Preparation method of compound coated type cerium sulfide red pigment and product prepared through preparation method

A technology of red pigment and cerium sulfide, applied in the field of inorganic pigments, can solve the problems of affecting the stability of production and preparation, product stability, poor compactness of product coating layer, difficult reaction control, etc., so as to achieve stable and reliable preparation process and improve acid corrosion resistance. and high temperature antioxidant capacity, the effect of expanding the application field

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

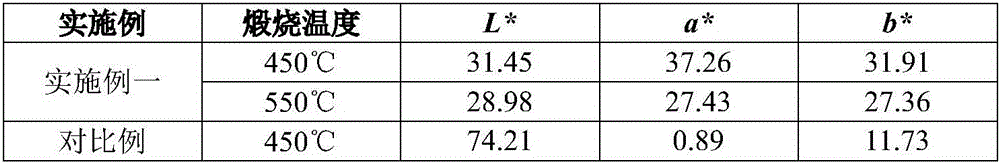

Embodiment 1

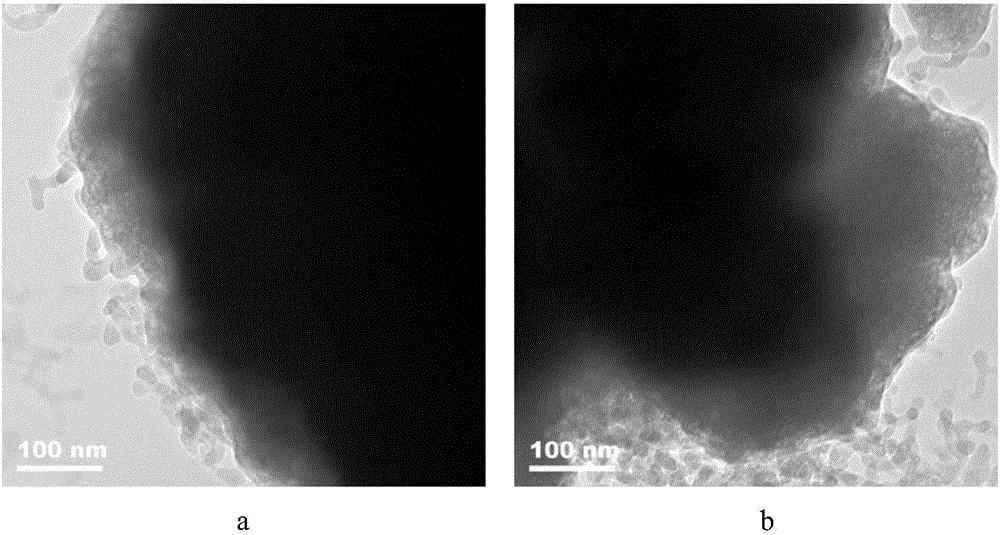

[0032] The preparation method of a kind of compound package type cerium sulfide red pigment of present embodiment, its steps are as follows:

[0033] (1) Prepare a hydrolysis raw material solution

[0034] Toner suspension: 0.5g γ-Ce 2 S 3 Toner and 0.05g dispersant cetyltrimethylammonium bromide (CTAB) were added to a mixed solution of 25ml absolute ethanol and 50ml deionized water, aged for 24h under magnetic stirring, and centrifuged once to remove excess dispersion. Add the pretreated colorant to 75ml of absolute ethanol again, magnetically stir and sonicate to carry out secondary dispersion, stir and disperse evenly, add 1mol / L sodium hydroxide to adjust the pH of the solution Value is 12, and prepared toner suspension;

[0035] Zirconium source solution: use 1ml zirconium butoxide as the zirconium source solution;

[0036] Hydrolysis aid: Dissolve 0.55g of anhydrous sodium acetate in 5ml of deionized water to prepare a hydrolysis aid;

[0037] (2) Prepare a packaged...

Embodiment 2

[0048] The preparation method of a kind of compound package type cerium sulfide red pigment of present embodiment, its steps are as follows:

[0049] (1) Prepare a hydrolysis raw material solution

[0050] Toner suspension: 0.5g γ-Ce 2 S 3 Toner and 0.05g dispersant cetyltrimethylammonium bromide (CTAB) were added to a mixed solution of 25ml absolute ethanol and 50ml deionized water, aged for 24h under magnetic stirring, and centrifuged once to remove excess dispersion. Add the pretreated colorant to 75ml of absolute ethanol again, magnetically stir and sonicate to carry out secondary dispersion, stir and disperse evenly, add 1mol / L sodium hydroxide to adjust the pH of the solution The value is 12.5, and the toner suspension is obtained;

[0051] Zirconium source solution: use 1ml zirconium butoxide as the zirconium source solution;

[0052] Hydrolysis aid: prepare an acetic acid solution with a concentration of 2 mol / as a hydrolysis aid;

[0053] (2) Prepare a packaged ...

Embodiment 3

[0063] The preparation method of a kind of compound package type cerium sulfide red pigment of present embodiment, its steps are as follows:

[0064] (1) Prepare a hydrolysis raw material solution

[0065] Toner suspension: 0.3g γ-Ce 2 S 3 Toner and 0.045g dispersant cetyltrimethylammonium bromide (CTAB) were added to a mixed solution of 25ml absolute ethanol and 50ml deionized water, aged for 24h under magnetic stirring, and centrifuged once to remove excess dispersion Add the pretreated colorant to 75ml of absolute ethanol again, magnetically stir and sonicate to carry out secondary dispersion, stir and disperse evenly, add 1mol / L sodium hydroxide to adjust the pH of the solution Value is 12, and prepared toner suspension;

[0066] Zirconium source solution: use 1ml zirconium butoxide as the zirconium source solution;

[0067] Hydrolysis aid: 0.52g of ammonium acetate was dissolved in 2ml of deionized water to prepare a hydrolysis aid;

[0068] (2) Prepare a packaged pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com