High-solid-content high-performance glycidyl tertiary carboxylic ester modified alkyd resin and preparation method thereof

A technology of glycidyl ester and alkyd resin, which is applied in coatings, anti-corrosion coatings, etc., can solve the problems of paint film anti-adhesion, insufficient weather resistance, paint film water resistance, poor acid corrosion resistance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with embodiment, but protection scope of the present invention is not limited to this:

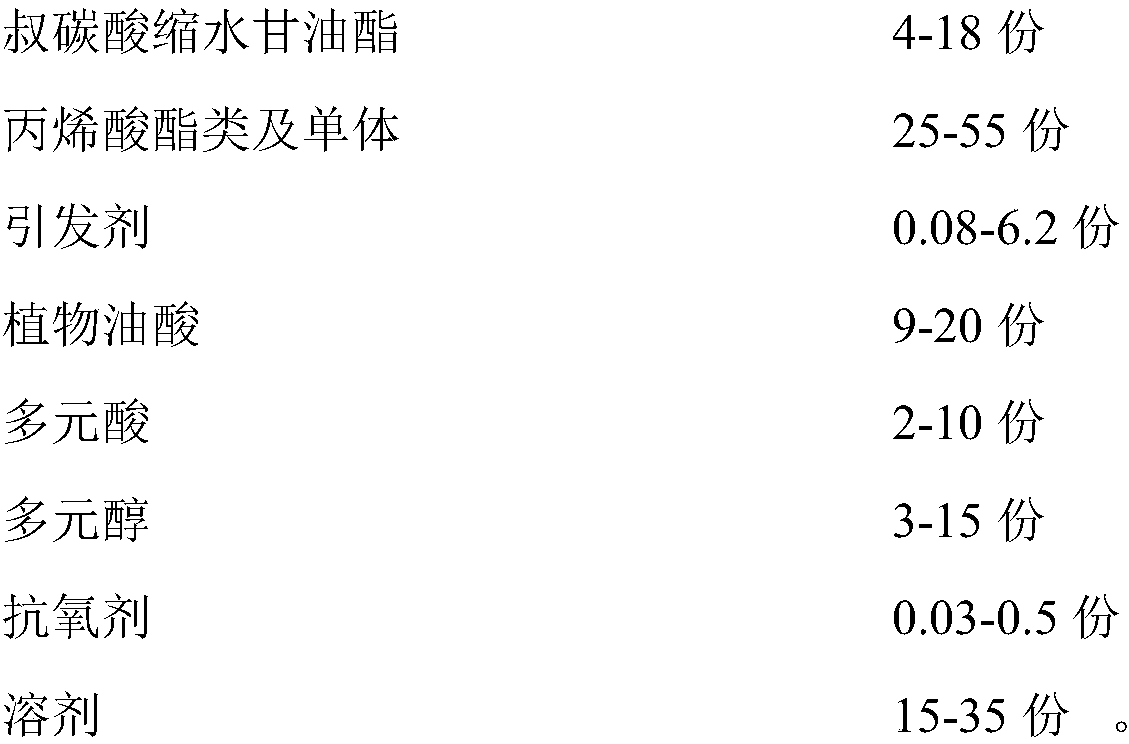

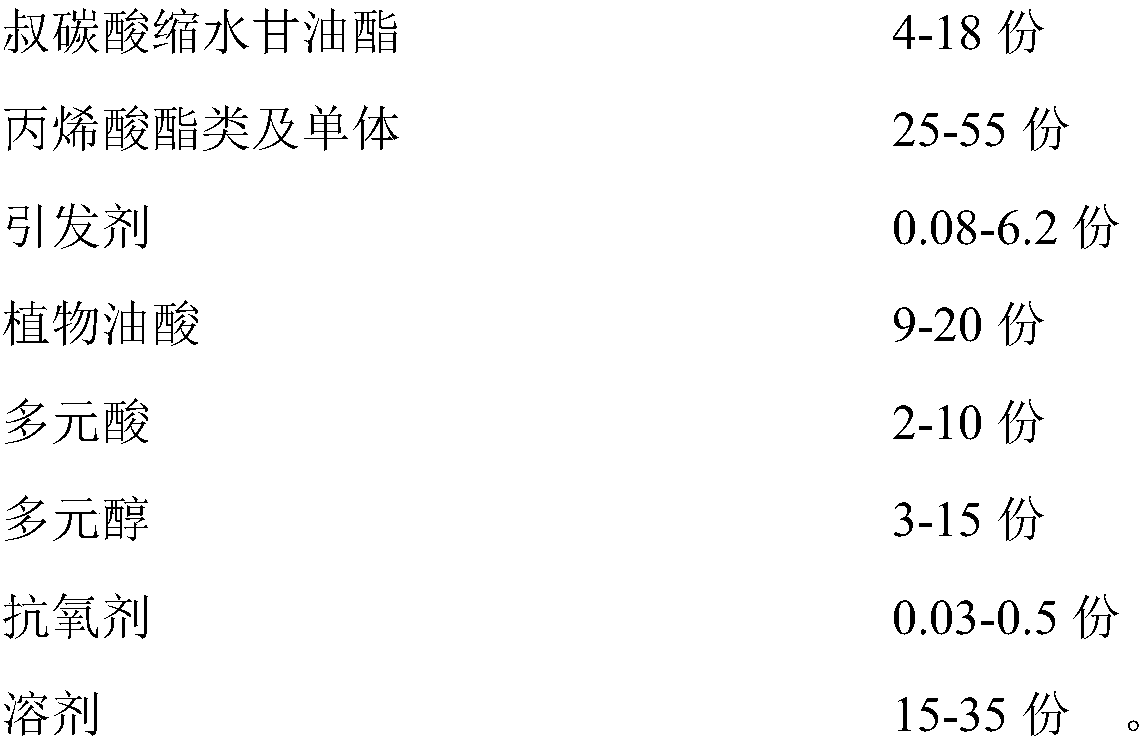

[0026] In the present invention, the formula components and mass percentages used in the high-solid high-performance tertiary carbonic acid glycidyl ester modified alkyd resin are shown in Table 1.

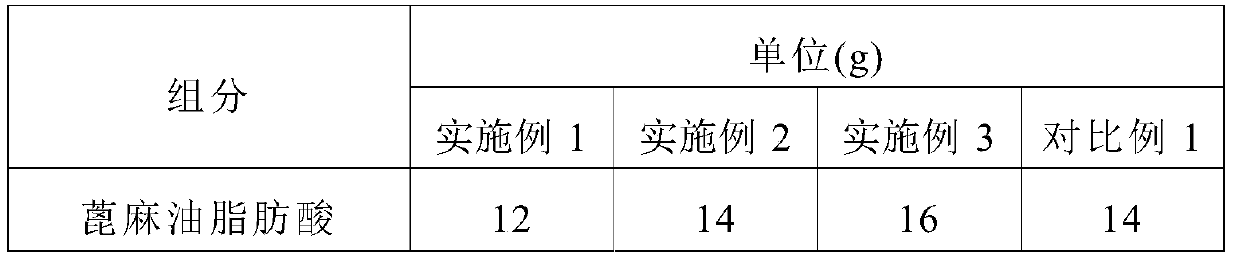

[0027] Table 1 High-solid content high-performance tertiary carbonic acid glycidyl ester modified alkyd resin formulation dosage of Examples 1-4 of the present invention

[0028]

[0029]

[0030] The preparation method of high-solid content high-performance tertiary carbonic acid glycidyl ester modified alkyd resin embodiment 1~3 and comparative example 1 in the present invention is as follows:

[0031] The first step: feed nitrogen, under anaerobic conditions, mix the vegetable oleic acid, polybasic acid, polyhydric alcohol, antioxidant and xylene of described component, then be warming up to (embodiment 1 is 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com