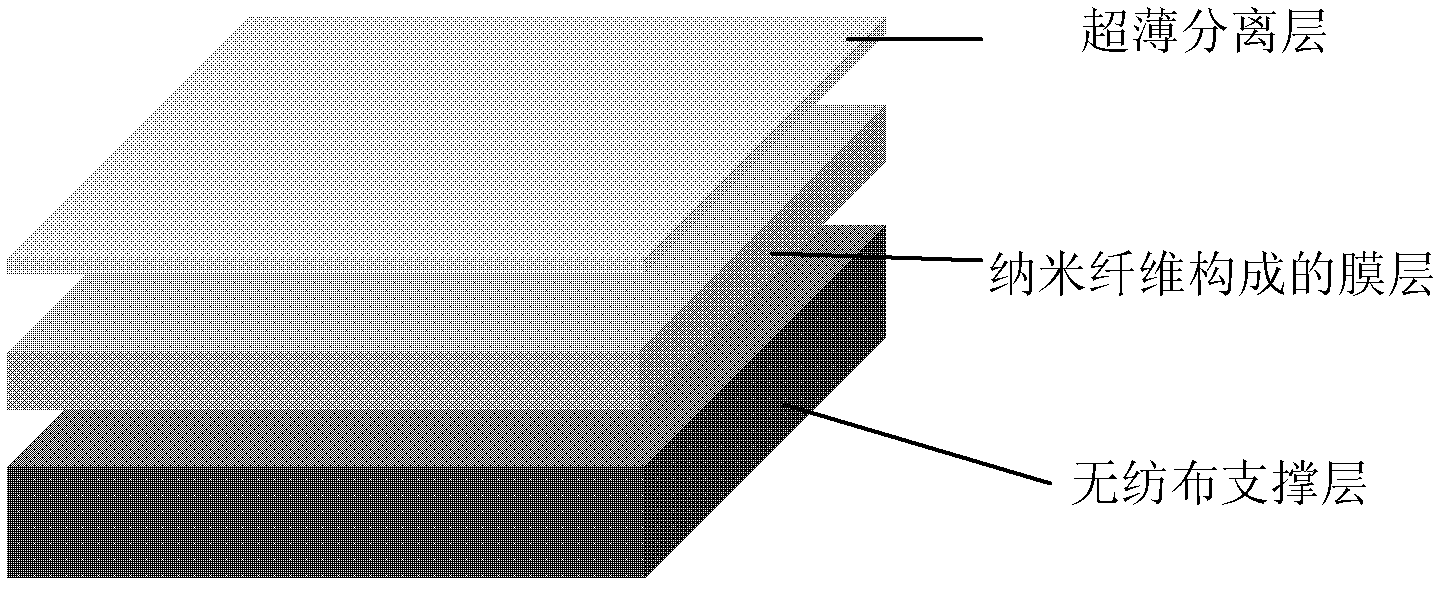

Composite ultrafiltration membrane of modified chitosan composite electrostatic spinning nanofiber and preparation method of composite ultrafiltration membrane

An electrospinning and nanofiber technology, applied in chemical instruments and methods, membrane technology, semi-permeable membrane separation, etc. The effect of uniform structure, high water flux and high porosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] (1) Dissolve polyvinylidene fluoride in a mixed solvent of N,N-dimethylformamide and acetone at 50°C, the ratio of the mixed solvent is DMF / Acetone=5 / 5, stir at constant temperature for 8 hours to make them Mix evenly to obtain a polyvinylidene fluoride electrospinning solution; the volume concentration of the polyvinylidene fluoride in the polyvinylidene fluoride electrospinning solution is 150 mg / mL;

[0054] (2) Put the polyvinylidene fluoride electrospinning solution prepared in step (1) into the liquid storage device of the electrospinning equipment under a constant temperature environment with a temperature of 50° C., the piston of the liquid storage device is connected to the syringe pump, The liquid storage device is connected to the metal (stainless steel) spinneret of the electrospinning equipment through the polytetrafluoroethylene infusion tube, and the metal spinneret is connected to the high-voltage generating device; A grounded metal (stainless steel) fla...

Embodiment 2

[0063] (1) Dissolve polyacrylonitrile in a mixed solvent of N,N-dimethylformamide and acetone at 50°C, the ratio of the mixed solvent is DMF / Acetone=5 / 5, stir at constant temperature for 8 hours to mix them Uniformly, a polyacrylonitrile electrospinning solution is obtained; the volume concentration of the polyacrylonitrile in the polyacrylonitrile electrospinning solution is 180mg / mL;

[0064] (2) Put the polyacrylonitrile electrospinning solution prepared in step (1) into the liquid storage device of the electrospinning equipment under a constant temperature environment with a temperature of 50° C., and the piston of the liquid storage device is connected with the syringe pump. The liquid storage device is connected to the metal (stainless steel) spinneret of the electrospinning equipment through the polytetrafluoroethylene infusion tube, and the metal spinneret is connected to the high-voltage generating device; the bottom of the metal spinneret is arranged There is a groun...

Embodiment 3

[0073] (1) Dissolve polyvinylidene fluoride in a mixed solvent of N,N-dimethylformamide and acetone at 50°C, the ratio of the mixed solvent is DMF / Acetone=5 / 5, stir at constant temperature for 8 hours to make them Mix evenly to obtain a polyvinylidene fluoride electrospinning solution; the volume concentration of the polyvinylidene fluoride in the polyvinylidene fluoride electrospinning solution is 150 mg / mL;

[0074] (2) Put the polyvinylidene fluoride electrospinning solution prepared in step (1) into the liquid storage device of the electrospinning equipment under a constant temperature environment with a temperature of 50° C., the piston of the liquid storage device is connected to the syringe pump, The liquid storage device is connected to the metal (stainless steel) spinneret of the electrospinning equipment through the polytetrafluoroethylene infusion tube, and the metal spinneret is connected to the high-voltage generating device; A grounded metal (stainless steel) fla...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com