A kind of amino-terminated fluorine-containing prepolymer modified acrylate coating and preparation method thereof

A technology of acrylate and prepolymer, which is applied in the direction of coating, etc., can solve the problems of poor compatibility between fluorine-containing polymers and acrylate resins, the difficulty of compounding at the molecular level, and the increase in cost, and achieve the effect of low surface energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

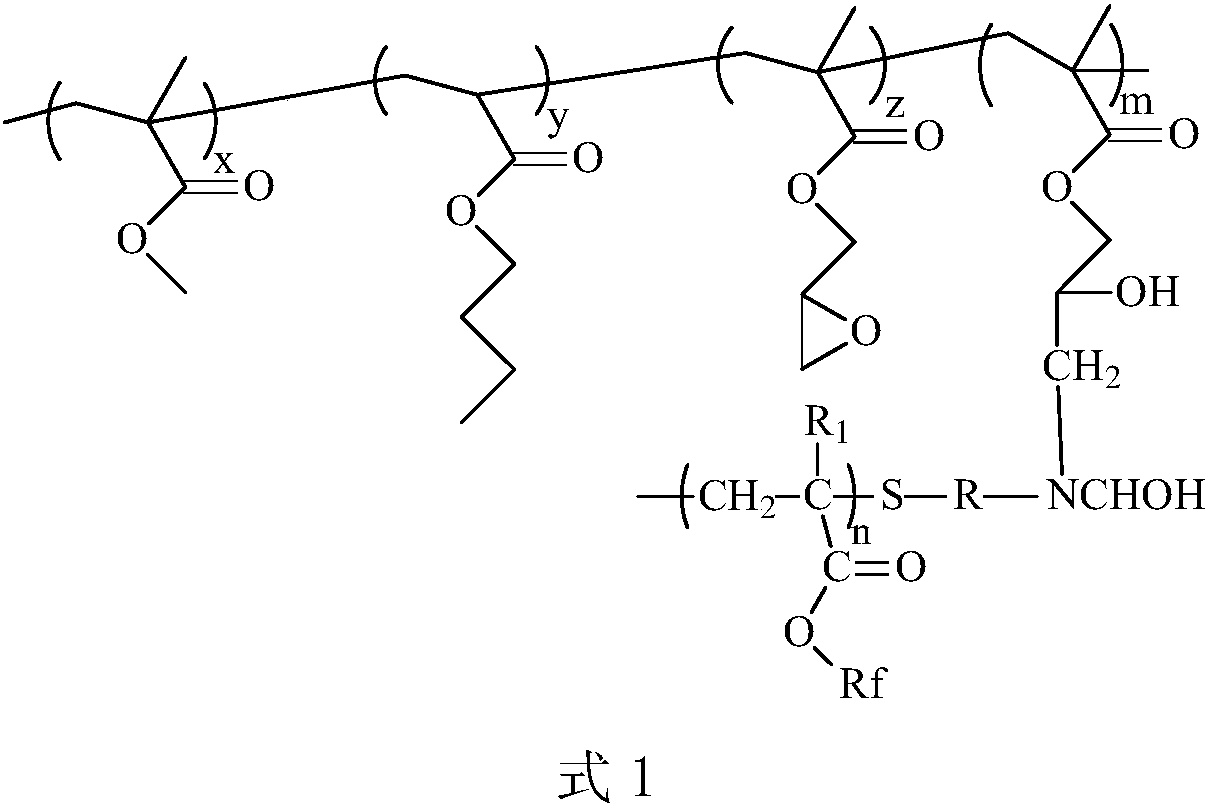

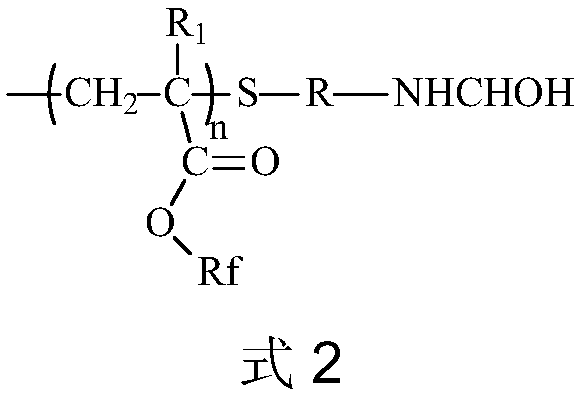

[0043] (1) Preparation of amino-terminated fluorine-containing prepolymer: Add 20 parts by mass of hexafluorobutyl methacrylate and 40 parts by mass of N,N-dimethylformamide into a container, heat up to 60°C, and add 1 part by mass of Cysteamine hydrochloride, 0.6 parts by mass of azobisisobutyronitrile, stirred and reacted for 8 hours, added triethylamine to make the pH = 8, then added 0.8 parts by mass of 37% formaldehyde aqueous solution, and stirred thoroughly for 1 hour to obtain The amino-terminated fluorine-containing prepolymer solution is obtained by distilling off the solvent under reduced pressure to obtain an amino-terminated fluorine-containing prepolymer. FT-IR (Bruker TENSOR27 (Germany) Fourier infrared spectrometer) has N-H single-peak absorption peak and C-N absorption peak at 3379~3558cm-1 and 1200cm-1, respectively, and 1H-NMR (deuterated chloroform as solvent) at 2.8ppm The proton absorption peak of N-H appears at , indicating that the end of the product is...

Embodiment 2

[0047] (1) Preparation of amino-terminated fluorine-containing prepolymer: Add 40 parts by mass of hexafluorobutyl methacrylate and 80 parts by mass of N,N-dimethylformamide into a container, heat up to 60°C, add 4 parts by mass of Mercaptoethylamine, 0.8 parts by mass of azobisisobutyronitrile, stirred and reacted for 9 hours, added triethylamine to make the pH = 8, and then added 2 parts by mass of 38% formaldehyde aqueous solution, and stirred thoroughly for 0.5 hours to obtain the terminal amino group A fluorine-containing prepolymer solution, and the solvent is distilled off under reduced pressure to obtain an amino-terminated fluorine-containing prepolymer. FT-IR (Bruker TENSOR27 (Germany) Fourier infrared spectrometer) has N-H single-peak absorption peak and C-N absorption peak at 3364~3458cm-1 and 1190cm-1 respectively, 1H-NMR (deuterated chloroform as solvent) at 2.8ppm The proton absorption peak of N-H appears at , indicating that the end of the product is an amino g...

Embodiment 3

[0051] (1) Preparation of amino-terminated fluorine-containing prepolymer: Add 30 parts by mass of hexafluorobutyl methacrylate and 60 parts by mass of N,N-dimethylformamide into a container, heat up to 110°C, and add 0.6 parts by mass of Mercaptoethylamine, 0.1 parts by mass of azobisisobutyronitrile, stirred and reacted for 9 hours, diisopropylethylamine was added to make the pH = 8, and 1.5 parts by mass of formaldehyde solution with a mass concentration of 40% was added, and after fully stirred for 2 hours, the obtained The amino-terminated fluorine-containing prepolymer solution is obtained by distilling off the solvent under reduced pressure to obtain an amino-terminated fluorine-containing prepolymer. FT-IR (Bruker TENSOR27 (Germany) Fourier infrared spectrometer) has N-H single-peak absorption peak and C-N absorption peak at 3364~3458cm-1 and 1190cm-1 respectively, 1H-NMR (deuterated chloroform as solvent) at 2.8ppm The proton absorption peak of N-H appears at , indica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com