High temperature vulcanization modified silicone rubber and production method thereof

A technology of high-temperature vulcanization and modification of silicon, applied in the field of polymer materials, can solve problems such as corrosion resistance that have not been seen, and achieve the effect of good UV resistance and acid corrosion resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Example 1: A high-temperature vulcanized modified silicone rubber, including the following substrates and other raw materials, wherein the substrates include 110-1, 110-2, 110-3; the above-mentioned 110-1: 110-2: 110-3 The weight ratio is 1:3:2. The molecular weights of 110-1, 110-2, and 110-3 are all above 600,000. 110-1, 110-2, and 110-3 are three specifications of methyl vinyl silicone rubber.

[0020] Other raw materials include: fumed silica, aluminum hydroxide micropowder, γ-trifluoropropylmethylpolysiloxane, silicone oil, silane, masterbatch, zinc oxide, triethanolamine and bis-pentasulfurizing agent; among them,

[0021] The addition of fumed silica is 35% of the total weight of the substrate; the fumed silica used is the high specific surface area fumed silica mM-5 model imported by Cabot Corporation of the United States, and then six Methyldisilazane is sprayed on the above-mentioned fumed silica and stirred evenly, so that most of the hydroxyl groups on the ...

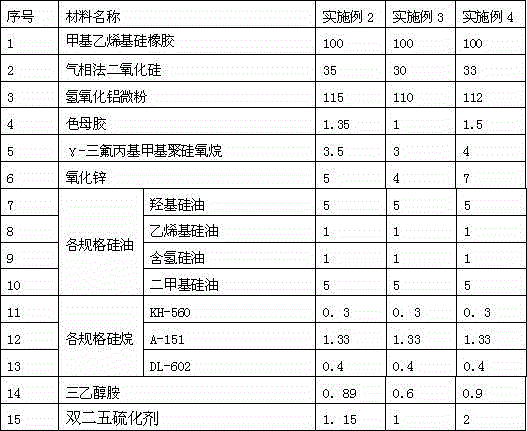

Embodiment 2

[0043] In Example 2, the weight ratio of the three specifications 110-1, 110-2, and 110-3 in the methyl vinyl silicone rubber is 1:2:2.

Embodiment 3

[0044] In Example 3, the weight ratio of the three specifications 110-1, 110-2, and 110-3 in the methyl vinyl silicone rubber is 2:5:3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com