Roller bearing and roller chain mounted with roller bearing

A technology of roller bearing and roller chain, applied in the field of roller chain, can solve the problems of difficult management, high cost, low production efficiency of roller 5, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0060] The following description is exemplary only and does not limit the invention or its application or use.

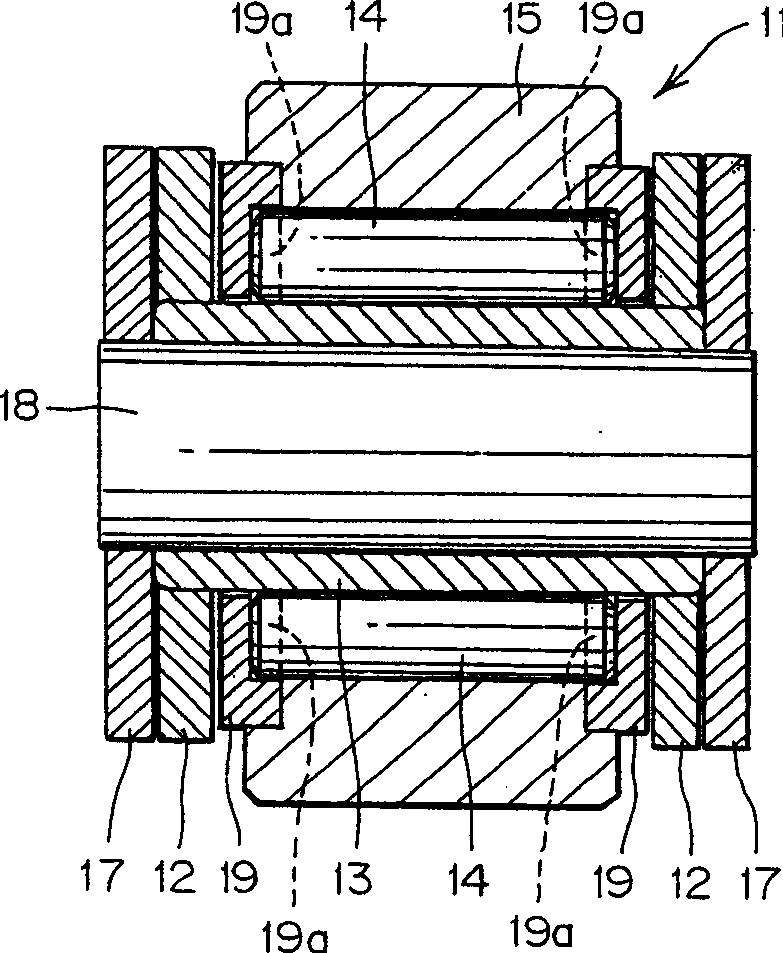

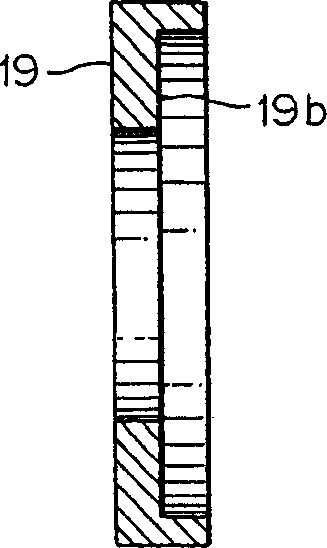

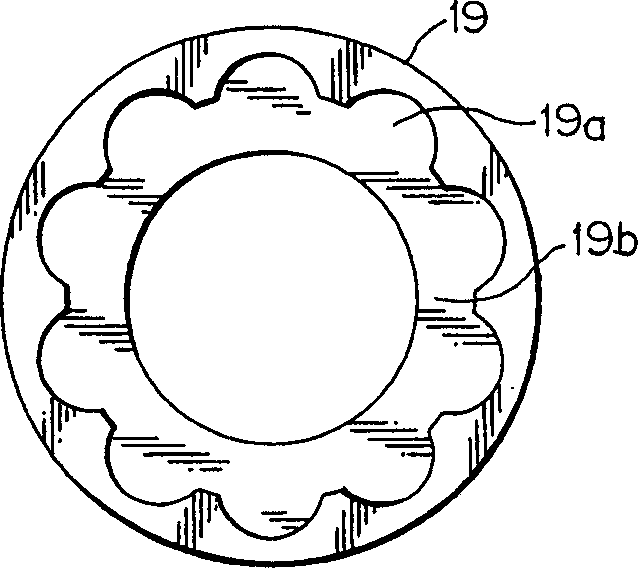

[0061] refer to figure 1 , FIG. 2(A) and FIG. 2(B) describe a first embodiment of the present invention. figure 1 is a sectional view of the roller chain with roller bearings according to the first embodiment of the present invention. Figures 2(A) and 2(B) are used in figure 1 The cage in the roller chain, in particular, Figure 2 (A) is its cross-sectional view, Figure 2 (B) is a top view. exist figure 1 In the roller chain 11 shown in , a plurality of rollers 14 are arranged on the outer circumference of the bushing 13, for example, there are 10 rollers 14 here, and the two ends of the bushing are connected with a pair of inner connecting plates 12, and the rollers Columns 15 are connected to surround the rollers 14 . Moreover, an outer connecting plate 17 is also provided on the outer side of the inner connecting plate 12 , and the outer connecting plates 17 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com