Molding powder for LOC box

A technology of plastic powder and shell powder, applied in the field of plastic powder, can solve the problems of inability to balance aging resistance and mechanical properties, affecting the service life of fans, hidden dangers, etc., to increase corrosion resistance and mechanical properties, and improve temperature difference resistance. and acid corrosion resistance, the effect of avoiding sag

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

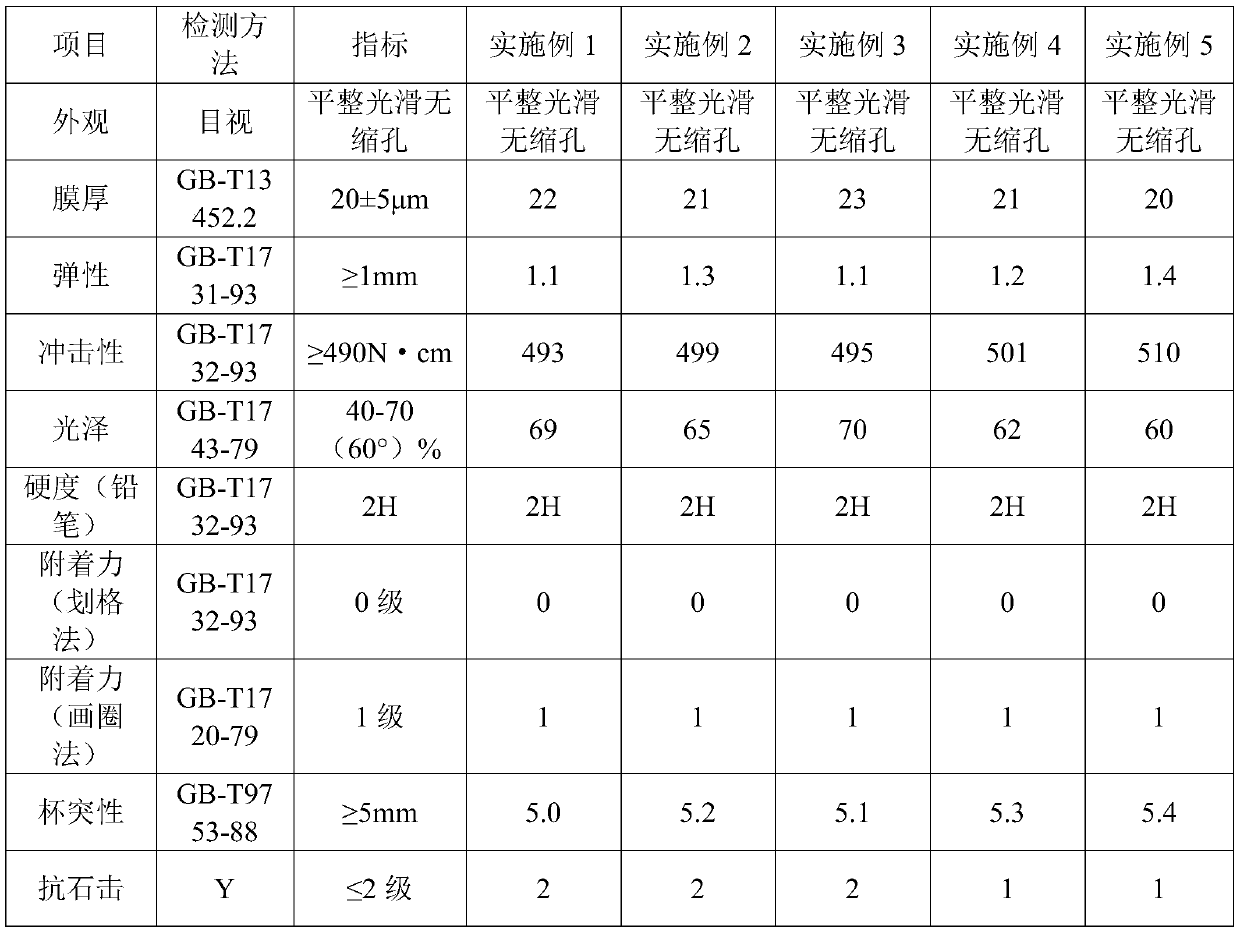

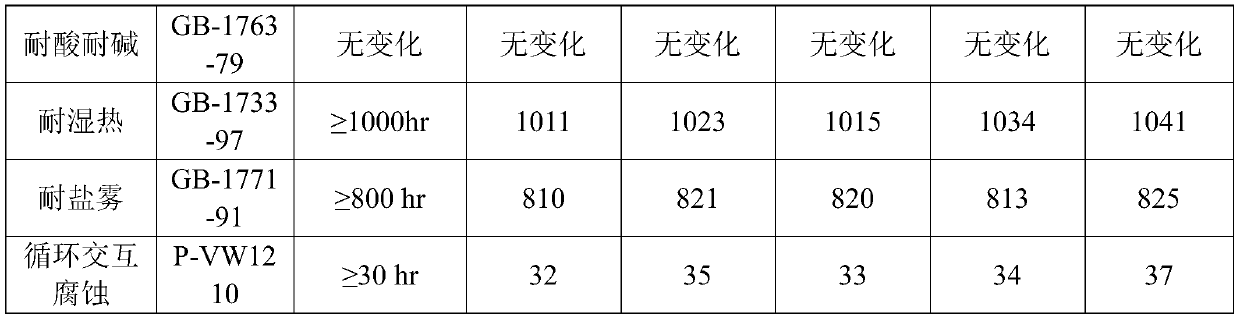

Examples

Embodiment 1

[0023] A kind of plastic powder for electrostatic spraying of LOC box, its raw material comprises by weight: 30 parts of epoxy resin, 30 parts of polyester resin, 10 parts of hydroxyl-containing fluorocarbon resin, tri-β-methyl glycidyl isocyanurate 8 parts, 1 part of triglycidyl isocyanate, 1 part of pigment, 25 parts of filler, 3 parts of leveling agent, 0.5 part of moisture-proof agent, 1 part of edge modifier, 0.5 part of benzoin, and 1.5 parts of coupling agent.

Embodiment 2

[0025] A plastic powder for LOC box electrostatic spraying, its raw materials include by weight: 35 parts of bisphenol F epoxy resin, 25 parts of polyester resin NH-3307, 15 parts of hydroxyl-containing fluorocarbon resin, tri-isocyanuric acid 4 parts of β-methyl glycidyl ester, 3 parts of triglycidyl isocyanate, 0.5 parts of pigment, 30 parts of filler, 2 parts of leveling agent, 1 part of moisture-proof agent, 0.5 part of edge modifier, 1 part of benzoin , 1 part of coupling agent;

[0026] Among them, shell powder with a particle size of 1 μm, potassium hexatitanate whiskers, and modified kaolin, wherein the weight ratio of shell powder, potassium hexatitanate whiskers, and modified kaolin is 5:1:10;

[0027] In the preparation process of modified kaolin, add kaolin to the aqueous solution of polyethylene glycol 400 and mix well, then ultrasonicate at 1000W for 10min, heat up to 60°C, cut at 1000rpm for 40min, let it stand, filter to take the filter cake, and dry Obtain th...

Embodiment 3

[0029] A plastic powder for LOC box electrostatic spraying, its raw materials include by weight: 31 parts of bisphenol F epoxy resin, 28 parts of polyester resin NH-3307, 11 parts of hydroxyl-containing fluorocarbon resin, tri-isocyanuric acid 7 parts of β-methyl glycidyl ester, 1.5 parts of triglycidyl isocyanate, 0.8 parts of pigment, 26 parts of filler, 2.8 parts of leveling agent, 0.6 part of moisture-proof agent, 0.8 part of edge modifier, 0.6 part of benzoin , 1.3 parts of coupling agent;

[0030] Among them, shell powder with a particle size of 0.5 μm, potassium hexatitanate whiskers, and modified kaolin, wherein the weight ratio of shell powder, potassium hexatitanate whiskers, and modified kaolin is 7:0.5:15;

[0031] During the preparation of modified kaolin, add kaolin to the aqueous solution of polyethylene glycol 400 and mix well, then ultrasonicate at 500W for 20min, heat up to 50°C, cut at 2000rpm for 20min, let stand, filter to take the filter cake, and dry Ob...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com