Production method of marine cement anti-wave mortar

A marine cement and production method technology, applied in the field of building materials, can solve the problems of low strength, low chloride ion erosion resistance and sulfate erosion resistance, and achieve improved impermeability, high chloride ion diffusion resistance, The effect of good compactness and volume stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

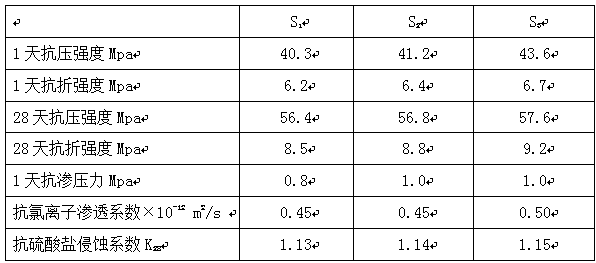

Examples

Embodiment 1

[0058] The production method of marine cement anti-wave mortar, which includes the following raw materials in parts by weight: 25 parts of limestone machine-made sand, 10 parts of rapid hardening sulfoaluminate cement, 1 part of superfine silica fume, 2 parts of composite coupling agent, acrylic acid 0.3 parts of rubber powder, 0.1 parts of methyl cellulose ether, 0.02 parts of potato starch ether, 0.05 parts of polycarboxylate superplasticizer, and 5 parts of slag powder.

[0059] The production method of marine cement anti-storm mortar comprises the following steps:

[0060] Firstly, limestone machine-made sand and high-strength ultra-fine fast-hardening sulfoaluminate cement are used as cementitious materials and aggregates, put into the mill for mixed grinding, and 0.08mm water sieve is used to control the fineness of the mill at 20±2% ;

[0061] The ground powder is mixed with superfine silicon powder, composite coupling agent, dispersible latex powder, cellulose ether, ...

Embodiment 2

[0063] The production method of marine cement anti-wave mortar, which includes the following raw materials in parts by weight: 30 parts of limestone machine-made sand, 15 parts of rapid hardening sulfoaluminate cement, 4 parts of superfine silica fume, 3 parts of composite coupling agent, acrylic acid 0.4 parts of rubber powder, 0.2 parts of hydroxyethyl cellulose ether, 0.03 parts of corn starch ether, 0.1 part of polycarboxylate superplasticizer, and 7 parts of slag powder.

[0064] Firstly, limestone machine-made sand and high-strength ultra-fine fast-hardening sulfoaluminate cement are used as cementitious materials and aggregates, put into the mill for mixed grinding, and 0.08mm water sieve is used to control the fineness of the mill at 20±2% ;

[0065] The ground powder is mixed with superfine silicon powder, composite coupling agent, dispersible latex powder, cellulose ether, starch ether, powdered polycarboxylate superplasticizer and slag powder and mixed evenly at hig...

Embodiment 3

[0067] The production method of marine cement anti-wave mortar, which includes the following raw materials in parts by weight: 35 parts of limestone machine-made sand, 20 parts of rapid hardening sulfoaluminate cement, 8 parts of superfine silica fume, 4 parts of composite coupling agent, acrylic acid 0.5 parts of rubber powder, 0.3 parts of hydroxypropyl methylcellulose ether, 0.04 parts of tapioca starch ether, 0.15 parts of polycarboxylate superplasticizer, and 9 parts of slag powder.

[0068] Firstly, limestone machine-made sand and high-strength ultra-fine fast-hardening sulfoaluminate cement are used as cementitious materials and aggregates, put into the mill for mixed grinding, and 0.08mm water sieve is used to control the fineness of the mill at 20±2% ;

[0069] The ground powder is mixed with superfine silicon powder, composite coupling agent, dispersible latex powder, cellulose ether, starch ether, powdered polycarboxylate superplasticizer and slag powder and mixed e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com