Environment-friendly cold-resistant polyvinyl chloride (PVC) waterproof coil and manufacturing technique thereof

A technology of polyvinyl chloride and waterproof coiled material, applied in the field of waterproof coiled material, can solve the problems of waterproof failure, poor cold resistance, cracking of PVC coiled material, etc., and achieve the effect of prolonging service life, good low temperature resistance and low comprehensive cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

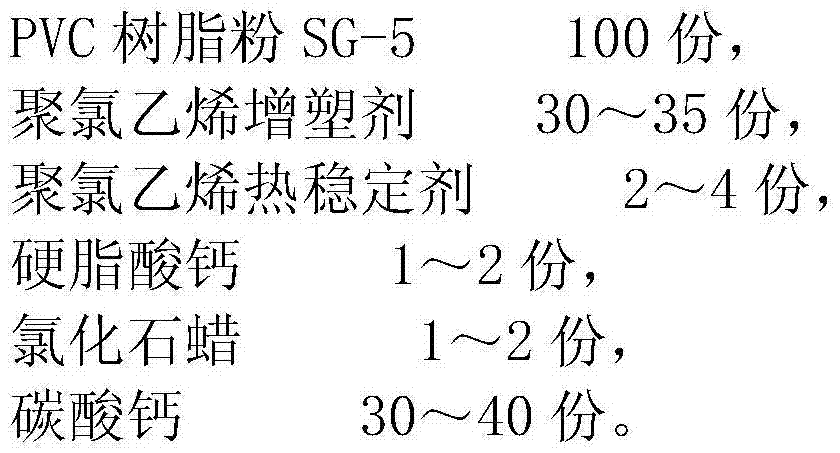

[0024] An environment-friendly cold-resistant polyvinyl chloride waterproof membrane: its composition is as follows in parts by mass:

[0025]

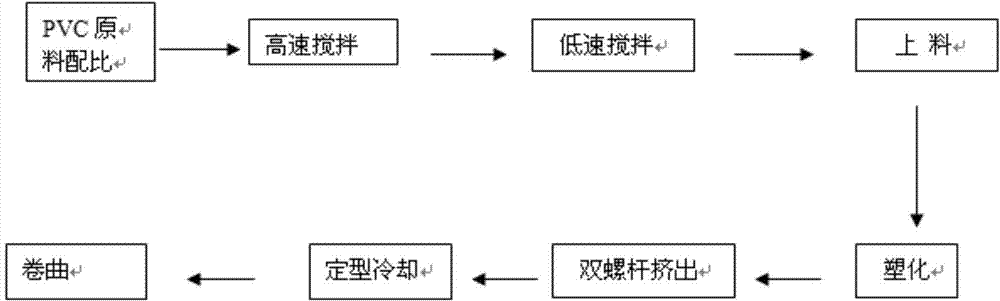

[0026] The manufacture craft of above-mentioned polyvinyl chloride waterproof coiled material, comprises:

[0027] Step 1: After mixing the above raw materials according to the number of parts, put the raw materials except the synthetic vegetable ester (produced by Suzhou Kunshan Yiget Chemical Co., Ltd.) into the high-speed mixer for stirring and blending. When the material temperature reaches 90-100 ° C, stop Stir; add synthetic vegetable ester, and then put it into a low-speed mixer and stir to 35-40°C, so as to prevent the PVC resin from attenuating and discoloring due to the temperature rise caused by high-speed stirring, and obtain a mixed base material;

[0028] Step 2: the mixed base material is fed to the twin-screw extruder with a screw feeder;

[0029] Step 3: plasticizing, the processing temperature of the twin-screw e...

Embodiment 2

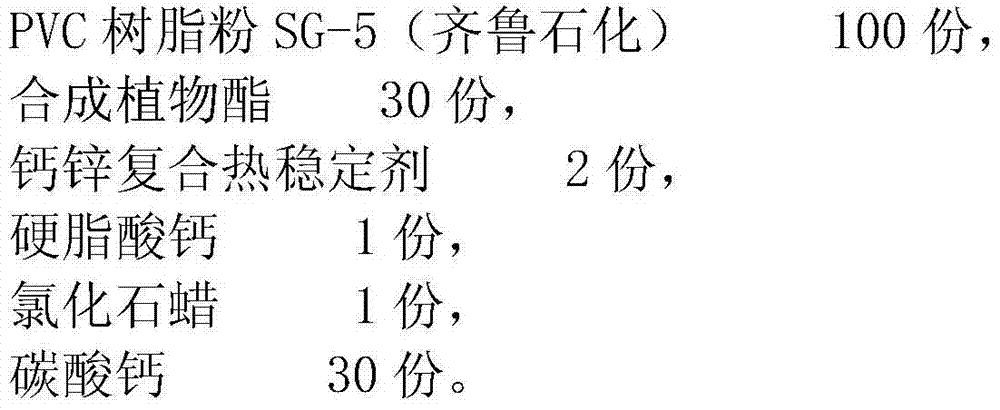

[0036] An environment-friendly cold-resistant polyvinyl chloride waterproof membrane: its composition is as follows in parts by mass:

[0037]

[0038] The manufacture craft of above-mentioned polyvinyl chloride waterproof coiled material, comprises:

[0039] Step 1: After the above-mentioned raw materials are prepared according to the number of parts, put the raw materials except ethylene terpolymer (produced by DuPont) into the high-speed mixer for stirring and blending. When the material temperature reaches 90-100°C, stop stirring; add Ethylene terpolymer, and then put it into a low-speed mixer and stir to 35-40°C to obtain a mixed base material;

[0040] Step 2: the mixed base material is fed to the twin-screw extruder with a screw feeder;

[0041] Step 3: plasticizing, the processing temperature of the twin-screw extruder is: zone 1: 115°C-125°C, zone 2: 135°C-145°C, zone 3: 155°C-165°C, zone 4: 165°C ~175°C, zone five: 165°C~175°C, zone six: 155°C~165°C;

[0042] M...

Embodiment 3

[0046] An environment-friendly cold-resistant polyvinyl chloride waterproof membrane: its composition is as follows in parts by mass:

[0047]

[0048] The manufacture craft of above-mentioned polyvinyl chloride waterproof coiled material, comprises:

[0049] Step 1: After mixing the above raw materials according to the number of parts, put the raw materials except polyol benzoate (manufactured by Shijiazhuang Yongguang Chemical Technology Co., Ltd.) into a high-speed mixer for stirring and blending. The temperature of the materials reaches 90-100 °C. Stop stirring; add polyol benzoate, and then put it into a low-speed mixer and stir to 35-40°C to obtain a mixed base material;

[0050] Step 2: the mixed base material is fed to the twin-screw extruder with a screw feeder;

[0051] Step 3: plasticizing, the processing temperature of the twin-screw extruder is: zone 1: 115°C-125°C, zone 2: 135°C-145°C, zone 3: 155°C-165°C, zone 4: 165°C ~175°C, zone five: 165°C~175°C, zone s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com