Acid-corrosion-resistant concrete pipe pile and preparation method thereof

A concrete pipe pile and acid resistance technology, applied in the field of building materials, can solve problems affecting the structural strength and service life of pipe piles, collapse of buildings and bridges, threats to people's lives and properties, etc., so as to improve the resistance to acid corrosion and acid corrosion The effect of improving capacity, improving structural strength and service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

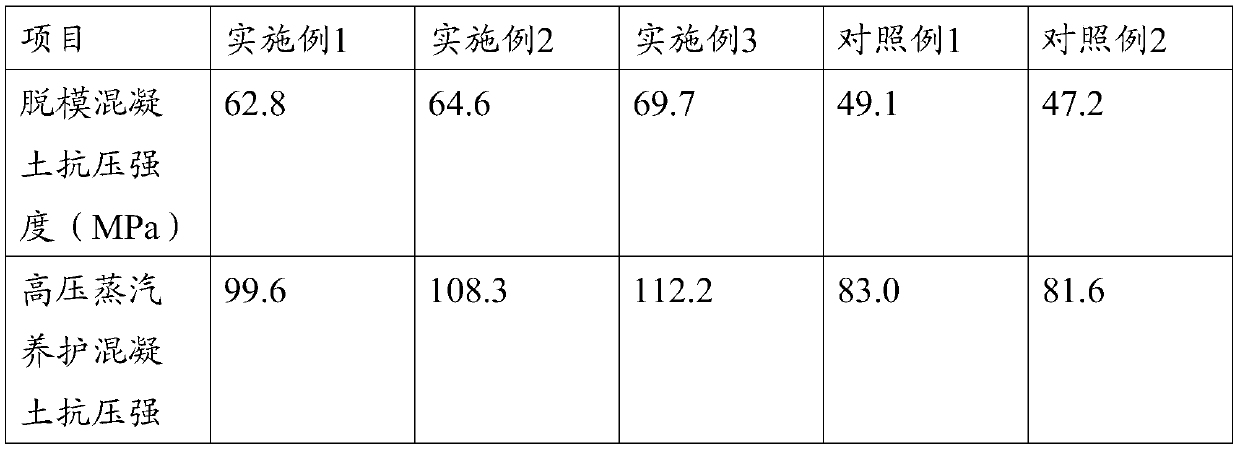

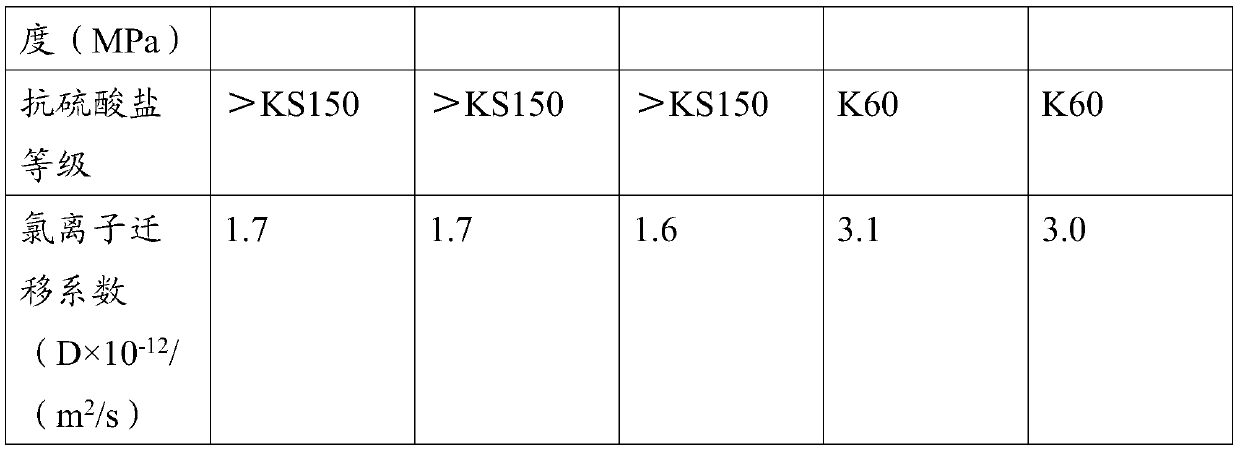

Examples

preparation example Construction

[0034] The present invention also relates to a method for preparing the above-mentioned acid corrosion-resistant concrete pipe pile, comprising the following steps:

[0035] Step 1. Preparation of concrete: Put quartz sand, cement, super fine powder of stone, 30% water, granite gravel, residual water and water reducing agent into the forced mixer in turn, and stir evenly; then put in potassium silicate and stir evenly, Finally, throw in aluminum tripolyphosphate and stir evenly to make fresh concrete with low slump of 30-50mm;

[0036] Step 2. Place the prepared steel bar skeleton in the centrifugal steel mold and connect it with the prestressed steel bar anchor plate, tension plate, and tension rod;

[0037] Step 3. Fill the lower half of the mold evenly with the prepared fresh concrete along the centrifugal steel mold, and spread more concrete at both ends;

[0038] Step 4. Lift the upper mold half above the lower mold half, and fix the upper and lower mold halves with bolt...

Embodiment 1

[0047] Components in parts by weight: 300 parts of cement, 140 parts of fine powder of stone, 1120 parts of granite crushed stone, 720 parts of quartz sand, 130 parts of water, 12 parts of water reducing agent, 30 parts of potassium silicate, 4.5 parts of aluminum tripolyphosphate share.

[0048] The cement is P·II 42.5R cement.

[0049] The ultrafine powder of the SiO 2 Content 92.1%, specific surface area 550m 2 / kg.

[0050] The crushed stones are granite crushed stones with a continuous gradation of 5-20mm, a crushing value of 6.5%, and a mud content of 0.2%.

[0051] The sand is quartz sand, wherein SiO 2 The content is 92.7%, the fineness modulus is 2.7, and the mud content is 0.4%.

[0052] The water reducer is selected from high-efficiency water reducer.

[0053] Described potassium silicate selects modulus 2.9 potassium silicate for use.

Embodiment 2

[0055]Components in parts by weight: 330 parts of cement, 160 parts of super fine powder of stone, 1100 parts of granite crushed stone, 690 parts of quartz sand, 135 parts of water, 14 parts of water reducing agent, 35 parts of potassium silicate, 5.5 parts of aluminum tripolyphosphate share.

[0056] The cement is P·II 42.5R cement.

[0057] The ultrafine powder of the SiO 2 Content 92.1%, specific surface area 550m 2 / kg.

[0058] The crushed stones are granite crushed stones with a continuous gradation of 5-20mm, a crushing value of 6.5%, and a mud content of 0.2%.

[0059] The sand is quartz sand, wherein SiO 2 The content is 92.7%, the fineness modulus is 2.7, and the mud content is 0.4%.

[0060] The water reducer is selected from high-efficiency water reducer.

[0061] Described potassium silicate selects modulus 2.9 potassium silicate for use.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com