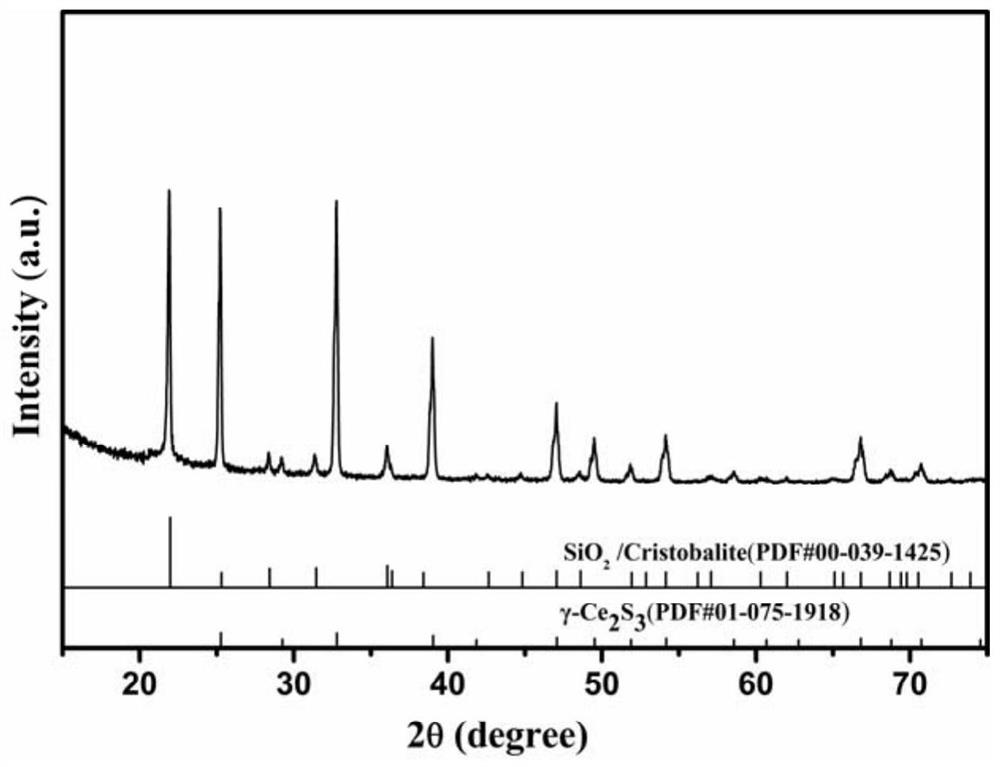

Preparation method of ultrafine cristobalite in-situ coated gamma-Ce2S3 bright red pigment and product prepared by preparation method

A color wrapping and wrapping technology, applied in the field of inorganic pigments, can solve the problems of not meeting the requirements of ceramic use, the stable temperature of wrapping colorants, etc., to break through the bottleneck of color wrapping technology, and contribute to the promotion and application of industrial production. , the effect of avoiding intrusion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

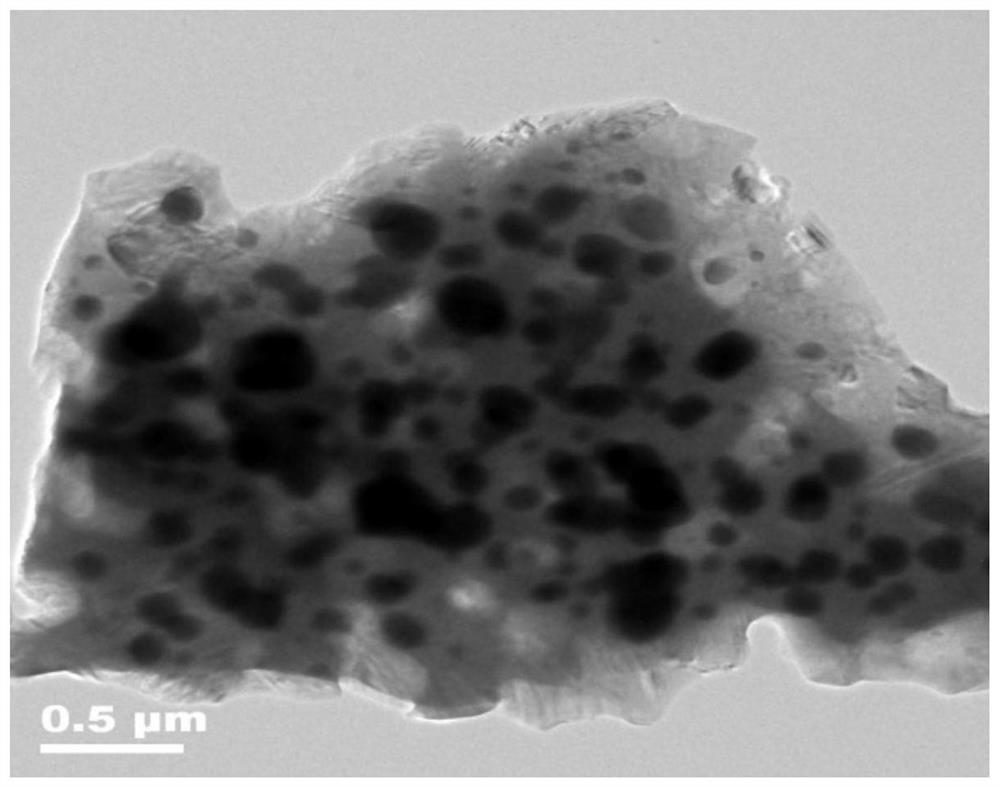

[0025] In this embodiment, an ultrafine cristobalite in-situ wrapped type γ-Ce 2 S 3 The preparation method of bright red material, its step is as follows:

[0026] (1) According to the molar ratio Ce:Si=1:3, 6.07gCe(SO 4 ) 2 4H 2 O was dissolved in 5 mL of water, and 9.37 g of ethyl orthosilicate was added to obtain a silicon-containing cerium ion solution; In phase solvent A, stir at room temperature for 3 hours to obtain microemulsion A; add 5 mL of concentrated ammonia water to oil phase solvent B composed of 28 mL of cyclohexane, 8 mL of triton, and 7 mL of n-hexanol, and stir at room temperature for 3 h to obtain microemulsion A Emulsion B; mixing the above-mentioned microemulsion A and microemulsion B and then stirring and reacting at room temperature for 3 hours to obtain the encapsulating colorant precursor solution;

[0027] (2) Add acetone to the above-mentioned packaged colorant precursor solution to break the emulsion, and the precipitate obtained after stand...

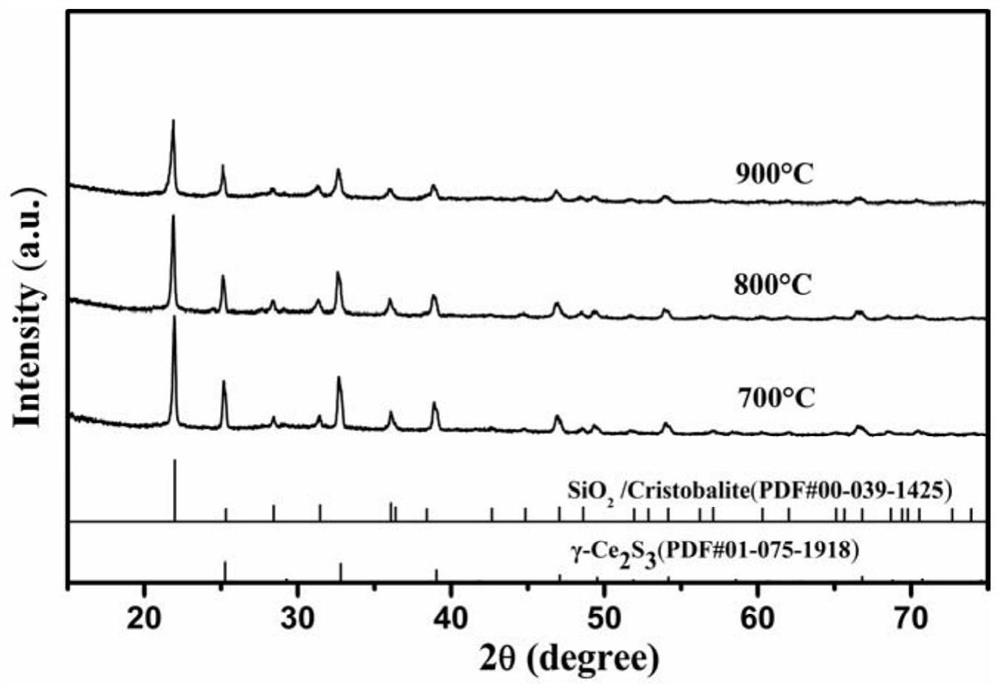

Embodiment 2

[0030] In this embodiment, an ultrafine cristobalite in-situ wrapped type γ-Ce 2 S 3 The preparation method of bright red material, its step is as follows:

[0031] (1) According to the molar ratio Ce:Si=1:7, 4.34gCe(NO 3 ) 3 ·6H 2 O was dissolved in 6 mL of water, and 14.58 g of ethyl orthosilicate was added to obtain a silicon-containing cerium ion solution; In phase solvent A, stir at room temperature for 4 hours to obtain microemulsion A; after dissolving 0.8g NaOH in 6mL water, add to oil phase solvent B composed of 32mL cyclohexane, 9mL triton, and 8mL n-hexanol, and stir at room temperature 4h to prepare microemulsion B; mixing the above microemulsion A with microemulsion B and then stirring and reacting at room temperature for 4h to obtain the encapsulating colorant precursor solution;

[0032] (2) Add acetone to the above-mentioned packaged colorant precursor solution to break the emulsion, and the precipitate obtained after standing for 15 minutes is centrifuged...

Embodiment 3

[0035] In this embodiment, an ultrafine cristobalite in-situ wrapped type γ-Ce 2 S 3 The preparation method of bright red material, its step is as follows:

[0036] (1) According to the molar ratio Ce:Si=1:10, 3.73gCeCl 3 ·7H 2 O was dissolved in 10 mL of water, and 28.42 g of Na 2 SiO 3 9H 2 O, to obtain a silicon-containing cerium ion solution; then the above-mentioned silicon-containing cerium ion solution was added to the oil phase solvent A composed of 35mL cyclohexane, 11mL triton, and 10mL n-hexanol, and stirred at room temperature for 5h to obtain microemulsion A ; Add 10mL of concentrated ammonia water into the oil phase solvent B composed of 35mL cyclohexane, 11mL triton, and 10mL n-hexanol, and stir at room temperature for 5h to obtain microemulsion B; after mixing the above microemulsion A with microemulsion B Stirring and reacting at room temperature for 5 hours to obtain the encapsulating colorant precursor solution;

[0037] (2) Add acetone to the above-m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com