Chemical-deposition nickel-plating method

A process method, the technology of electroless nickel plating, applied in the field of chemical treatment of the surface of metal materials, can solve the problems of acid and alkali corrosion resistance, poor wear resistance and pressure resistance, inconvenience, service life, product hardness, etc., to achieve enhanced Hardness, improvement of product quality, and high alkali corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

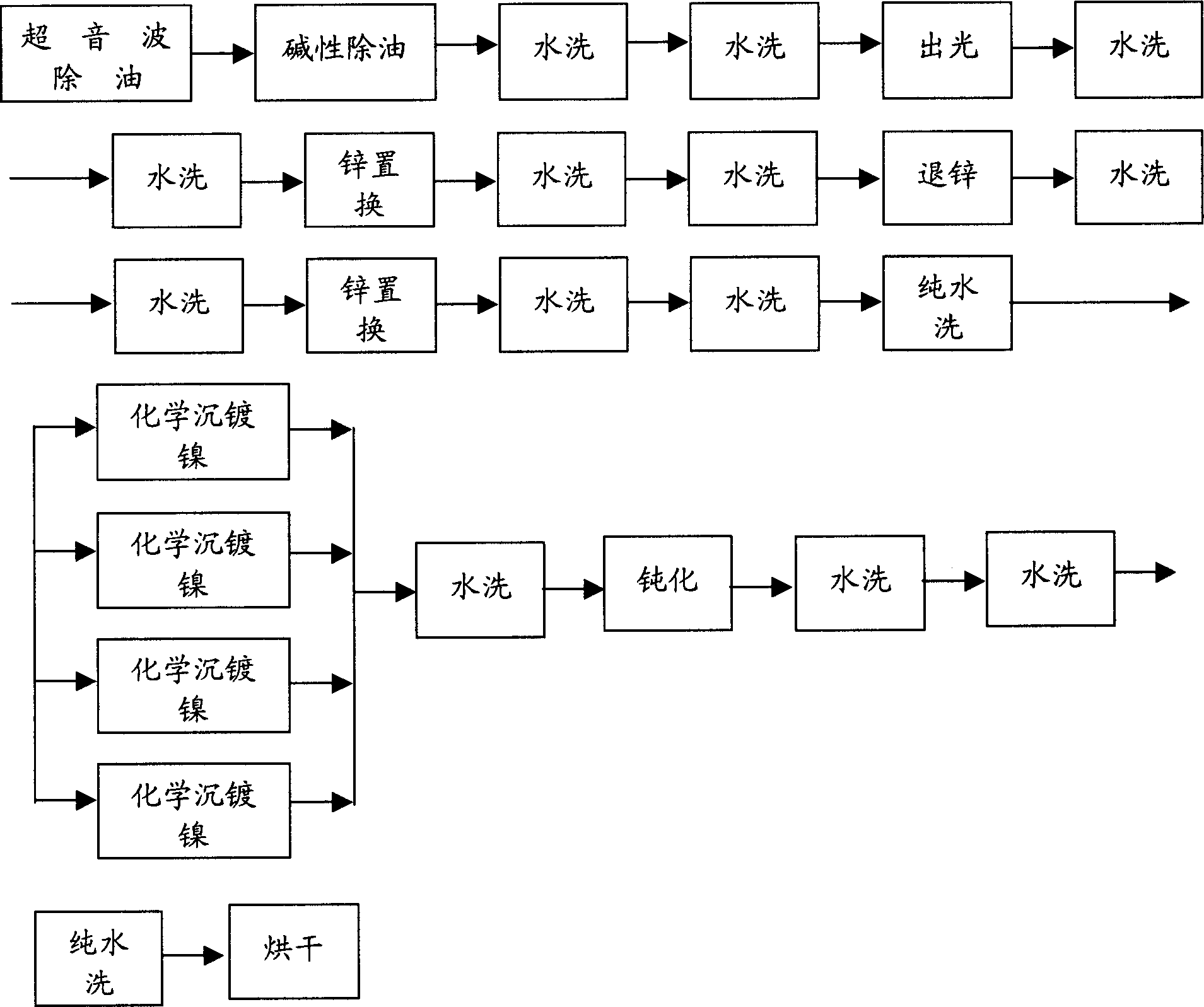

[0028] The electroless nickel plating process of the present invention mainly refers to nickel plating on an aluminum substrate, and generally includes steps such as degreasing-water washing-zinc replacement-water washing-zinc replacement-water washing-electroless nickel plating-water washing-drying, as shown in Figure 1 As shown, and can be subdivided into 27 processes, it is currently the most advanced nickel deposition process in China.

[0029] The first process: ultrasonic degreasing. Using mechanical vibration, the dead corners of the workpiece and the oil and debris in the cracks can be cleaned more effectively.

[0030] The second process: alkaline degreasing. Further remove the oil on the surface of the workpiece, and gradually remove the oxide film on the surface of the aluminum.

[0031] The third process: washing. Make the oil stain on the surface of the workpiece cleaner, and at the same time separate the thick liquid between the tanks, and thoroughly clean the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com