The invention discloses a gas shielded welding stainless steel welding wire with high hardness and strong acid corrosion resistance and its preparation method and application. The welding wire includes the following elements in mass percentage: C≤0.03%, Mn 0.6-1.5%, Si 0.5~1.2%, Cr 14.0~19.0%, Ni 4.0~8.0%, Mo 2.0~3.0%, Cu 2.0~5.0%, B 0.5~2.5%, Nb 0.2~0.7%, V 0.2~0.5%, S≤0.03 %, P≤0.03%, and the balance is Fe. The billet of this kind of welding wire is precisely smelted under vacuum and inert gas atmosphere. The welding wire of the present invention aims to solve the technical problem of requiring the deposited metal to have high hardness and strong acid corrosion resistance at the same time.

Owner:郑州凯博焊割设备有限公司

High temperature vulcanization modified silicone rubber and production method thereof

ActiveCN103360770BImproves UV resistanceImprove acid corrosion resistanceAcid etchingPolymer science

The invention discloses high-temperature vulcanized modified silicon rubber which is mainly prepared from the following base materials: 110-1 methyl vinyl silicone rubber, 110-2 methyl vinyl silicone rubber and 110-3 methyl vinyl silicone rubber at the weight ratio of (1-2):(2-5):(1-3). The high-temperature vulcanized modified silicon rubber has the advantages of all excellent property of high-temperature vulcanized silicon rubber and better ultraviolet resistant property and acid etching resistant property. According to the IEC62217 standard, after the high-temperature vulcanized modified silicon rubber is aged through ultraviolet light (xenon-arc method) for 1500 hours, the material is intact; after the high-temperature vulcanized modified silicon rubber is soaked in a 65% nitric acid solution for 45 minutes, the material is intact.

Owner:JIANGSU SOUTH PORCELAIN INSULATOR CO LTD

A preparation method of superfine cristobalite in-situ wrapped type γ-ce2s3 red material and its products

ActiveCN112175416BFine granularityImprove hair colorRare earth metal sulfidesNanotechnologyColourantCalcination

The invention discloses an ultrafine cristobalite in-situ wrapped type γ-Ce 2 S 3 The preparation method of the bright red material is firstly to introduce the cerium source and the silicon source into the microemulsion system, and after the precipitation reaction, centrifuge, wash and dry to obtain the wrapped color material precursor powder, and then carry out vulcanization treatment and high-temperature calcination to produce Obtained ultra-fine cristobalite in-situ wrapped type γ~Ce 2 S 3 Big red material. In addition, the product prepared by the above-mentioned preparation method is also disclosed. The invention synchronously synthesizes the inner color agent γ-Ce through a simple and controllable preparation process 2 S 3 Pigment particles and cristobalite coating layer crystals are wrapped in situ to form the core colorant γ~Ce 2 S 3 The pigment particles are evenly stacked and embedded in the cristobalite coating layer, which is like a pomegranate seed coating structure, which greatly improves the high temperature stability and acid corrosion resistance of the pigment, thereby greatly expanding its application field.

Owner:JINGDEZHEN CERAMIC UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com