Ore efficient aeration vibration cleaning device

A cleaning device and ore technology, applied in the field of ore washing, can solve problems affecting ore processing, low work efficiency, complex structure, etc., and achieve the effect of improving cleaning effect, improving work efficiency and effect, and improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

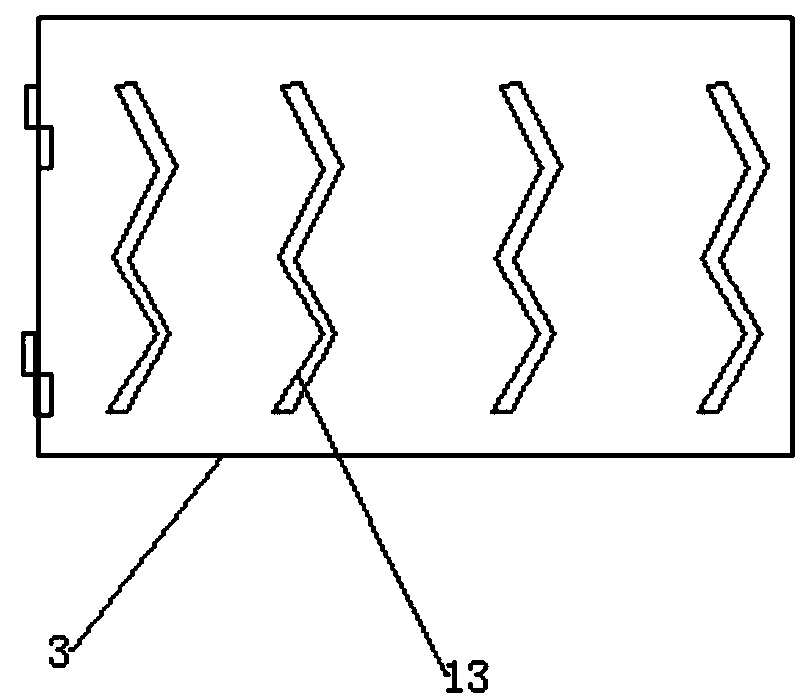

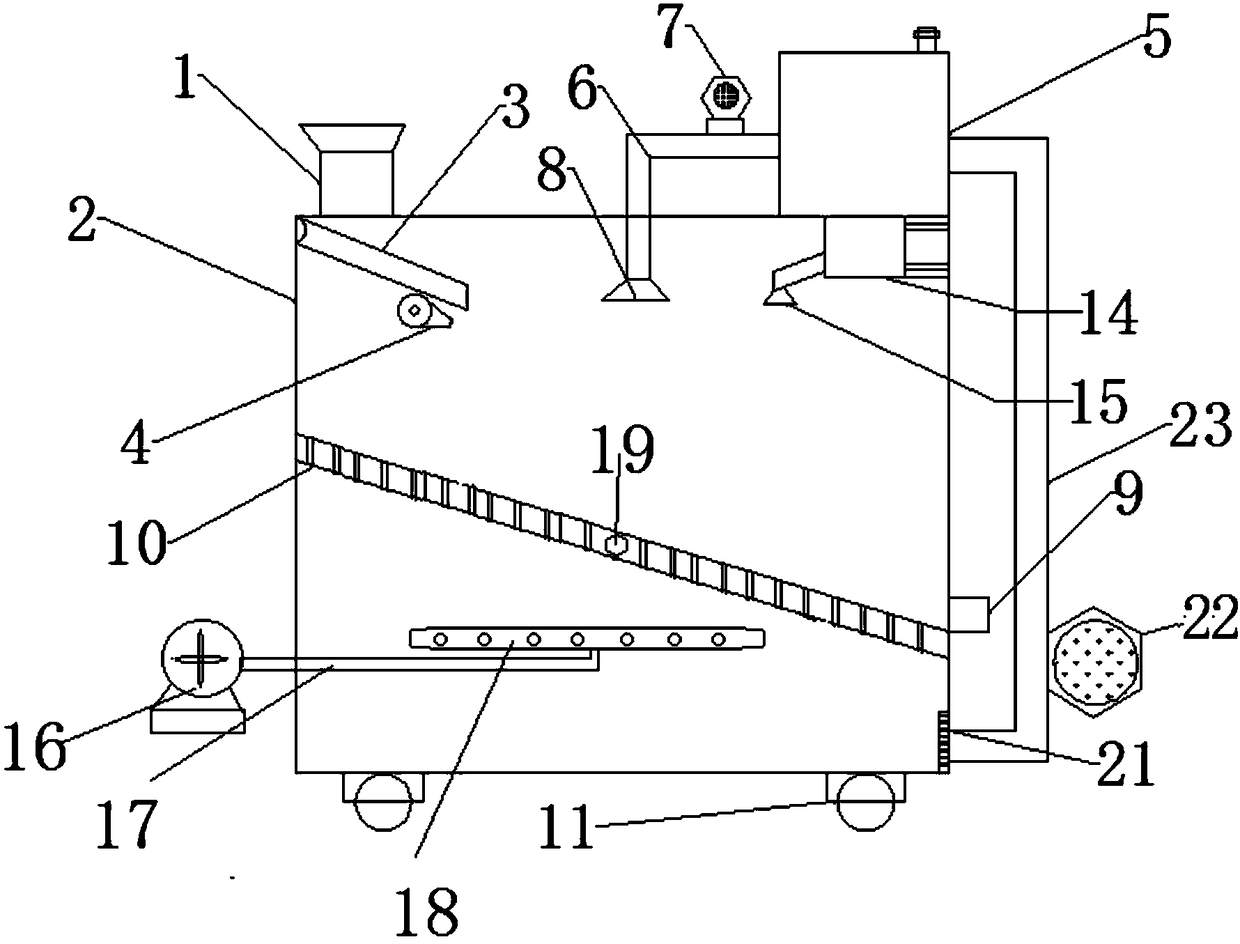

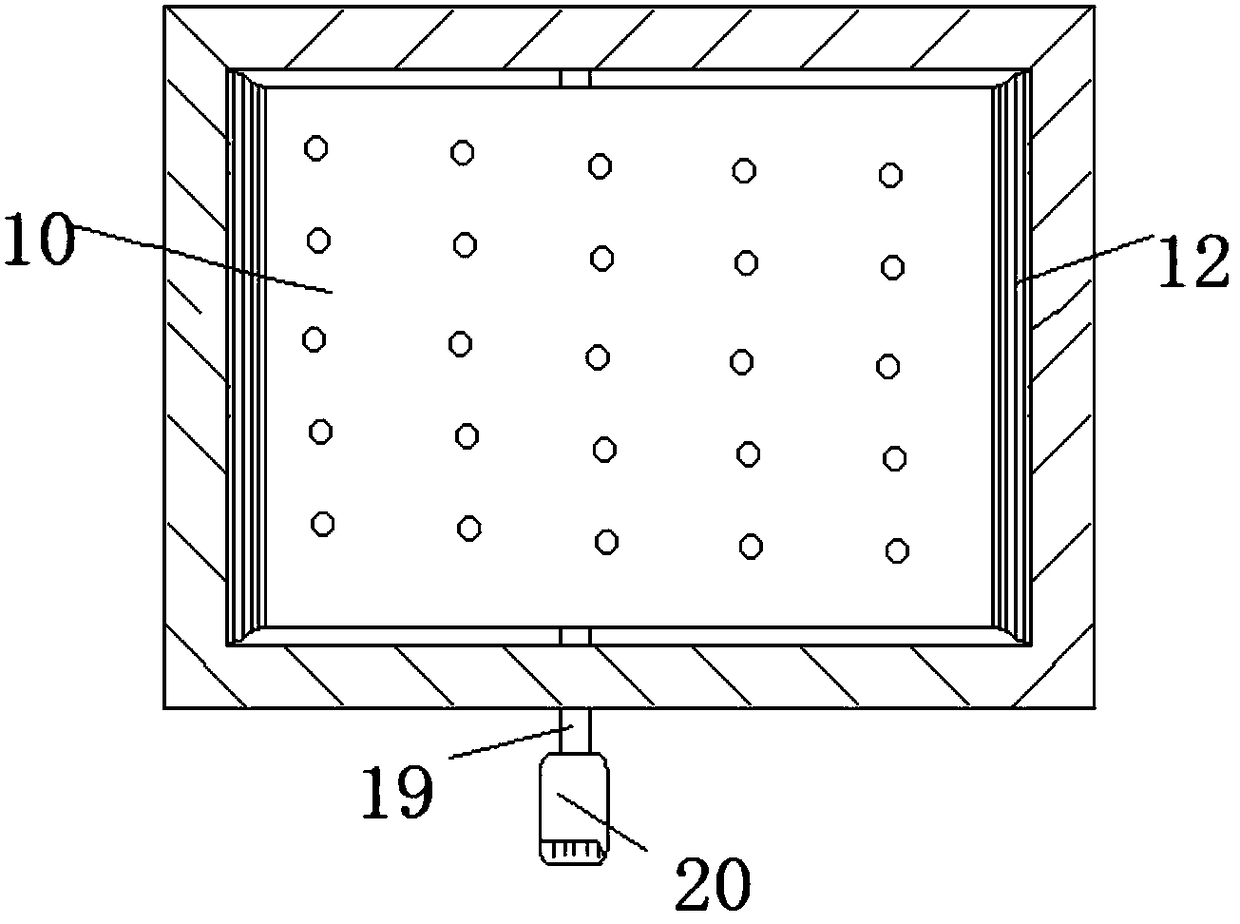

[0018] see Figure 1-3 , a high-efficiency aeration and vibration cleaning device for ore, comprising a feed pipe 1, a treatment box 2, a shaker plate 3, a water storage tank 5, a water spray pipe 6, an ore discharge pipe 9, a sieve plate 10, a vacuum cleaner 14, and an aerator 16. The central rotating shaft 19 and the return pipe 23, the top of the treatment box 2 is provided with a feed pipe 1, the ore enters the treatment box 2 through the feed pipe 1 for processing, and the inside of the treatment box 2 is also provided with a shaker plate 3. One end of the material plate 3 is hinged with the inner wall of the top of the processing box 2, and a cam 4 is arranged under the other end of the material shaking plate 3. The surface is evenly equipped with a broken-line deceleration corrugator 13, and the cam 4 is connected with the external motor. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com