High temperature-resistant anti-adhesion over-printing varnish

An anti-blocking and varnish technology, which is applied in the field of printing inks, can solve problems such as high heating temperature, impact on production efficiency, and coking of the printing surface, and achieve improved product appearance, strong adhesion, and improved chalking resistance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

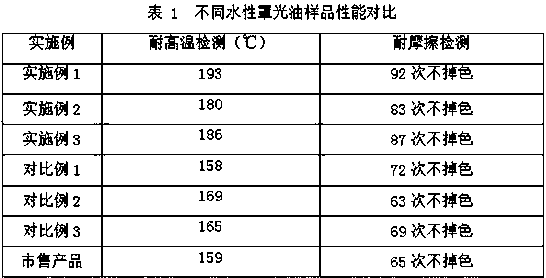

Examples

Embodiment 1

[0035] Add 200 parts of cyclohexane, 20 parts of polyethylene wax, 40 parts of oxidized polyethylene wax, 1.8 parts of ethylenediamine and 0.6 parts of biodegradable methanesulfonic acid into a flask equipped with a thermometer, a spherical condenser and an electric stirrer , the speed is adjusted to 500r / min, the temperature is slowly raised to reflux, and reflux is carried out for 30 minutes, cyclohexane is recovered under reduced pressure, residual cyclohexane and low boilers are recovered by adding water and vacuum distillation, 15 parts of lauryl glucoside, lauryl phosphoric acid 6 parts of ester potassium salt, 10 parts of fatty alcohol polyoxyethylene ether, add water and cool to 40°C to obtain water-based wax emulsion for later use;

[0036] Mix 6 parts of water, 4 parts of ethanol, 50 parts of hard styrene-acrylic copolymer emulsion, 30 parts of soft styrene-acrylic copolymer emulsion, 10 parts of water-based self-crosslinking acrylic emulsion, 10 parts of water-based ...

Embodiment 2

[0038] Add 150 parts of cyclohexane, 10 parts of polyethylene wax, 30 parts of oxidized polyethylene wax, 1.2 parts of ethylenediamine and 0.2 parts of biodegradable methanesulfonic acid into a flask equipped with a thermometer, a spherical condenser and an electric stirrer , the rotating speed is adjusted to 450r / min, the temperature is slowly raised to reflux, and reflux is carried out for 25 minutes, cyclohexane is recovered under reduced pressure, residual cyclohexane and low boilers are recovered by adding water and vacuum distillation, 5 parts of lauryl glucoside, lauryl phosphoric acid 4 parts of ester potassium salt, 8 parts of fatty alcohol polyoxyethylene ether, add water and cool down to 30°C to obtain water-based wax emulsion for later use;

[0039] Mix 4 parts of water, 2 parts of ethanol, 40 parts of hard styrene-acrylic copolymer emulsion, 20 parts of soft styrene-acrylic copolymer emulsion, 5 parts of water-based self-crosslinking acrylic emulsion, 8 parts of wa...

Embodiment 3

[0041] Add 175 parts of cyclohexane, 15 parts of polyethylene wax, 35 parts of oxidized polyethylene wax, 1.6 parts of ethylenediamine and 0.4 parts of biodegradable methanesulfonic acid into a flask equipped with a thermometer, spherical condenser and electric stirrer , the rotation speed is adjusted to 400r / min, the temperature is slowly raised to reflux, and reflux is carried out for 20 minutes. Cyclohexane is recovered under reduced pressure, residual cyclohexane and low boilers are recovered by adding water and vacuum distillation, and 10 parts of lauryl glucoside and lauryl phosphoric acid are added. 5 parts of ester potassium salt, 9 parts of fatty alcohol polyoxyethylene ether, add water and cool to 30°C to obtain water-based wax emulsion for later use;

[0042] Mix 5 parts of water, 3 parts of ethanol, 45 parts of hard styrene-acrylic copolymer emulsion, 25 parts of soft styrene-acrylic copolymer emulsion, 7.5 parts of water-based self-crosslinking acrylic emulsion, 9 pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com