Protective material and application thereof as protective layer for building surfaces and in repair of corroded parts of buildings

A protective material and moisture protection technology, applied in building maintenance, building construction, construction, etc., can solve the problems of organic coatings such as difficulty in guaranteeing long-term performance, difficult repair construction, poor anti-aging performance, etc., to achieve raw material ratio and particle size The gradation is scientific and reasonable, the effect of improving the difficulty of construction and increasing the bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

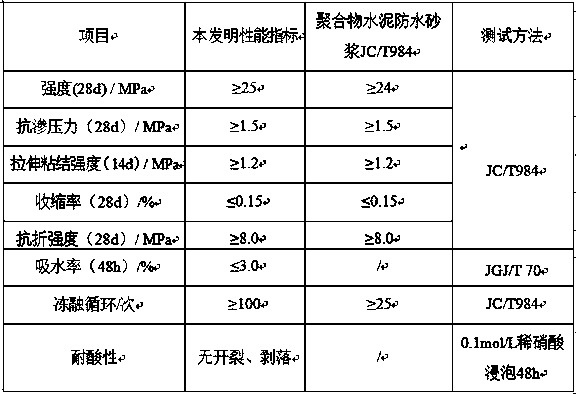

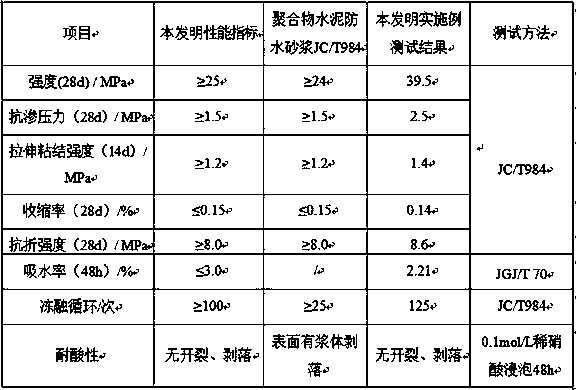

Examples

Embodiment 1

[0042] The protection material described in the present invention is 100g of raw material silicate 42.5 cement; 200g of clean natural fine sand with a particle size less than 1.18mm (can be adjusted within 150~250g according to actual needs, and note that the mud content is not more than 3%. Moisture content not greater than 0.2%); 0.15g of Dura fiber with a nominal length of 20mm and an equivalent diameter of 40μm; 5g of moisture migration inhibitor; 5g of metakaolin mixed;

[0043] Among them, metakaolin is obtained by calcining commercially available kaolin at 750°C~800°C, and then grinding to a fineness of 500 mesh; in order to ensure the use effect of the final protective material, SiO in metakaolin 2The content is not less than 50%, Al 2 o 3 The content is not less than 40%, and the specific surface area is not less than 15000m2 2 / kg.

[0044] In order to improve the waterproof performance of the finished protective material, the water migration inhibitor used in the...

Embodiment 2

[0054] Repair corroded concrete, the corrosive type is heavy carbonic acid decomposition type medium corrosion. According to the actual situation, the damage model of the concrete slab was simulated and made. The model showed that the concrete mortar was lost, the aggregate was exposed, and the corrosion depth was about 15mm.

[0055] Prepare the protective material slurry according to the ratio of Example 1; clean the corroded surface, expose the fresh concrete interface, and keep the interface as flat as possible. During the construction process, keep the interface moist and free of clear water.

[0056] Apply a total of three layers, the thickness of the first layer is 5.5mm±0.5 mm, and the thickness of each subsequent layer is 5mm, and a layer of glass fiber mesh cloth is covered between the two layers of coating; when applying appropriate pressure, strive to make the coating dense. The maintenance method after smearing is the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com