Patents

Literature

153results about How to "Slow down the sliding speed" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

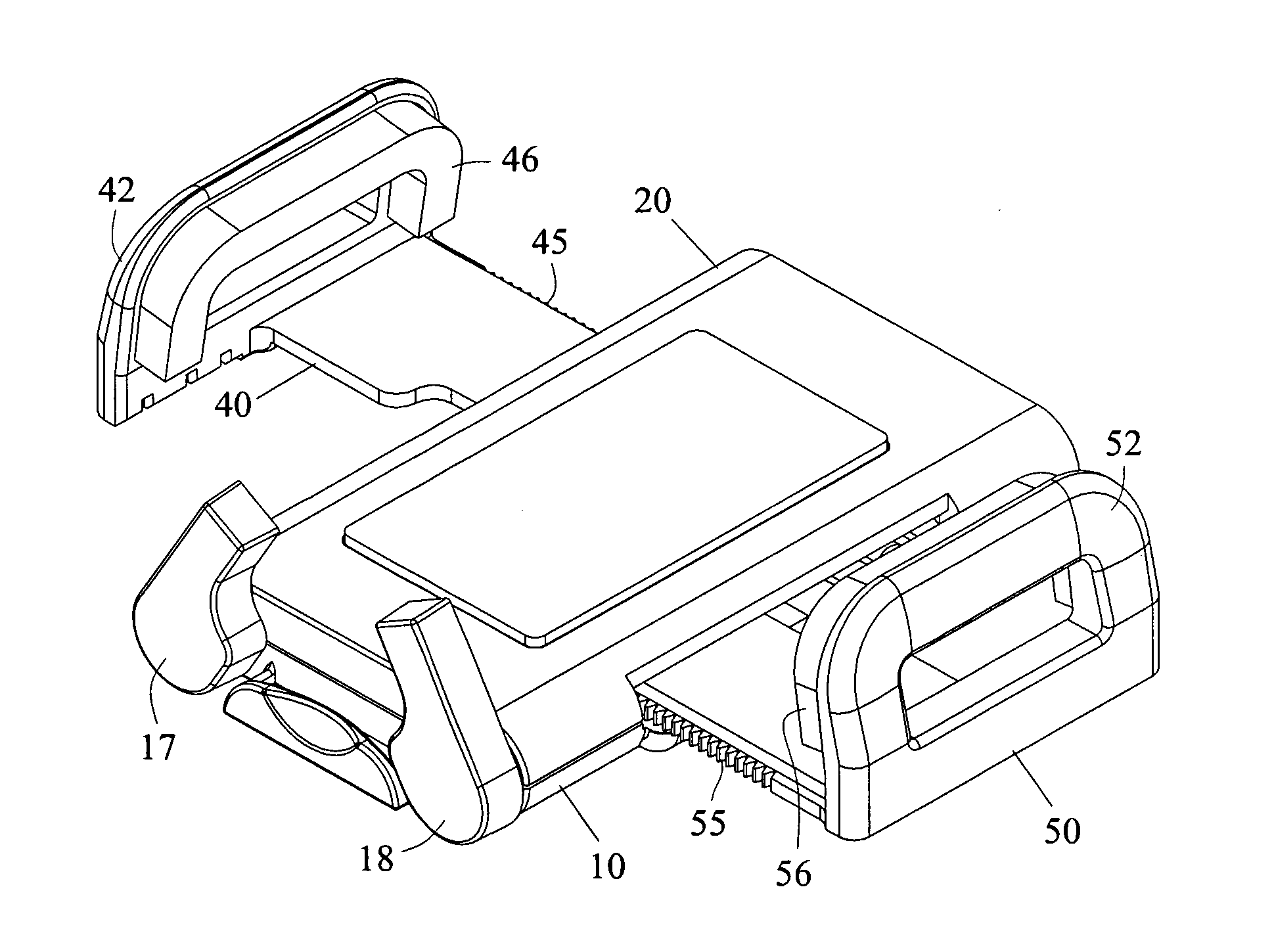

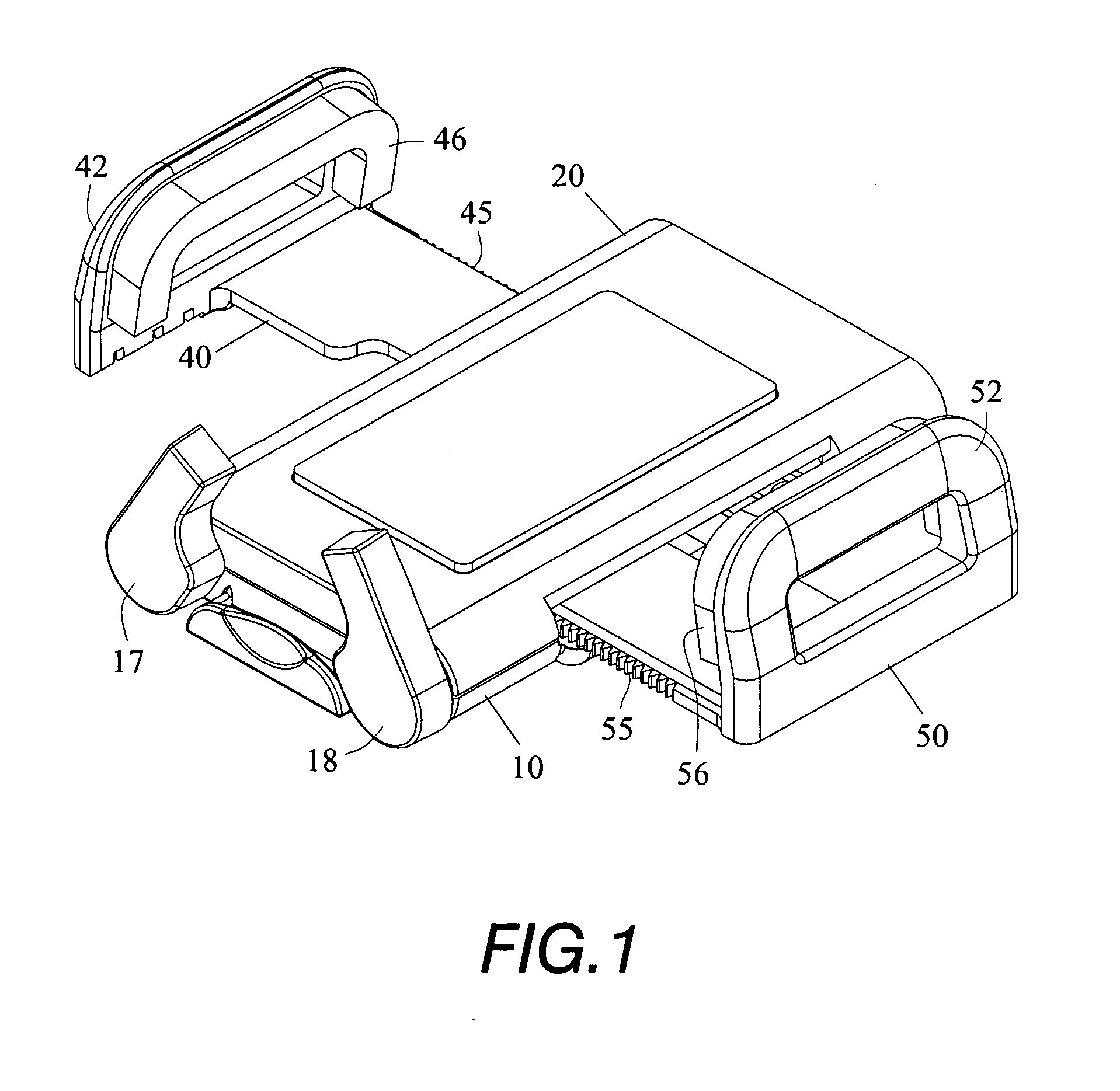

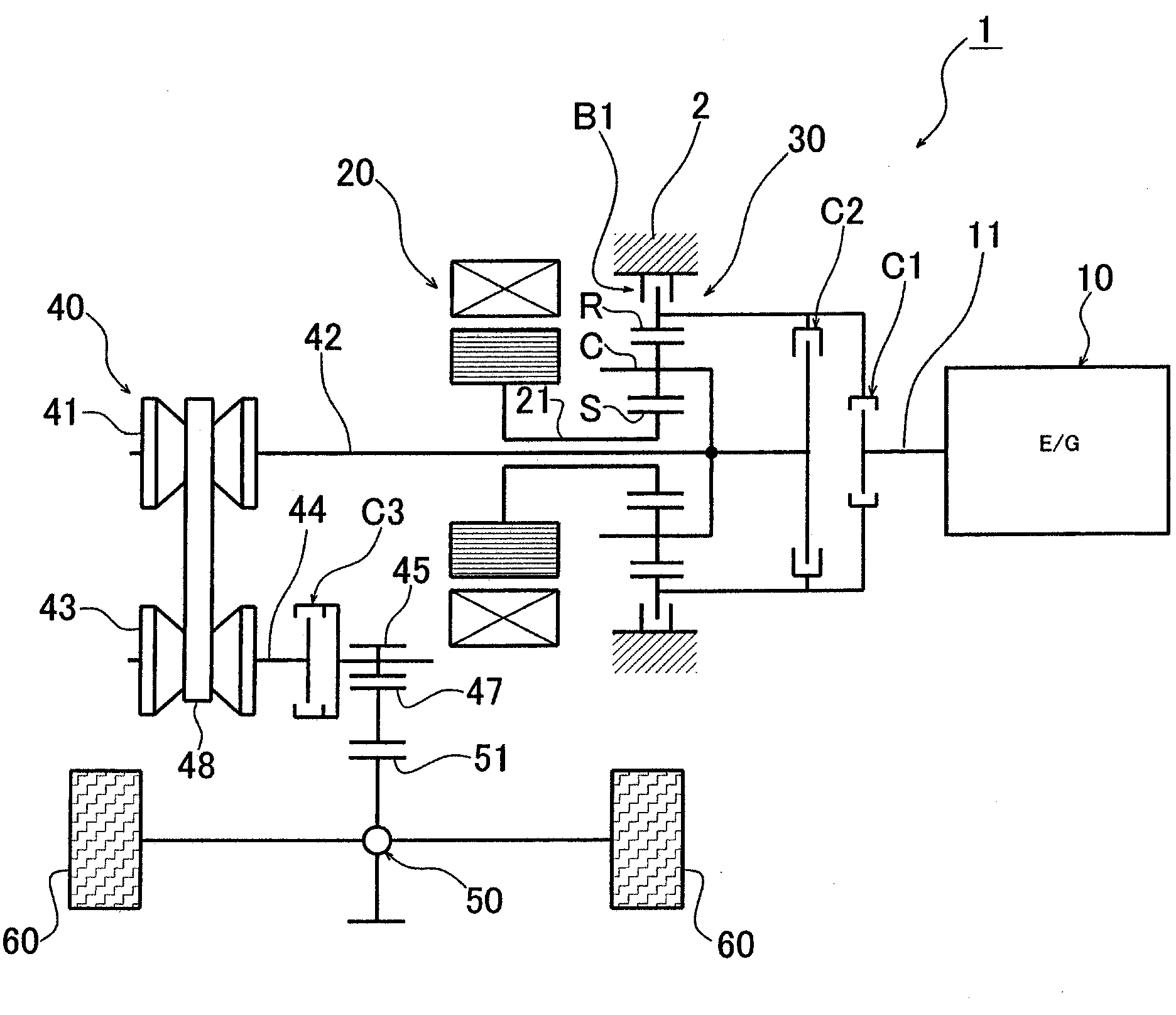

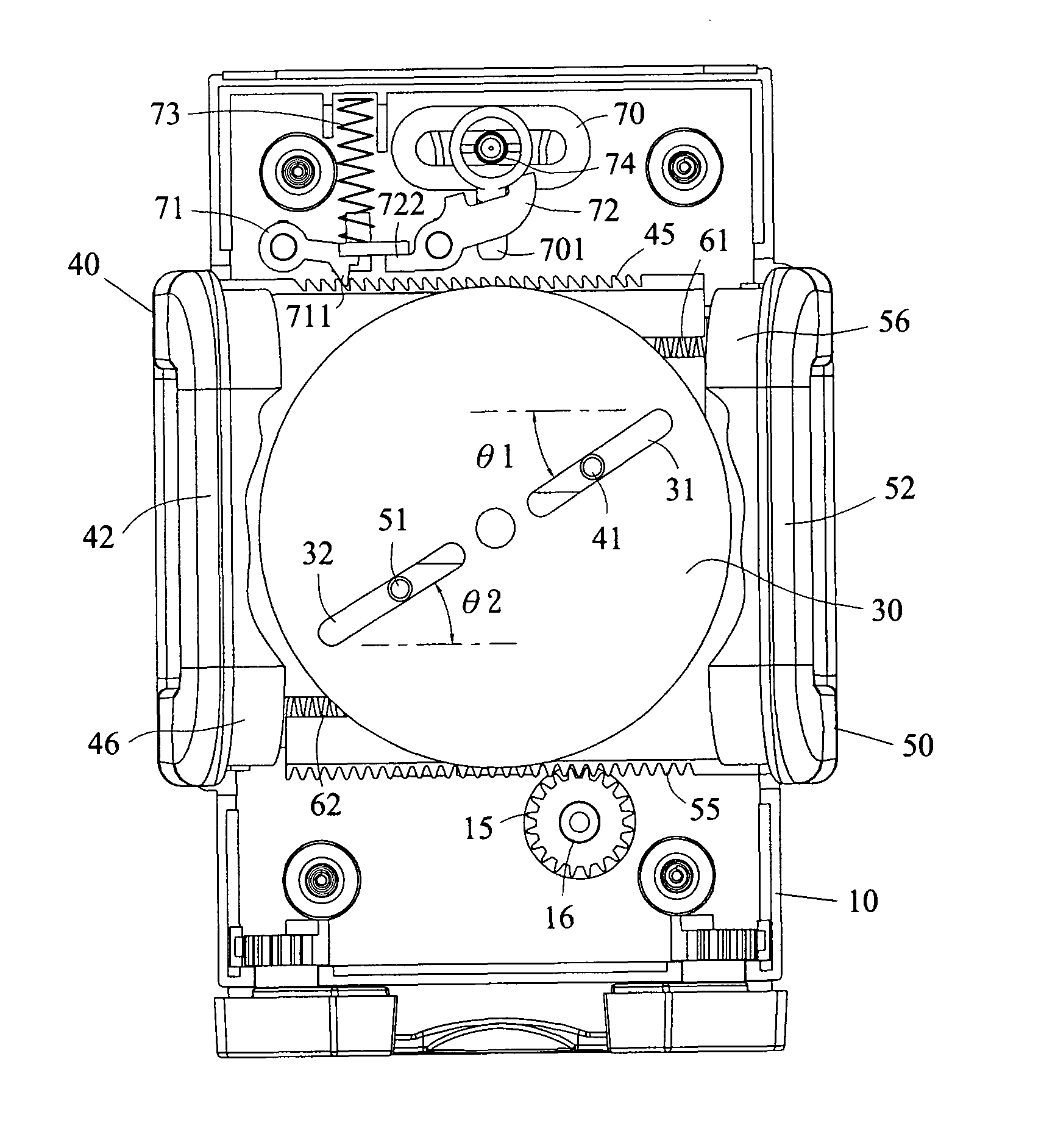

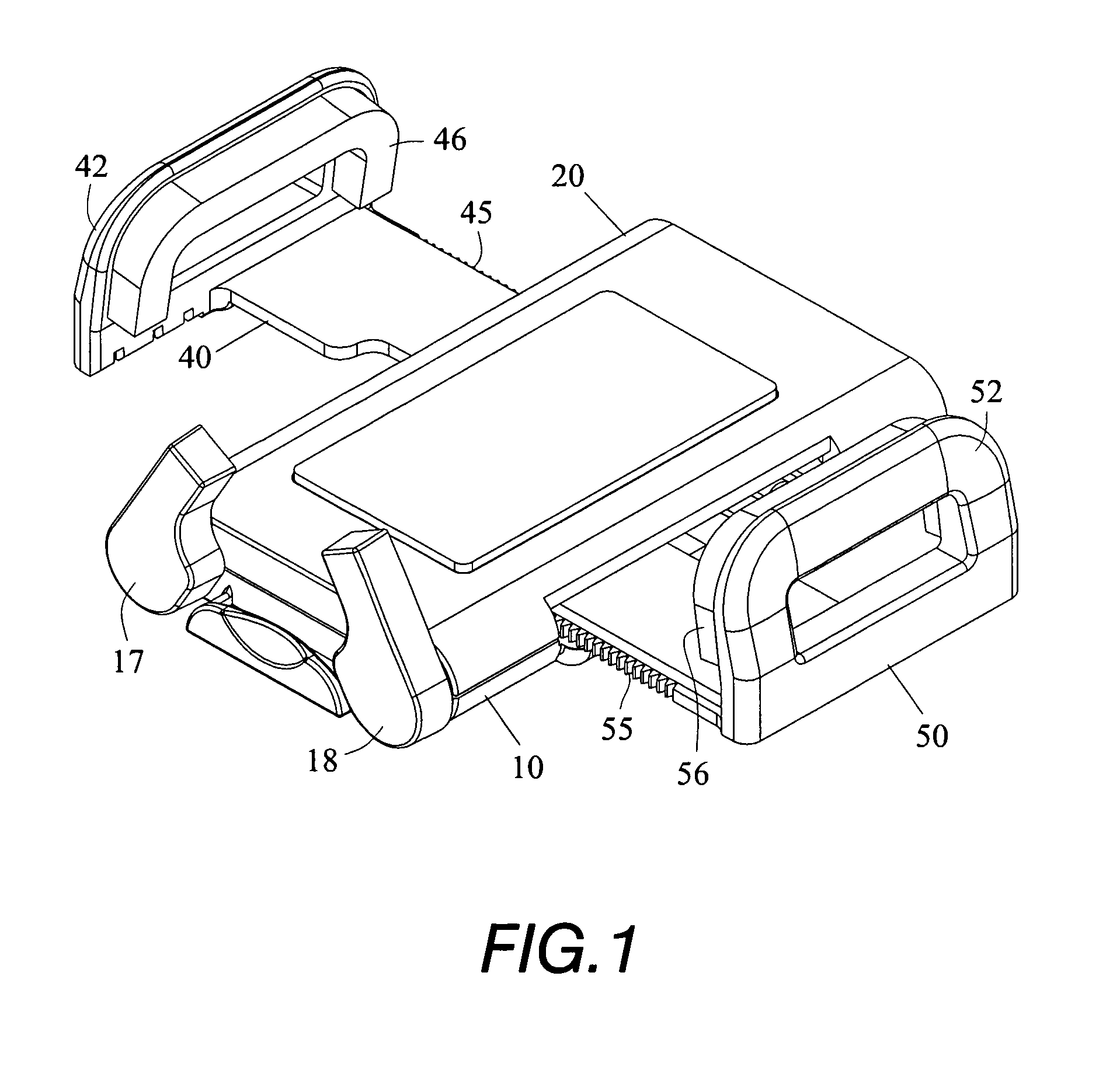

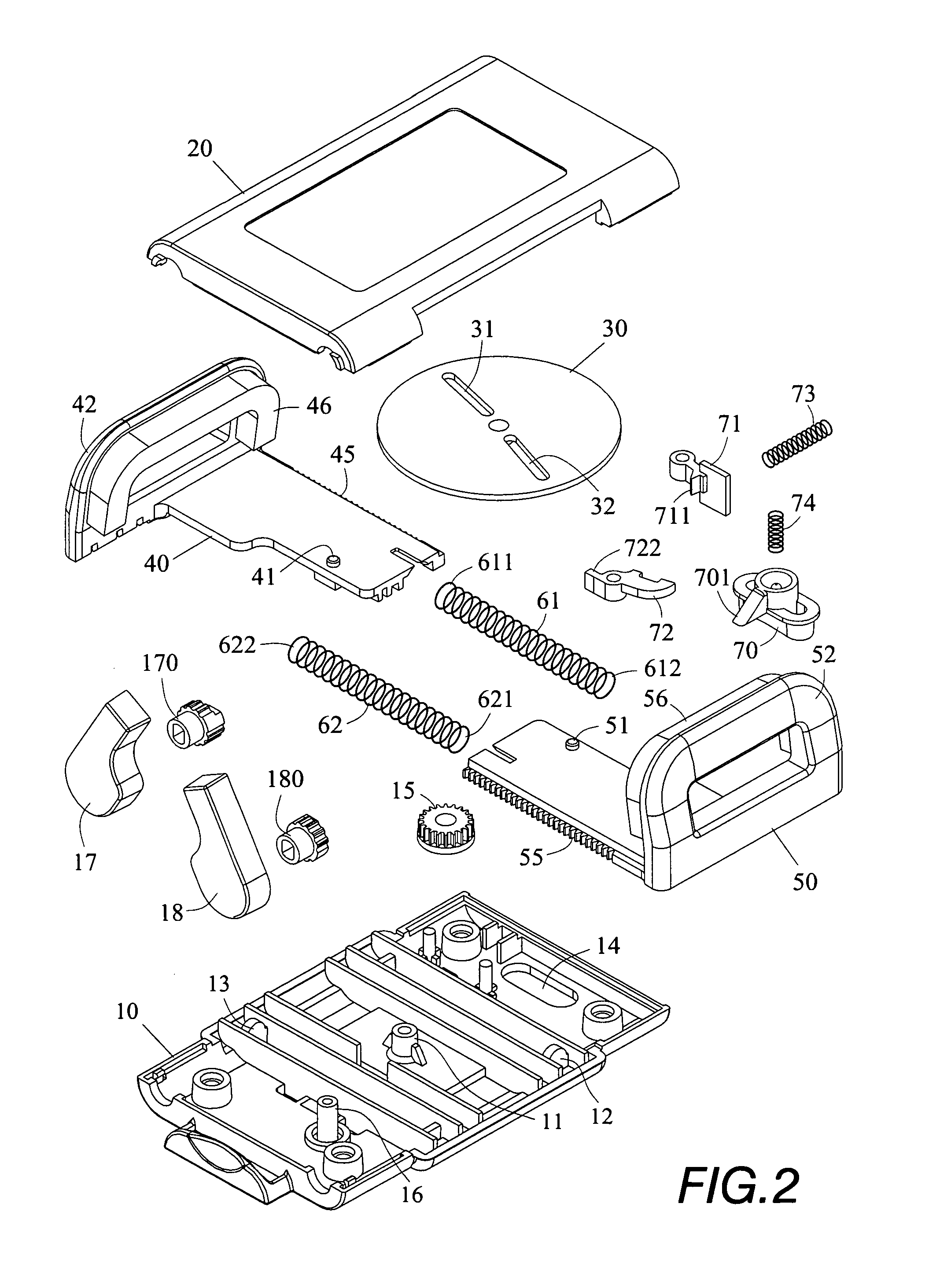

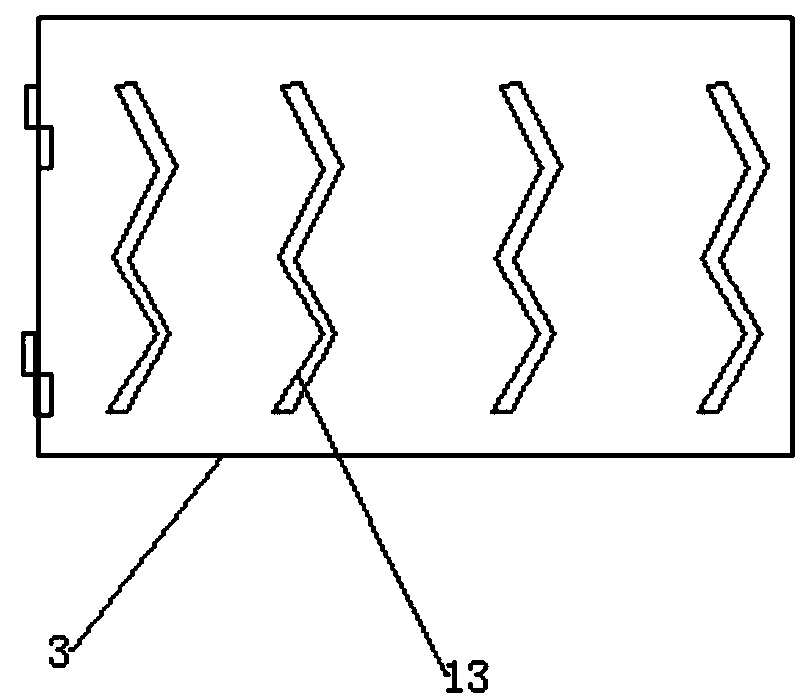

Clamping device with a linking member

ActiveUS20100295228A1Slow down the sliding speedMore stable of the second slide memberSemiconductor/solid-state device manufacturingDrawing boardsEngineeringSharp angle

Owner:COMART CORP

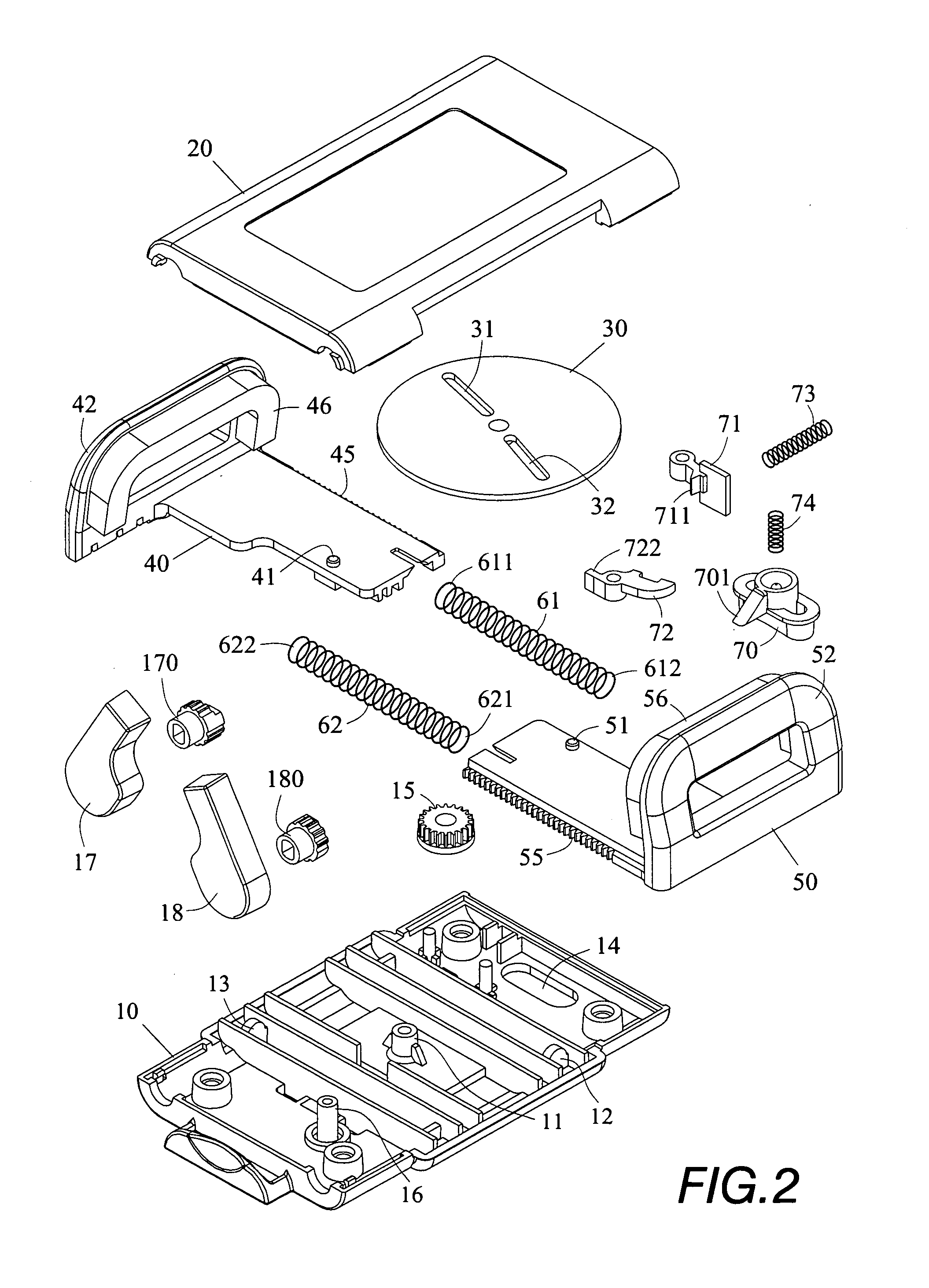

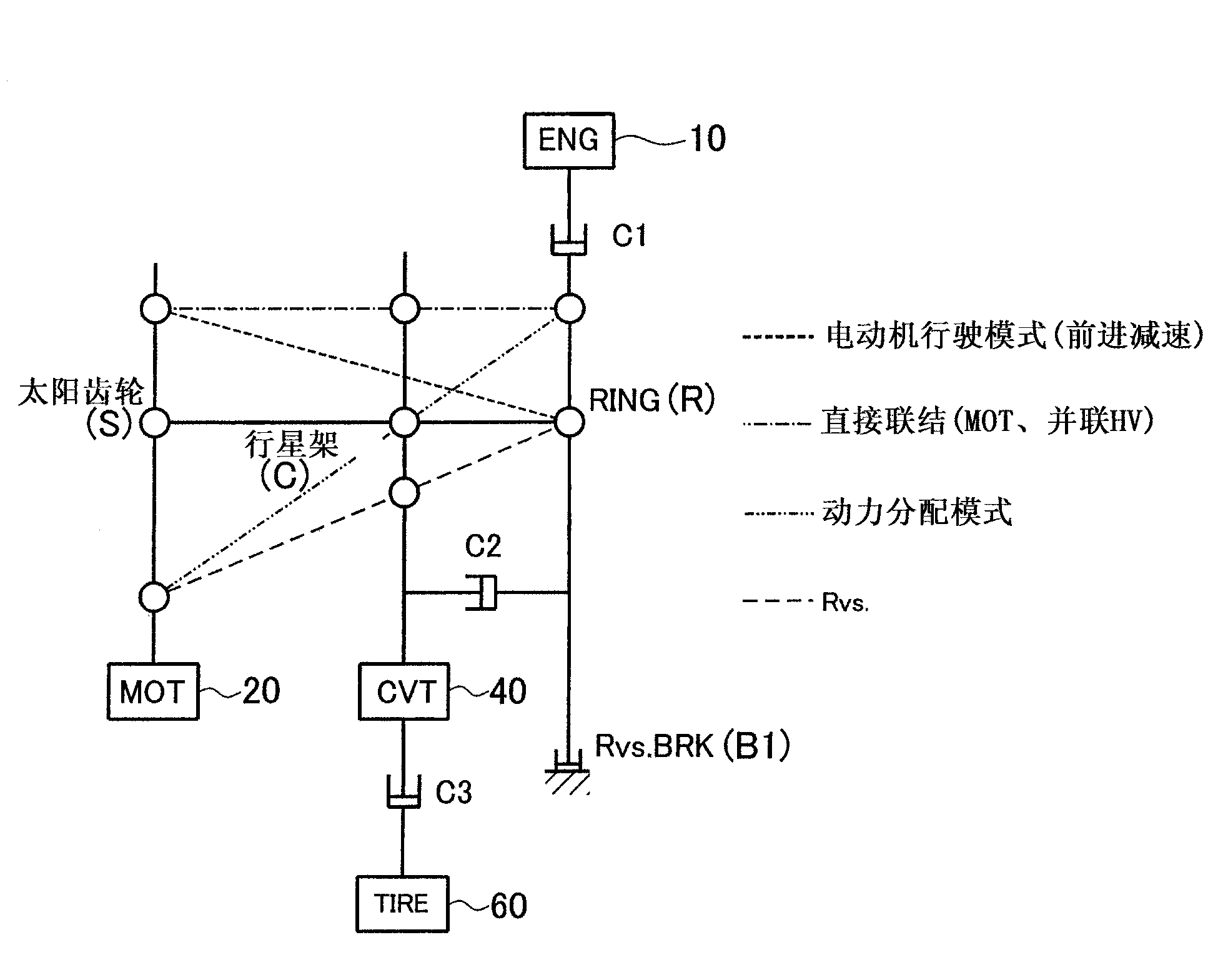

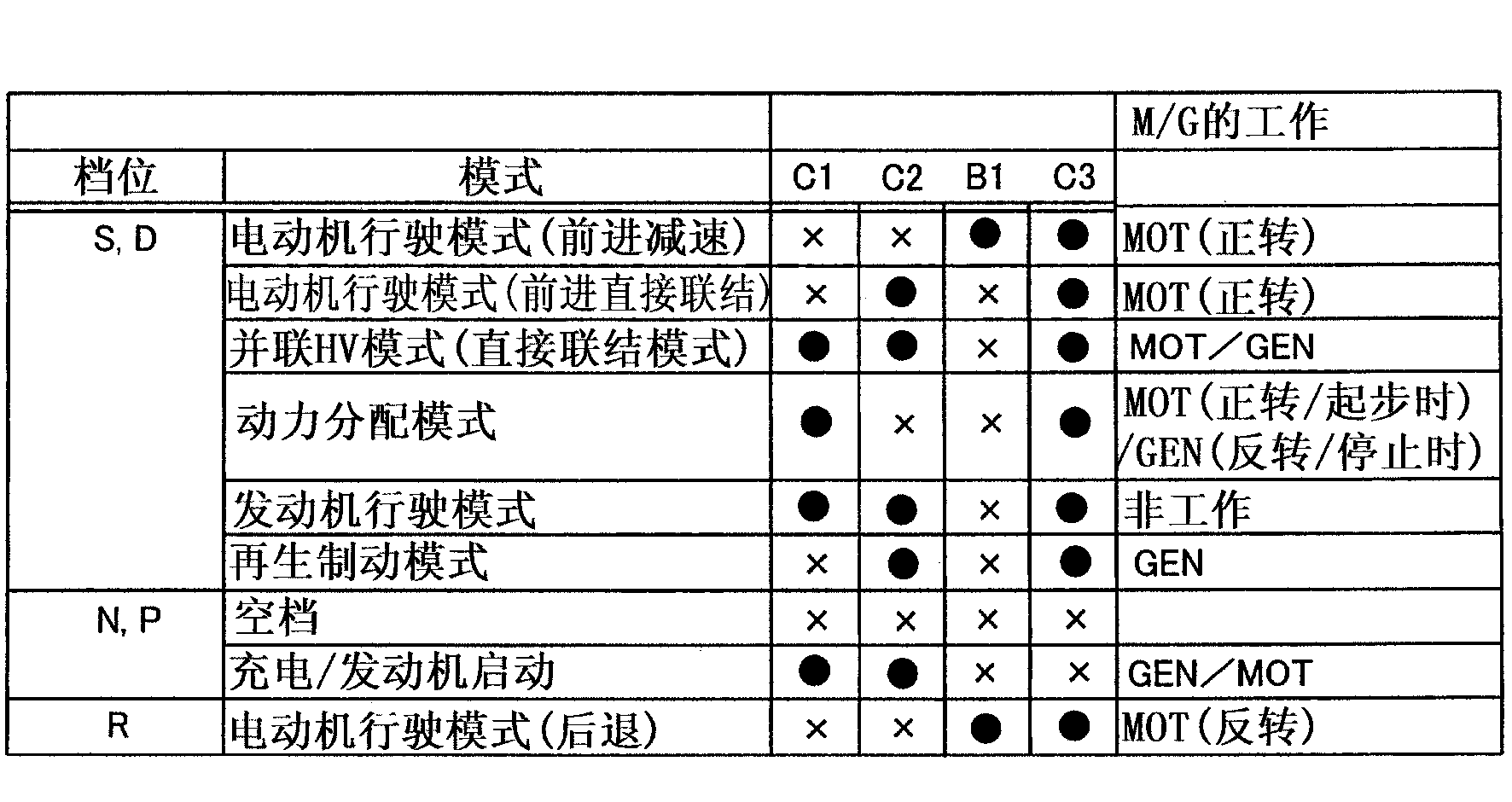

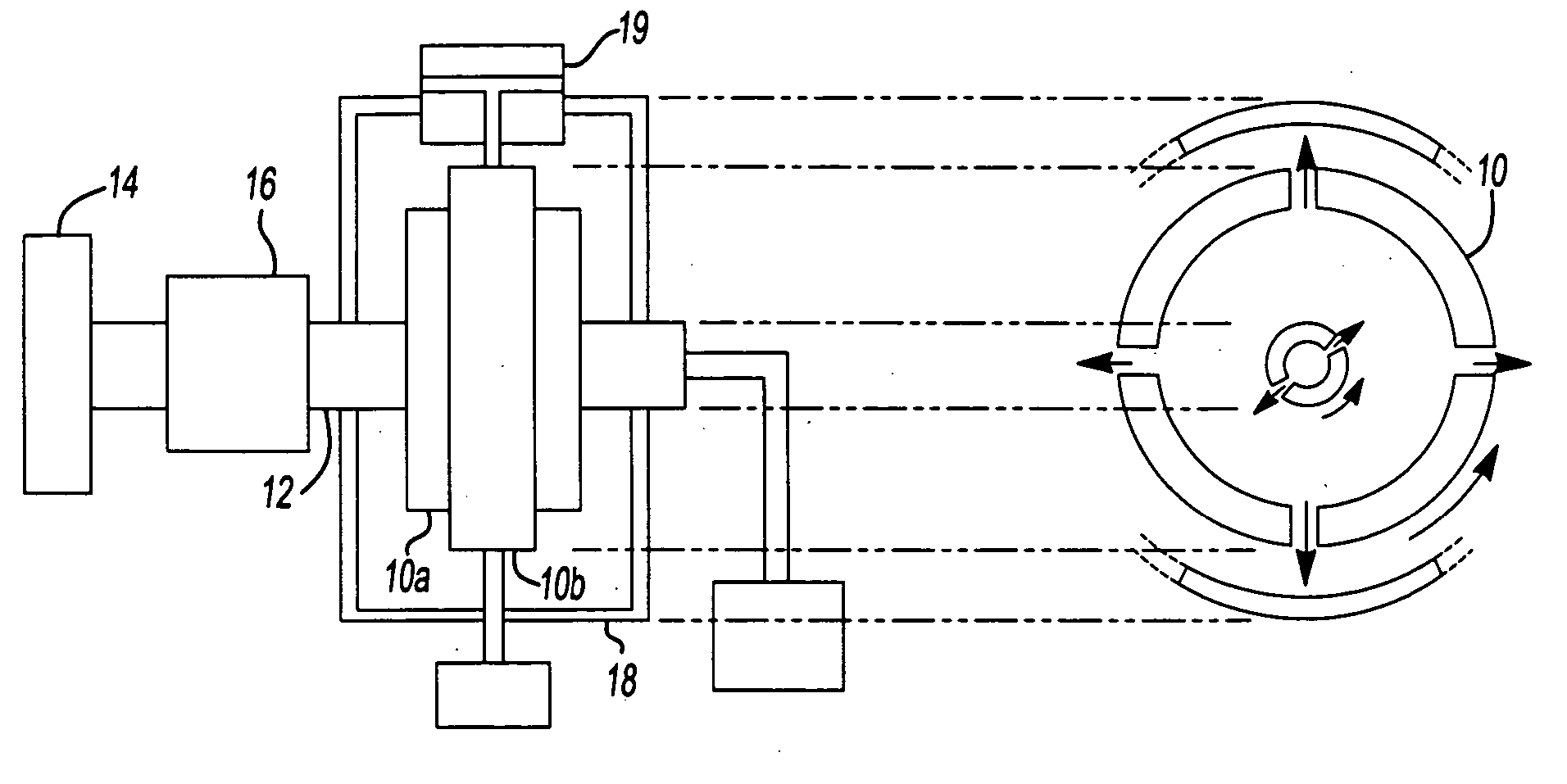

Hybrid drive apparatus

InactiveCN102910066APower transmission loss is smallEfficient regenerationGas pressure propulsion mountingPlural diverse prime-mover propulsion mountingDrive wheelControl theory

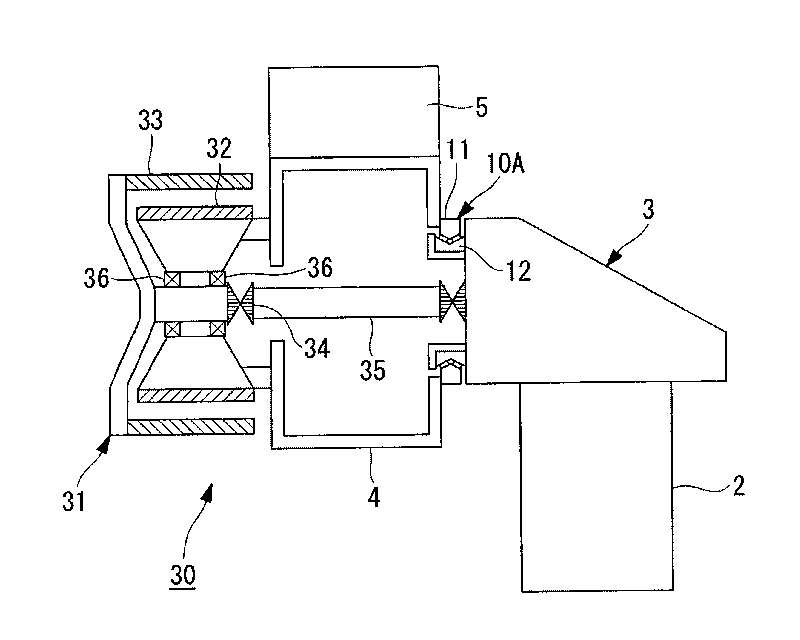

A hybrid drive apparatus is provided and enables efficient energy regeneration by the motor generator by separating the power transmission path through which the driving force from the engine is transmitted, from the power transmission path between the motor generator and the drive wheels, and also makes it possible to achieve a variety of driving modes while improving power transmission efficiency. In a hybrid drive apparatus (1) having an engine (10), a motor generator (20), and a planetary gear mechanism (30) in which the output shaft (21) of the motor generator (20) is coupled to a sun gear (S), the output shaft (11) of the engine (10) is coupled to a ring gear (R), and the input shaft (42) of a continuously variable transmission mechanism (40) is coupled to a carrier (C), the hybrid drive apparatus (1) includes a first clutch (C1) that can switch engagement / disengagement between the output shaft (11) of the engine 11 and the ring gear (R), a second clutch (C2) that can switch engagement / disengagement between the carrier (C) and the ring gear (R), and a third clutch (C3) that can switch engagement / disengagement on the input shaft (42) of the transmission mechanism (40).

Owner:HONDA MOTOR CO LTD

Clamping device with a linking member

ActiveUS8262070B2Slow down the sliding speedMore stable of the second slide memberSemiconductor/solid-state device manufacturingDrawing boardsEngineeringSharp angle

Owner:COMART CORP

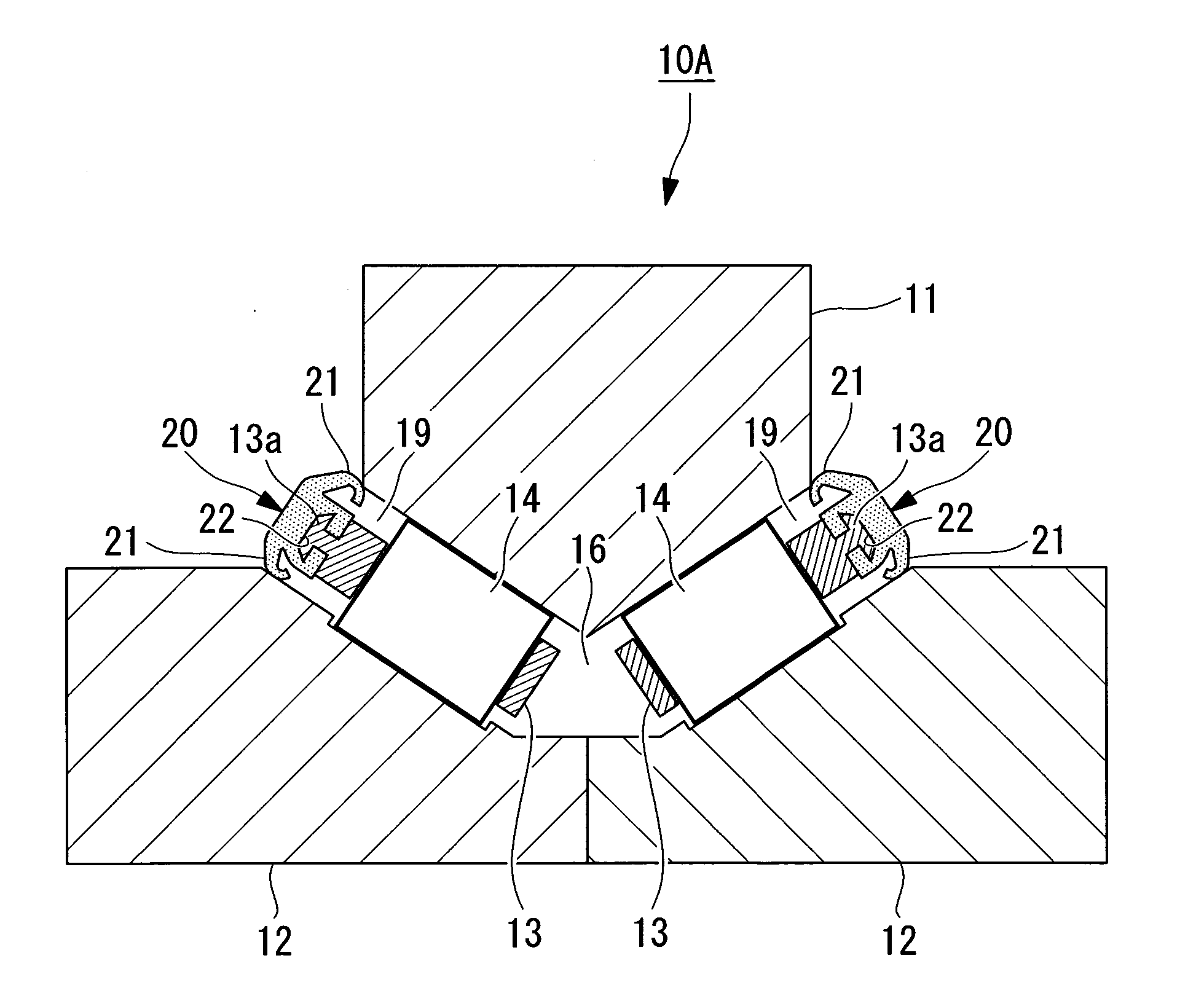

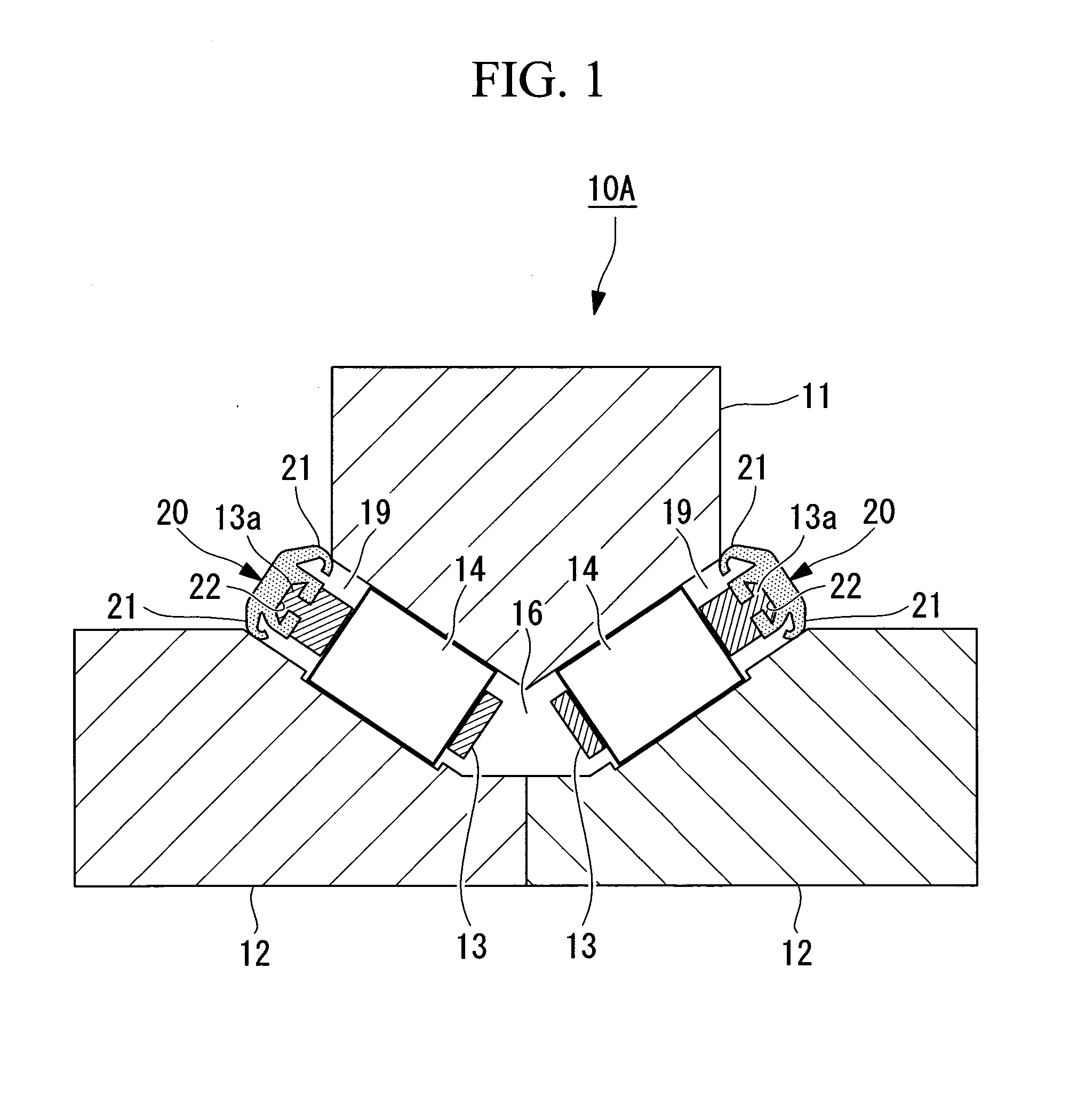

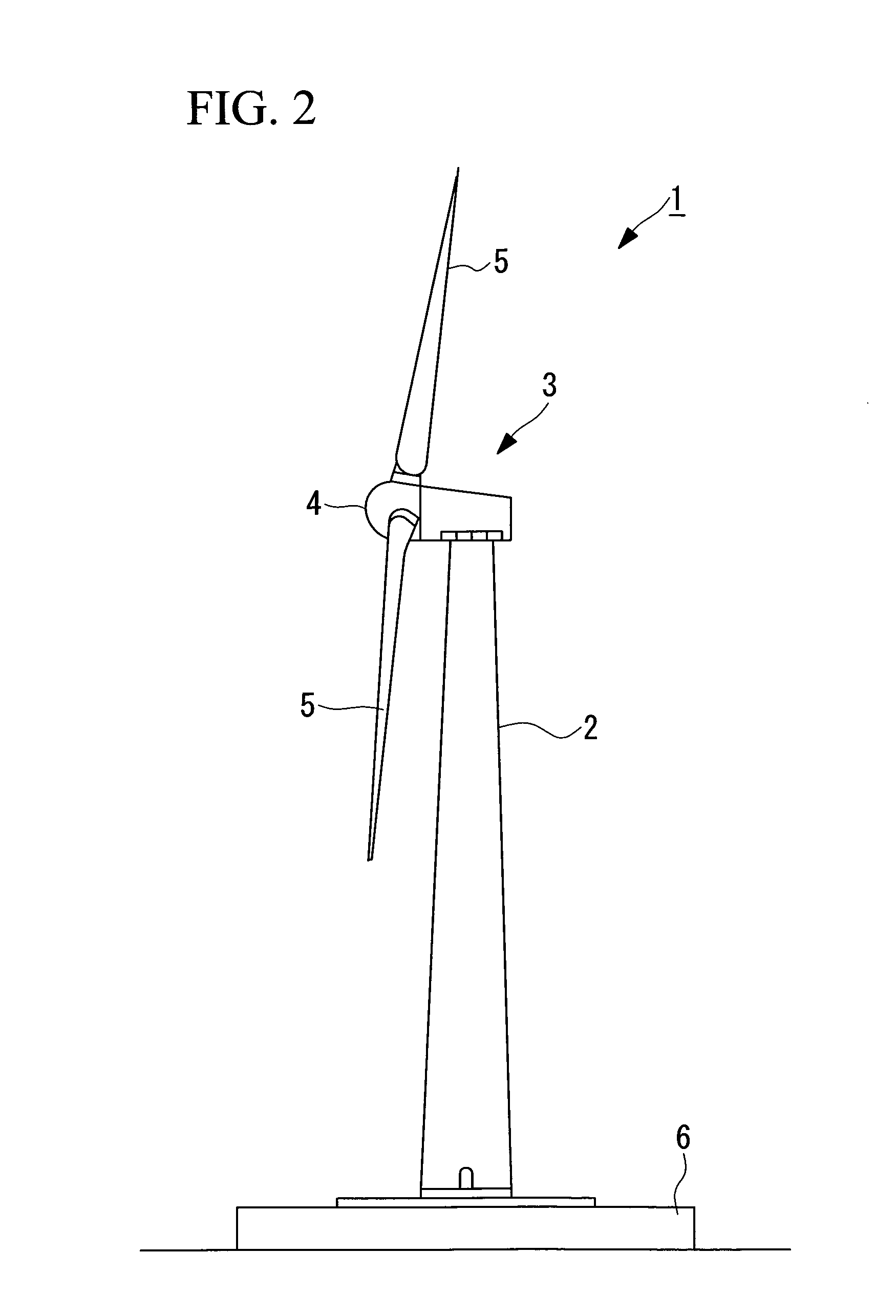

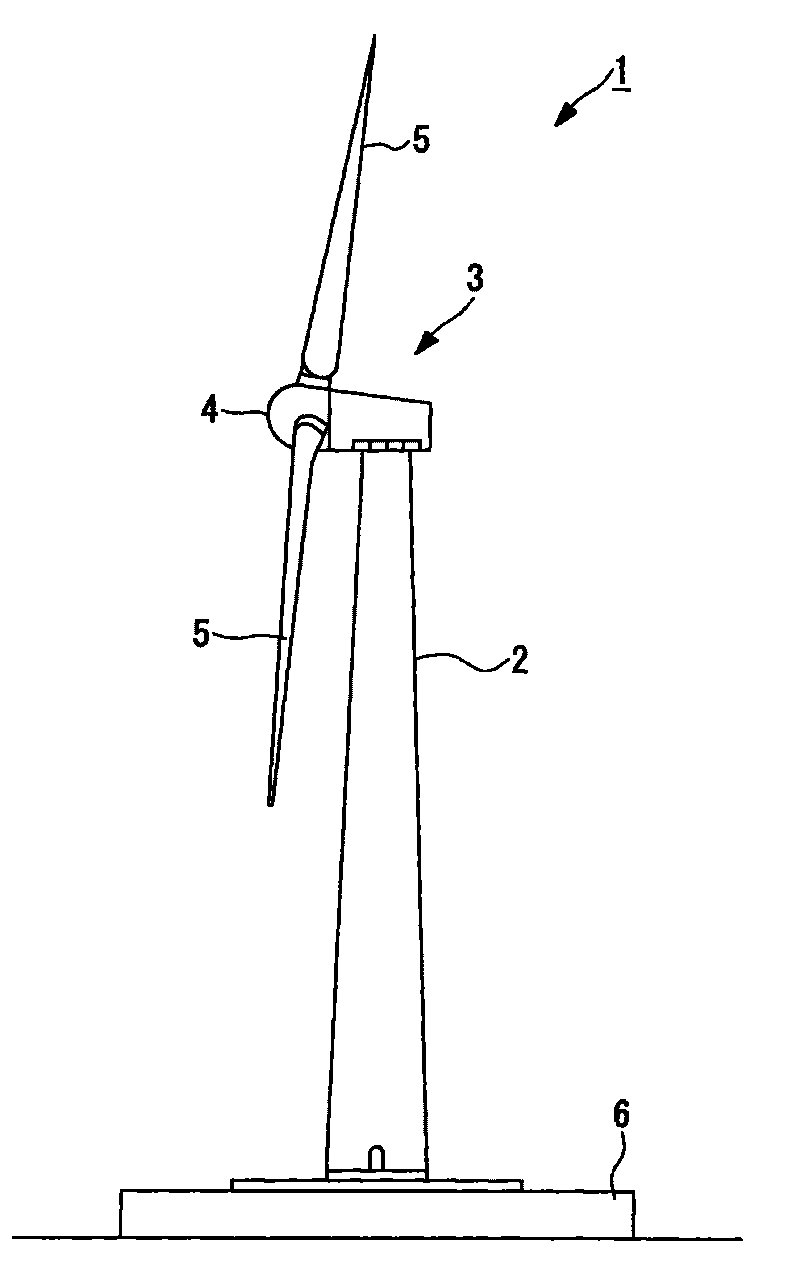

Bearing structure and wind turbine generator

InactiveUS20100308594A1Sliding surface is reducedDeformation to temperature differenceRoller bearingsBearing assemblyTemperature differenceEngineering

A bearing structure that reduces the relative sliding speed of a sealing ring and a contact surface and suppresses relative deformation due to a temperature difference of inner and outer rings is provided. A rolling member is disposed inside a space formed between an outer ring and an inner ring, the outer ring or the inner ring rotating relatively via the rolling element, wherein a sliding section of the surface of the rolling member and the inner surface of the space is lubricated with a lubricant supplied into the space, and a sealing ring attached to a supporter supporting the rolling element seals an opening of the space at an end section in the axial direction.

Owner:MITSUBISHI HEAVY IND LTD

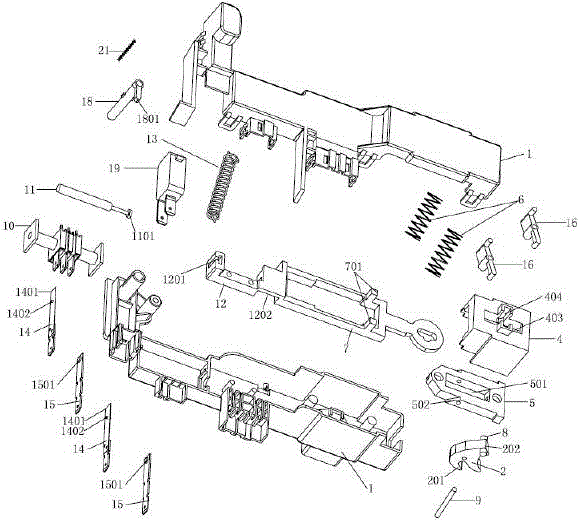

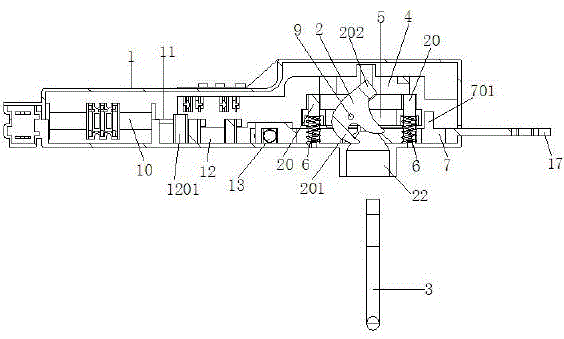

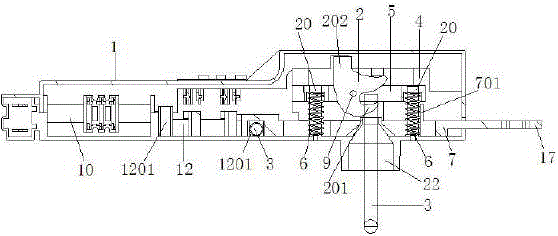

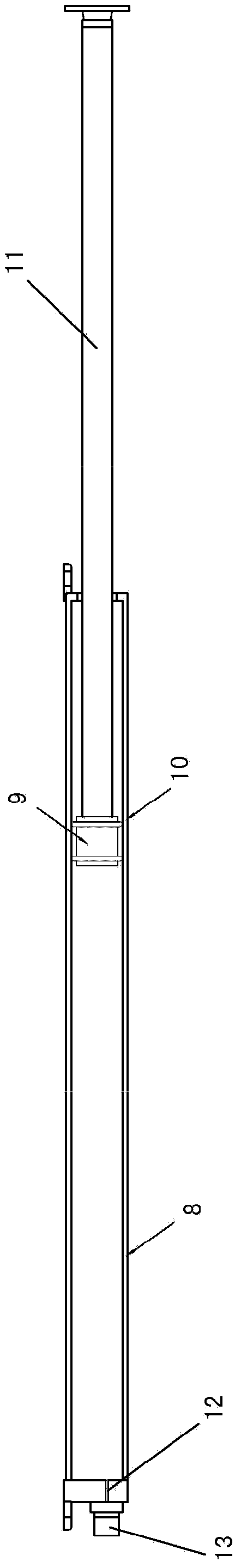

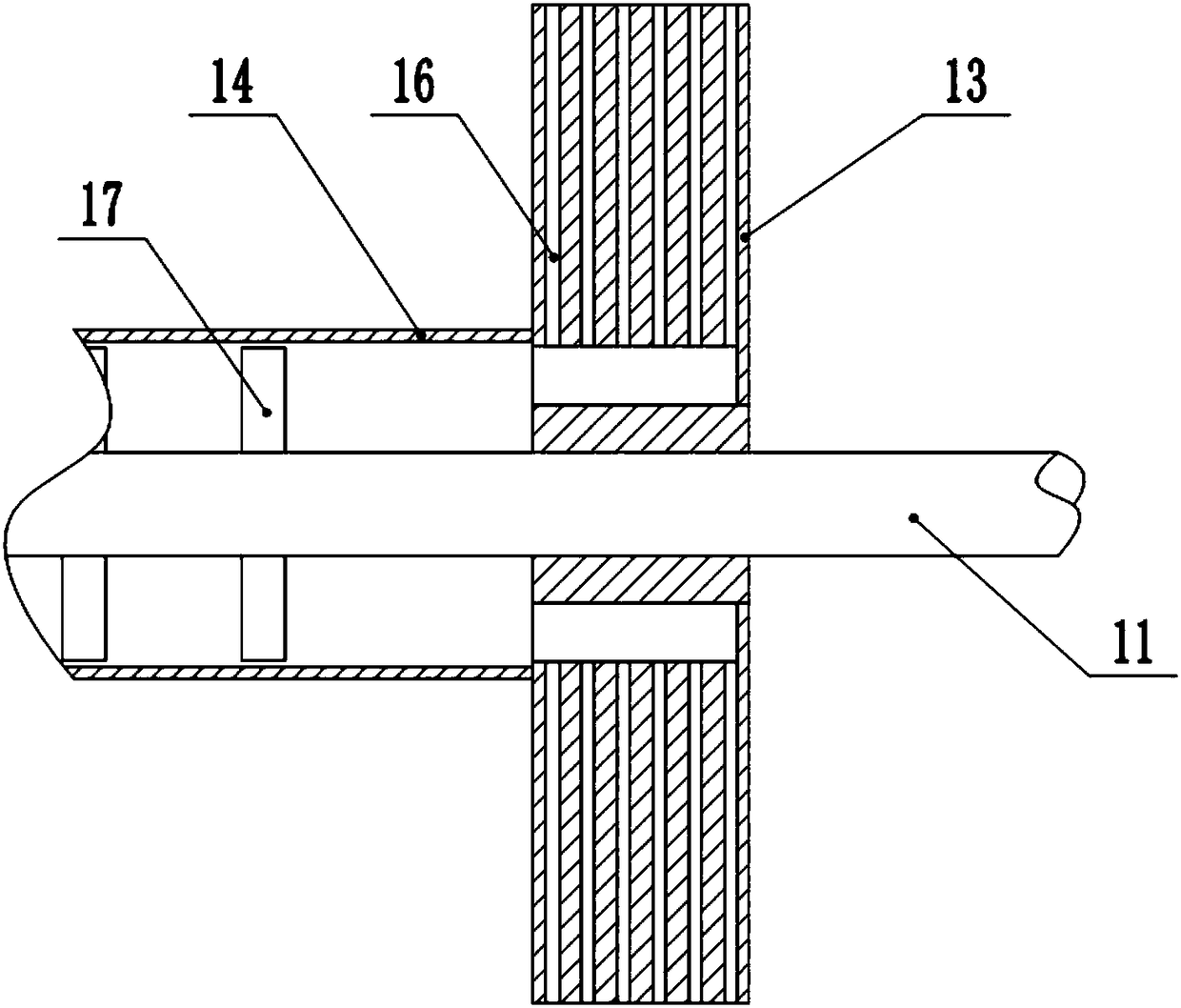

Washing machine door lock

ActiveCN104805644AEasy processing and assemblySimple cooperationOther washing machinesTextiles and paperLaundry washing machineControl theory

The invention discloses a washing machine door lock. The washing machine door lock comprises a lock case, a rotating part hooked up with a door hook and a locking device for locking or unlocking the rotating part combined with the door hook; the locking device comprises a first limiting part formed with a lug with a first inclined surface and capable of sliding left and right, a second limiting part formed with a second inclined surface matched with the first inclined surface and capable of sliding up and down, a limiting biasing part for applying bias pressure to the second limiting part towards the first limiting part, and a locking rod capable of locking or unlocking the second limiting part under the control of the first control device; the rotating part drives the first limiting part to move left and right by use of a first connecting structure; the limiting biasing element pushes the second limiting part to slide towards the first limiting part by virtue of the matching of the first inclined surface and the second inclined surface. According to the washing machine door lock, the rotating part is locked or unlocked by virtue of the sliding matching of the first limiting part, the second limiting part and the locking rod so that the washing machine door lock can be opened or closed; the washing machine door lock is easy to manufacture and assembly, and good in stability.

Owner:WENZHOU TIANJIAN ELECTRIC APPLIANCE

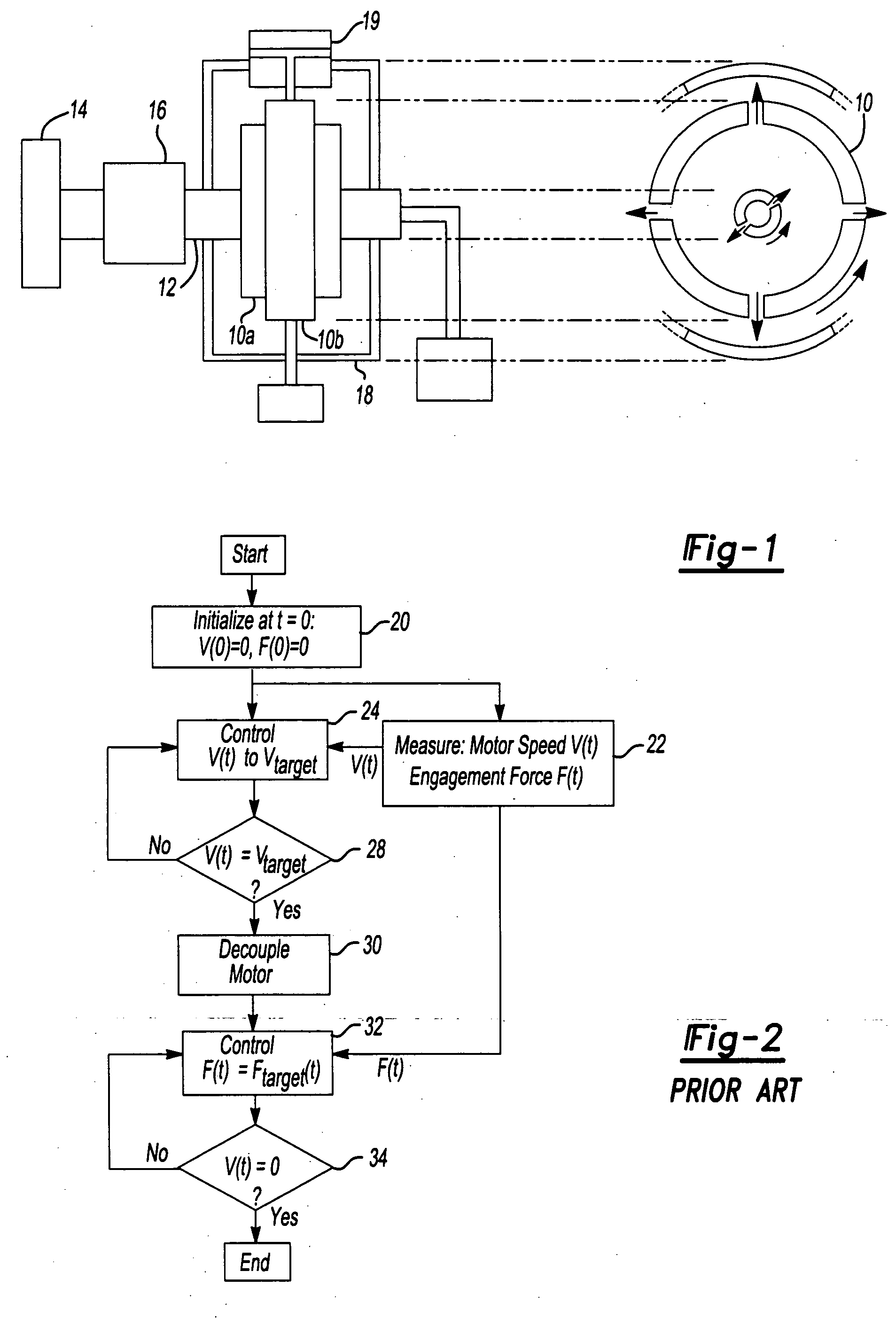

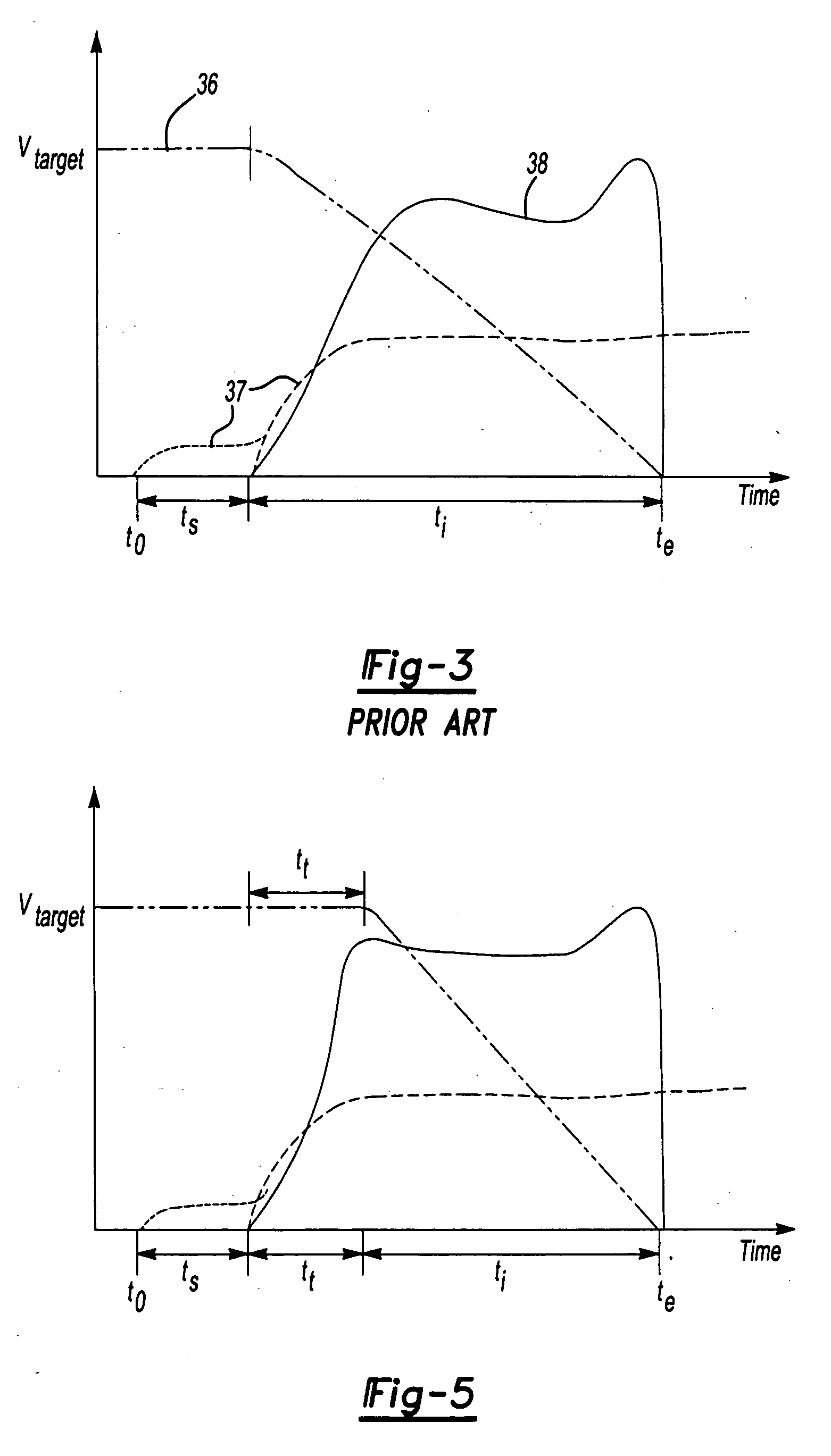

Method of testing friction components for automatic transmissions

InactiveUS20050126272A1Accurately simulate friction component performanceContinue operationMachine gearing/transmission testingEngine testingVariatorMotor drive

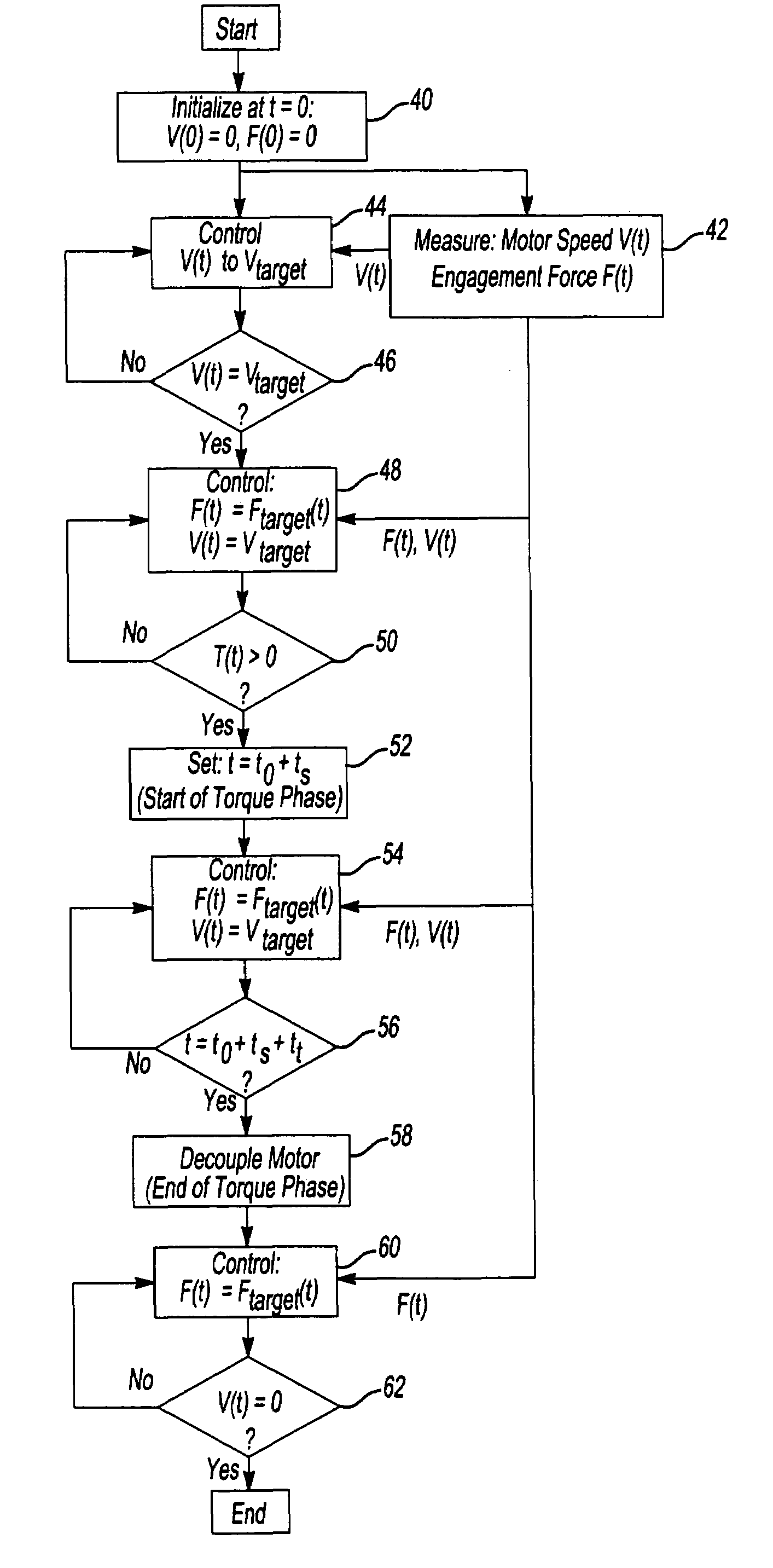

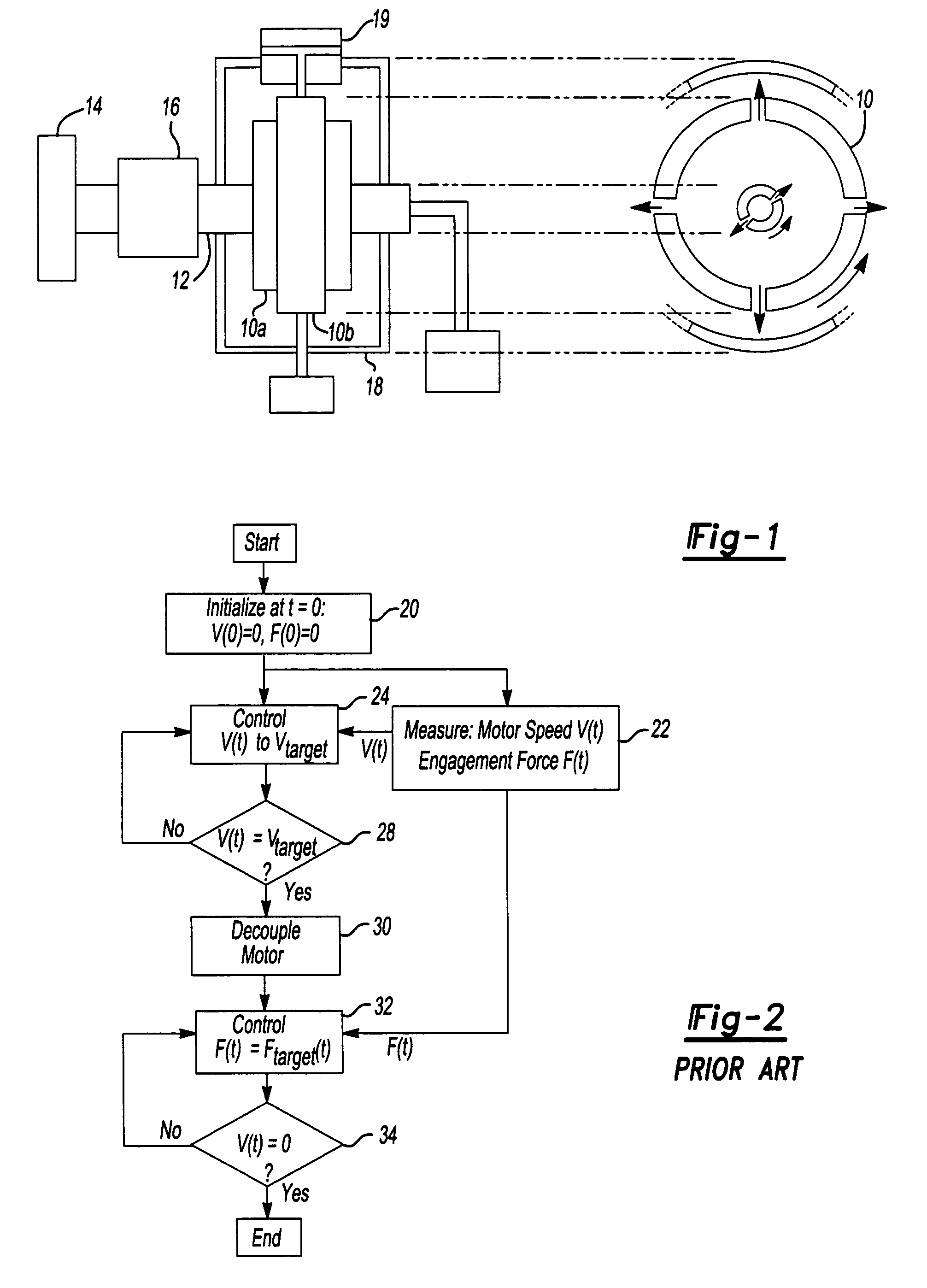

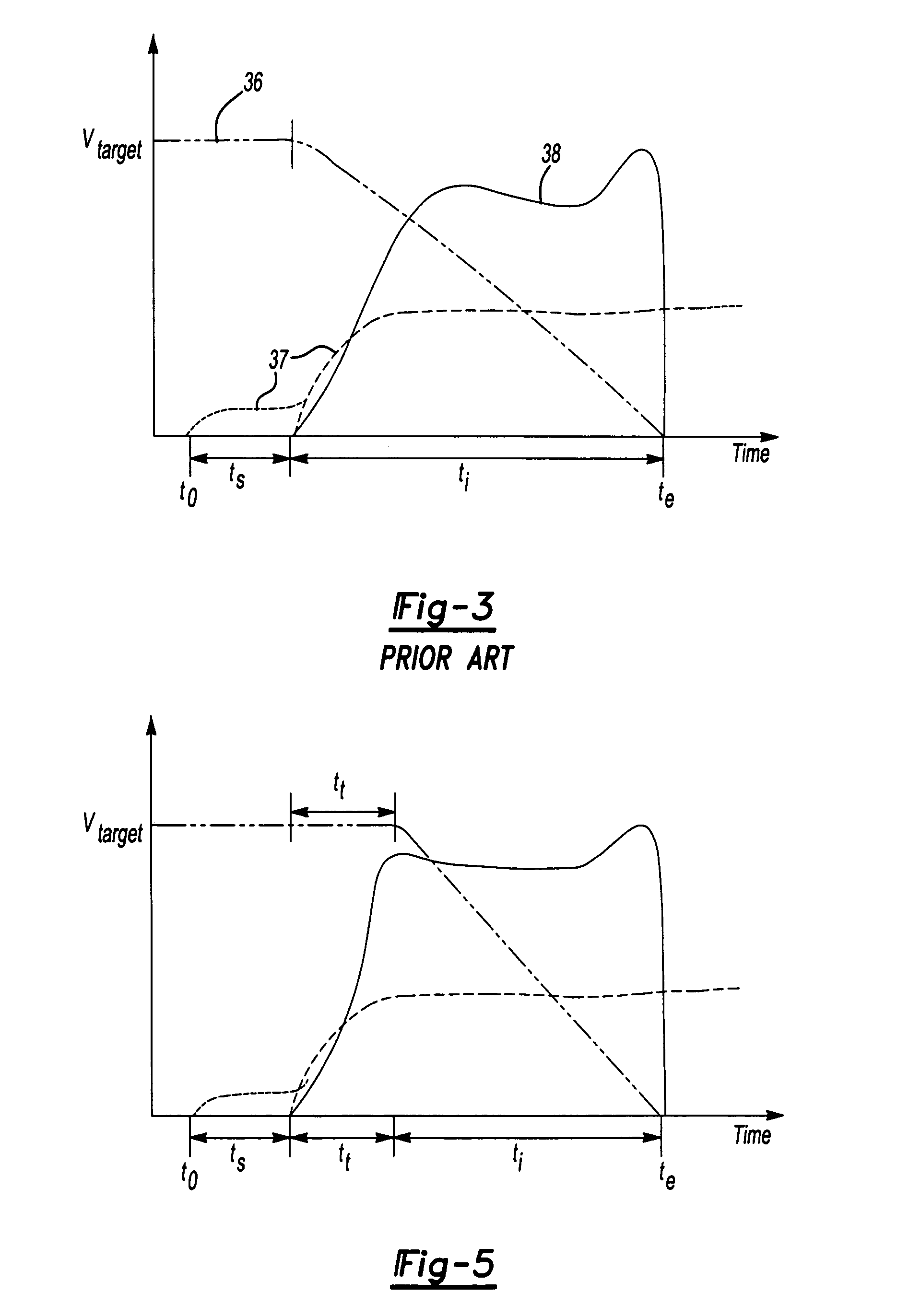

A method of testing a friction component for a transmission that has first and second parts. The first part of the friction component is attached to a drive shaft and the second part is attached to a grounding element. The first part of the friction component is rotated until the drive shaft and the first part of the friction component rotate at a target sliding speed Vtarget. An actuation force is applied to the friction component at a time t0. Operation of the motor drive is continued to maintain the speed of rotation of the drive shaft at Vtarget until a predetermined level of engagement torque Tth is obtained. The motor torque is then reduced to a predetermined level Tm. The sliding speed of the drive shaft is then decreased and the test is terminated when the sliding speed falls to zero.

Owner:LINK ENG

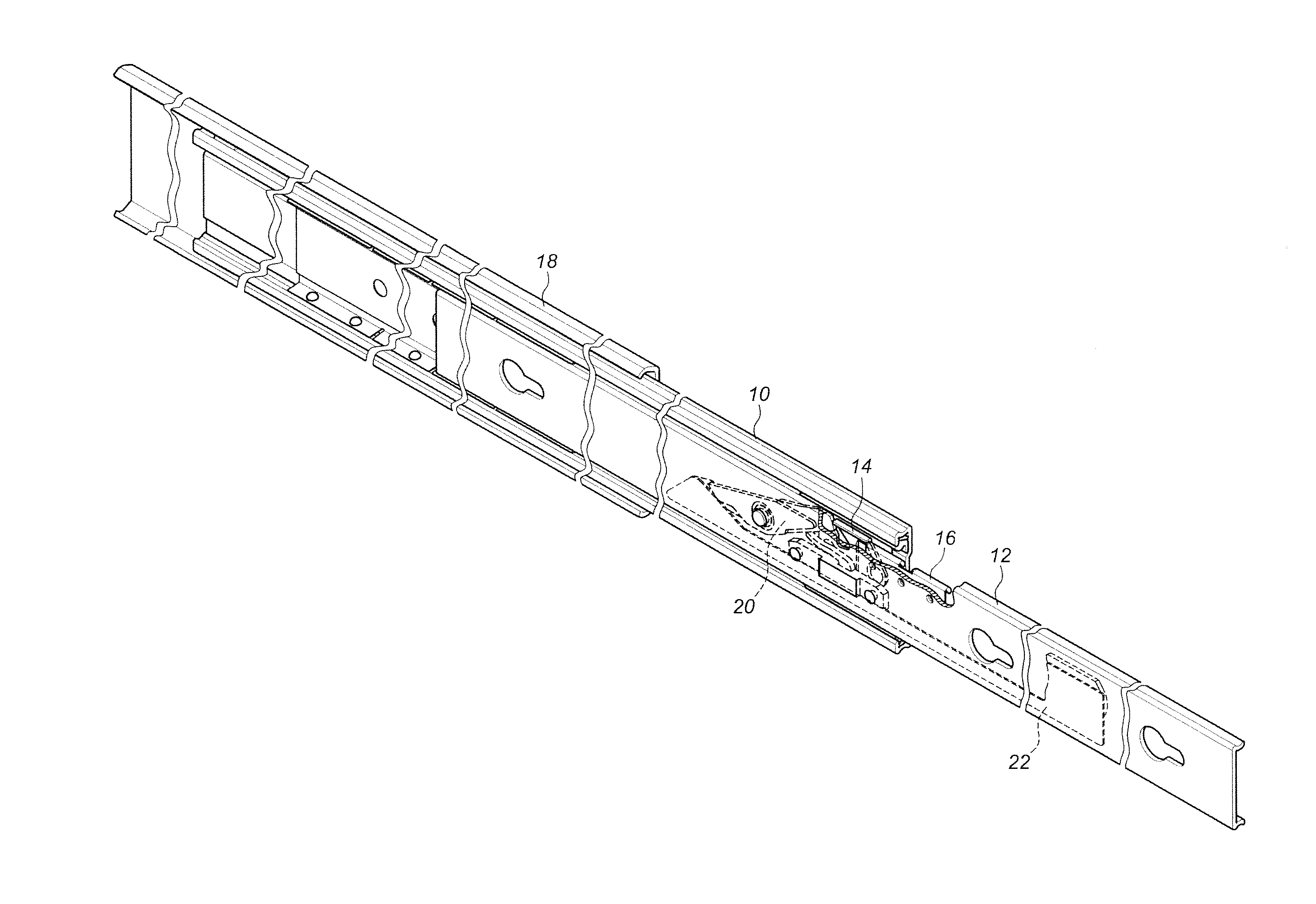

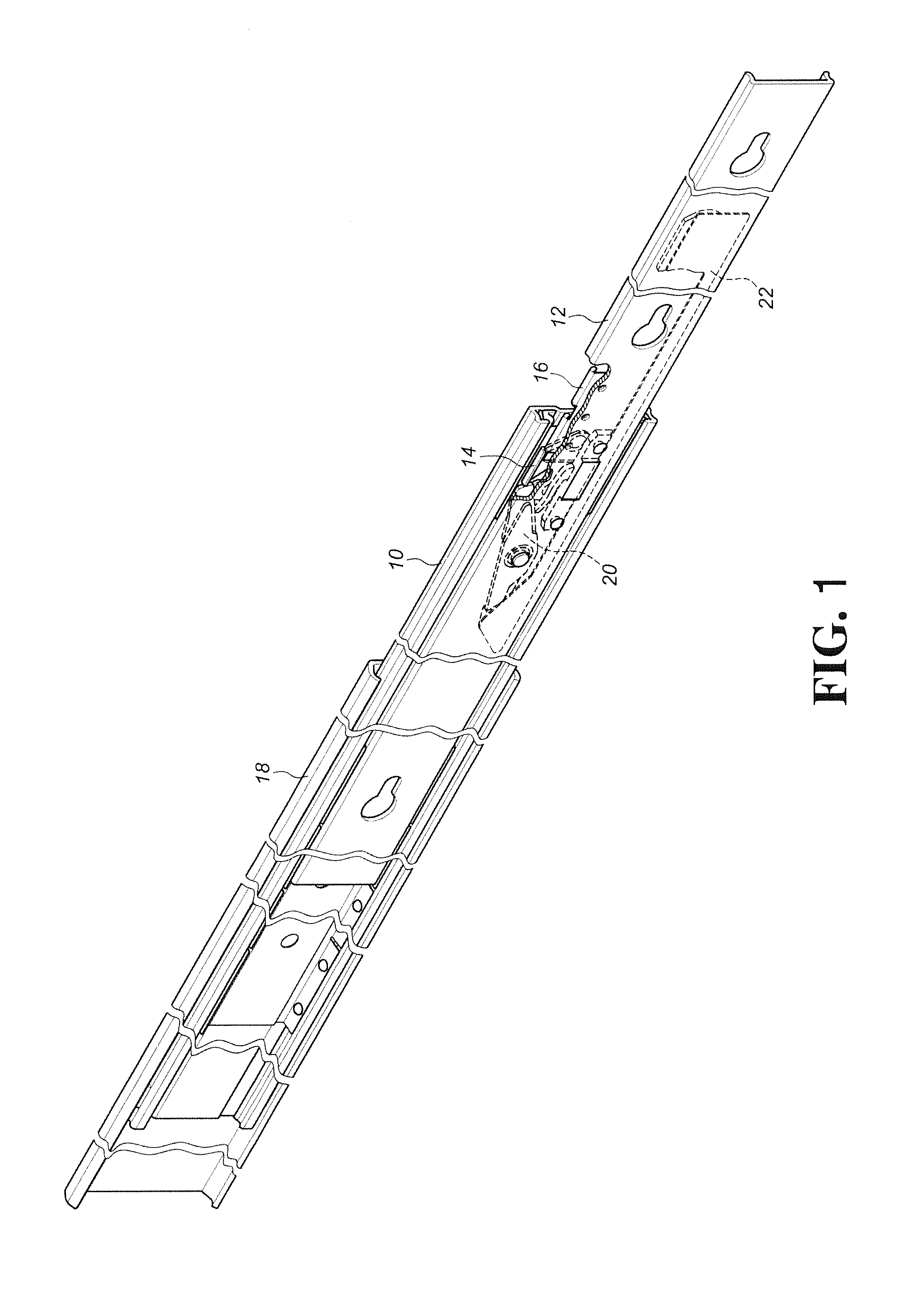

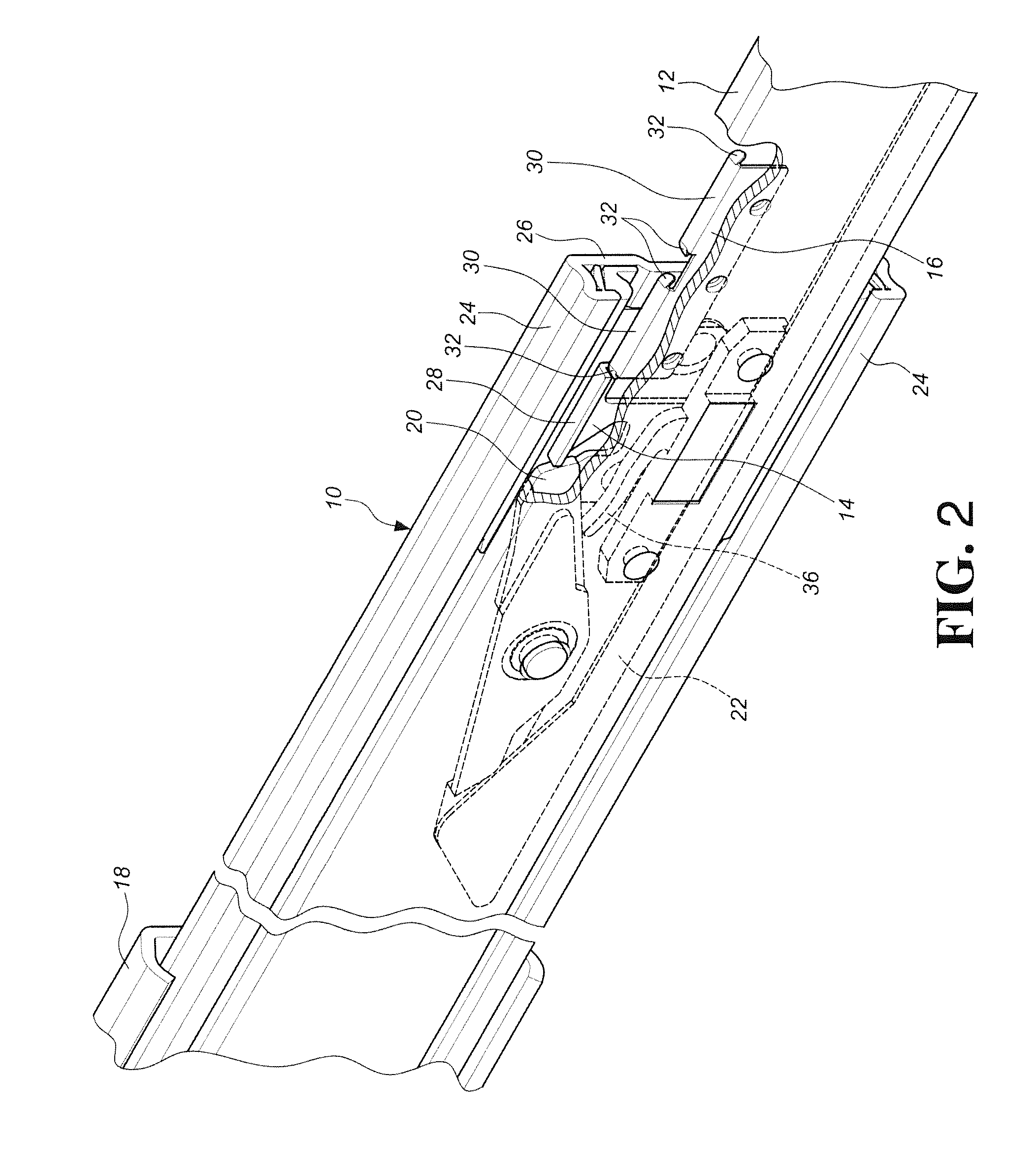

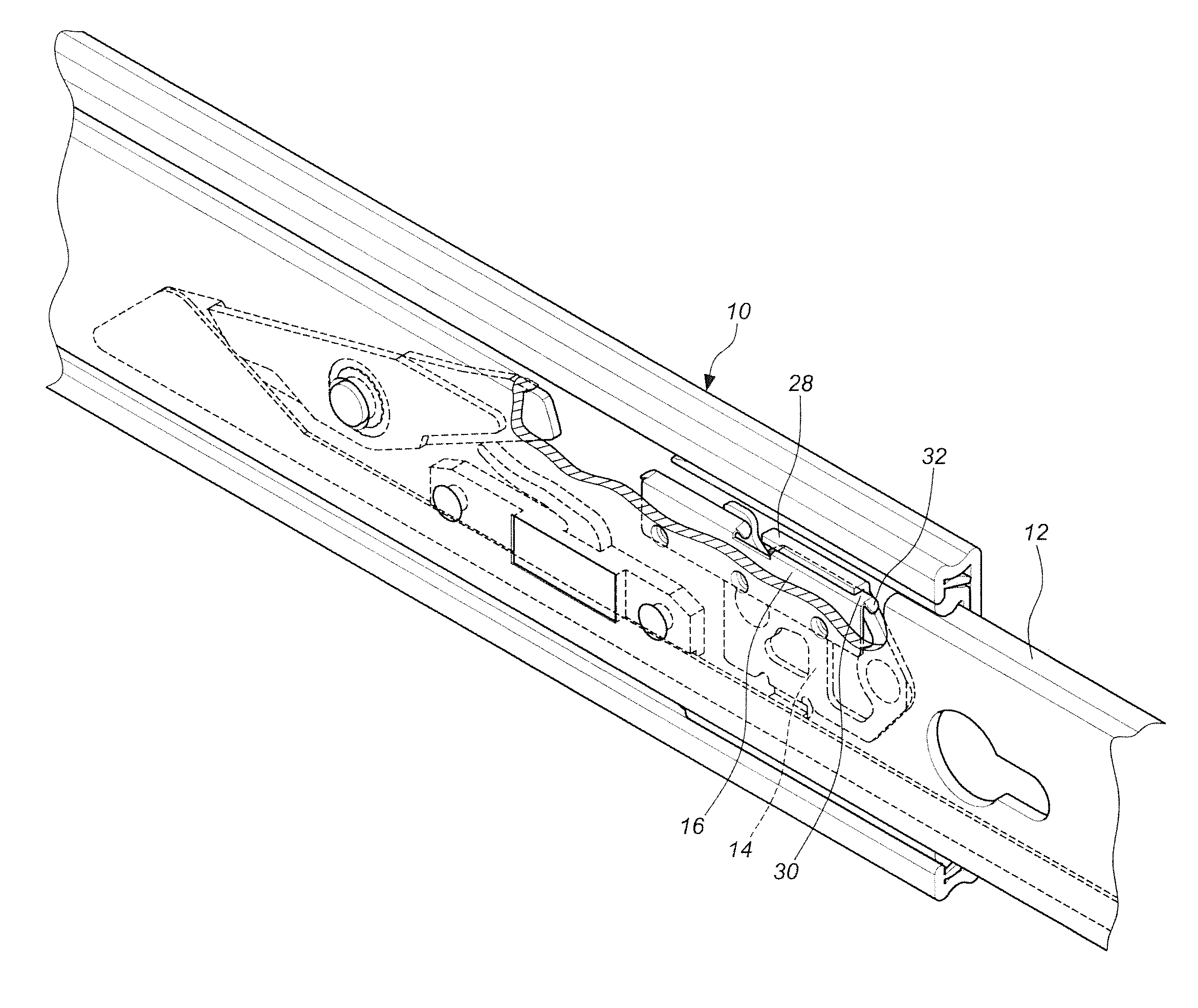

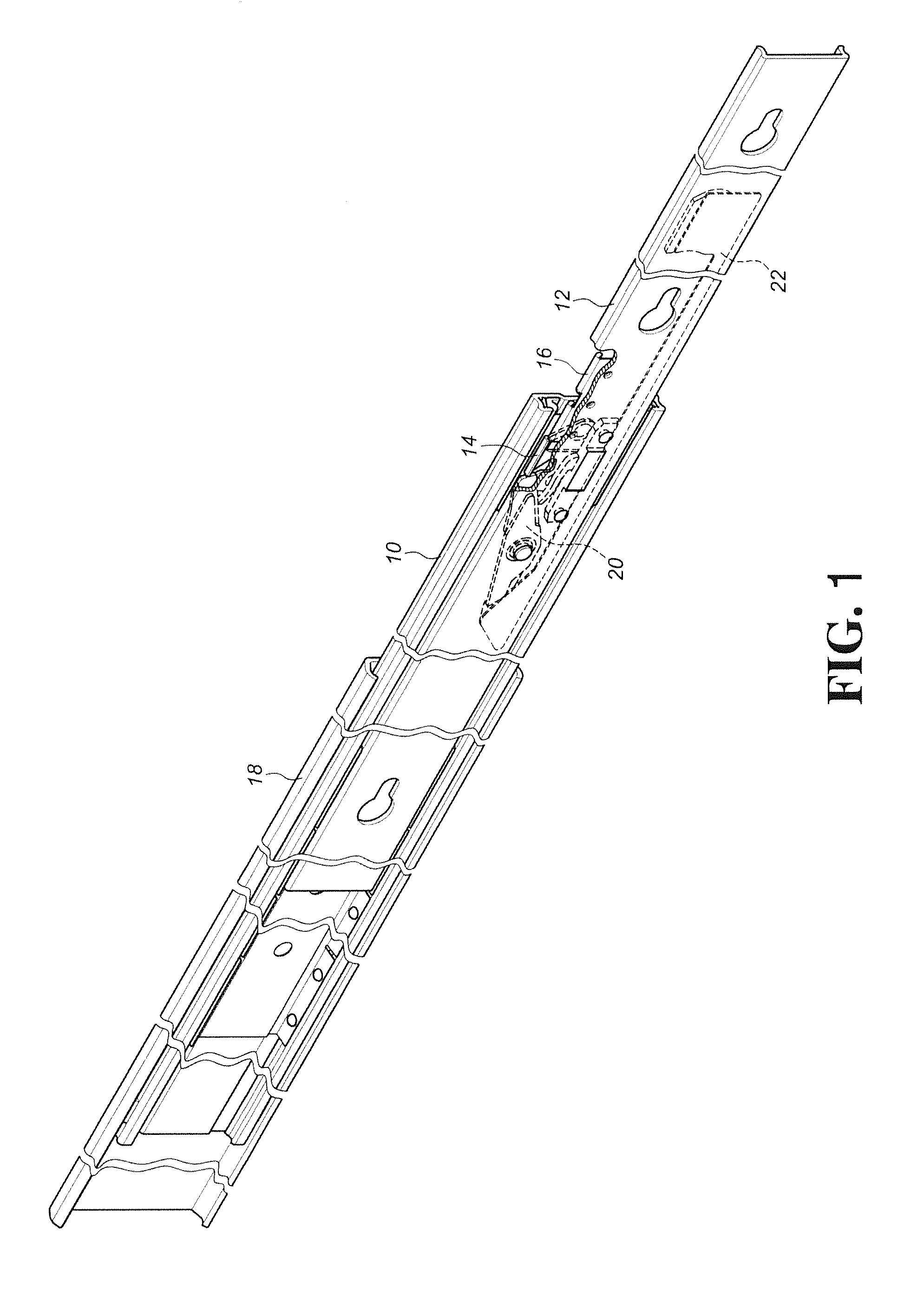

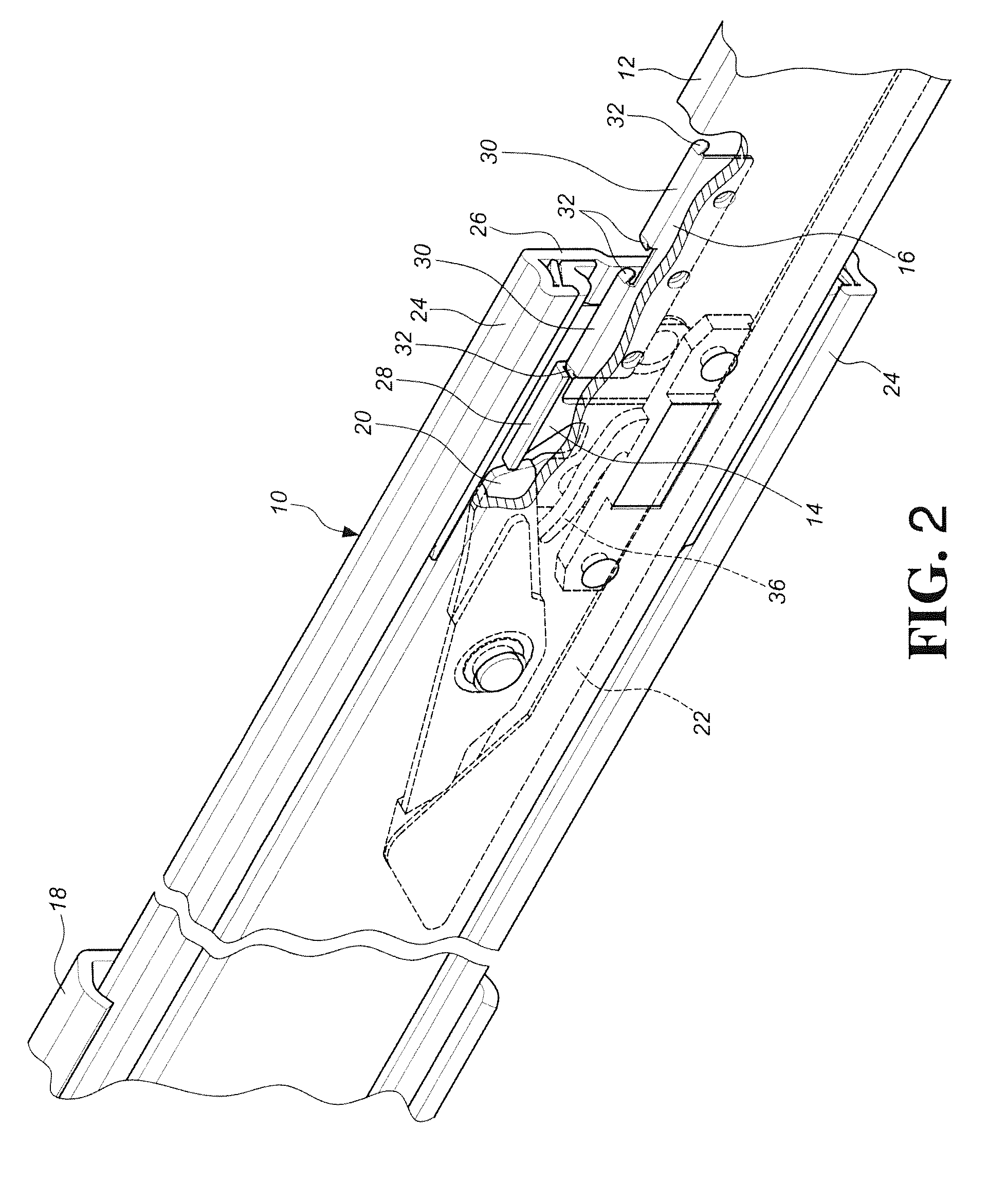

Slide assembly with deceleration device

ActiveUS20140327352A1Reduce sliding speedReduce impact force and noiseBuilding braking devicesWing suspension devicesEngineeringMechanical engineering

A slide assembly includes a first rail, a second rail, a stop member and a friction member. The first rail includes two sidewalls with a connection wall connected therebetween. The second rail is slidably located between the two sidewalls of the first rail. The stop member is fixed to the connection wall and has a stop plate which is perpendicular to the connection wall. The friction member is fixed to the second rail and has an extension portion. The extension portion has a guide face. When the second rail is moved relative to the first rail after the friction member touches the stop plate and overlaps the stop member by the guide face, the friction member is slidably and flexibly in contact with the stop plate.

Owner:KING SLIDE WORKS CO LTD +1

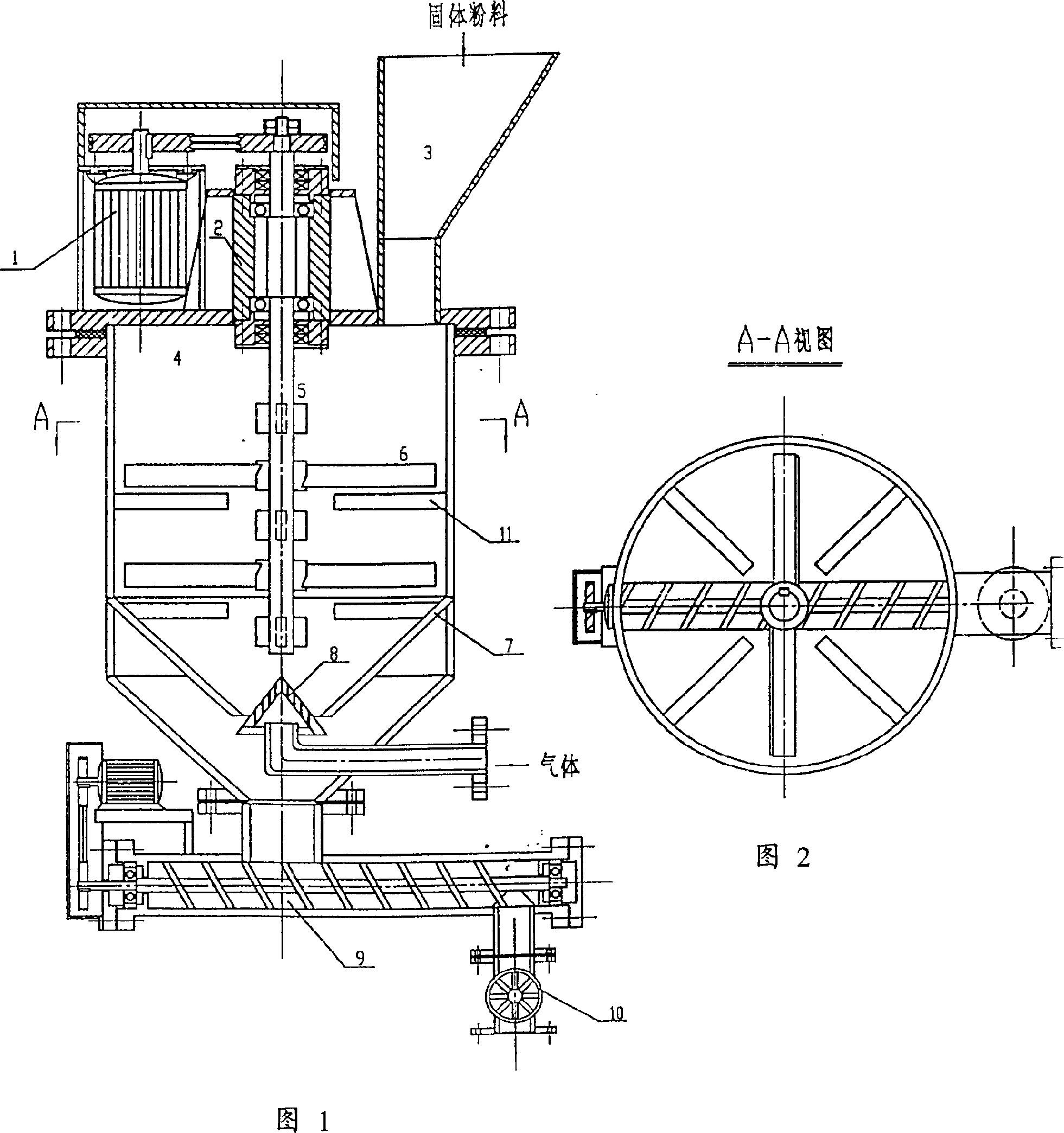

Gas-solid reactor

InactiveCN1448211ATake advantage ofImprove mass transfer conditionsMixing gases/vapours with solidsGas solidSpool valve

The gas-solid reactor includes the main parts of main body, solid feeding port, tail gas exhausting port, stirring shaft, stirring blades, truncated cone solid discharger, turned conic gas distributor, screw conveyor, air sealed slide valve and baffle. The main body includes cylindrical upper part and conic lower part; the solid feeding port and the tail gas exhausting port are in the top of thereactor; the stirring shaft with fixed stirring blades is perpendicular to the central axis of the reactor; the inner wall of the reactor has one or several layers of baffles set; the solid discharger is in the lower part of the reactor; the gas distributor with homogeneously distributed holes is below the solid discharger; and the bottom of the reactor is connected to the screw conveyor; and theslide valve is set on the material discharging pipe of the screw conveyor.

Owner:CHINA PETROLEUM & CHEM CORP +1

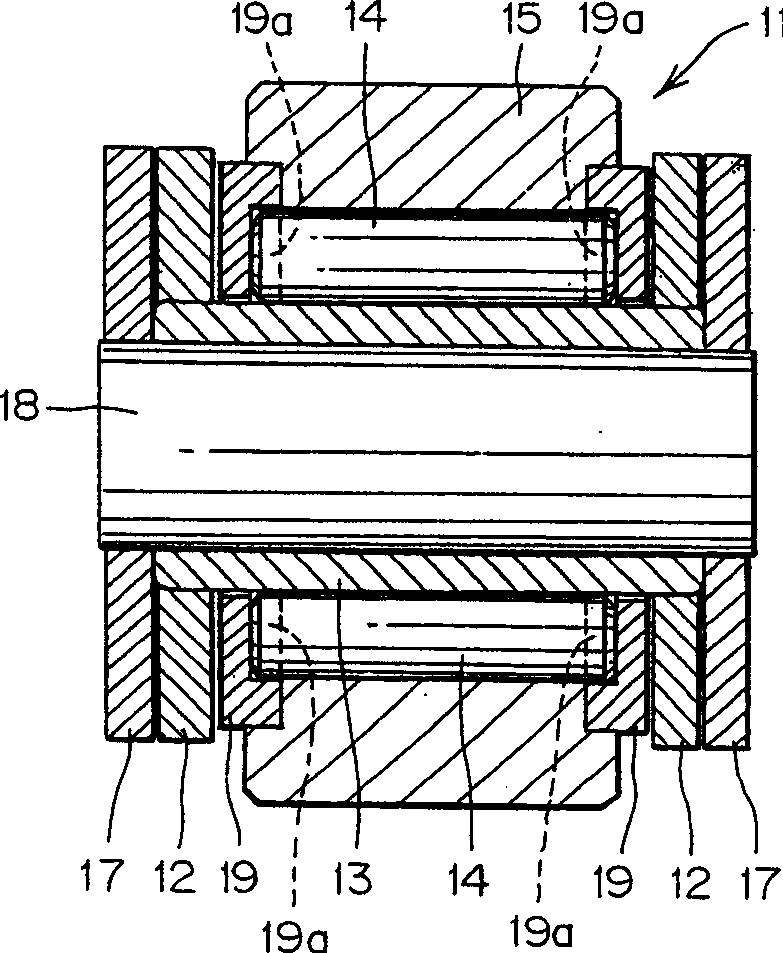

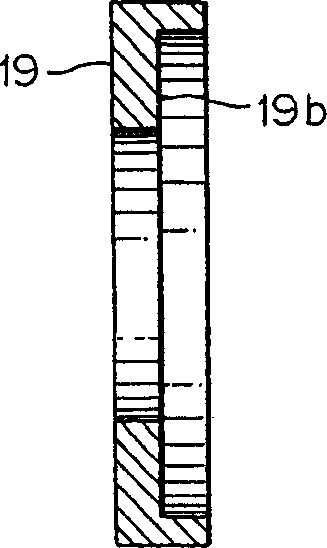

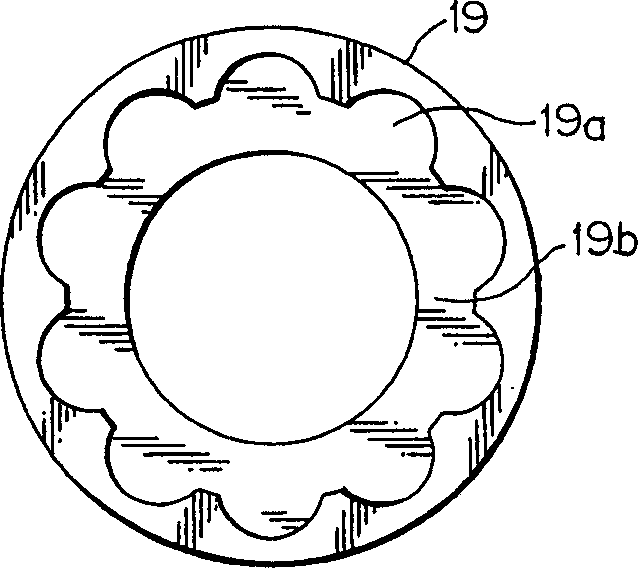

Roller bearing and roller chain mounted with roller bearing

InactiveCN1374463ASmooth rotationImprove wear resistanceConveyorsRotary combination bearingsRoller chainMechanical engineering

A roller chain equipped with roller bearings, in which a plurality of rollers are arranged between a roller as an outer ring and a bush as an inner ring, including a substantially Ring cage. The cage includes a plurality of pockets for guiding at least a portion of each of the rollers inside the cage.

Owner:TSUBAKIMOTO CHAIN CO

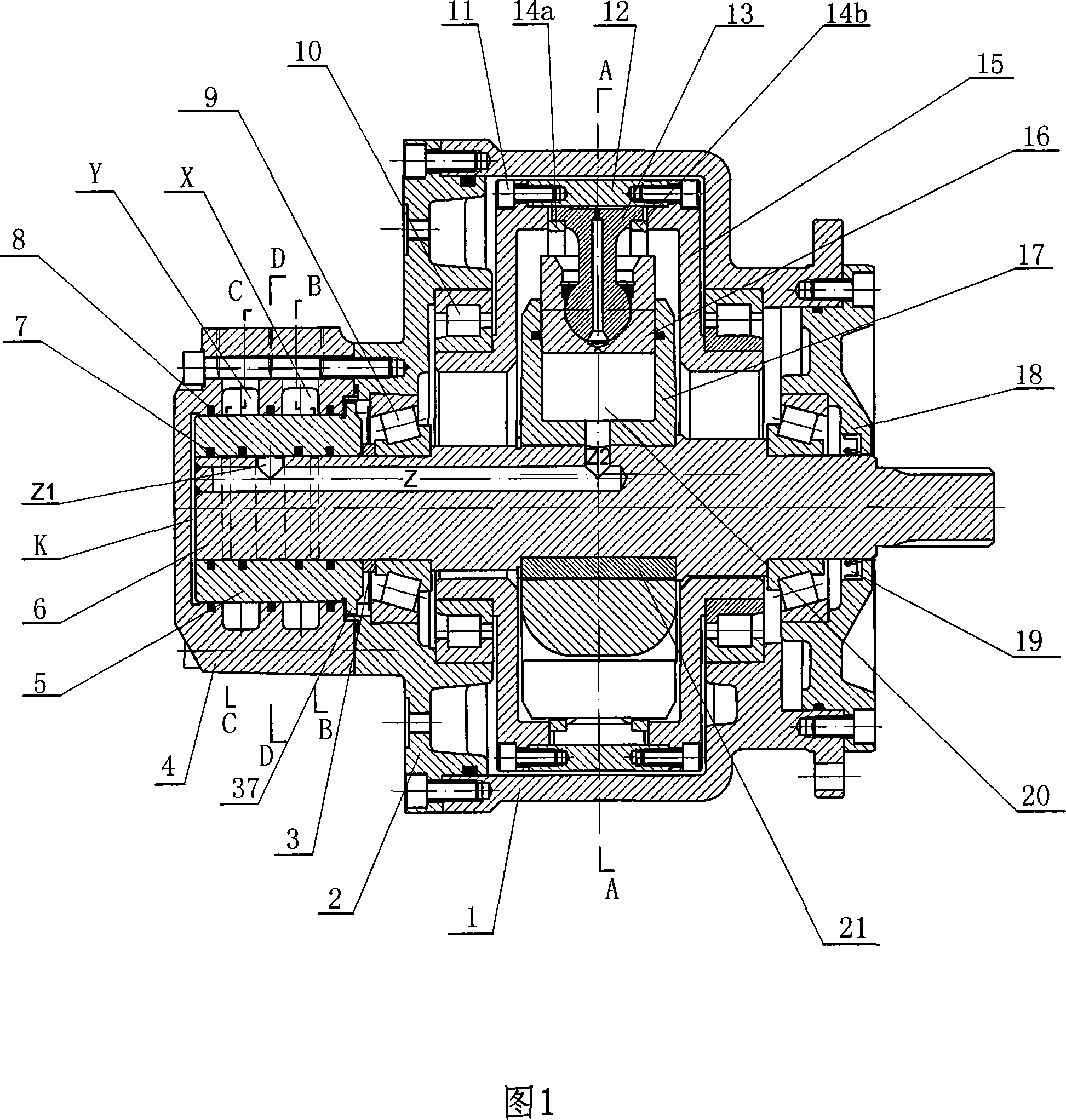

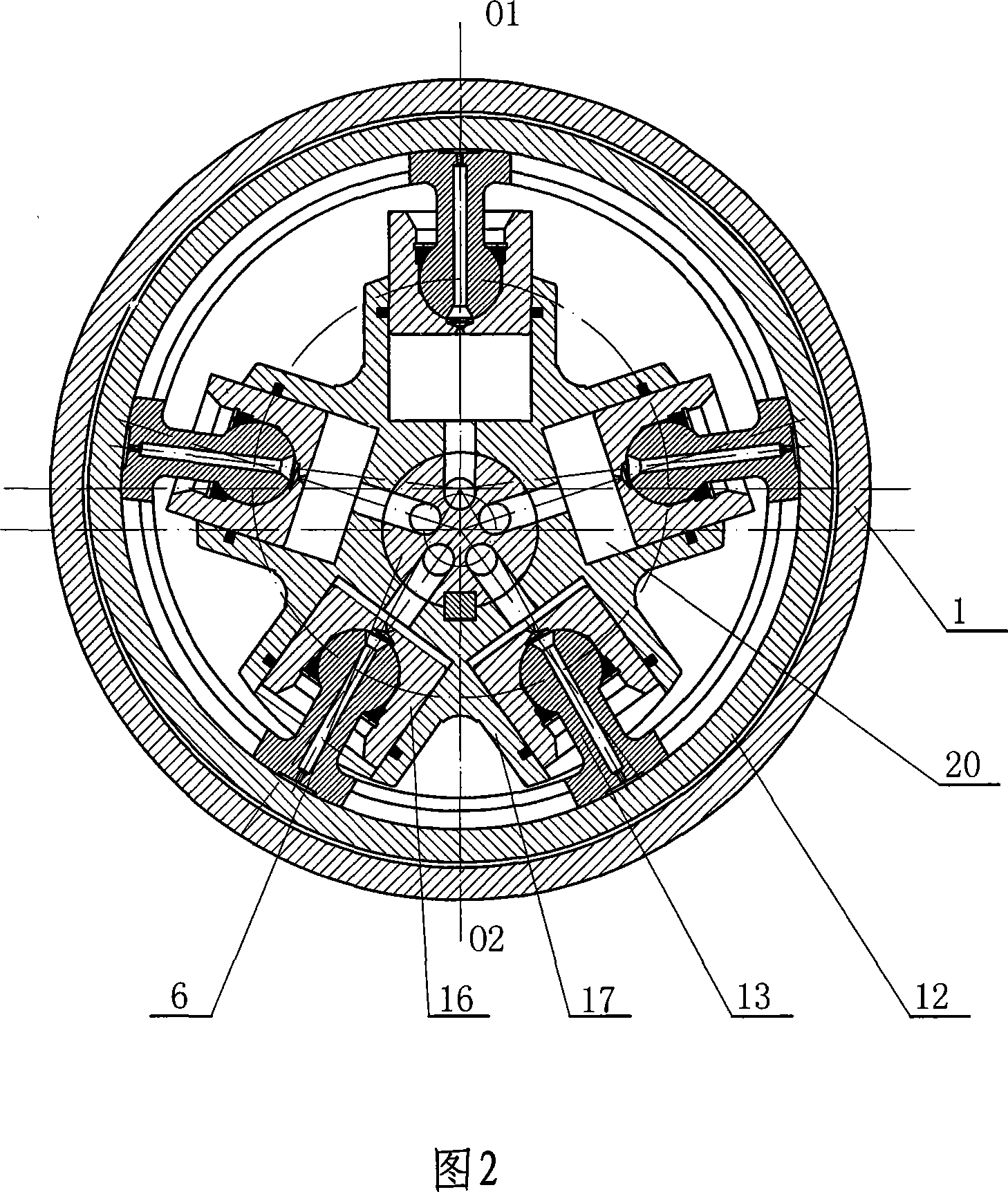

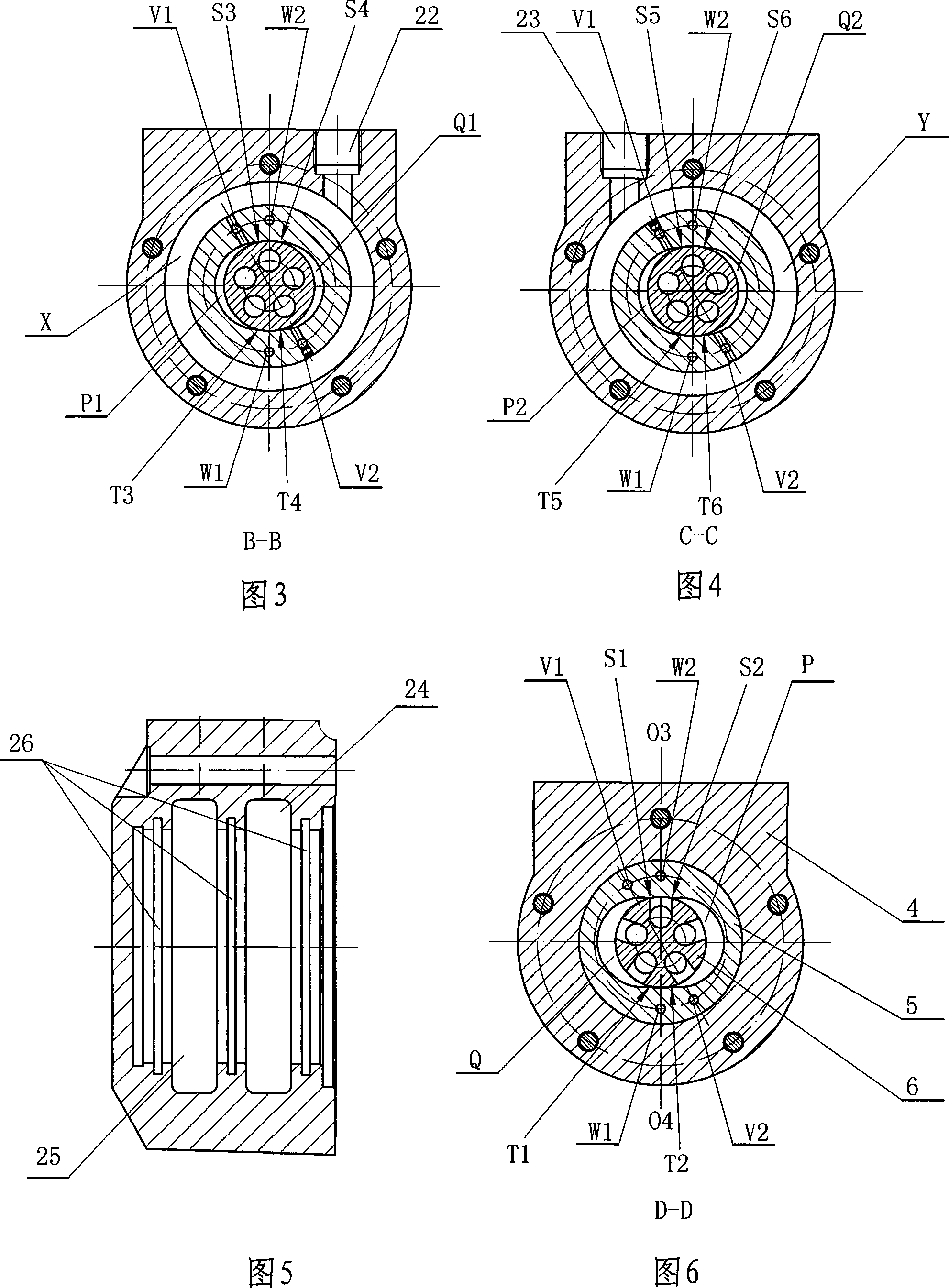

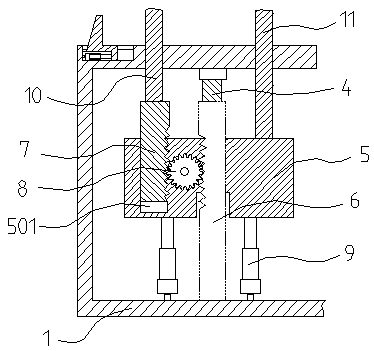

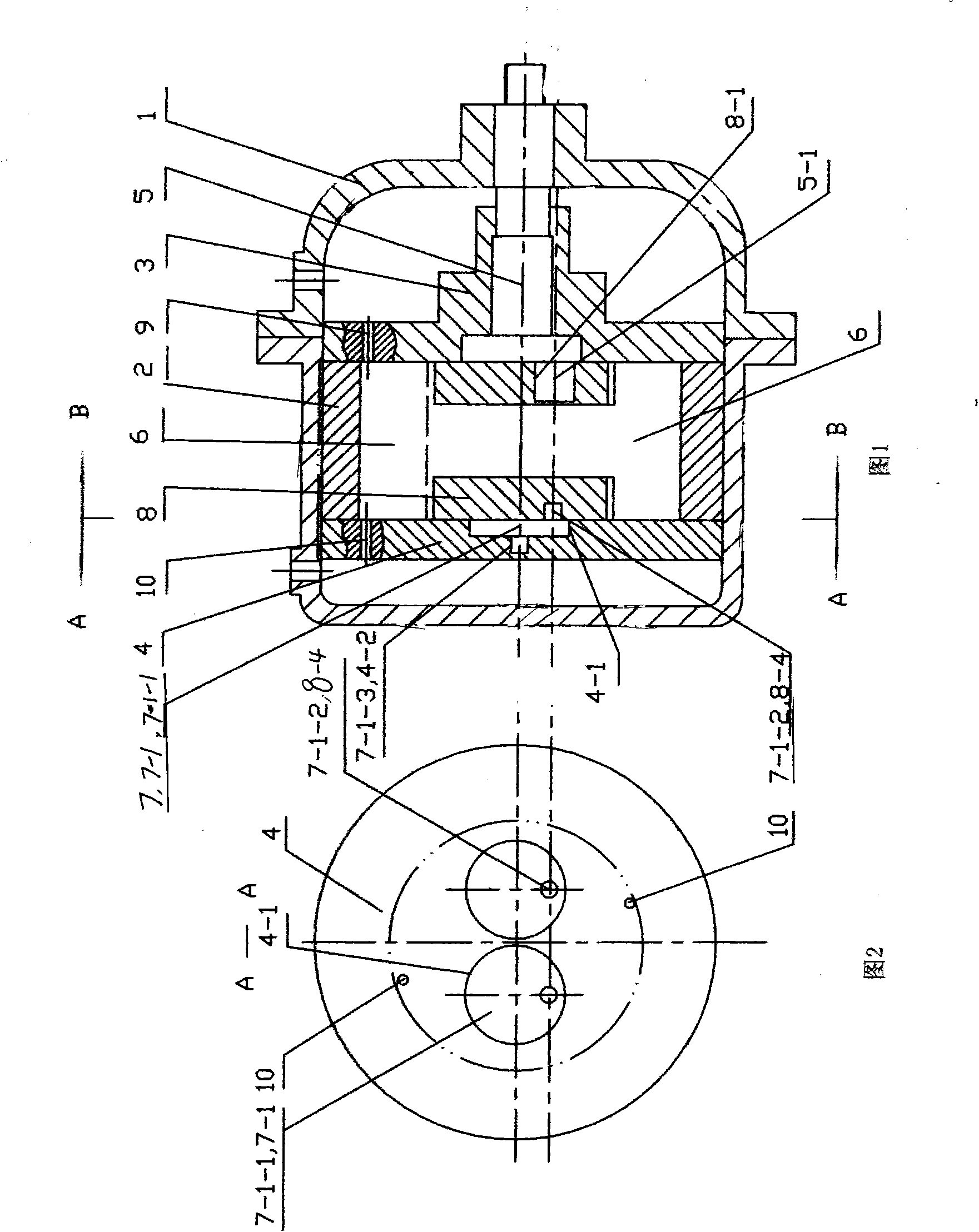

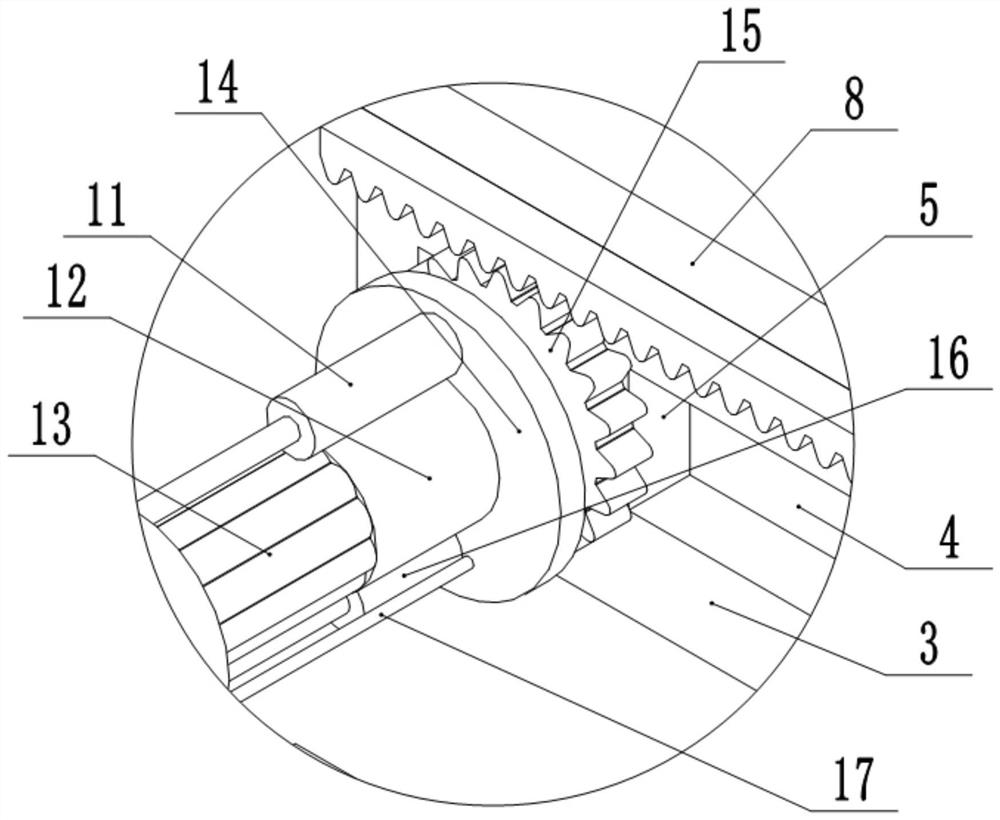

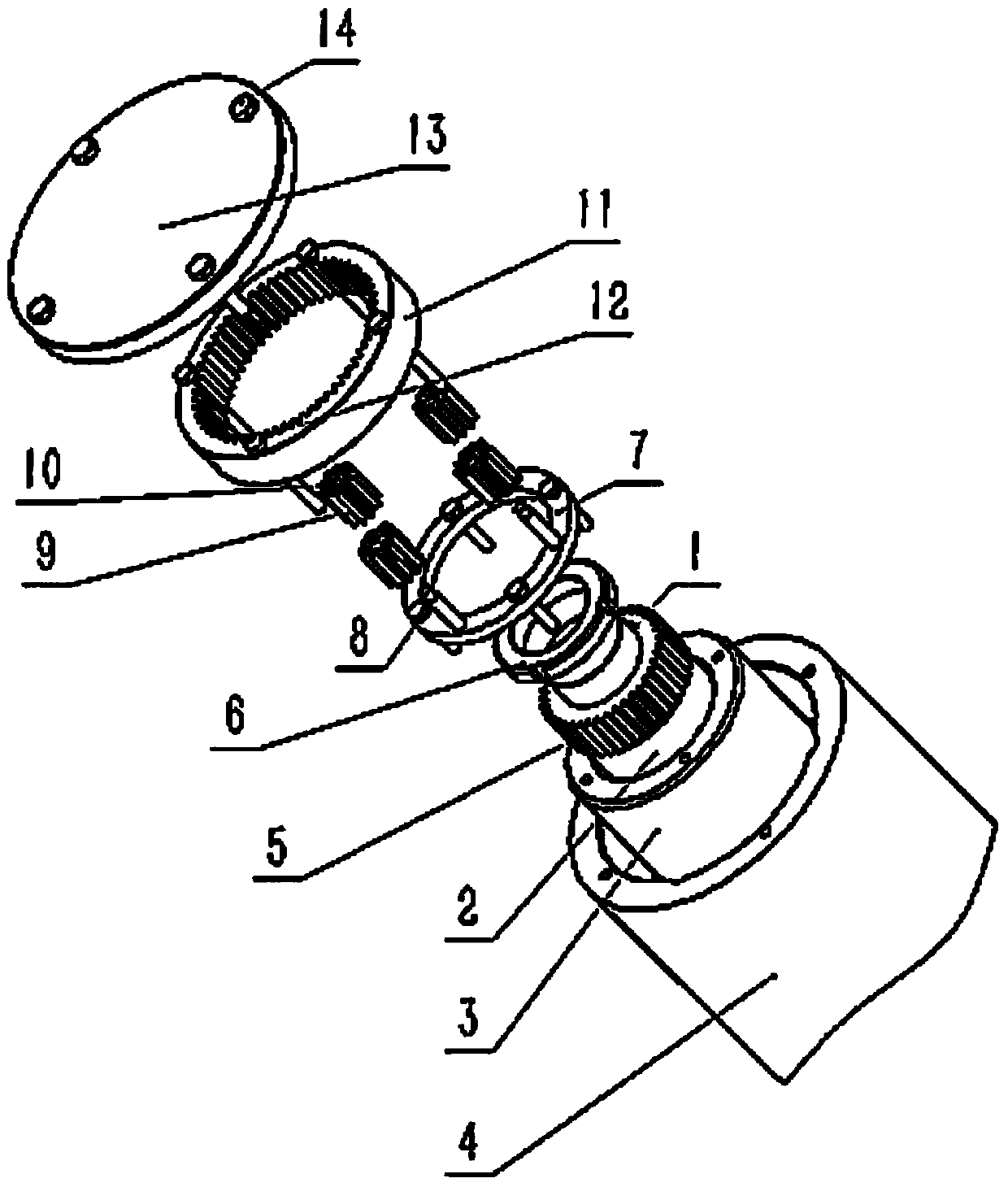

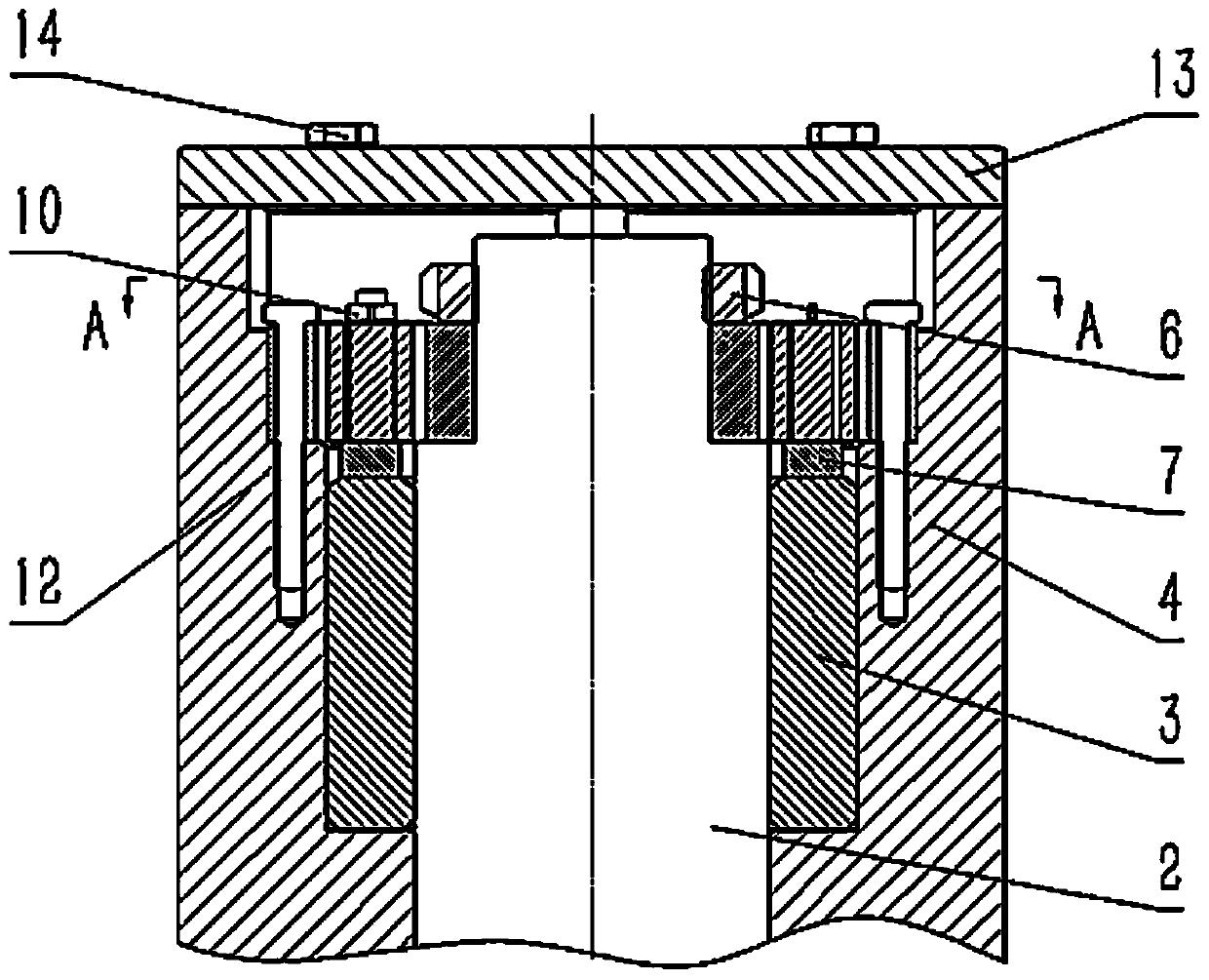

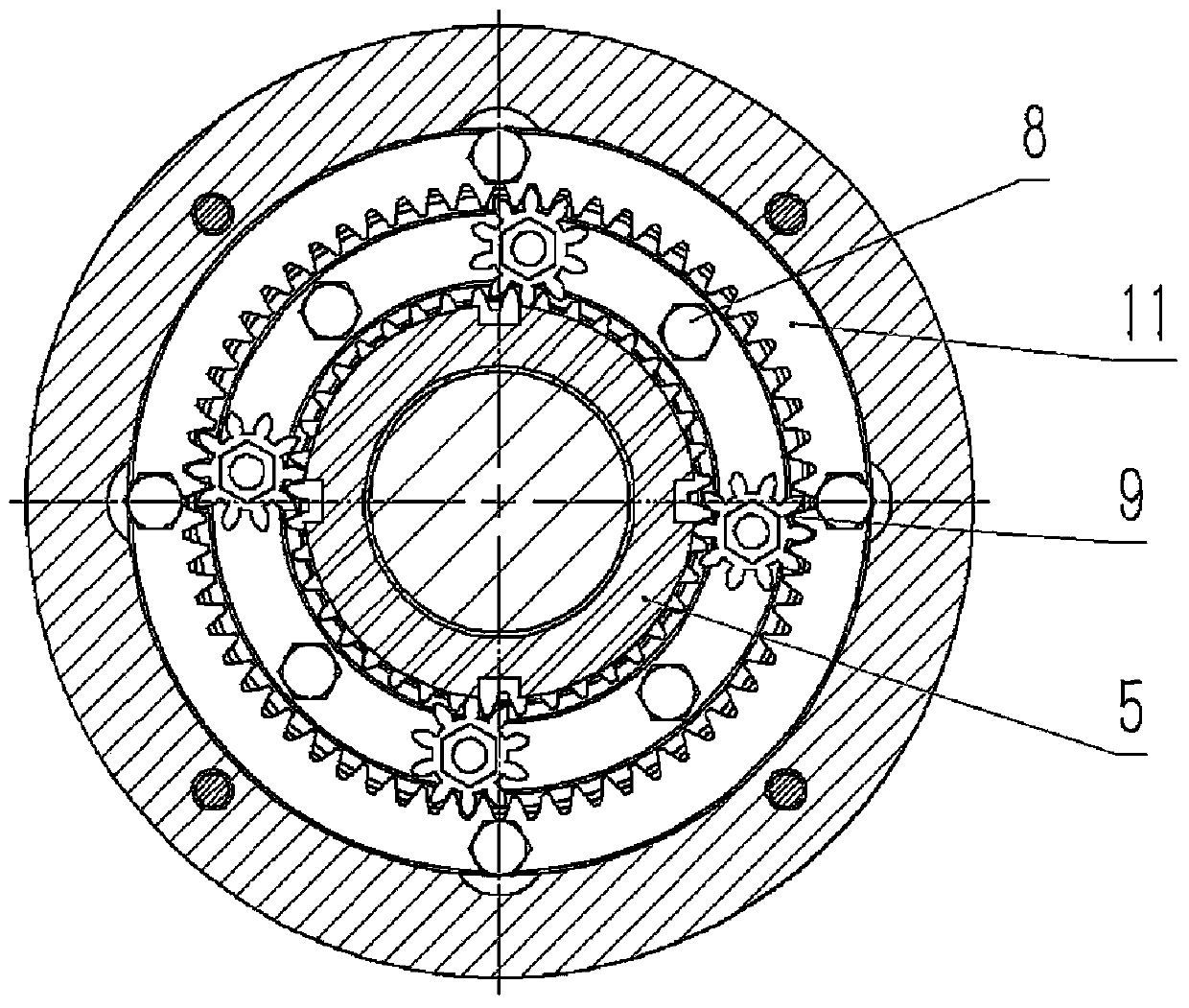

Oil distribution axle linkage rod type hydraulic motor

InactiveCN101117938AReduce axial sizeShaft oil distribution is compactReciprocating piston enginesPistonLinkage concept

A shaft-distribution-oil link-type oil hydraulic motor is improved on the basis of the original shell, the shaft-distribution-oil configuration, the rotating shaft, and the plunger piston-link assembly, etc., namely that the shaft-distribution-oil configuration consists of an oil-through disk and an oil distribution jacket. No.1 and No.2 hydraulic fluid ports are opened on the oil-through disk, and No.1 and No.2 ring grooves are opened on one of the interfaces of the oil-through disk and the oil distribution jacket to airproof and form No.1 and No.2 oil reservoirs; at the same time, No.1 and No.2 under cut slots which are separated by the contact crown faces are symmetrically opened on the same ring face of the inner wall of the oil-through jacket. The No.1 and No.2 under cut slots are arranged between the No.1 and No.2 oil reservoirs to airproof and form the No.1 and No.2 main oil reservoirs. A plurality of flow passages corresponding to the main oil reservoirs and connected with the plunger piston are arranged on the rotating shaft. The adopted structure forms the oil-through configuration and the oil distribution configuration into adjacency configurations, approximately distributing in the same orientation to greatly decrease the axial size of the oil distributor, and make the structure of the oil hydraulic motor closer and more reasonable.

Owner:宁波欧易液压有限公司

Slide assembly with deceleration device

ActiveUS8919897B2Slow down the sliding speedReduce forceBuilding braking devicesWing suspension devicesEngineeringMechanical engineering

A slide assembly includes a first rail, a second rail, a stop member and a friction member. The first rail includes two sidewalls with a connection wall connected therebetween. The second rail is slidably located between the two sidewalls of the first rail. The stop member is fixed to the connection wall and has a stop plate which is perpendicular to the connection wall. The friction member is fixed to the second rail and has an extension portion. The extension portion has a guide face. When the second rail is moved relative to the first rail after the friction member touches the stop plate and overlaps the stop member by the guide face, the friction member is slidably and flexibly in contact with the stop plate.

Owner:KING SLIDE WORKS CO LTD +1

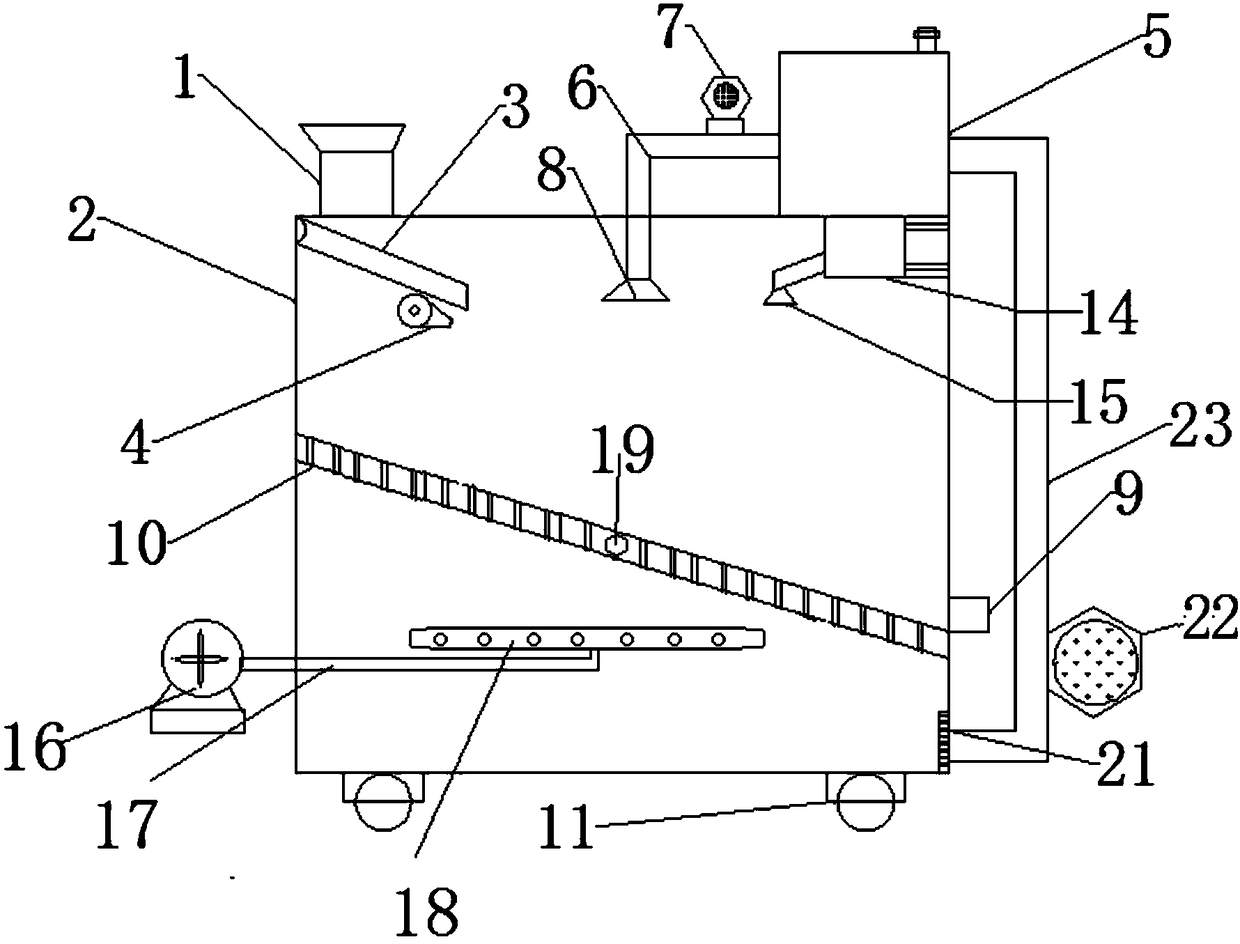

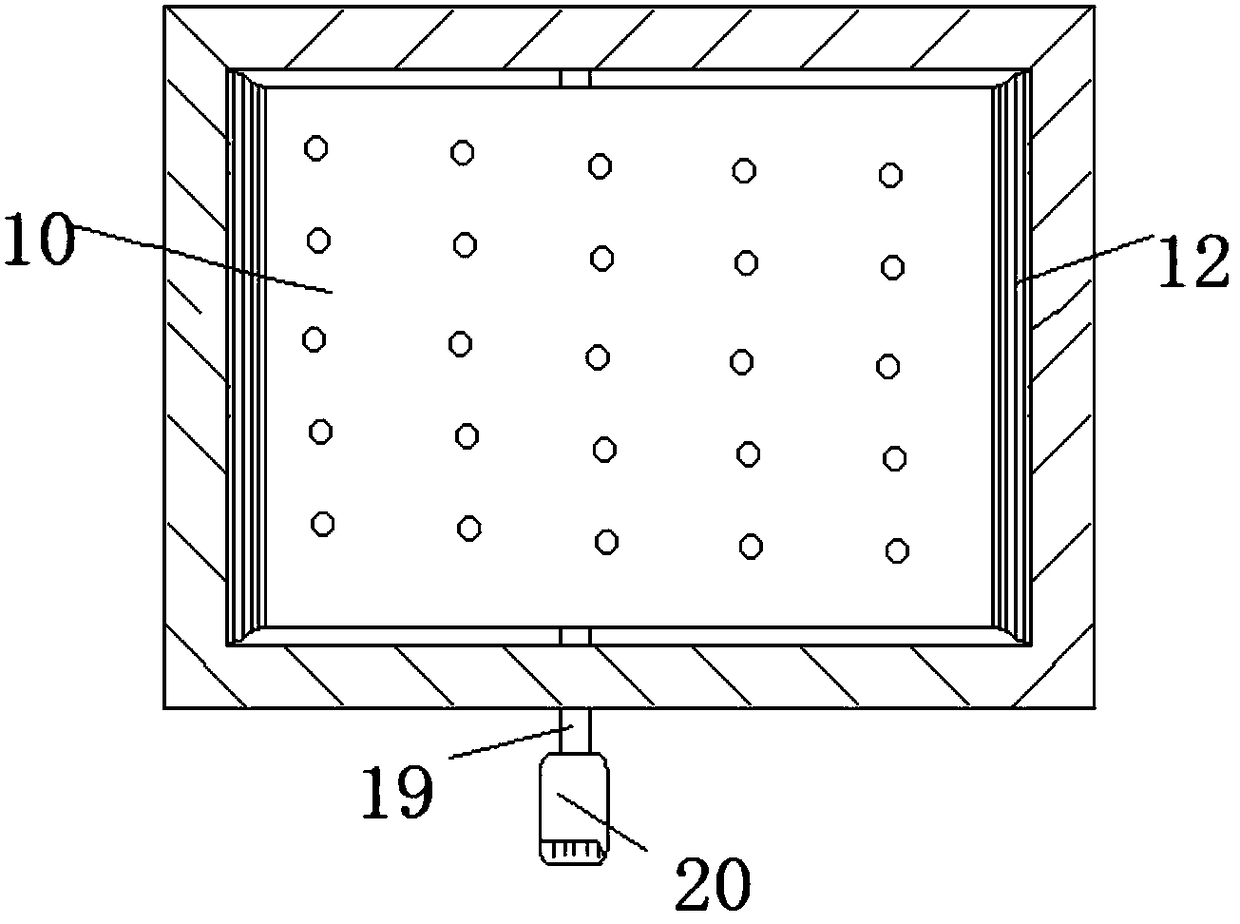

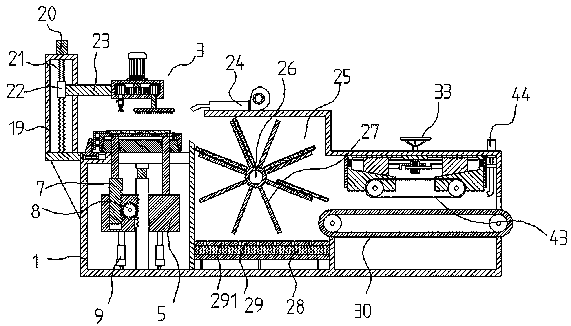

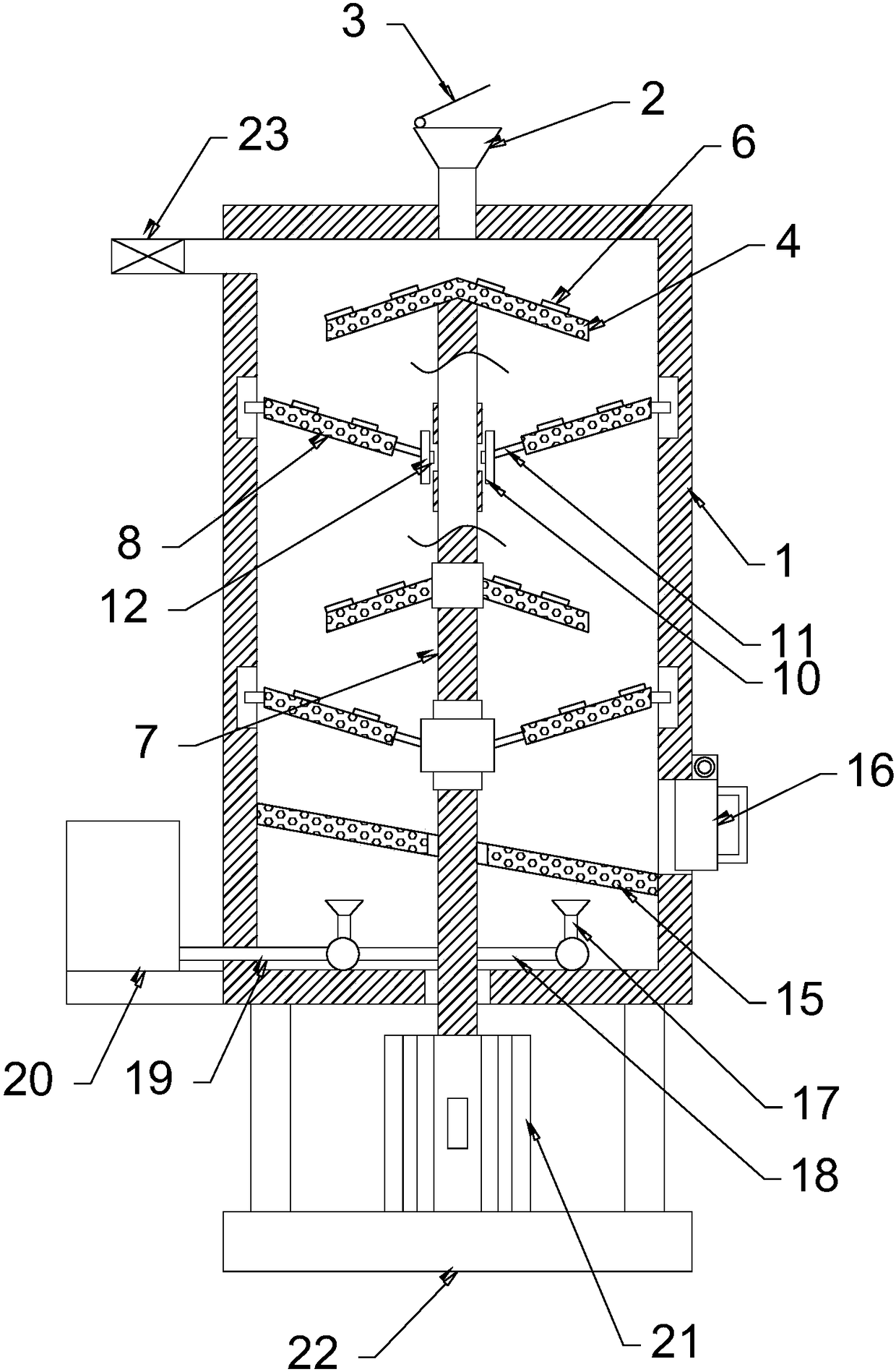

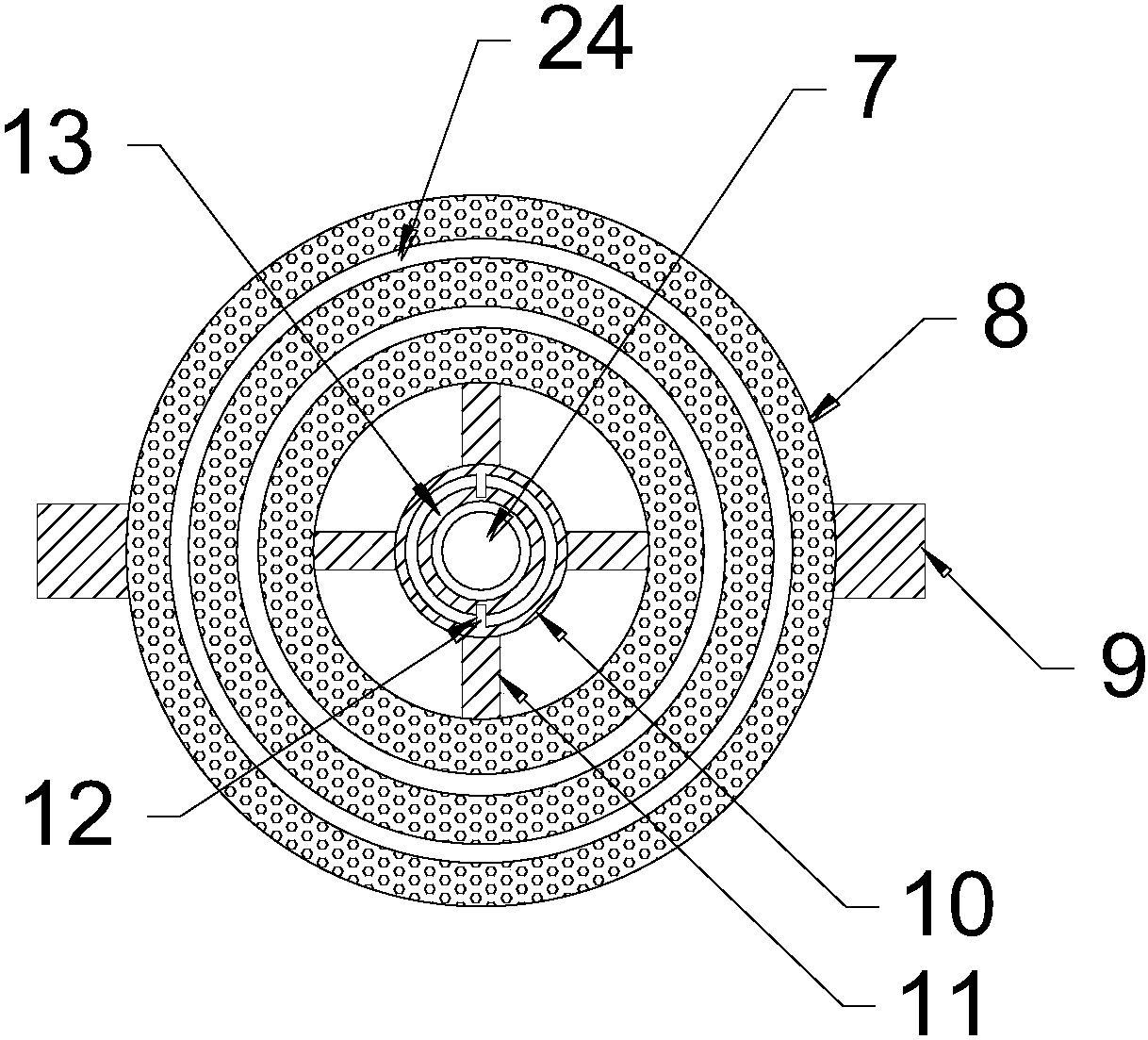

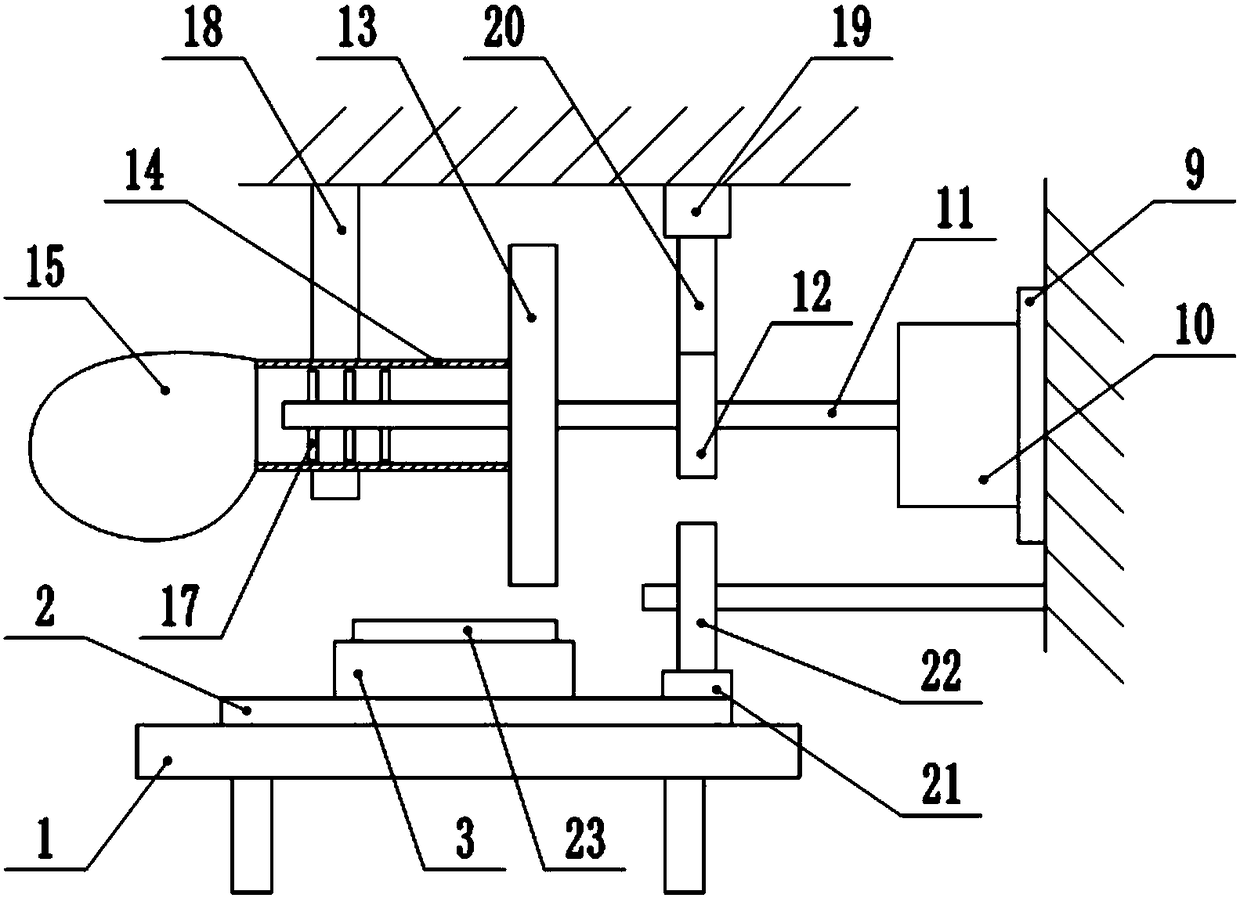

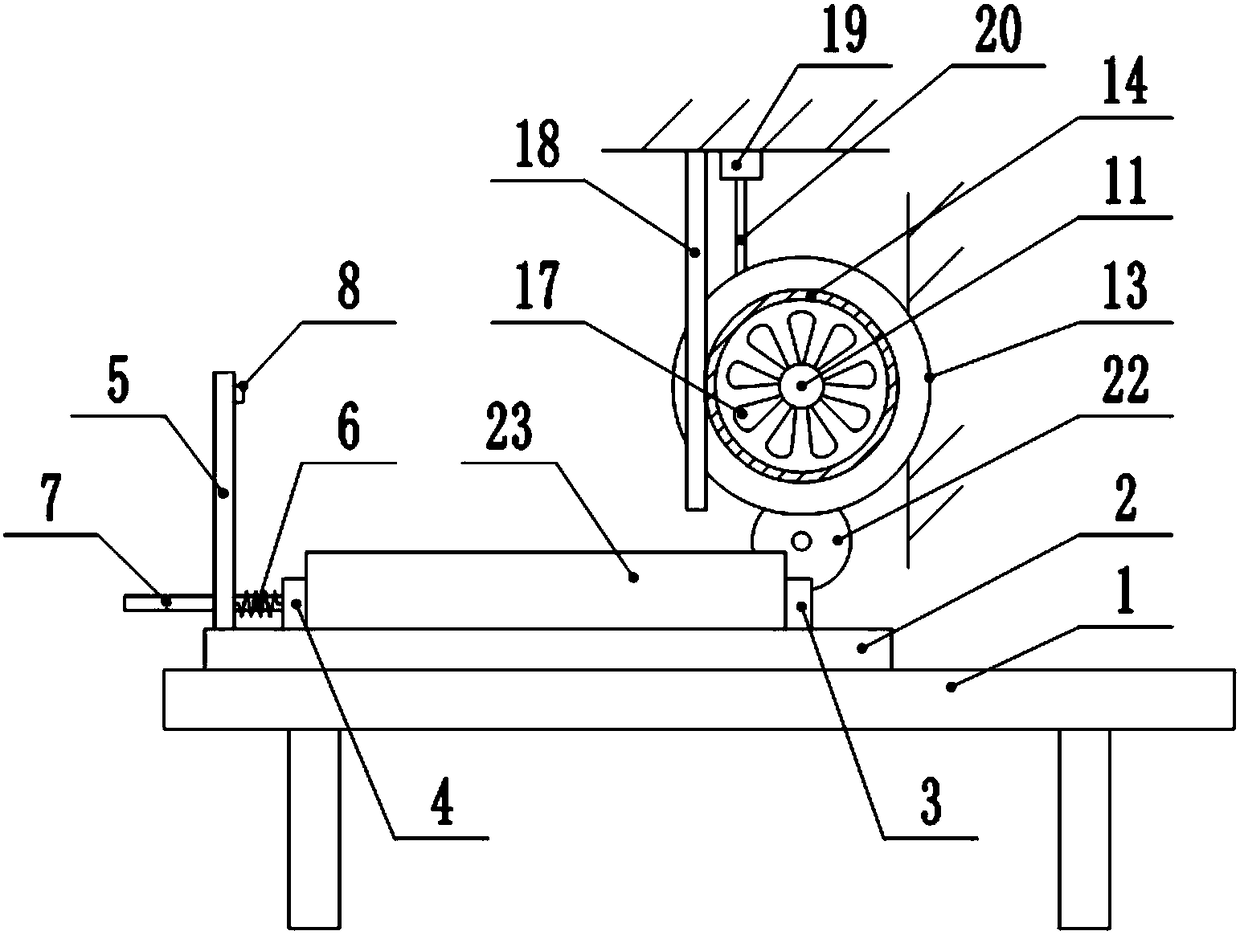

Ore efficient aeration vibration cleaning device

The invention discloses an ore efficient aeration vibration cleaning device which comprises a feeding pipe, a treatment box, a material shake plate, a water storage box, a water spray pipe, a screen plate, a dust collector, an aeration machine, a center rotating shaft and a backflow pipe. The feeding pipe is arranged at the top end of the treatment box. The material shake plate is further arrangedin the treatment box. The water storage box is mounted at the top end of the treatment box. The water spray pipe is arranged on the water storage box. A spray head is arranged at the outlet end of the water spray pipe. The dust collector is mounted on the inner wall of the top end of the treatment box. The screen plate is obliquely arranged in the treatment box. An ore discharging pipe is arranged on the side wall of the treatment box. The center rotating shaft is fixedly arranged at the center position of the screen plate. One end of the center rotating shaft penetrates the side wall of thetreatment box to be connected with an output shaft of a forward and reverse rotation motor. The treatment box communicates with the aeration machine. According to the ore efficient aeration vibrationcleaning device, safety is improved; the ore surfaces can be cleaned conveniently; the work efficiency and effect are improved; water is cyclically used; energy is saved; the use cost is reduced; thestructure is simple; use is convenient; and popularization is facilitated.

Owner:ZHENGZHOU GERUITA ELECTRONICS INFORMATION TECH CO LTD

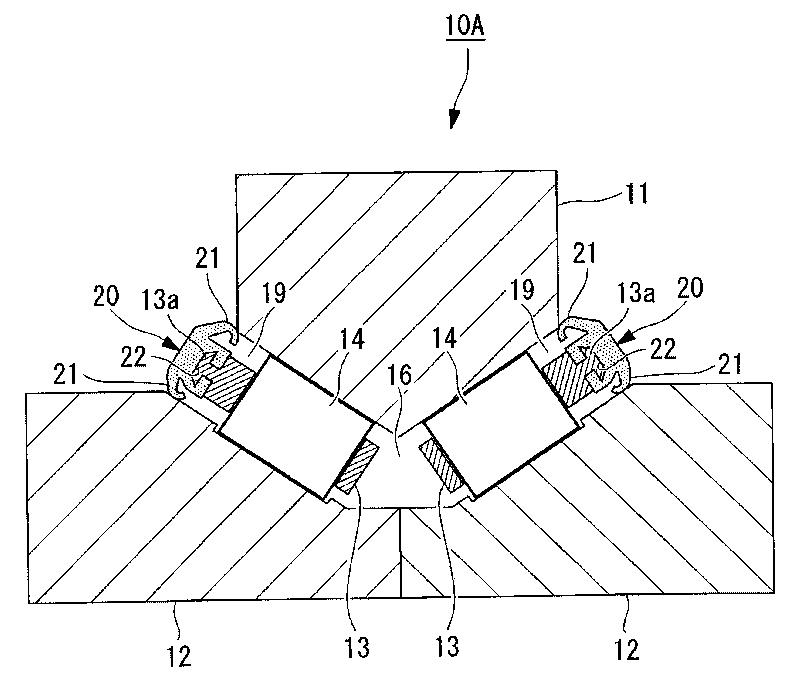

Bearing structure and wind power generator

InactiveCN101715520ASlow down the sliding speedReduce frictional heatRoller bearingsBearing assemblyEngineeringLubricant

The invention provides a bearing structure which reduces the relative sliding speed between a seal ring (20) and contact surfaces and suppresses relative deformation due to a difference between the temperatures of inner and outer rings (11, 12). Rolling elements (14) are disposed in a space portion (16) formed between the inner ring (11) and the outer rings (12) to relatively rotate the inner ring (11) or the outer rings (12) via the rolling elements (14). The sliding portions of the surfaces of the rolling bodies (14) and the inner surface of the space portion (16) are cooled with a lubricant supplied into the space portion (16). The axial end opening of the space portion (16) is covered with the seal ring (20) attached to the retainer (13) retaining the rolling elements (14).

Owner:MITSUBISHI HEAVY IND LTD

Method of testing friction components for automatic transmissions

InactiveUS6923049B2Simulation is accurateSlow down the sliding speedMachine gearing/transmission testingEngine testingAutomatic transmissionMotor drive

A method of testing a friction component for a transmission that has first and second parts. The first part of the friction component is attached to a drive shaft and the second part is attached to a grounding element. The first part of the friction component is rotated until the drive shaft and the first part of the friction component rotate at a target sliding speed Vtarget. An actuation force is applied to the friction component at a time t0. Operation of the motor drive is continued to maintain the speed of rotation of the drive shaft at Vtarget until a predetermined level of engagement torque Tth is obtained. The motor torque is then reduced to a predetermined level Tm. The sliding speed of the drive shaft is then decreased and the test is terminated when the sliding speed falls to zero.

Owner:LINK ENG

Ceramic waxing and polishing machine

InactiveCN108908023AIncrease contact areaReduce mechanical wear and tearLiquid surface applicatorsGrinding drivesSlide plateEngineering

The invention discloses a ceramic waxing and polishing machine. The ceramic waxing and polishing machine comprises a machine body, a workbench, a conveying mechanism, a waxing mechanism and a polishing device; the polishing device comprises an adjusting wheel arranged at the side end of the machine body and provided with a gear member; the two sides of the gear member are each engaged with one setof toothed plate blocks; an upper sliding table is arranged on the machine body; a set of upper pressing blocks are slidably arranged on the upper sliding table; the toothed plate blocks are connected with the upper pressing blocks correspondingly; the upper pressing blocks are trapezoidal bodies with tapered portions at the lower ends; two side sliding bases are arranged on the machine body; lower sliding plates are arranged on the side sliding bases; reset tension springs are connected between the lower sliding plates and the upper sliding table; the upper ends of the lower sliding plates are provided with tapered portions matched with the upper pressing blocks; the lower sliding plates are provided with polishing wheels; and the polishing wheels are provided with sheet polishing belts.The ceramic waxing and polishing machine is provided aiming at the problems, the polishing belts of the machine are arranged transversely, and the lower sliding plates are pushed by the adjusting wheel to press downwards, so that the polishing height is adjusted, mechanical losses during operation are small, operation is stable, and noise is low.

Owner:DONGGUAN UNIV OF TECH

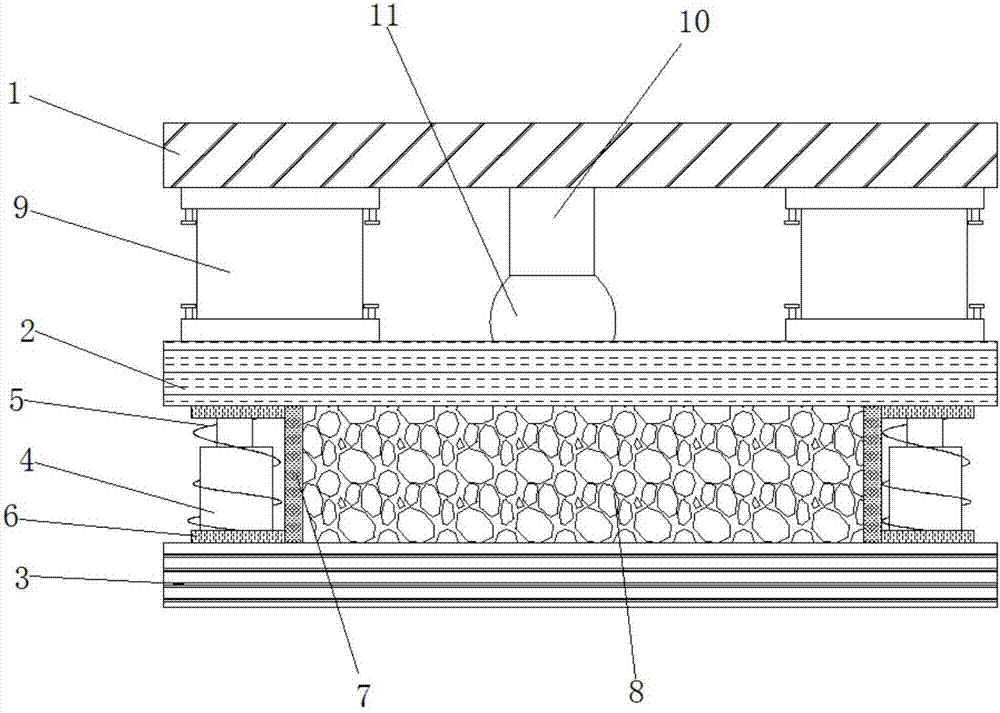

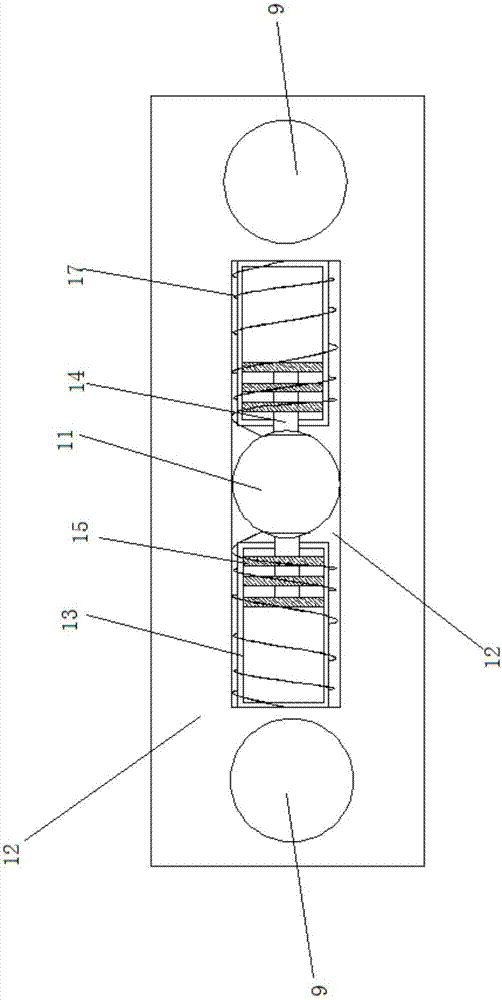

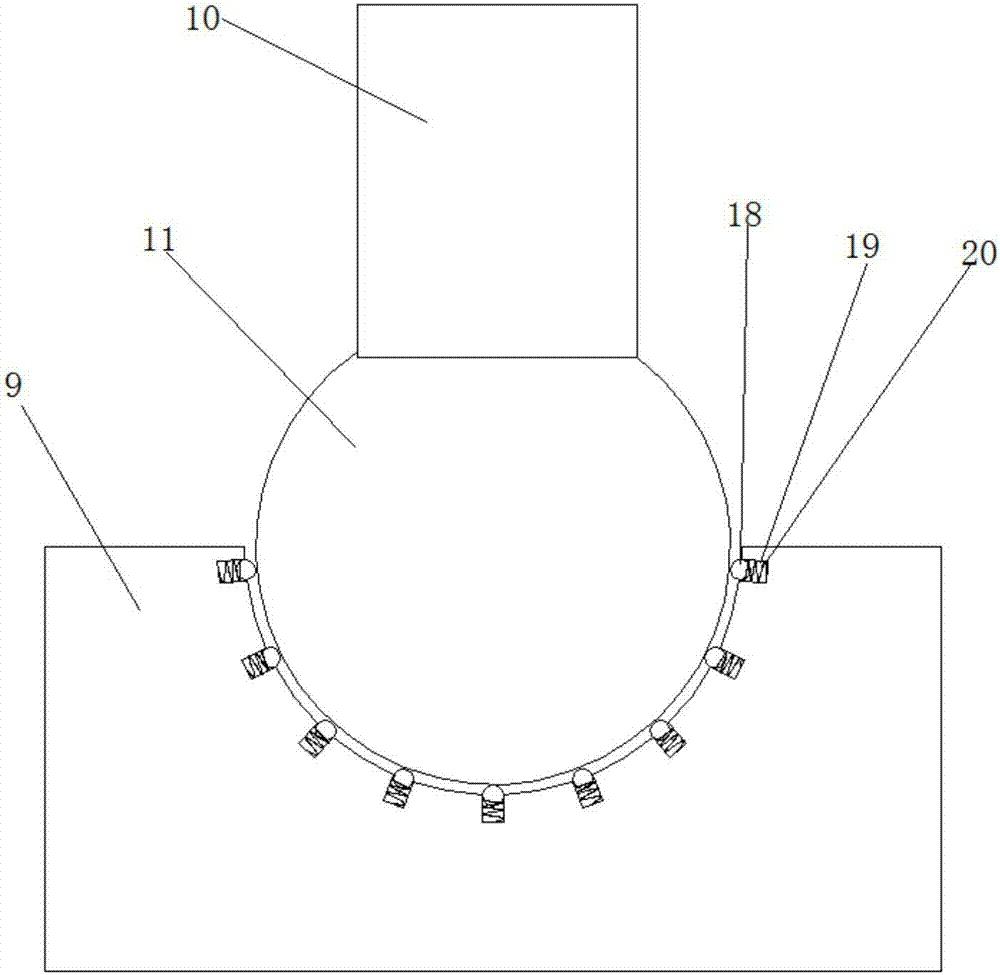

Shock-isolating device for foundation of high-rise building

InactiveCN107100207AReduce wearExtended service lifeProtective foundationRolling resistanceHigh rise

The invention belongs to the technical field of shock-isolating devices and particularly relates to a shock-isolating device for a foundation of a high-rise building. The shock-isolating device for the foundation of the high-rise building aims to solve the technical problem that the stretching recovery capacity of a shock-isolating device is continuously lowered. According to the technical scheme, the shock-isolating device for the foundation of the high-rise building comprises a building base, an installation seat and the foundation, wherein the building base, the installation seat and the foundation are sequentially arranged from top to bottom and are sequentially connected, the two sides of the top of the foundation are provided with telescopic supporting columns, two fixing plates are welded to the top and the bottom of each telescopic supporting column and are connected through a spiral compression spring, and the outer walls of the telescopic supporting columns are sleeved with the spiral compression springs. According to the shock-isolating device for the foundation of the high-rise building, a bulb and rolling beads are in rolling friction, the wear of the bulb and the inner wall of a sliding groove is reduced, the service lives of the bulb and the sliding groove are prolonged, buffering devices can apply action force on the bulb, the bulb is prevented from sliding for a long distance, metal parts are greatly prevented from being rusted, and the stability of the device is improved.

Owner:ZHONGYUAN ENGINEERING COLLEGE +1

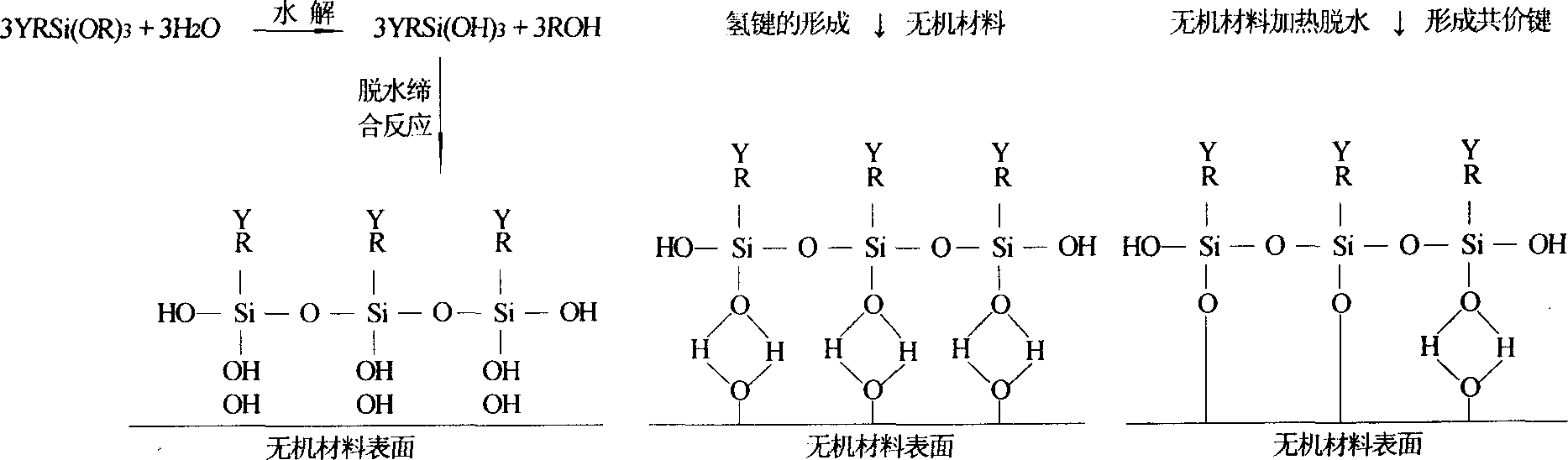

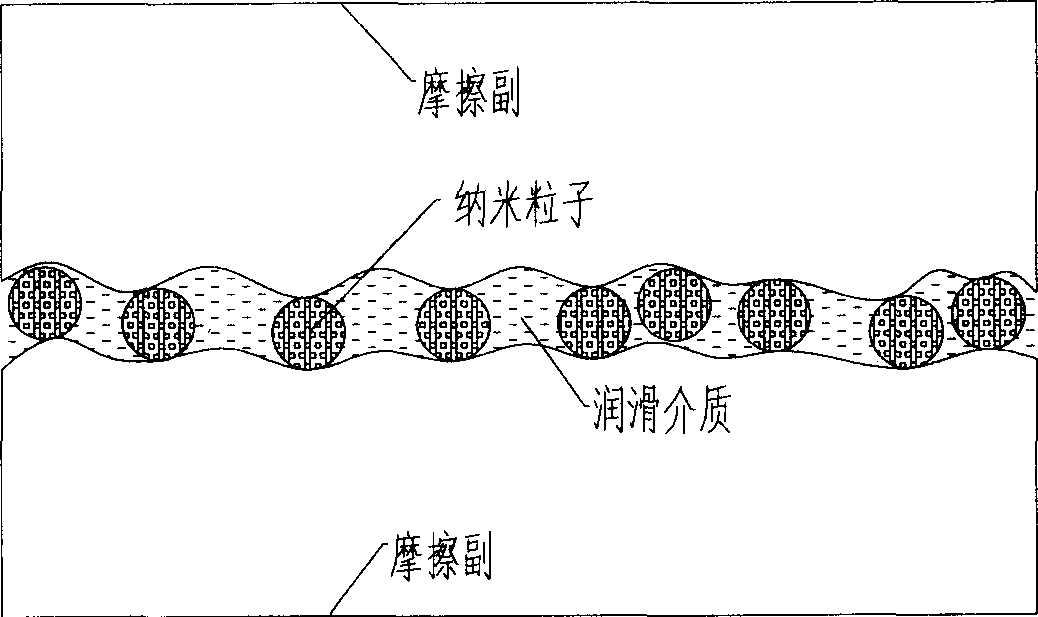

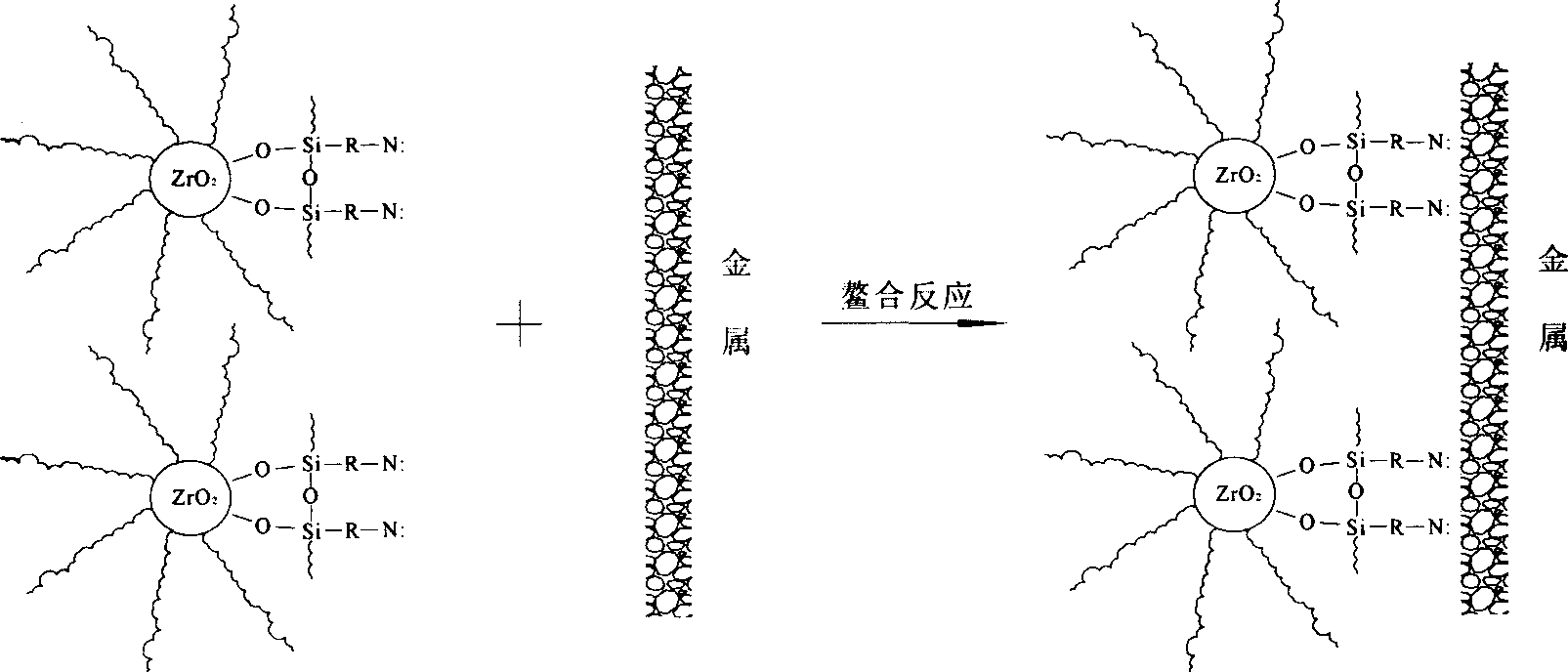

Nano-zirconium dioxide surface modified lubricating oil additive, lubricating oil and its preparation method

InactiveCN1904003ARigid enoughRigidity hasAdditivesPigment treatment with organosilicon compoundsOil additiveZirconium dioxide

The present invention relates to a nano ZrO2 surface modified lubricating oil additive, lubricating oil in which said additive is added and its preparation method. Said lubricating oil additive is made up by mixing nano ZrO2 powder body in lubricating oil matrix, the described nano ZrO2 powder body is made up by combining an unimolecular layer of silane coupler on surface of amorphous nano ZrO2, the chemical structural general formula of the described silane coupler is Y-R-SiX3, and the weight percentage of nano ZrO2 powder body contained in lubricating oil is 0.01-0.5%.

Owner:UNIV OF JINAN

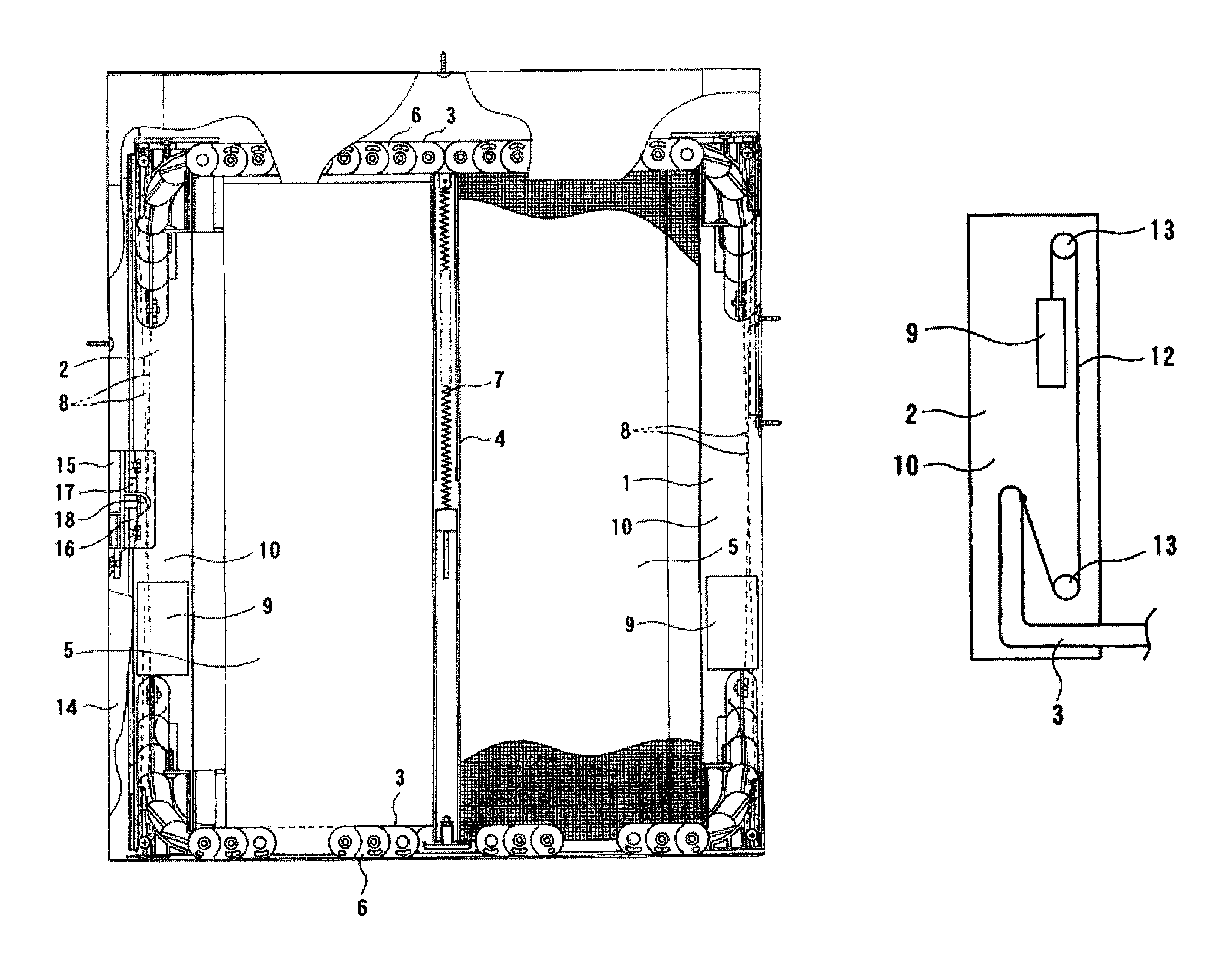

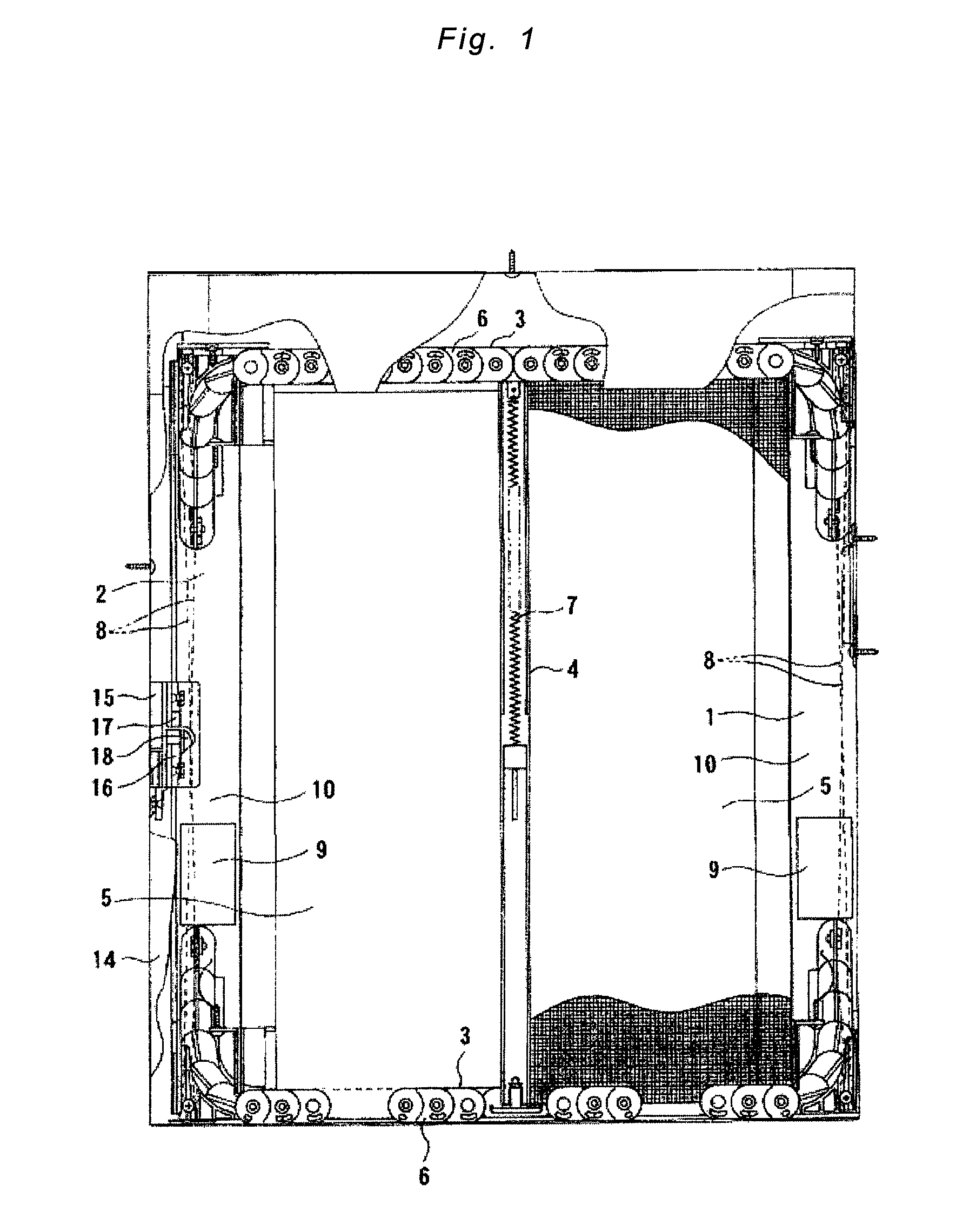

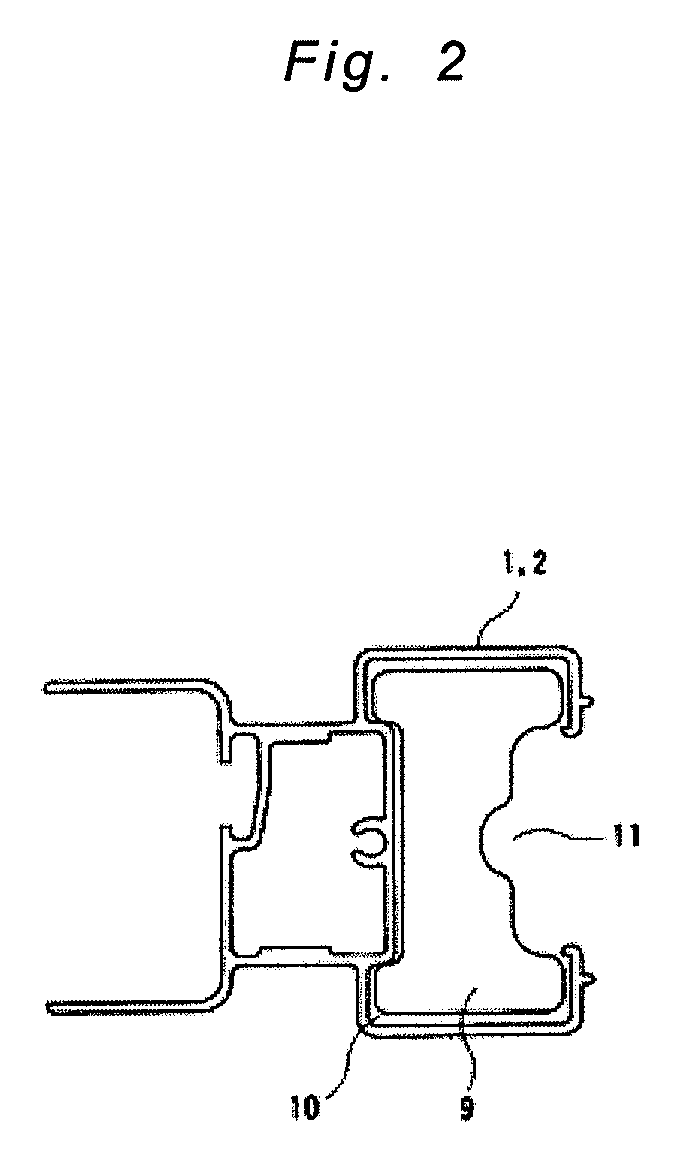

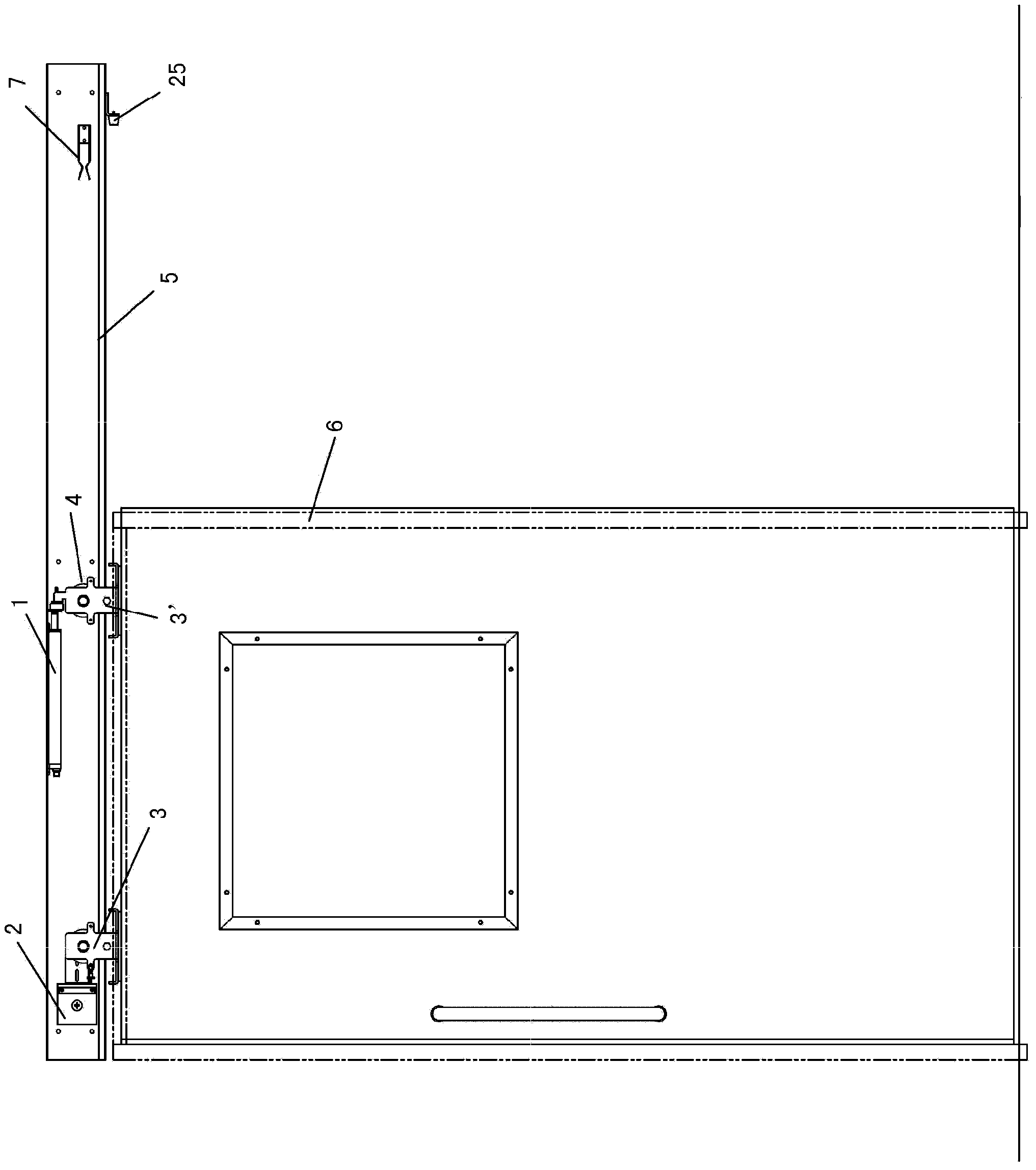

Screen device

ActiveUS8191601B2Decrease slide bar in sliding speedImprove securityScreensShutters/ movable grillesEngineeringMechanical engineering

A weight moving in a height direction interlocking with development and reception of a slide guide frame is provided, and the weight brakes reception of the slide guide frame owing to an increase in potential energy and promotes development of the slide guide frame owing to a decrease in potential energy, whereby an operating force is decreased, a feeling of operating a slide bar is made light, and the slide bar is decreased in sliding speed at the time of closing to achieve an improvement in safety.

Owner:METACO INC

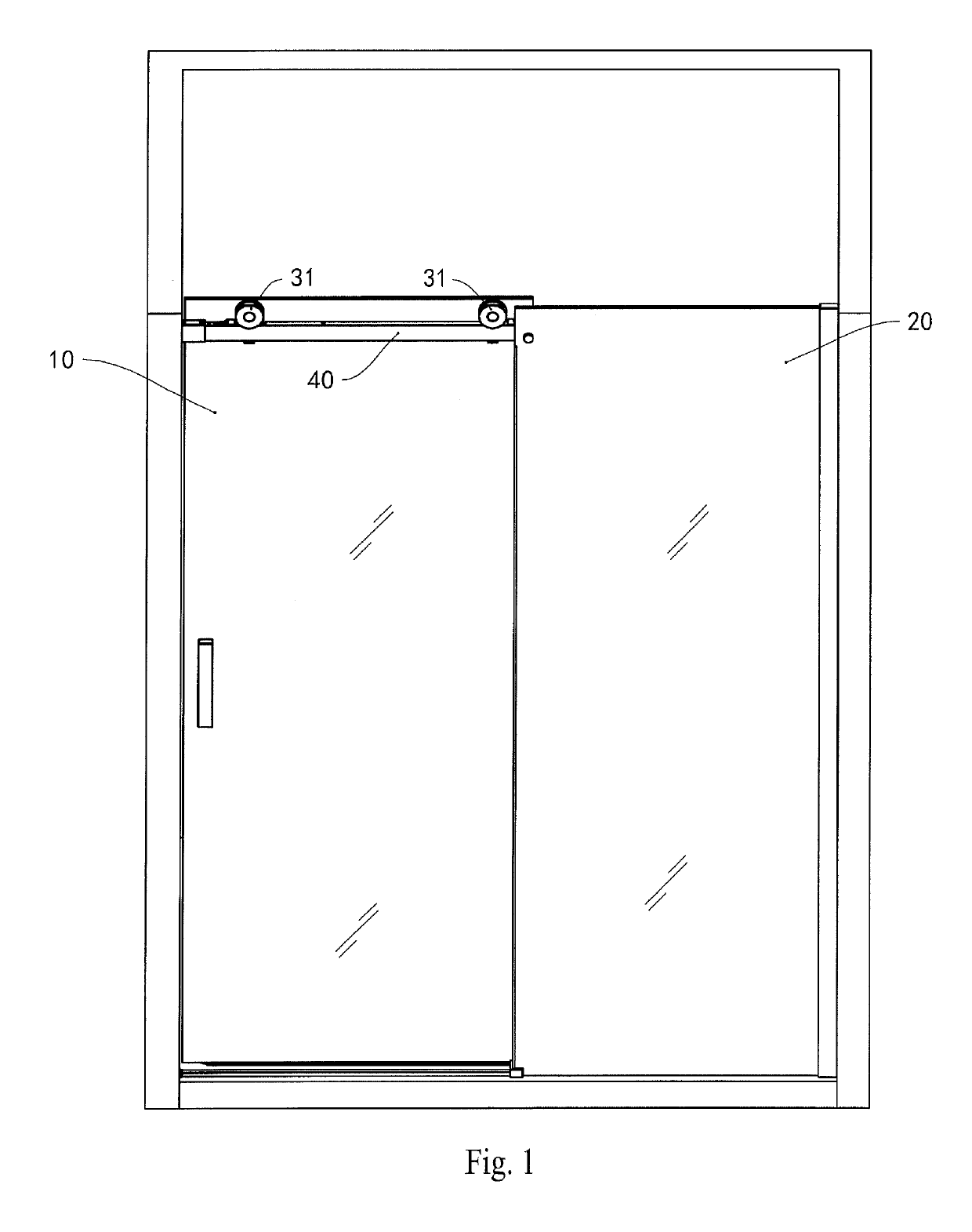

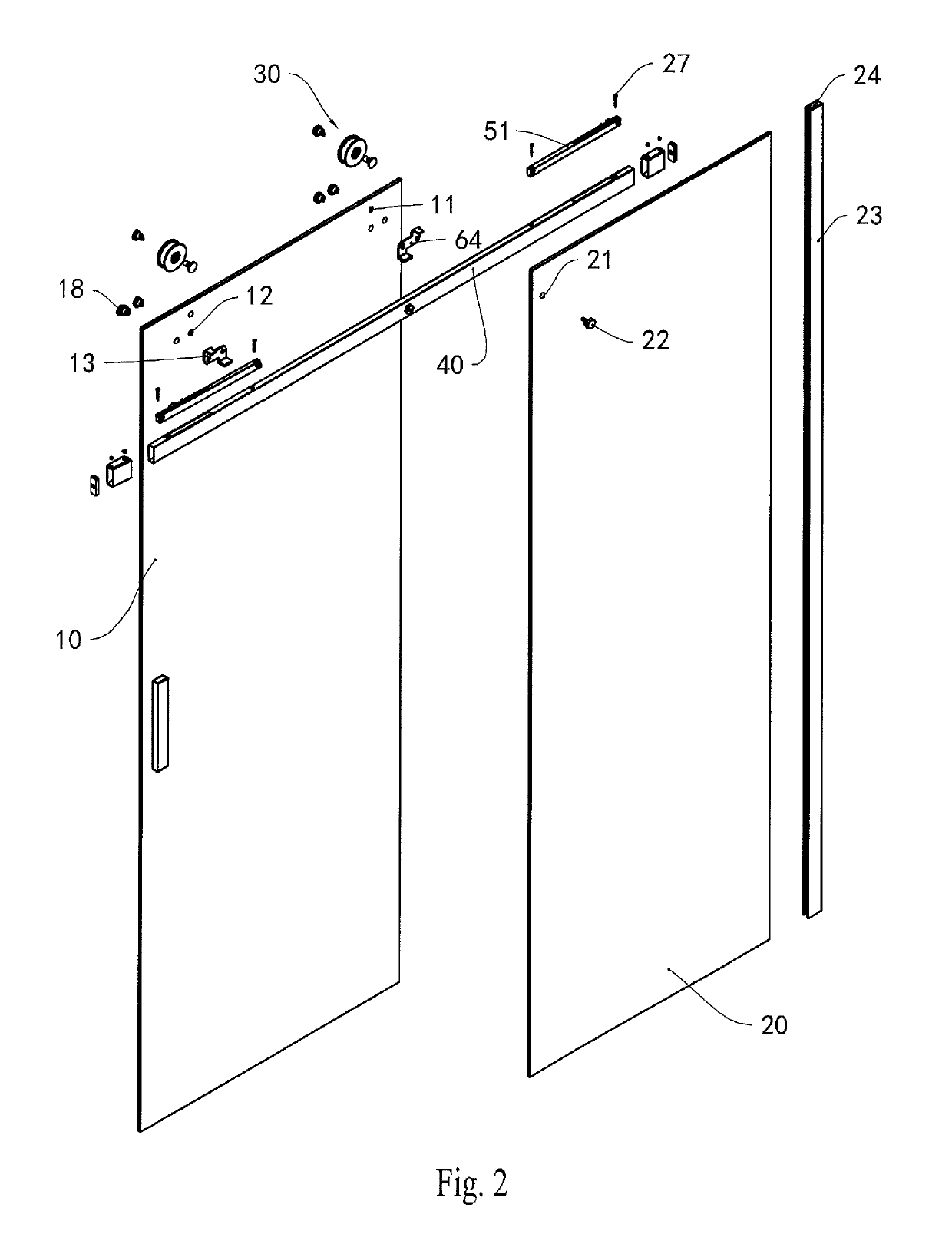

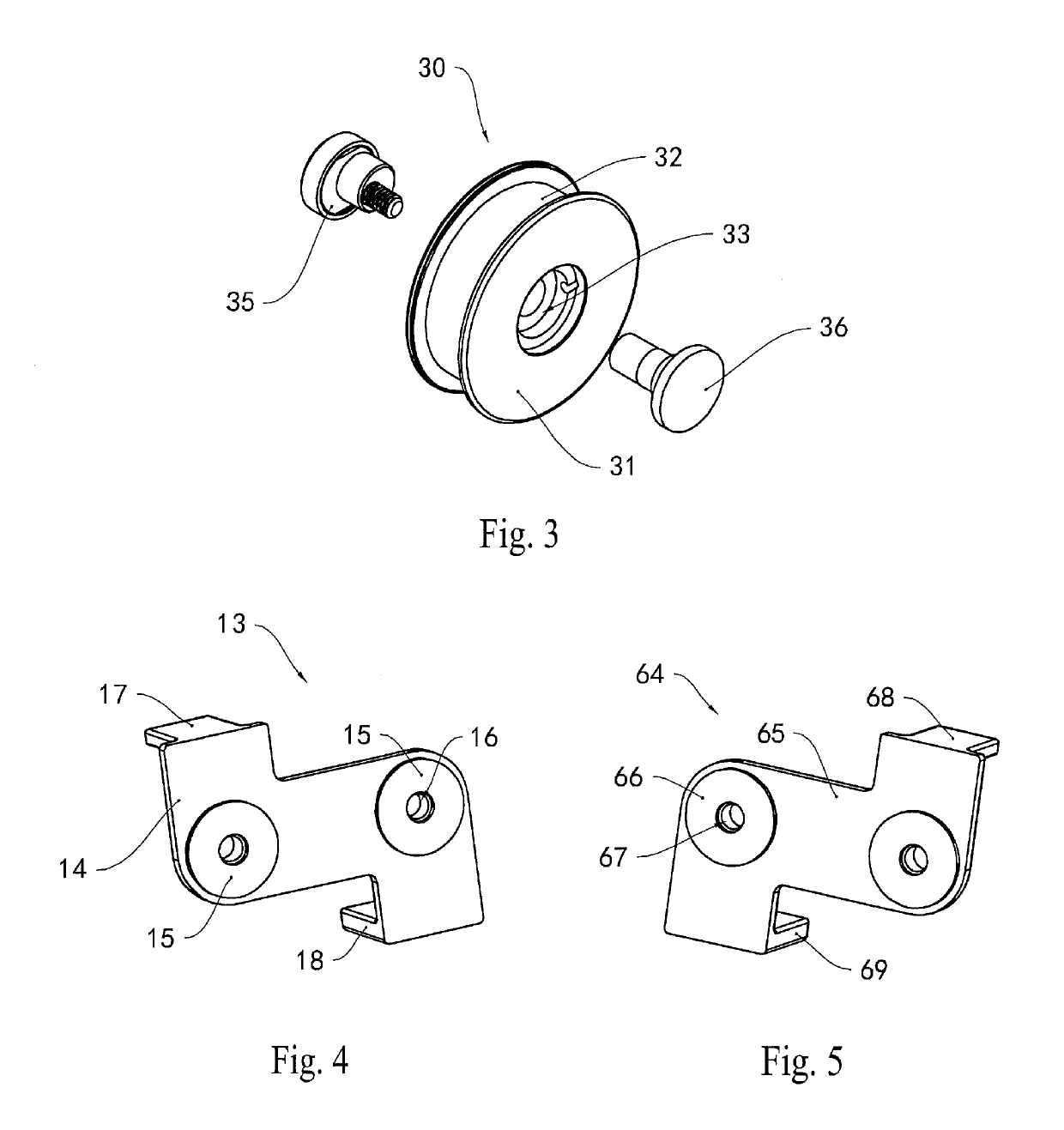

Shower door

ActiveUS10455989B2Slow down the sliding speedPrevent goodBathsBuilding braking devicesEngineeringMechanical engineering

A shower door comprises a movable door, wherein at least one rolling wheel is fixed on the movable door, and at least one limiting member is fixed on the movable door; the shower door further comprises a track, the track is arranged below the rolling wheel, a closer is fixed on the track, the closer comprises a clamping member and a middle portion of the clamping member is provided with a clamping mouth facing upwards; and the limiting member comprises a limiting block and an anti-bouncing block, wherein the limiting block is located above the track, the limiting block is capable of being clamped in the clamping mouth of the clamping member and the anti-bouncing block is located below the track.

Owner:IDEAL SANITARY WARE CO LTD

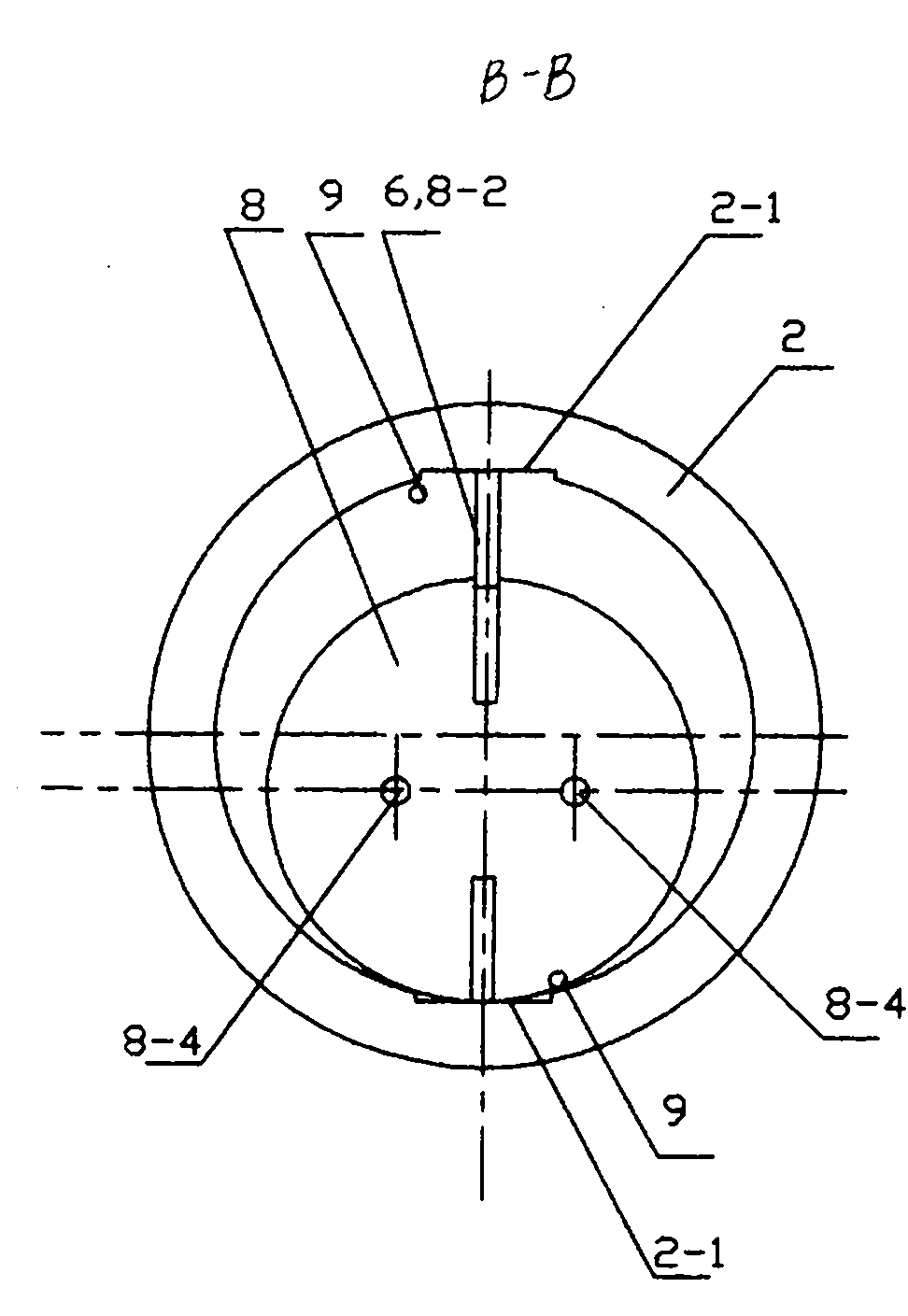

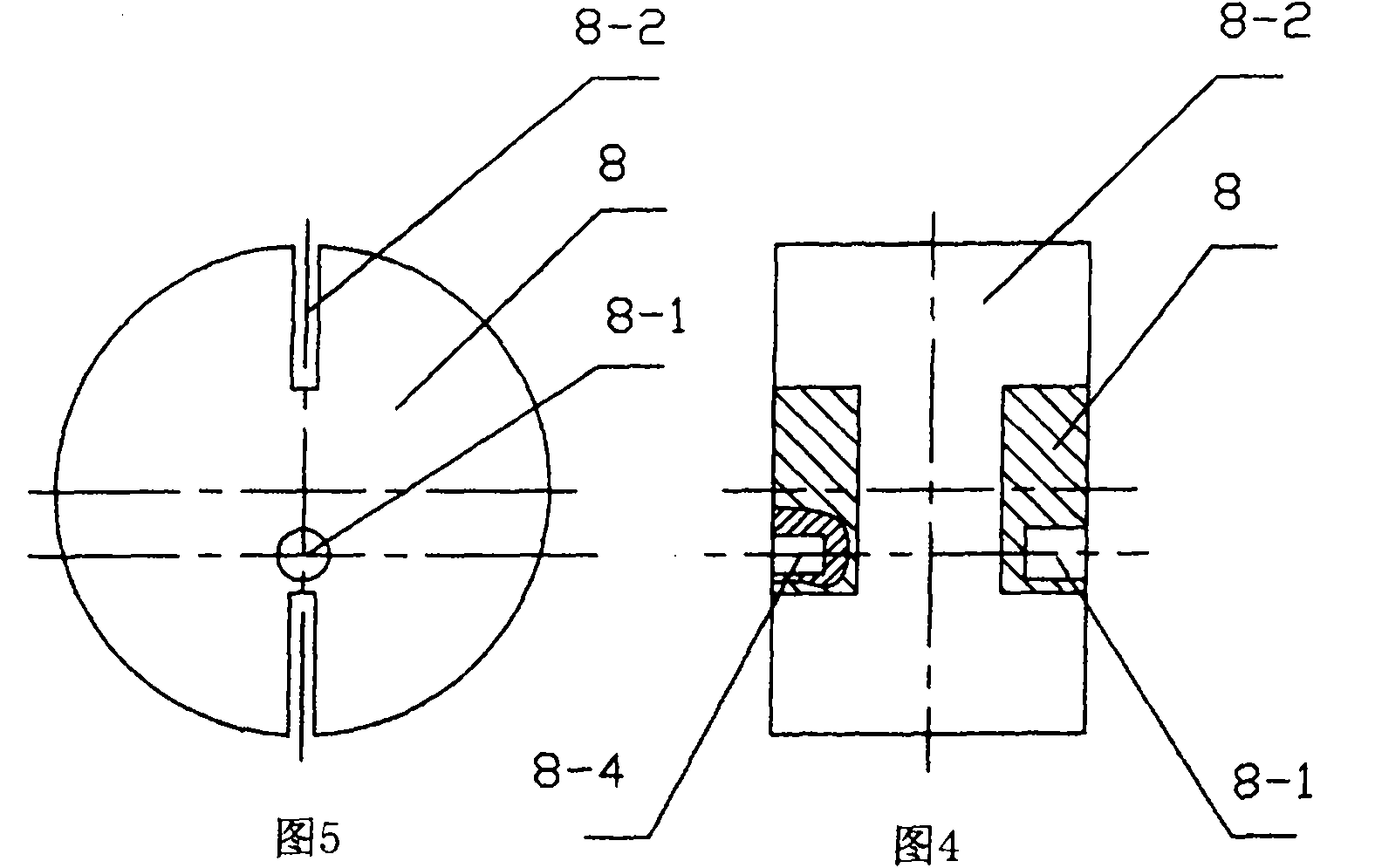

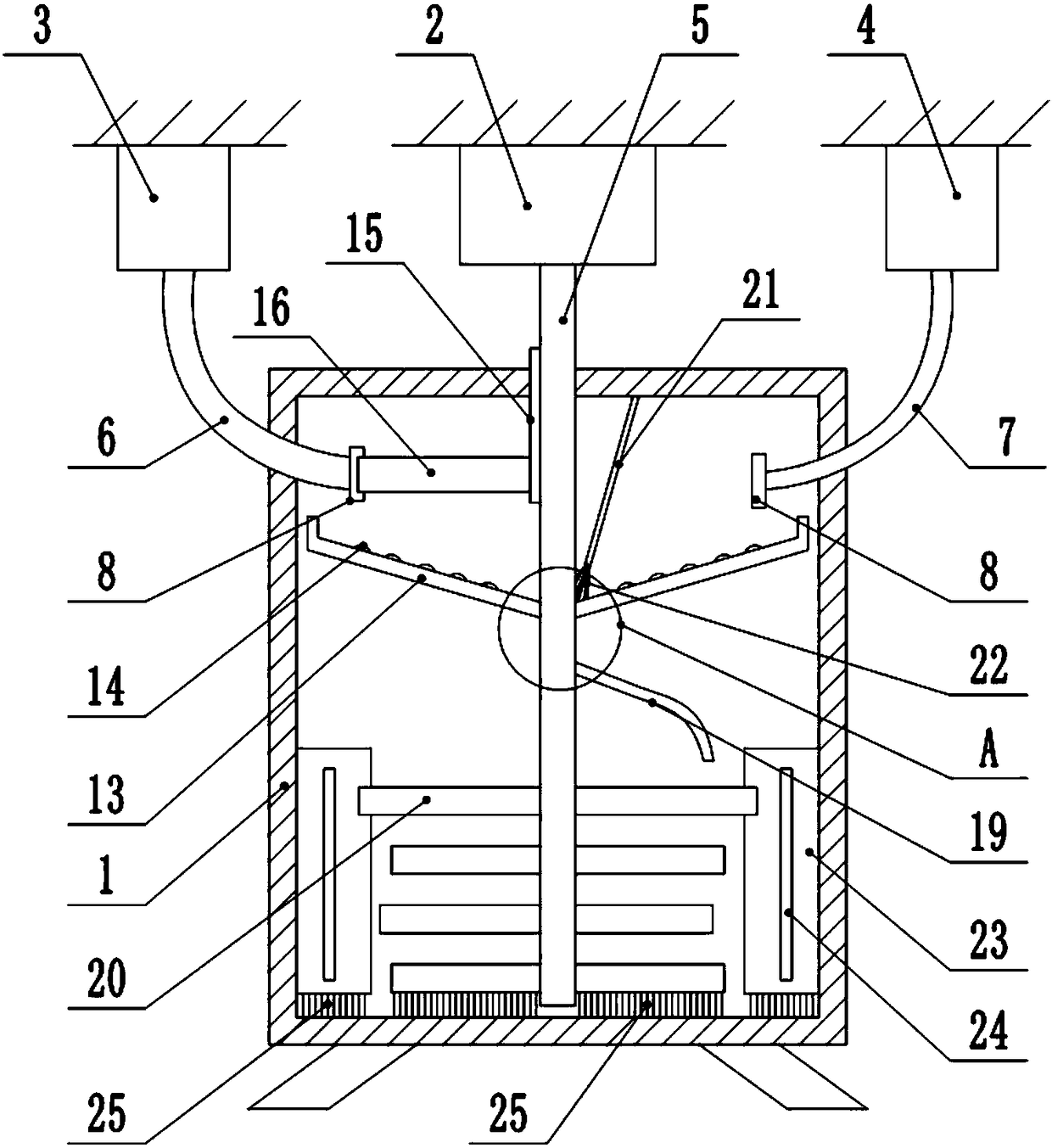

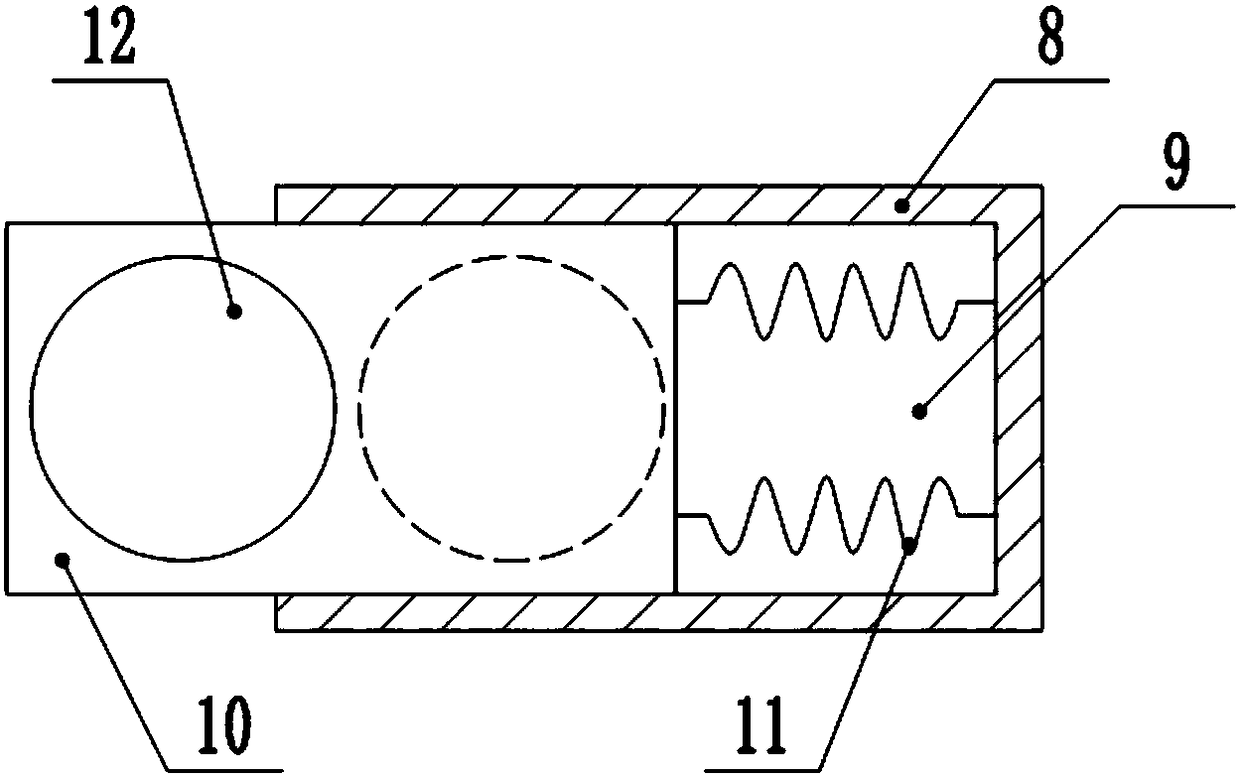

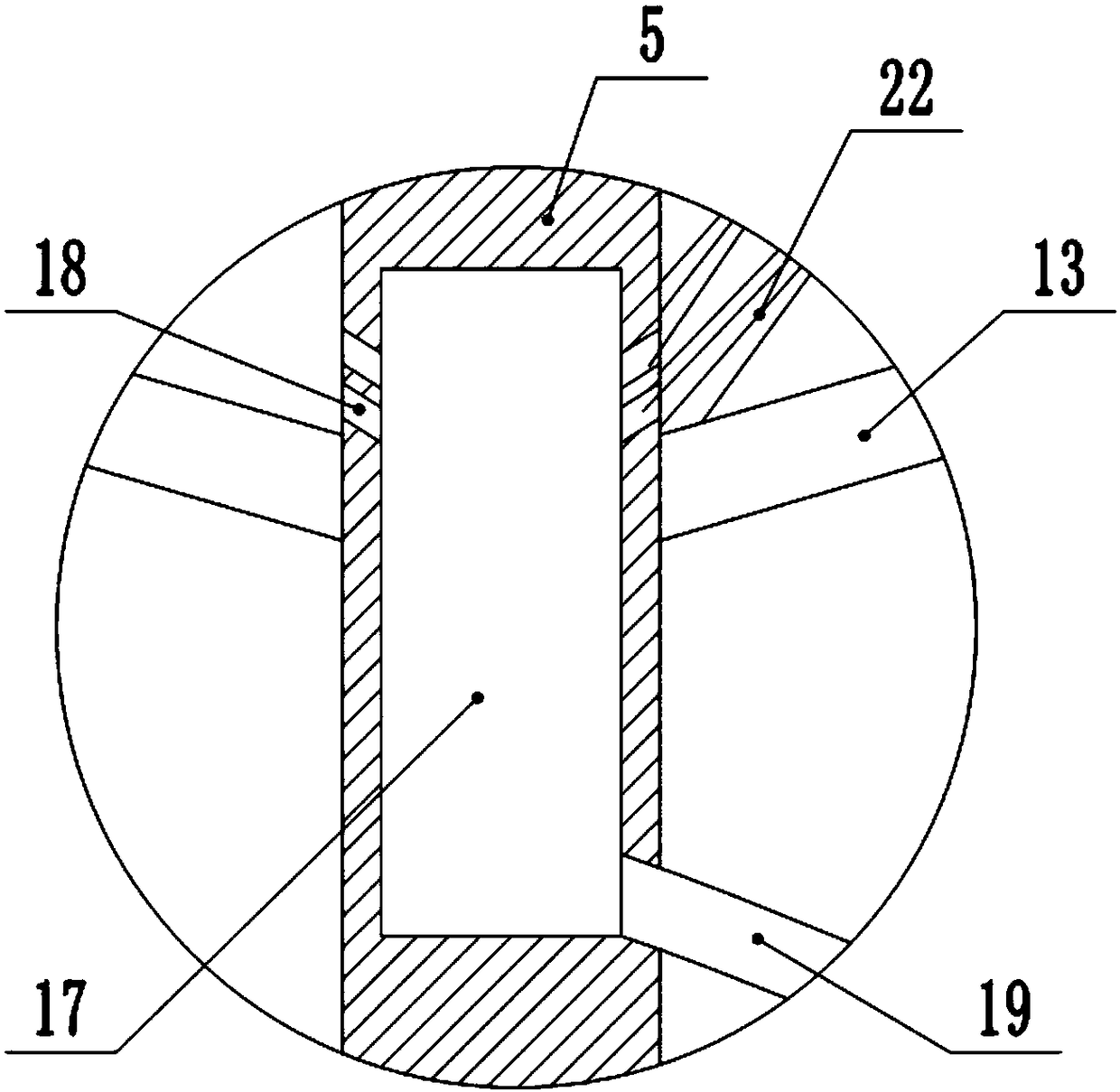

Translation penetrating blade type air-conditioner compressor

InactiveCN101865134ALess contact friction pointsSlow down the sliding speedRotary piston pumpsRotary piston liquid enginesLow noiseEngineering

The invention discloses a translation penetrating blade type air-conditioner compressor which comprises a casing (1), a cylinder body (2), a front end cover (3), a back end cover (4), a main shaft (5), blades (6), a translation mechanism (7) and a translation disk (8), wherein the cylinder body (2) is fixedly arranged in the casing (1); the front end cover (3) and the back end cover (4) are respectively hermetically connected on the front end and the back end of the cylinder body (2); the main shaft (5) is respectively in shaft hole movable fit with the front end cover (3) and the casing (1); the blades (6) are penetrating type blades; the cylinder body is in a circle and is provided with two circular tangent sections (2-1) which are mutually symmetrical and are arranged in parallel; the translation disk (8) is driven by the main shaft (5) to move horizontally; and the blades (6) shift along with the translation disk (8) and mainly linearly shift along the circular tangent sections (2-1). The invention has the characteristics of simple structure, large variable volume in the cylinder body, large displacement, small friction and wear, low noise, small power consumption, low manufacturing cost, long service life and the like.

Owner:陆春晖 +1

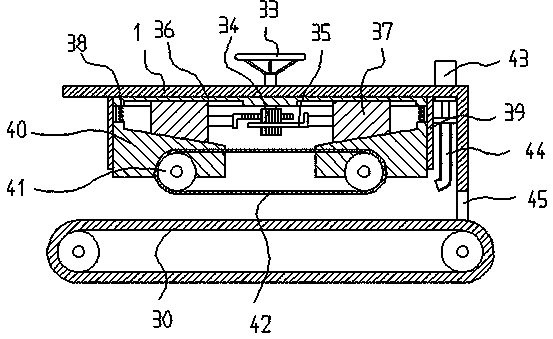

Xiang pig feed mixing equipment

ActiveCN108465426ARealize intermittent feedingImprove uniformityFeeding-stuffTransportation and packagingEngineeringFeed additive

The invention relates to the field of livestock breeding equipment and in particular discloses Xiang pig feed mixing equipment which comprises a mixing tank, a motor and two storage chambers, whereinthe motor is arranged above the mixing tank; the output end of the motor is coaxially fixedly connected with a rotating shaft; the storage chambers are connected with discharge tubes; control mechanisms are mounted at discharge holes of the discharge tubes; the rotating shaft is hinged with push plates for opening the control mechanisms; holding discs are arranged below the discharge holes; a cavity is formed inside the rotating shaft; feeding holes are formed in the side wall of the rotating shaft; the feeding holes are communicated with the cavity and the mixing tank; a third discharge tubeis communicated with the bottom of the cavity; the rotating shaft is coaxially fixedly connected with a plurality of stirring blades; a plurality of vertically arranged rotating plates are hinged withthe side wall of the mixing tank along the circumference of the mixing tank; the rotating plates are pushed to rotate in the rotation process of the stirring blades. By adopting the equipment, primary mixing of feed with feed additives can be achieved through the holding discs, secondary mixing can be achieved through the stirring blades, meanwhile, feed on the side wall of the mixing tank can bestirred and mixed through rotation of the rotating plates, and the uniformity degree of the feed and the feed additives can be increased.

Owner:湖南俊旺科技饲料有限公司

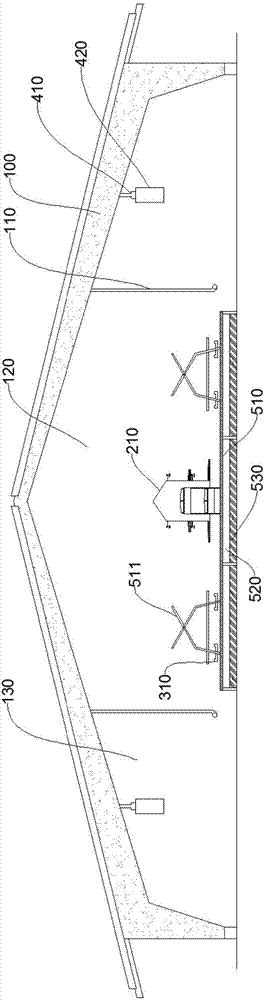

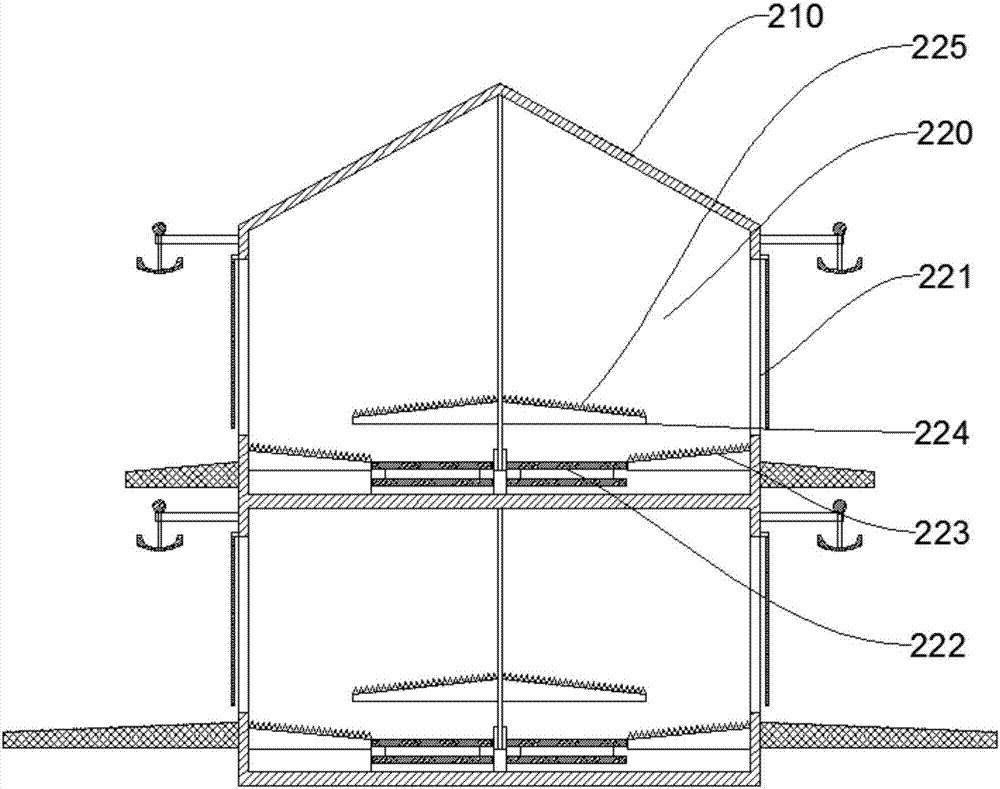

Chicken house for large-scale and organic cultivation of laying hens

The invention discloses a chicken house for large-scale and organic cultivation of laying hens. The chicken house comprises a chicken house body, an egg collecting system, a feed feeding system, a fodder feeding system and a manure collecting system, wherein two pieces of shade cloth are vertically and oppositely arranged in the chicken house body in a lifting mode so as to divide the chicken house body into a first area, which is located in the middle of the chicken house body, and two second areas which are located on both sides of the chicken house body; the egg collecting system, the feed feeding system and the manure collecting system are arranged in the first area, and the egg collecting system is used for collecting eggs laid by the laying hens; the feed feeding system is used for conveying feed into the chicken house, and the manure collecting system is used for collecting and processing manure generated in the first area; the fodder feeding system is disposed in the second area and used for adding fodder to the second area. According to the chicken house for large-scale and organic cultivation of the laying hens, through the chicken house, the incidence of the laying hens can be reduced, the drug residues in the eggs can be reduced, and the quality of the eggs can be ensured.

Owner:都尔霍姆(武汉)有机农业有限公司

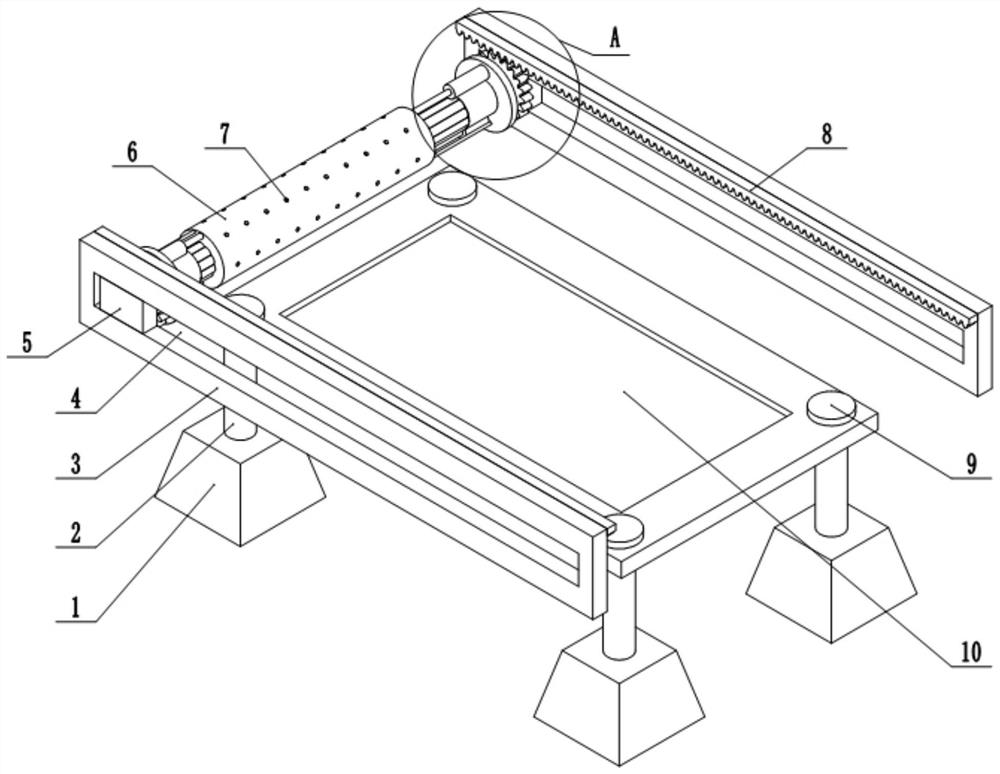

Processing equipment for aluminum panel for light-weight aluminum panel curtain wall

ActiveCN111633491AAvoid damaging the aluminum veneerAvoid the problem of poor sanding effectGrinding carriagesGrinding drivesPolishingSingle plate

The invention belongs to the field of building processing, and particularly discloses processing equipment for an aluminum panel for a light-weight aluminum panel curtain wall. A working table is arranged on a rack; a fixing mechanism for fixing the aluminum panel is arranged on the working table; a polishing mechanism is arranged on the rack and comprises a sliding plate slidably connected onto the rack; an installation base is slidably connected onto the sliding plate; a rotary shaft is rotatably connected onto the installation base; a polishing roller is in spline connection onto the rotaryshaft; an installation plate is fixed to the end part of the rotary shaft; a pressure sensor is arranged on the surface of one side, close to the polishing mechanism, of the working table; a controller in signal connection with the pressure sensor is further arranged; the input end of the controller is used for receiving a pressure signal of the pressure sensor; and the output end of the controller controls the sliding speed of the installation base driven by a second drive piece and the sliding frequency of the polishing roller driven by a fourth drive piece. By adopting the scheme of the invention, the problem of lower manual polishing efficiency can be solved.

Owner:重庆津浦科技发展有限公司

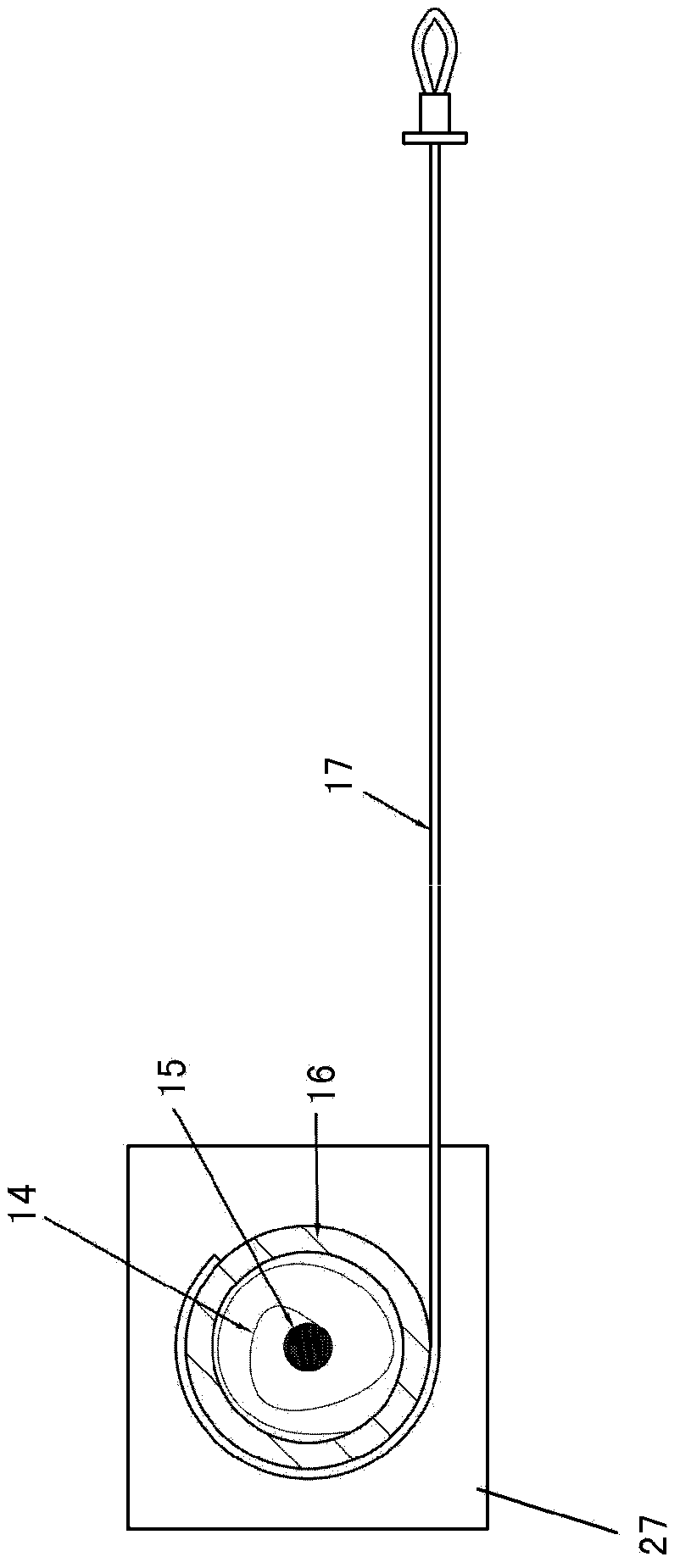

Sliding door pulling and buffering device

ActiveCN103422760ASlow down the sliding speedSimple structureBuilding braking devicesWing openersEngineeringMechanical engineering

The invention discloses a sliding door pulling and buffering device which is composed of a pulling device and a buffering device. The pulling device comprises a shell, a rotating shaft and a winding drum. The rotating shaft is movably supported in the shell, one end of a winding spring is fixed on the rotating shaft while the other end of the same is fixed on the winding drum, a pulling rope is fixed on the outer surface of the winding drum, and one end of the pulling rope can extend out of the shell. The buffering device comprises a cylindrical body and a piston rod. A piston is arranged at one end of the piston rod, the outer surface of the piston contacts with the surface of an inner cavity of the cylindrical body, and an air hole is formed at the bottom end of the inner cavity of the cylindrical body. The sliding door pulling and buffering device has the advantages that the device is simple in structure and convenient to use, sliding speed of a sliding door can be reduced automatically and effectively, noise is reduced, service lives of the sliding door and accessories thereof are prolonged, and the like.

Owner:坂口俊 +1

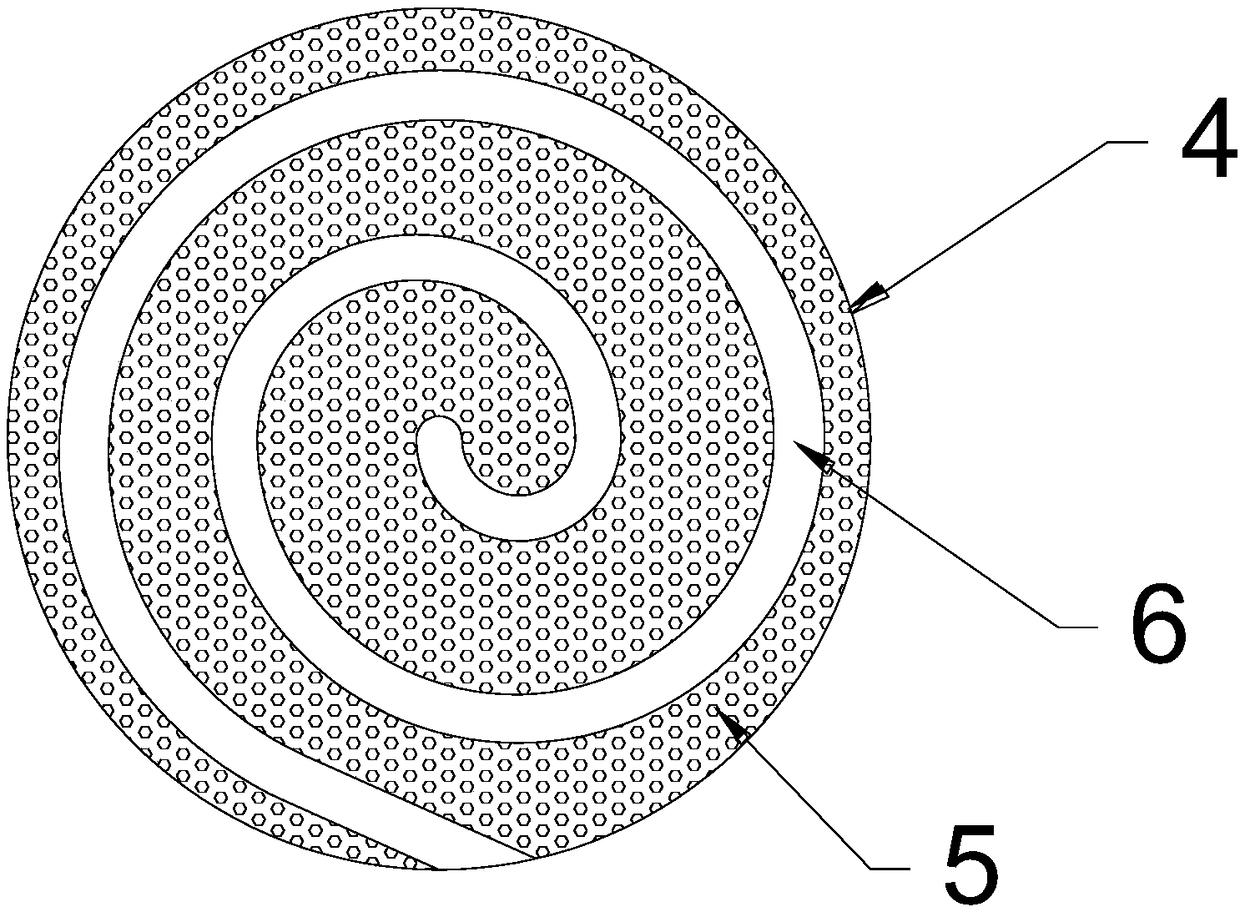

Puer tea drying device

InactiveCN108332544ADry evenly and thoroughlyAvoid accumulationPre-extraction tea treatmentTea dryingDrive shaftEngineering

The invention discloses a puer tea drying device. The puer tea drying device comprises a box. The part, located below a feeding hopper, of the box is internally provided with scattering drying discs,and meshes are evenly distributed in the scattering drying discs. The surfaces of the scattering drying discs are fixedly connected with spiral-shaped spiral protruding strips. The scattering drying discs are fixedly connected with a drive shaft, and the drive shaft extends to the position below the box and is connected with a drive motor. Through the arrangement of multiple sets of rotating scattering drying discs and vibration gathering drying discs, puer tea is constantly overturned, puer tea stacking is avoided, the overturned puer tea is dried through hot air, and drying is more uniform and thorough; meanwhile, the scattering drying discs are provided with the spiral protruding strips, the gathering drying discs are provided with annular protruding strips, the slipping speed of the puer tea is delayed, and the drying time is prolonged; and the prepared puer tea appearance and inner quality are superior to the appearance and the inner quality of puer tea prepared through an ordinary oven, and the drying effect is improved.

Owner:苏州高新区鼎正精密机电有限公司

Processing technology for camellia oil

InactiveCN109593598AImprove shelling ratePure tasteFatty-oils/fats refiningFatty-oils/fats productionBranFood processing

The invention provides a processing technology for camellia oil and relates to the technical field of food processing. By taking camellia seeds, the oil content of which is 28-30%, as a raw material,the processing technology comprises the following steps: drying the camellia seeds and quick-freezing the camellia seeds; shelling the quick-frozen camellia seeds to obtain camellia seed kernels; mixing the micro-roasted camellia seed kernels with fresh bran coats uniformly, and carrying out low-temperature squeezing to obtain squeezed oil; and carrying out centrifugal filtration and distillationto obtain the camellia oil. The processing technology for camellia oil prevents generation of B(a)P in the processing course, is high in oil yield, and keeps the inherent smells and taste of the camellia oil. The camellia oil is pure in taste and natural nutritional components are kept intactly.

Owner:湖南泥头山油茶开发有限公司

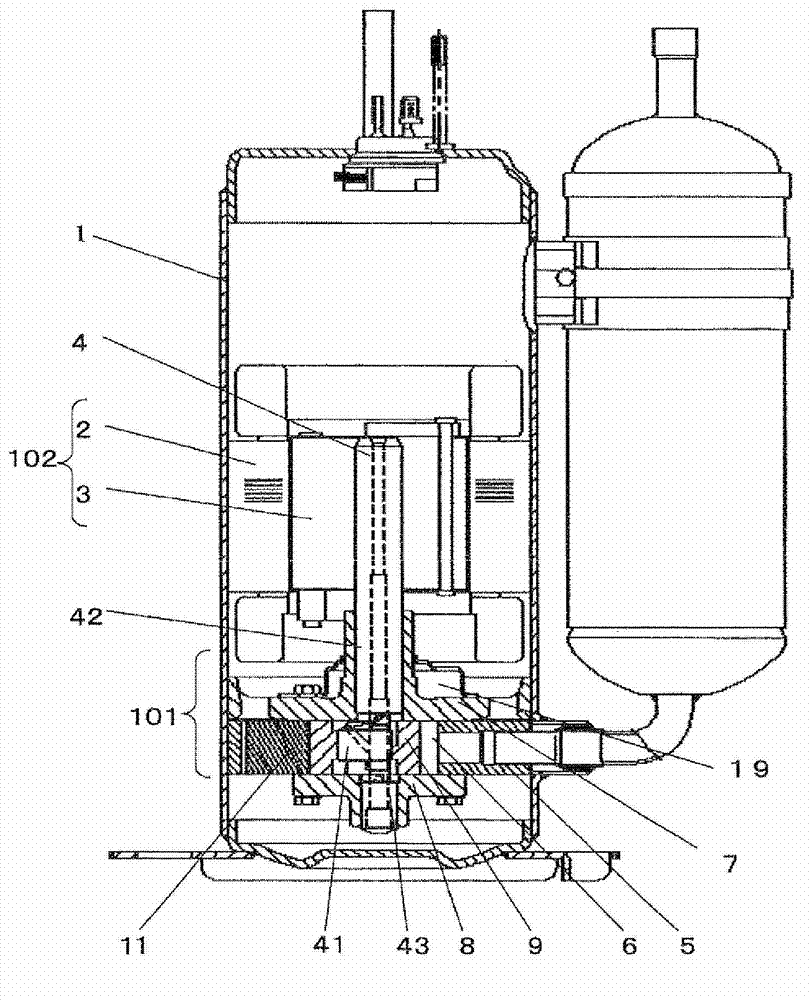

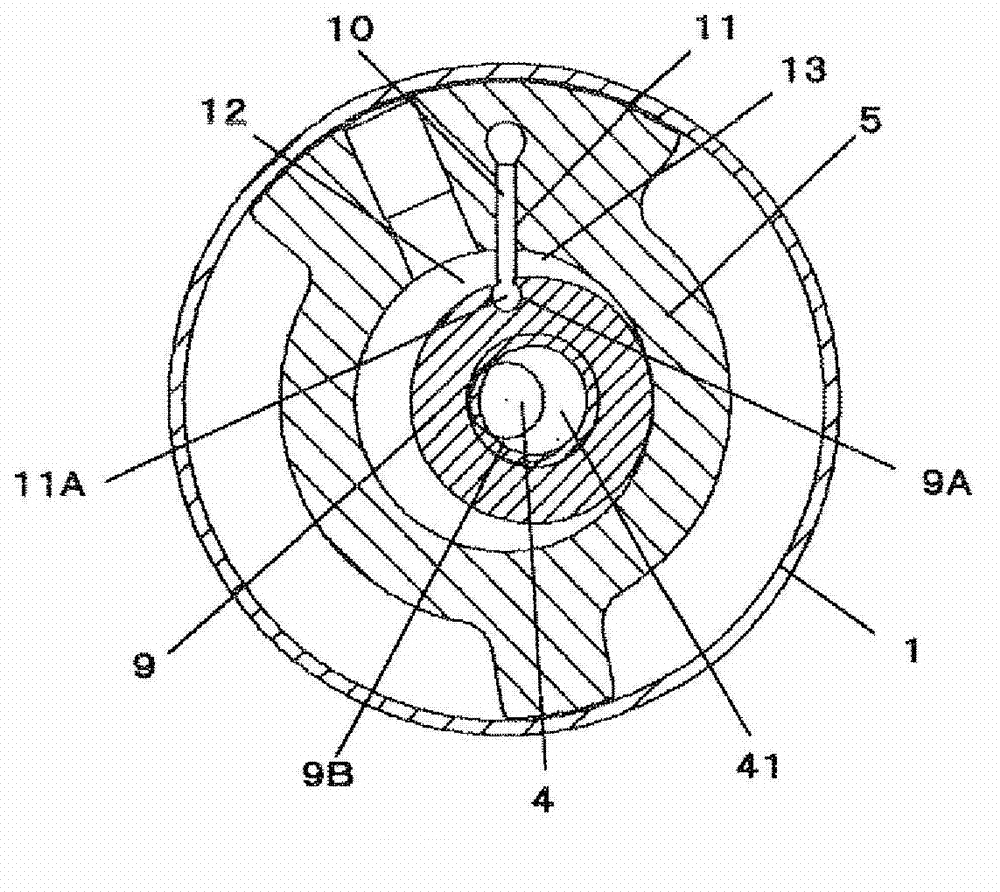

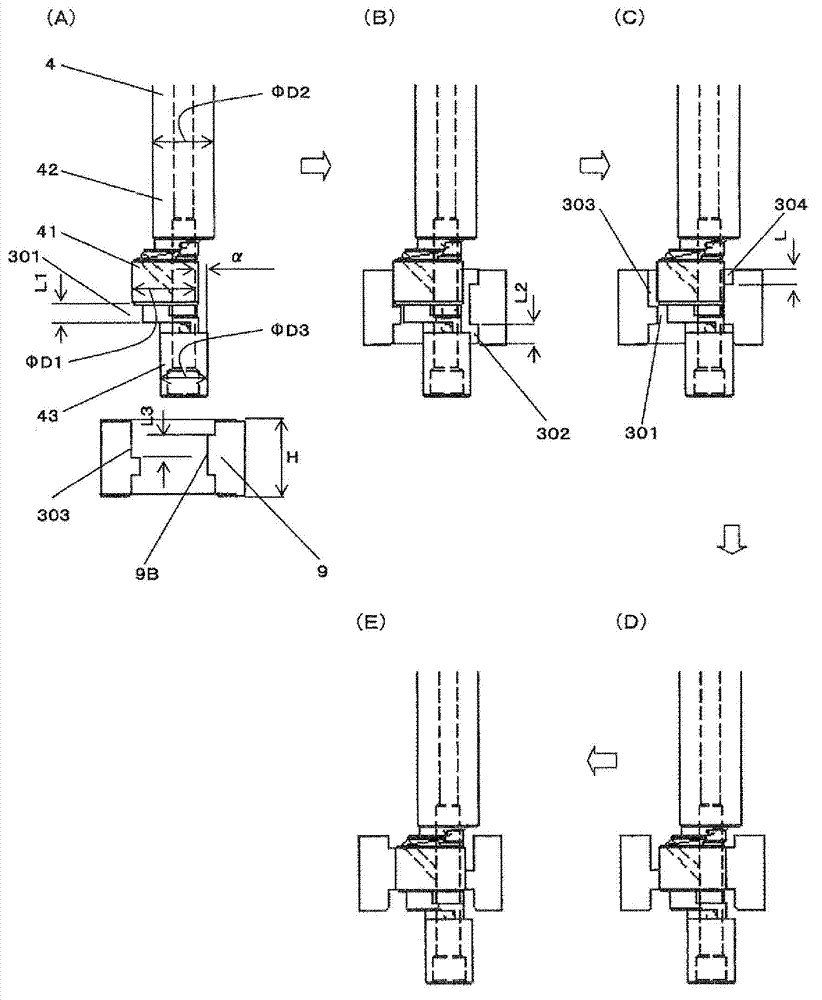

Rotary compressor

ActiveCN102971537AGuaranteed Strength and ReliabilityReduce shaft diameterRotary piston pumpsRotary piston liquid enginesReciprocating motionPiston

Disclosed is a vane rotary-type rotary compressor wherein the opposite eccentric shaft-side outer peripheral surface of an eccentric portion (41) of a shaft (4) is deviated further inward than the outer peripheral surface of a main shaft portion (42) to be fitted in a main bearing (7) and the outer peripheral surface of a subsidiary shaft portion (43) to be fitted in a subsidiary bearing (8), and clearance means necessary when a piston (9) is assembled with the shaft (4) are provided on the inner peripheral surface of the piston (9) and the eccentric portion (41) of the shaft (4), so that the shaft diameter of the eccentric portion (41) is reduced. Thus, the viscous force of oil applied to the eccentric portion (41) of the shaft (4) and the inner peripheral surface of the piston (9) can be reduced, and the rotational moment around the center of the eccentric portion (41) of the shaft (4), which is applied to the piston (9) in the rotational direction of the shaft (4), can be reduced. Therefore, the sliding loss generated due to the reciprocation of a vane (11) within a vane groove (10) can be reduced.

Owner:PANASONIC INTELLECTUAL PROPERTY MANAGEMENT CO LTD

Plastic sheet polishing equipment

InactiveCN108381365ACausing unevennessAchieve regulationPolishing machinesGrinding work supportsEngineeringSlide plate

The invention relates to the technical field of plastic machining, and particularly discloses plastic sheet polishing equipment. The plastic sheet polishing equipment comprises a machine frame and a working table, a first sliding plate is horizontally connected to the working table in a sliding manner, the first sliding plate is provided with a mechanism used for clamping plastic sheets, a secondsliding plate is in sliding connection to the machine frame and is connected with a motor, a rotating shaft is connected with the output end of the motor, a first gear and a polishing wheel used for polishing the plastic sheets are coaxially and fixedly connected to the rotating shaft, a vent pipe is rotationally connected to the polishing wheel, a channel is formed in the polishing wheel and is used for communicating the surface of the outer circumference of the polishing wheel and the vent pipe, and a plurality of fan blades are coaxially installed on the rotating shaft and are located in the vent pipe; and a first rack meshed with the first gear is connected to the machine frame, a second rack is arranged on the first sliding plate, a second gear is meshed with the second rack, and thefirst gear can be meshed with the second gear after the first gear and the first rack are meshed. By means of the plastic sheet polishing equipment, the plastic sheets can be polished, and dust generated during polishing can be treated in time.

Owner:宁波隆锐机械制造有限公司

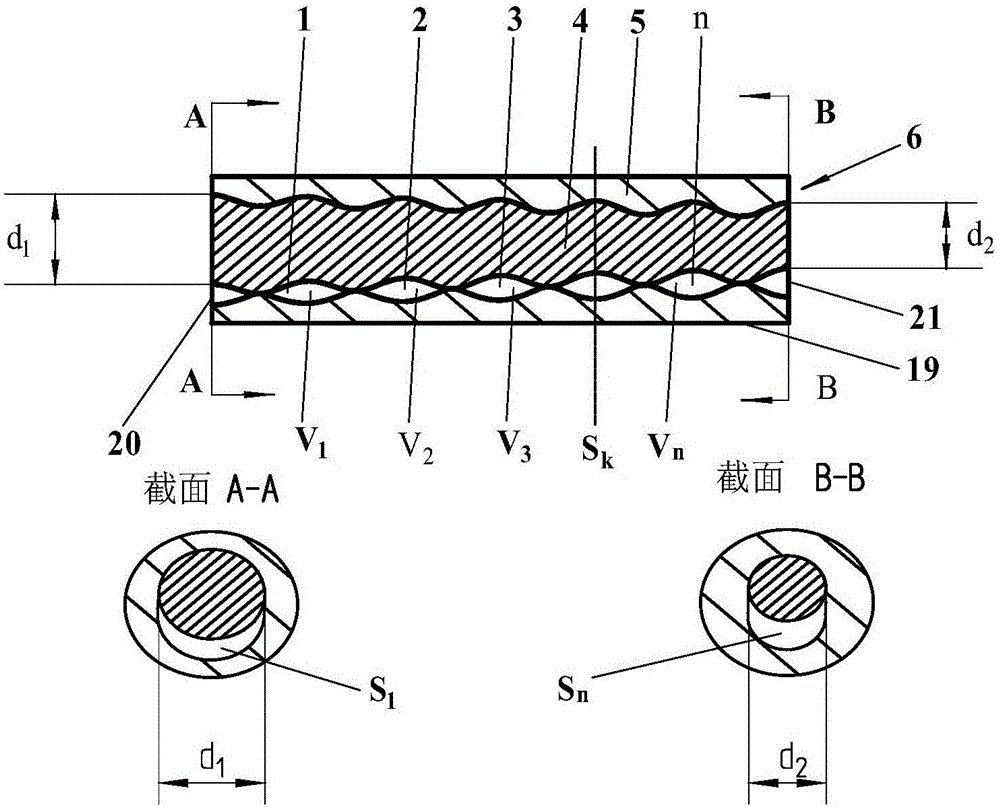

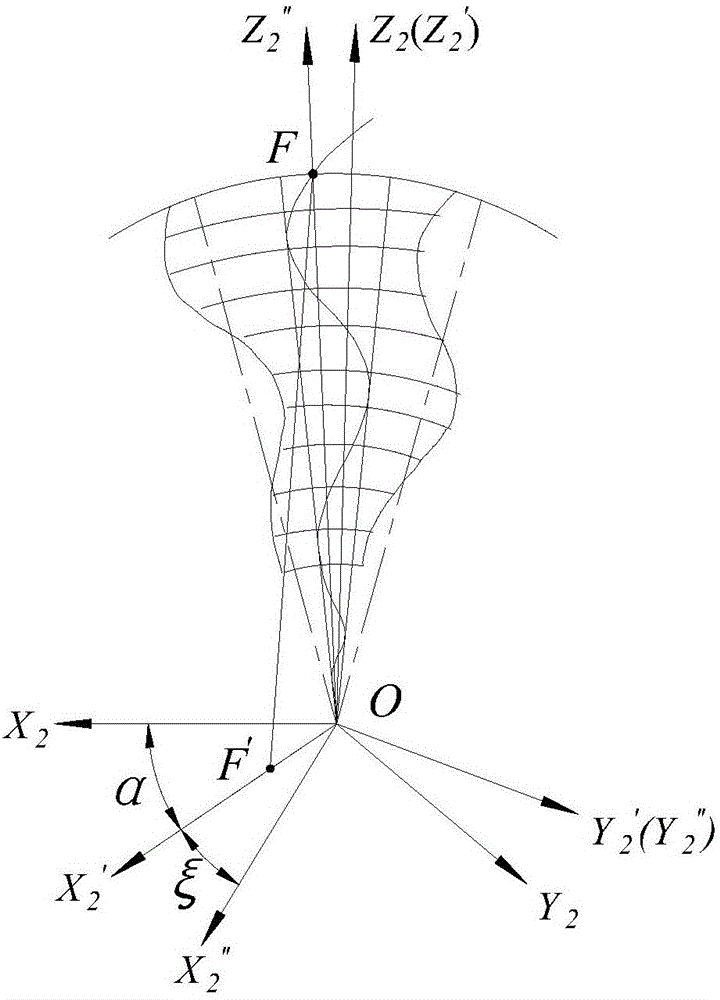

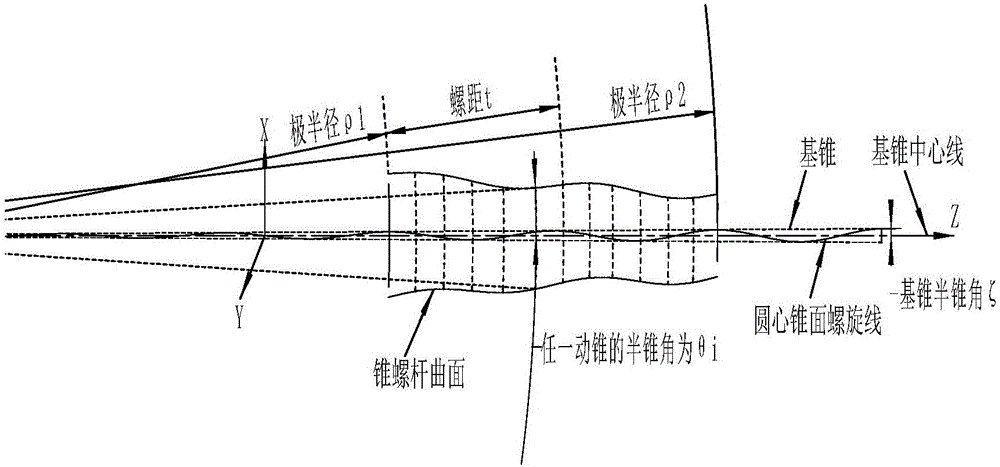

Equal-flow area conical screw-sleeve pair

InactiveCN106640627APromote theoretical researchIncrease displacementRotary piston pumpsRotary piston liquid enginesPressure riseEngineering

The invention discloses an equal-flow area conical screw-sleeve pair, which belongs to the application field of single-screw pumps. A conical sleeve comprises an inner curved conical sleeve surface, a big conical sleeve end surface, a small conical sleeve end surface, and an outer cylindrical conical sleeve surface; a big conical screw end surface and the big conical sleeve end surface compose an inlet end of the conical screw-sleeve pair; and a small conical screw end surface and the small conical sleeve end surface compose an outlet end of the conical screw-sleeve pair. The flow area of one section of the conical screw-sleeve pair is defined as a difference between the area of the inner curved conical sleeve surface and the area of an outer curved conical screw surface in the section. The equal-flow area characteristic and equal-cavity characteristic of the conical screw-sleeve pair can help increase the displacement of a single-head conical screw pump and reduce pressure fluctuation, so that flow is smoother; moreover, pressure rise from the inlet end to the outlet end is relatively small, relative sliding speed is low in the process of movement, consequently, abrasion is reduced, and the service life is prolonged.

Owner:BEIJING UNIV OF TECH

Water-lubricated sliding bearing

InactiveCN103994204ADecrease Relative Motion Swipe SpeedIncrease working speedPortable liftingToothed gearingsEngineeringGear drive

Owner:XI AN JIAOTONG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com