Method for producing green ecological cement resistant to seawater corrosion with lime plant waste

An ecological cement and anti-seawater technology is applied in the field of producing green ecological cement resistant to seawater corrosion from lime plant waste, which can solve the problems of inconvenient construction and engineering quality control, lack of uniform standards for preparation technology, and unfavorable production and construction costs. Good density and volume stability, high resistance to chloride ion diffusion, good economic and social benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

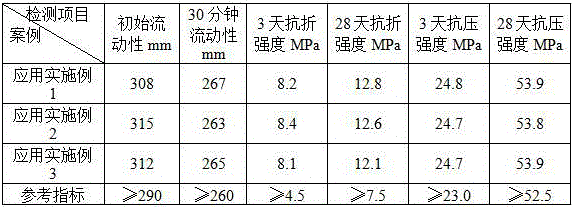

Embodiment 1

[0038] The green ecological cement that resists seawater corrosion is produced with lime plant waste, and its production method comprises the following steps:

[0039] a. Drying: The waste from the lime plant is sent to the vertical dryer for drying through the belt conveyor. After drying, the waste from the lime plant is sent to the waste warehouse of the lime plant through the elevator for storage, and the water content is less than 2.5%.

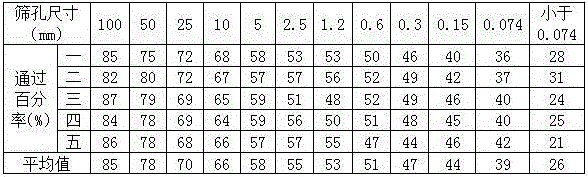

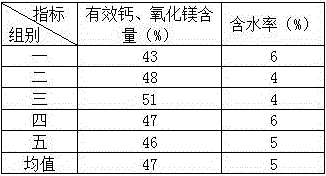

[0040] b. Grinding: Grind the dried lime plant waste obtained in step a with a cement mill so that its passing rate through a 100 mesh sieve reaches more than 95%, and 45 parts of the lime plant waste obtained in step a and the prepared sulfur aluminum Add 40 parts of salt cement clinker, 0.04 parts of composite activator and 1 part of early strength agent into the cement mill in parts by weight, spray atomized water to the inside of the cement mill, and control the temperature of the grinding process at 115 ±3°C, the material coming out ...

Embodiment 2

[0044] The green ecological cement that resists seawater corrosion is produced with lime plant waste, and its production method comprises the following steps:

[0045] a. Drying: The waste from the lime plant is sent to the vertical dryer for drying through the belt conveyor. After drying, the waste from the lime plant is sent to the waste warehouse of the lime plant through the elevator for storage, and the water content is less than 2.5%.

[0046] b. Grinding: Grind the dry lime plant waste obtained in step a with a cement mill so that its passing rate through a 100 mesh sieve reaches more than 95%, and 50 parts of the lime plant waste obtained in step a and the prepared sulfur aluminum Add 45 parts of salt cement clinker, 0.05 parts of composite activator and 2 parts of early strength agent into the cement mill in parts by weight, spray atomized water to the inside of the cement mill, and control the temperature of the grinding process at 115 ±3°C, the material coming out o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com