Preparation method of cracking-resistant and waterproof concrete admixture

A waterproof concrete and admixture technology, applied in the field of building materials, can solve problems such as reducing the service life of concrete structures, achieve the effects of reducing subsidence, improving chloride ion penetration resistance, and reducing hygroscopicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

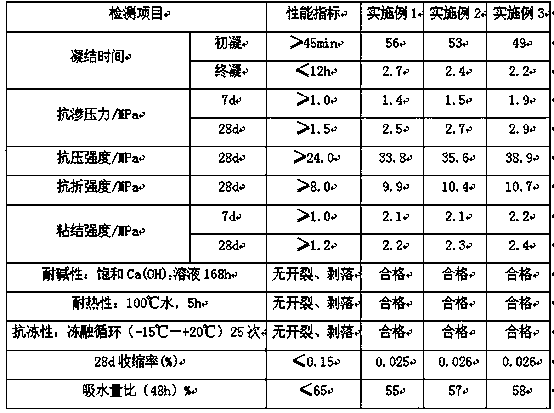

Examples

Embodiment 1

[0041] An anti-cracking and waterproof concrete admixture, which includes the following parts by weight of raw materials:

[0042] 40 copies of marble powder;

[0043] 10 parts of granite powder;

[0044] 0.6 parts of composite activator;

[0045] 4 parts of early strength agent;

[0046] 1 part of water reducing agent;

[0047] 6 parts of additives;

[0048] Retarder 1 part;

[0049] 3 parts of flame retardant mixture;

[0050] 12 parts of modified nano calcium carbonate.

[0051] The composite activator is prepared by mixing calcium aluminate, sodium sulfate, ferrous sulfate and sodium naphthalenesulfonate formaldehyde condensate, adding catalyst triisopropanolamine and calcium sulfate, and then grinding it in a ball mill or mortar; The parts by weight of each component are: 25-30 parts of calcium aluminate, 17-20 parts of sodium sulfate, 10-15 parts of ferrous sulfate, 0.5-1 parts of sodium naphthalenesulfonate formaldehyde condensate, 1.8 parts of triisopropanolamine -2.0 parts, 2-4 pa...

Embodiment 2

[0065] An anti-cracking and waterproof concrete admixture, which includes the following parts by weight of raw materials:

[0066] 45 shares of marble powder;

[0067] 15 parts of granite powder;

[0068] 0.7 parts of compound activator;

[0069] 5 parts of early strength agent;

[0070] 2 parts of water reducing agent;

[0071] 7 parts of additives;

[0072] 2 parts of retarder;

[0073] 4 parts of flame retardant mixture;

[0074] 13 parts of modified nano calcium carbonate.

[0075] The composite activator is prepared by mixing calcium aluminate, sodium sulfate, ferrous sulfate and sodium naphthalenesulfonate formaldehyde condensate, adding catalyst triisopropanolamine and calcium sulfate, and then grinding it in a ball mill or mortar; The parts by weight of each component are: 25-30 parts of calcium aluminate, 17-20 parts of sodium sulfate, 10-15 parts of ferrous sulfate, 0.5-1 parts of sodium naphthalenesulfonate formaldehyde condensate, 1.8 parts of triisopropanolamine -2.0 parts, 2-...

Embodiment 3

[0089] An anti-cracking and waterproof concrete admixture, which includes the following parts by weight of raw materials:

[0090] 50 copies of marble powder;

[0091] 20 parts of granite powder;

[0092] 0.8 parts of composite activator;

[0093] 6 parts of early strength agent;

[0094] 3 parts of water reducing agent;

[0095] 8 parts of additives;

[0096] 3 parts of retarder;

[0097] 5 parts of flame retardant mixture;

[0098] 14 parts of modified nano calcium carbonate.

[0099] The composite activator is prepared by mixing calcium aluminate, sodium sulfate, ferrous sulfate and sodium naphthalenesulfonate formaldehyde condensate, adding catalyst triisopropanolamine and calcium sulfate, and then grinding it in a ball mill or mortar; The parts by weight of each component are: 25-30 parts of calcium aluminate, 17-20 parts of sodium sulfate, 10-15 parts of ferrous sulfate, 0.5-1 parts of sodium naphthalenesulfonate formaldehyde condensate, 1.8 parts of triisopropanolamine -2.0 parts, 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com