Monovinyl-terminated fluorine-containing prepolymer/epoxy (methyl) acrylate composite UV-cured paint, preparation and applications thereof

A technology for acrylate and curing coatings, which is applied in the field of polymer materials, and can solve the problems of reduced coating body performance, difficult migration of fluorine-containing groups, and poor compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0060] (1) Preparation of epoxy methacrylate resin: 100 parts by mass of bisphenol A type epoxy resin (epoxy value 0.01) is added in the reactor that reflux condenser, dropping funnel, thermometer and stirrer are housed, Heat and stir to 60°C, then add 2.5 parts by mass of tetrabutylammonium bromide, 0.5 parts by mass of hydroquinone and 20 parts by mass of methacrylic acid, raise the temperature to 130°C, and react for 2 hours to obtain epoxy methacrylate resin.

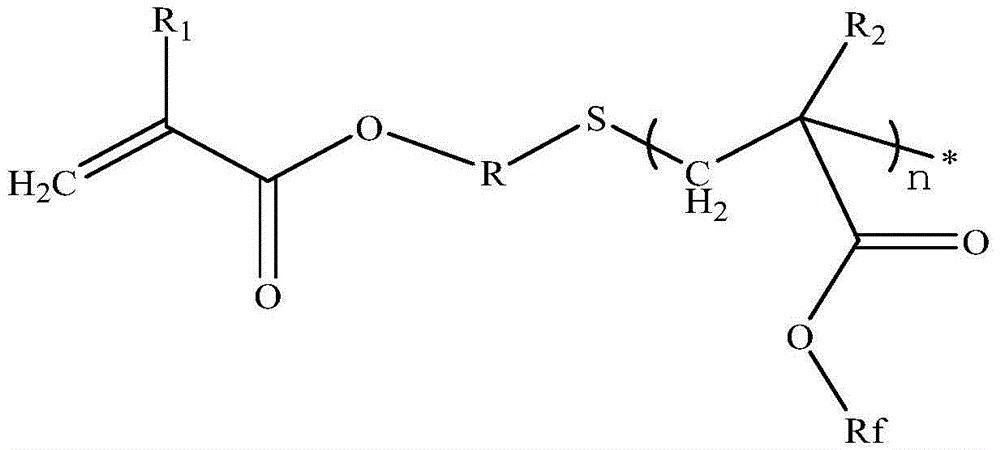

[0061] (2) Preparation of monovinyl-terminated fluorine-containing prepolymer: Add 20 parts by mass of hexafluorobutyl methacrylate and 40 parts by mass of dioxane into a container, heat up to 85°C, add 2-mercaptoethanol 1 parts by mass, 0.6 parts by mass of azobisisobutyronitrile, stirred and reacted for 7 hours to obtain a fluorine-containing prepolymer solution with terminated hydroxyl groups; the temperature was cooled to 0°C in an ice bath, and 1.3 parts by mass of triethylamine and 1.2 parts by mass of methacr...

Embodiment 2

[0064] (1) Preparation of epoxy acrylate resin: get 100 mass parts of bisphenol S type epoxy resin (epoxy value 0.51) and add in the reactor equipped with reflux condenser, dropping funnel, thermometer and stirrer, heat and stir to 85°C, then add 3 parts by mass of tetrabutylammonium bromide, 0.05 parts by mass of hydroquinone, and 100 parts by mass of acrylic acid, raise the temperature to 125°C, and react for 6.5 hours to obtain an epoxy acrylate resin.

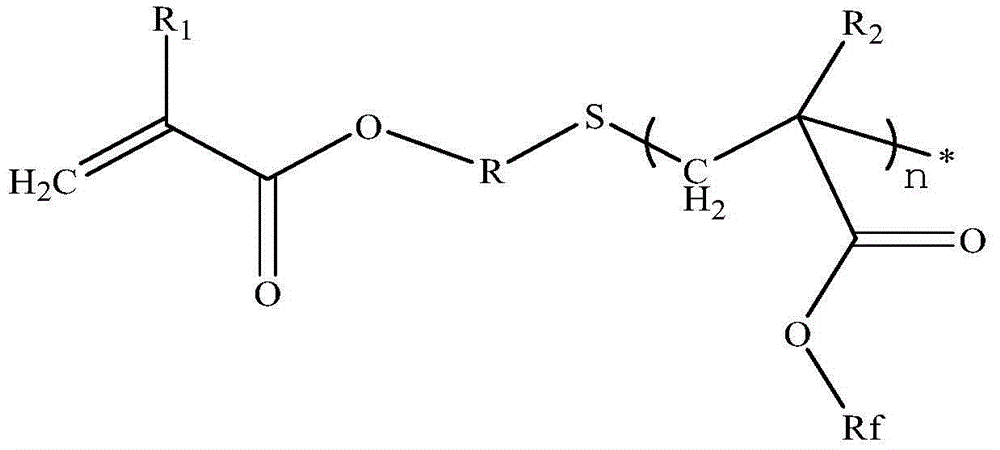

[0065] (2) Preparation of monovinyl-terminated fluorine-containing prepolymer: Add 20 parts by mass of trifluoroethyl methacrylate and 40 parts by mass of butanone into a container, heat up to 78°C, and add 4 parts by mass of 2-mercaptoethanol , 0.8 parts by mass of azobisisoheptanonitrile, stirred and reacted for 6 hours to obtain a fluorine-containing prepolymer solution with terminal hydroxyl groups; the temperature was cooled to 0°C in an ice bath, and 5 parts by mass of triethylamine and 4.4 parts by mass of methacryloy...

Embodiment 3

[0068] (1) Preparation of epoxy methacrylate resin: get 100 mass parts of epoxidized novolac resin (epoxy value 0.50, Wuxi Resin Factory, model F51) and add reflux condenser, dropping funnel, thermometer and stirring In the reactor of the reactor, heat and stir to 90°C, then add 0.05 parts by mass of tetrabutylammonium bromide, 3 parts by mass of hydroquinone, and 0.1 parts by mass of methacrylic acid, raise the temperature to 110°C, and react for 1 hour to obtain Epoxy methacrylate resin.

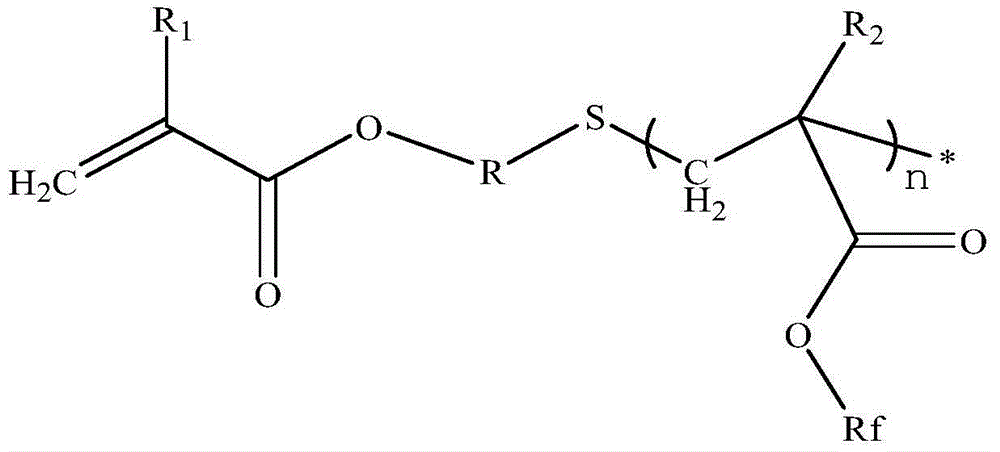

[0069](2) Preparation of monovinyl-terminated fluorine-containing prepolymer: Add 40 parts by mass of dodecafluoroheptyl methacrylate and 40 parts by mass of ethylene glycol dimethyl ether in a container, heat up to 85°C, add 2- 0.6 parts by mass of mercaptoethanol, 0.1 part by mass of azobisisobutyronitrile, stirred for 8.5 hours to obtain a fluorine-containing prepolymer solution with terminal hydroxyl groups; cooled to 0°C in an ice bath, 1 part by mass of triethylamine, 1 part by mass ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| epoxy value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com