Preparation method of acid-corrosion-resistant enamel glass glaze

A technology of acid corrosion resistance and glass glaze, which is applied in the field of materials, can solve the problem that the enamel coating cannot meet the long-term work, and achieve the effect of improving compactness and acid corrosion resistance, improving the cladding structure, and improving the compactness strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

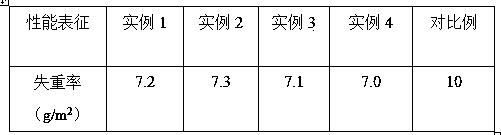

Examples

Embodiment Construction

[0026] Take attapulgite and grind it, pass through a 200-mesh sieve and weigh 45-50 parts of deionized water, 3-5 parts of manganese nitrate and 10-15 parts of attapulgite particles in a beaker , stirred and mixed and kept at 65-75°C for 2-3 hours. The reaction solution was obtained and dried at 100-110°C until constant weight was obtained. The dried particles were collected and heated to 280-300°C at a rate of 5°C / min. After calcination for 3 to 5 hours, the calcined particles were collected and ground through a 1000-mesh sieve to obtain calcined modified particles; the magnesium bars were taken and ground and pulverized, and passed through a 200-mesh sieve to obtain magnesium bar particles. Stir and mix the particles with methanol and place them in a three-necked flask, pass nitrogen to remove the air and control the rate of nitrogen introduction to 45-50mL / min, place it at 75-85°C for 1-2 hours, collect the reaction liquid and mix it according to the mass ratio of 1 : 10, t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com