Organic silicon/organic fluorine dual-modified polyurethane composite UV photocureable coating as well as preparation and application thereof

A light-curing coating, dual modification technology, applied in the direction of polyurea/polyurethane coatings, coatings, etc., can solve the problems of reduced coating properties, difficult migration of fluorine-containing groups, poor compatibility, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

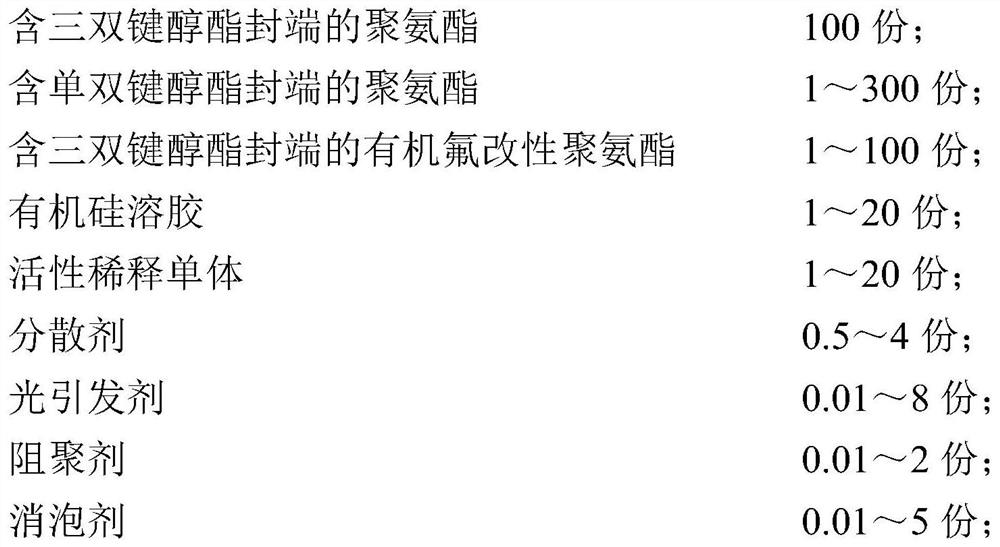

Method used

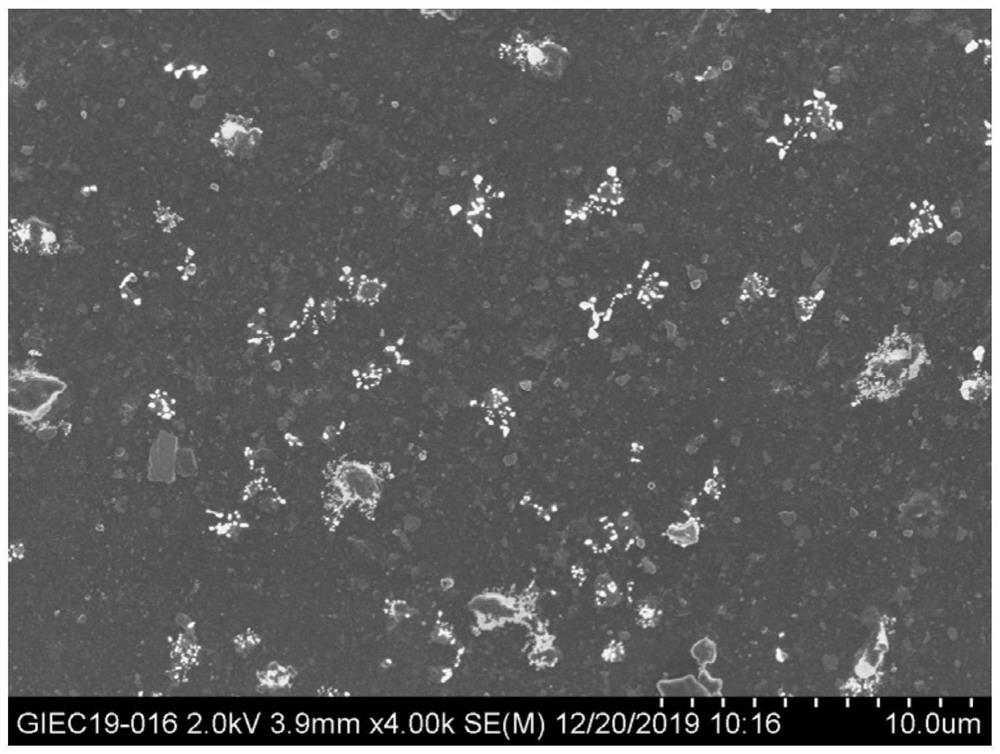

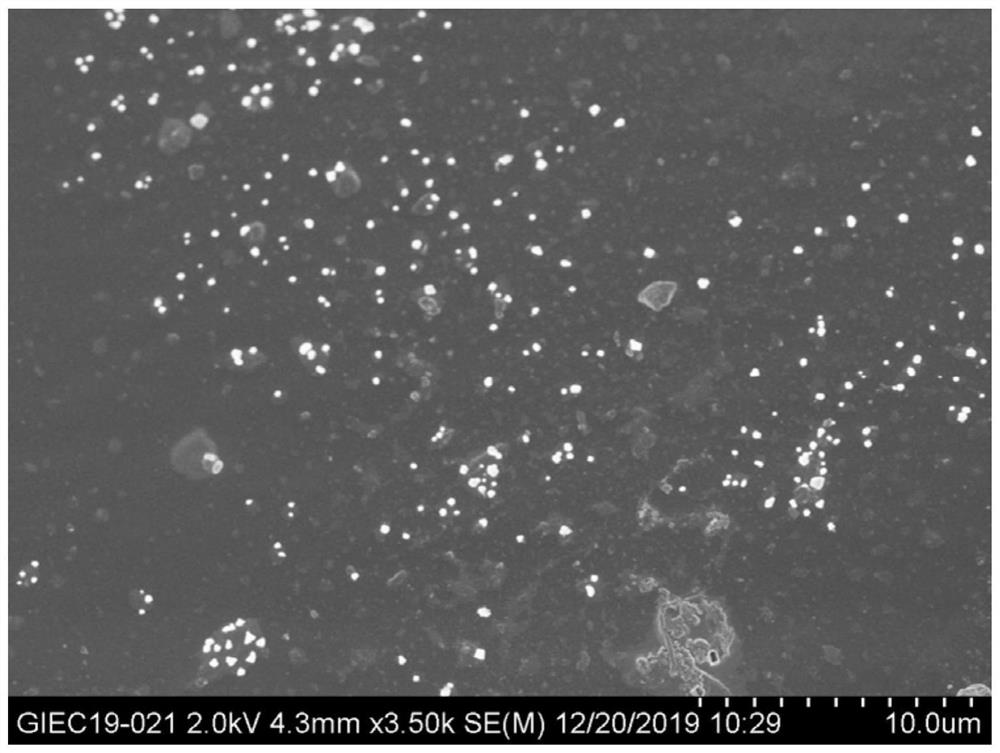

Image

Examples

Embodiment 1

[0077] (1) The preparation of the polyurethane that contains triple double bond alcohol ester termination: the butanone solvent of 160 mass parts, the polycaprolactone diol of 100 mass parts are added the reaction that reflux condenser, dropping funnel, thermometer and stirrer are housed , heat and stir to 60°C, then add 40 parts by mass of isophorone diisocyanate, 2.5 parts by mass of catalyst dibutyltin dilaurate and 0.5 parts by mass of inhibitor (hydroquinone), then heat up to 80°C, and react After 6 hours, a polyurethane prepolymer was obtained, and then 30 parts by mass of pentaerythritol triacrylate was added to the system, reacted for 5 hours, and the solvent was removed by rotary evaporation to obtain a polyurethane terminated with an alcohol ester containing a triple double bond. FT-IR (BrukerTENSOR27 (Germany) Fourier transform infrared spectrometer) at 1730cm -1 with 1635cm -1 There are C=O and C=C absorption peaks at 1 HNMR shows CH at 6.1ppm, 5.6ppm2 =C(CH 3 )...

Embodiment 2

[0086] (1) Preparation of polyurethane containing triple double bond alcohol ester end-blocking: 180 mass parts of toluene solvent, 100 mass parts of polycaprolactone diol are added in the reaction that reflux condenser, dropping funnel, thermometer and stirrer are housed , heated and stirred to 55°C, then added 45 parts by mass of isophorone diisocyanate, 2.6 parts by mass of catalyst dibutyltin dilaurate and 0.5 parts by mass of inhibitor (hydroquinone), then heated to 80°C, and reacted for 5 hours, to obtain a polyurethane prepolymer, and then add 30 parts by mass of pentaerythritol triacrylate to the system, react for 5 hours, and remove the solvent by rotary evaporation to obtain a polyurethane containing a triple bond alcohol ester terminated. FT-IR (BrukerTENSOR27 (Germany) Fourier transform infrared spectrometer) at 1730cm -1 with 1635cm -1 There are C=O and C=C absorption peaks at the 1 HNMR shows CH at 6.1ppm, 5.6ppm 2 =C(CH 3 )- proton absorption peak, indicatin...

Embodiment 3

[0094] (1) Preparation of polyurethane containing triple double bond alcohol ester end-capping: 140 mass parts of dioxane solvent, 100 mass parts of polycaprolactone diol are added In the reaction, heat and stir to 60°C, then add 30 parts by mass of isophorone diisocyanate, 2 parts by mass of catalyst dibutyltin dilaurate and 0.4 parts by mass of inhibitor (hydroquinone), then heat up to 80°C , reacted for 6 hours to obtain a polyurethane prepolymer, and then added 25 parts by mass of pentaerythritol triacrylate to the system, reacted for 4 hours, and removed the solvent by rotary evaporation to obtain a polyurethane terminated with an alcohol ester containing triple and double bonds. FT-IR (BrukerTENSOR27 (Germany) Fourier transform infrared spectrometer) at 1730cm -1 with 1635cm -1 There are C=O and C=C absorption peaks at the 1 HNMR shows CH at 6.1ppm, 5.6ppm 2 =C(CH 3 )- proton absorption peak, indicating that there is a double bond at the end of the product.

[0095]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com