Environment-friendly regenerated rubber and preparation method

A technology of regenerated rubber and waste rubber, which is applied in the direction of plastic recycling and recycling technology, which can solve the problems of high energy consumption, high production pressure, unstable quality of regenerated rubber, etc., and achieve the effect of low energy consumption and uniform heating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0032] The formula of waste tire rubber powder and chemical additives is as follows (parts by mass, the same below): 30 mesh waste tire rubber powder 100, regeneration activator (420 activator) 0.8, regeneration swelling agent (regenerated grease) 12, other processing aids Agent (Coumarone Resin) 1. The premixing time was 5min, the premixing temperature was 100°C, and the premixing pressure was normal pressure; the heating medium temperature of the regeneration equipment was set to 180°C, and the regeneration time was 30min.

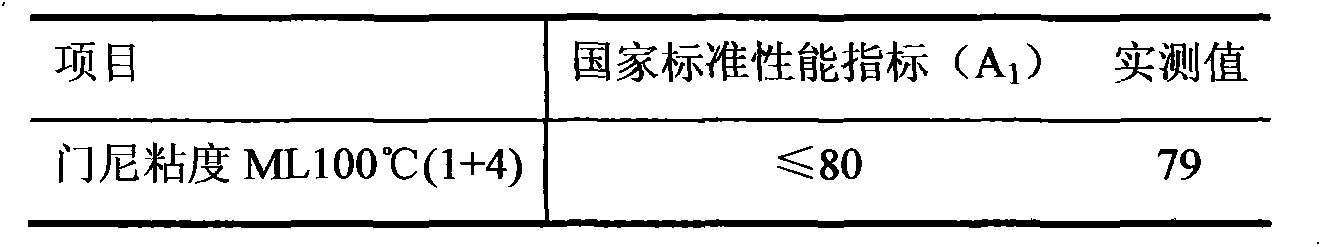

[0033] According to the national standard GB / T 13460-2008, the performance of reclaimed rubber was detected, and the basic performance of the reclaimed rubber in this example was in line with the national reclaimed rubber A. 1 level standard.

[0034]

[0035]

example 2

[0037] Formula of waste tire rubber powder and chemical additives: 30 mesh waste tire rubber powder 100, regeneration activator (420 activator) 1.5, regeneration swelling agent (aromatic oil) 16, other processing aids (silica and modified mixture of petroleum resins) 4. The premixing time was 5min, the premixing temperature was 100°C, and the premixing pressure was normal pressure; the heating medium temperature of the regeneration equipment was set to 180°C, and the regeneration time was 30min.

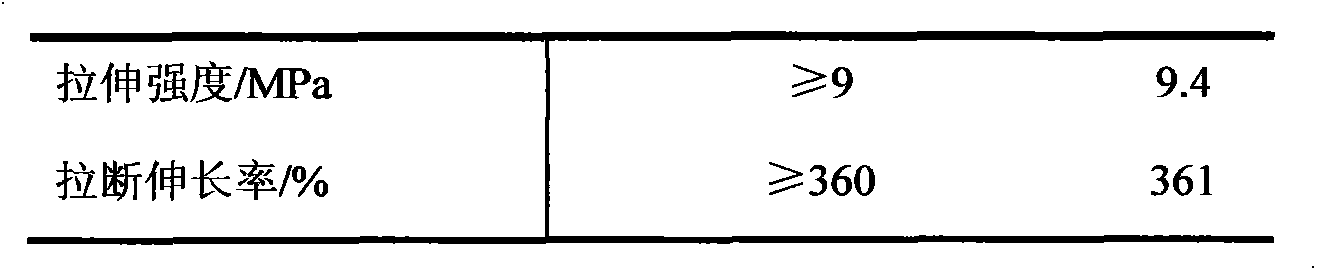

[0038] According to the national standard GB / T 13460-2008, the performance of the reclaimed rubber was tested, and the basic performance of the reclaimed rubber in this example was in line with the national reclaimed rubber TA. 2 level standard.

[0039]

example 3

[0041] Waste tire rubber powder and chemical additives formula: 30 mesh waste tire rubber powder 100, regeneration activator (420 activator) 1, regeneration swelling agent (mixture of shea butter vegetable oil and aromatic oil) 20, other processing Auxiliary (mixture of light calcium, silica and coumarone resin) 6. The premixing time was 5min, the premixing temperature was 100°C, and the premixing pressure was normal pressure; the heating medium temperature of the regeneration equipment was set to 180°C, and the regeneration time was 30min.

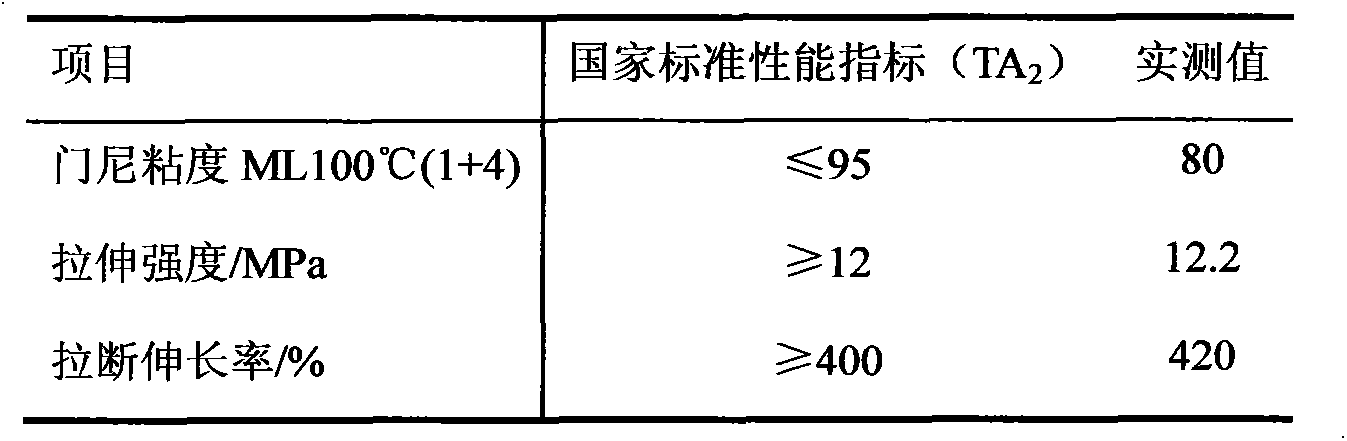

[0042] According to the national standard GB / T 13460-2008, the performance of reclaimed rubber is tested, and the basic properties of the reclaimed rubber in this example are in line with the national reclaimed rubber A. 2 level standard.

[0043]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com