Sulphoaluminate maritime work cement and preparation method thereof

A technology of marine cement and sulfoaluminate, applied in the field of cement, can solve the problems of high content of impermeability and corrosion resistance, slow hydration speed, building damage, etc., to achieve improved impermeability, continuous strength growth, high resistance The aggressive effect of sulfate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

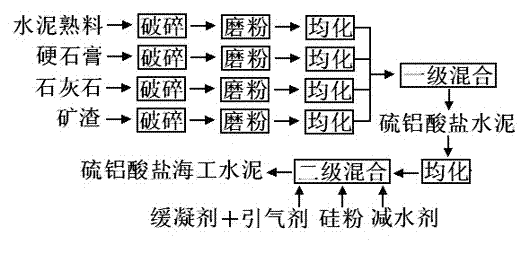

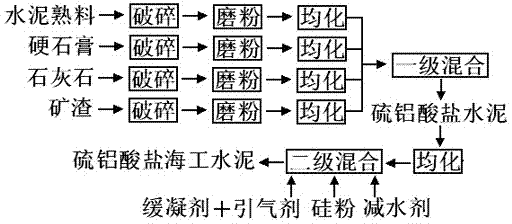

[0044] 1. Preparation method

[0045] All blocky raw materials are crushed separately and ground into powder for later use; the crushed cement clinker, anhydrite, limestone and slag are homogenized and then proportioned, then ground by a mill and mixed to obtain sulphoaluminate cement; Sulphoaluminate marine cement is obtained by adding water reducer, air-entraining agent, retarder and silica fume in a mill by adding water reducing agent, air-entraining agent, retarder and silica fume in proportion to aluminate cement.

[0046] Second, the process formula

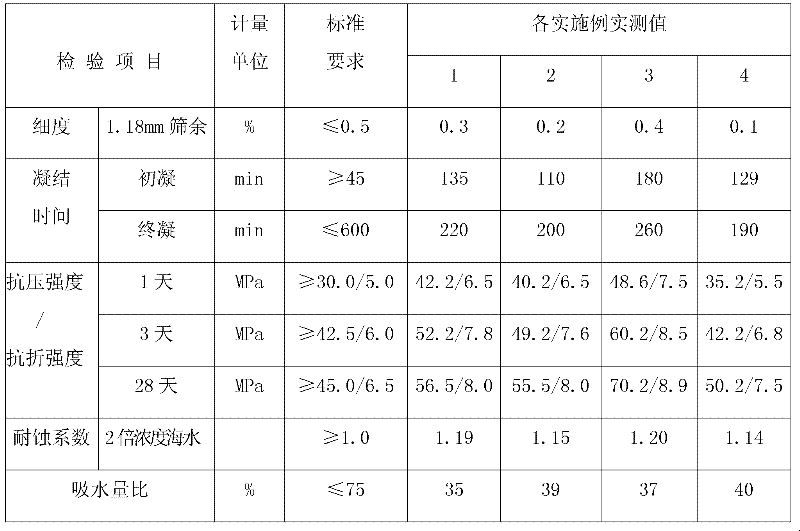

[0047] The technical formula of each embodiment is shown in Table 1.

[0048] Table 1 Process formula table of each embodiment Unit of measurement: part

[0049] Example

Sulfur aluminum clinker

limestone

polycarboxylate

air entraining agent

retarder

1

63

15

10

12

0.2

2

0.002

0.2

2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com