Lead-free low-temperature glass for manufacturing diode glass shell

A low-temperature glass and diode technology, applied in the field of lead-free low-temperature glass, can solve the problems of cracking and acid corrosion resistance that cannot meet the requirements for use, and achieve the effect of improving acid corrosion resistance and maintaining appearance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

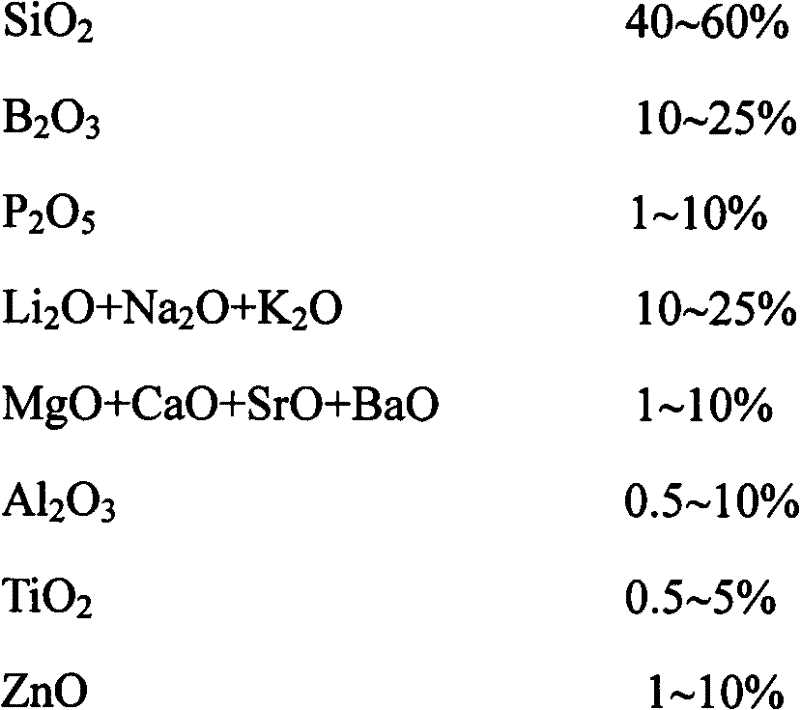

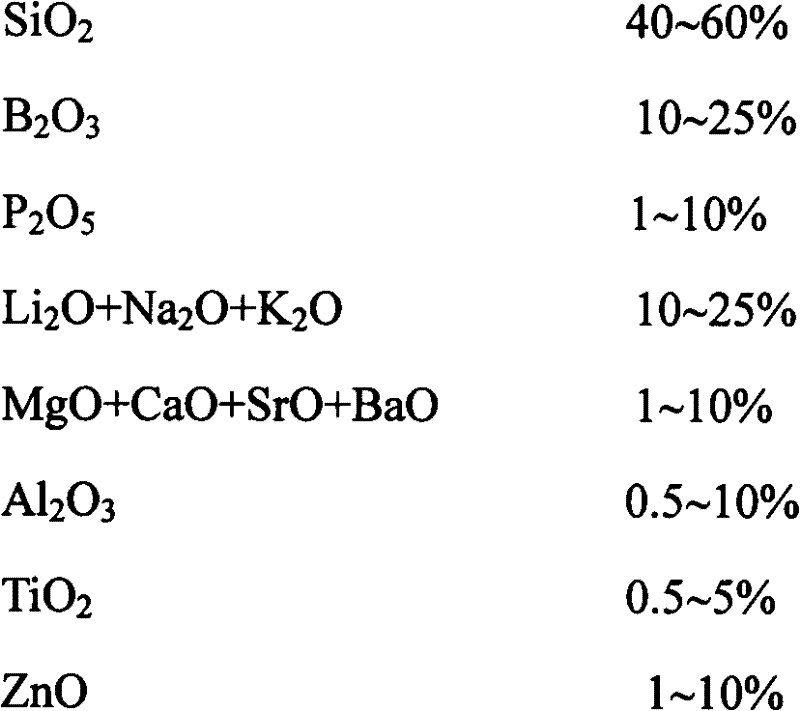

Method used

Image

Examples

Embodiment Construction

[0022] The technical solution of the present invention is specifically described below through examples, and the content of the present invention is not subject to any restriction by the following examples.

[0023] The present invention melts glass samples by means of a laboratory high-temperature electric furnace, and the raw materials used are all high-purity ore raw materials or chemically pure reagents, such as the introduction of SiO 2 of high-purity quartz sand, the introduction of B 2 o 3 of boric acid, the introduction of P 2 o 5 Ammonium dihydrogen phosphate, the introduction of carbonates of alkali metal oxides and alkaline earth metal oxides, the introduction of Al 2 o 3 aluminum hydroxide, introducing TiO 2 Titanium oxide, zinc oxide introduced into ZnO, etc., and with the help of a small amount of Sb 2 o 3 And the joint action of nitrate to realize the clarification of glass liquid. The batch materials of each component were put into a platinum crucible a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com