Three-dimensional graphene/phase change energy storage composite material and preparation method thereof

A phase-change energy storage material and phase-change energy storage technology, which is applied in the field of three-dimensional graphene/phase-change energy storage composite materials and its preparation, can solve the problems of low thermal conductivity, achieve low thermal expansion coefficient, prevent seepage, and improve The effect of heat transfer efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

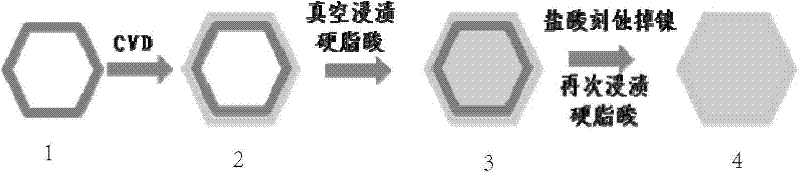

[0037] see figure 1 , the preparation method of the three-dimensional graphene / phase change energy storage composite material provided by the invention comprises:

[0038] Using metal foam 1 as a template, growing three-dimensional graphene by CVD to obtain the operation A of graphene / metal foam composite 2;

[0039] Compositing the graphene / metal foam composite obtained in the process A with the melted phase-change energy storage material by vacuum impregnation to form a composite 3 of graphene / metal foam / phase-change energy storage material;

[0040] Step C of removing metal foam from the composite of graphene / metal foam / phase-change energy storage material prepared in step B to obtain a composite of graphene / phase-change energy storage material;

[0041] The graphene / phase change energy storage material composite in step C is further compounded with the phase change energy storage material by vacuum impregnation to form step D of graphene / phase change energy storage compos...

Embodiment 1

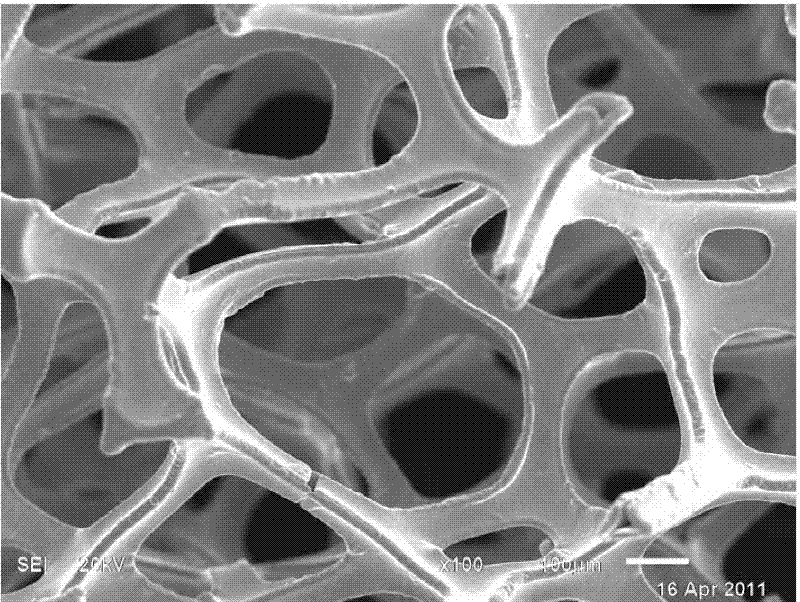

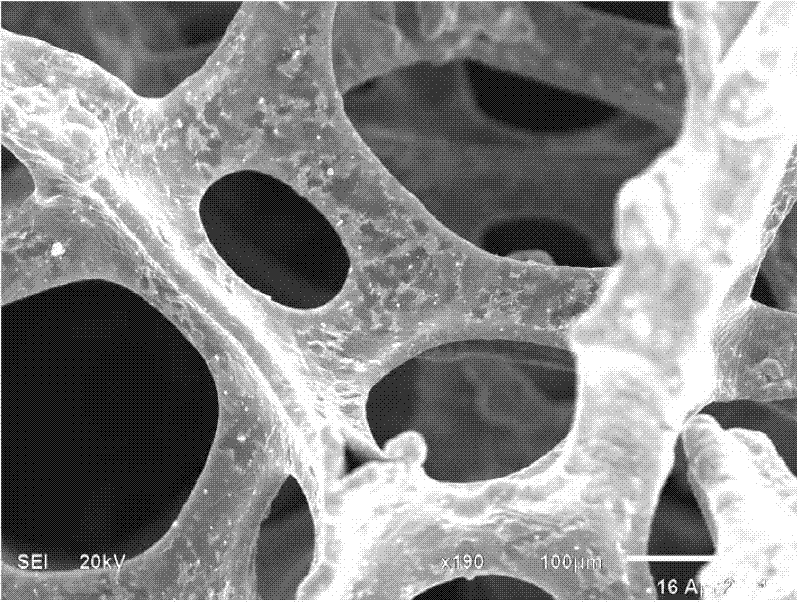

[0049] Adopt CVD method, with nickel foam (see its SEM photo figure 2 ) as a template to prepare a three-dimensional graphene foam (1-3 layers), and obtain a graphene / nickel foam composite system (see the SEM photo of the image 3 , see Table 1 for thermal conductivity);

[0050] Put stearic acid, a phase-change energy storage material, in a vacuum drying oven at 80°C. After the stearic acid is melted, impregnate the graphene / nickel foam above into the stearic acid, and vacuum the system to a degree of 0.09MPa. Keep vacuum state 1 hour, obtain Graphene / nickel foam / stearic acid composite system (its SEM photo sees Figure 4 , see Table 1 for thermal conductivity);

[0051] At room temperature, the above-mentioned graphene / nickel foam / stearic acid composite system was immersed in 65% hydrochloric acid. After 48 hours, after the nickel foam was completely reacted with hydrochloric acid, the sample was taken out, washed with water until neutral, and graphene / stearic acid was ob...

Embodiment 2

[0055] The preparation process and steps in this example are exactly the same as those in Example 1 above. The difference is: lauric acid is selected as the phase change energy storage material, and the test results are shown in Table 1;

[0056] The test results show that the graphene / lauric acid composite system and the graphene / stearic acid composite system have similar thermophysical parameters of thermal conductivity.

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com