Preparation method of hydrophobic and lipophilic self-supporting membrane polymer porous membrane and composite hydrophobic and lipophilic separation material

A self-supporting membrane, hydrophobic and lipophilic technology, applied in the direction of separation methods, semi-permeable membrane separation, chemical instruments and methods, etc., can solve the problems that limit wide application, etc., achieve low substrate selectivity, simple preparation process, and good adhesion Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0037] The preparation method of the hydrophobic and lipophilic self-supporting polymer porous membrane is to mix the polymer material solution with a stabilizer and then stir to form a stable emulsion, and then spread the obtained mixed solution on the surface of substrate plates of different materials, and wait for the solvent to volatilize Hydrophobic and lipophilic self-supporting membrane polymer porous membrane or porous modified composite material can be obtained.

[0038] As a preferred embodiment of the present invention, the method includes the following specific steps:

[0039] Dissolving the target polymer in a solvent to prepare a polymer solution;

[0040] Configure stabilizer solution;

[0041] The above two solutions are mixed and vigorously stirred to obtain an emulsion;

[0042] Leave the emulsion for a period of time to obtain a stable emulsion;

[0043] Cast the rested emulsion into a watch glass to spread it evenly;

[0044] After the solvent in it is ...

Embodiment 1

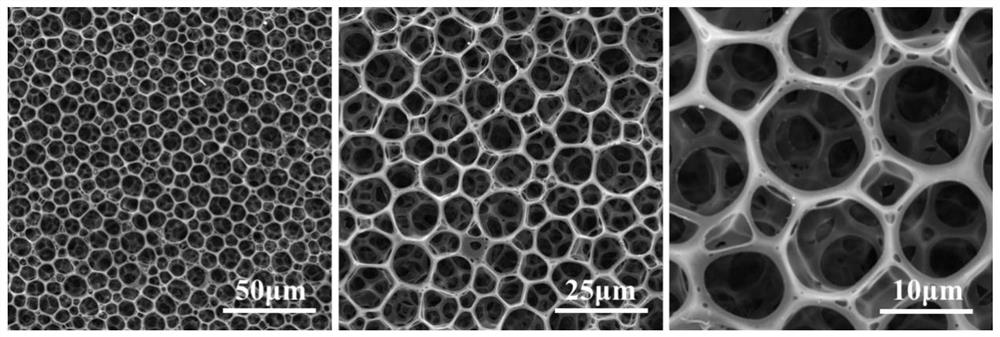

[0058] Weigh the polymer POSS-(PMMA-Cl) of 50mg 8 Put it in a conical flask, add 5mL of toluene solvent to dissolve it, add 5mL of ultrapure water after the polymer is completely dissolved, and use a high-speed homogeneous stirrer to stir at a speed of 10000r / min for 5min to prepare an emulsion. Spread it on a petri dish, let the solvent dry naturally at room temperature for 24 hours, then peel off the prepared film from the petri dish to obtain a hydrophobic and lipophilic self-supporting membrane polymer porous membrane. Its thickness is 100 μm, and the average pore diameter is 9.0±0.5 μm.

Embodiment 2

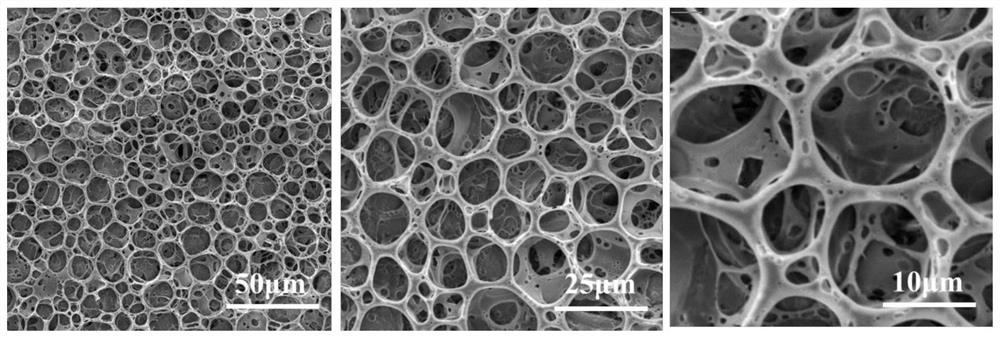

[0060] Weigh the polymer POSS-(PMBA-Cl) of 50mg 8 Put it in a conical flask, add 5mL of toluene solvent to dissolve it, and add Na at a concentration of 1mol / L after the polymer is completely dissolved 2 CO 3 5mL of the aqueous solution was homogeneously stirred for 5min with a high-speed homogeneous agitator at a speed of 10000r / min to prepare an emulsion. will be Na 2 CO 3 The aqueous solution is the emulsion prepared in the water phase and stands still for a week. After the emulsion is stable, it is spread in a petri dish, and the solvent is allowed to evaporate naturally at room temperature for 24 hours. Rinse the film with water to remove excess salt, and let it dry at room temperature to obtain a hydrophobic and lipophilic porous polymer film. Its thickness is 100 μm, and the average pore diameter is 6.0±0.5 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com