Gas-solid reactor

A technology of gas-solid reaction and reactor, which is applied in the direction of gas/steam and solid mixing, dissolution, chemical instruments and methods, etc. It can solve the problems that are not involved in continuous operation of gas-solid reactors, etc., so as to delay the falling speed of solids and control Reaction time, effect of preventing uneven particle distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

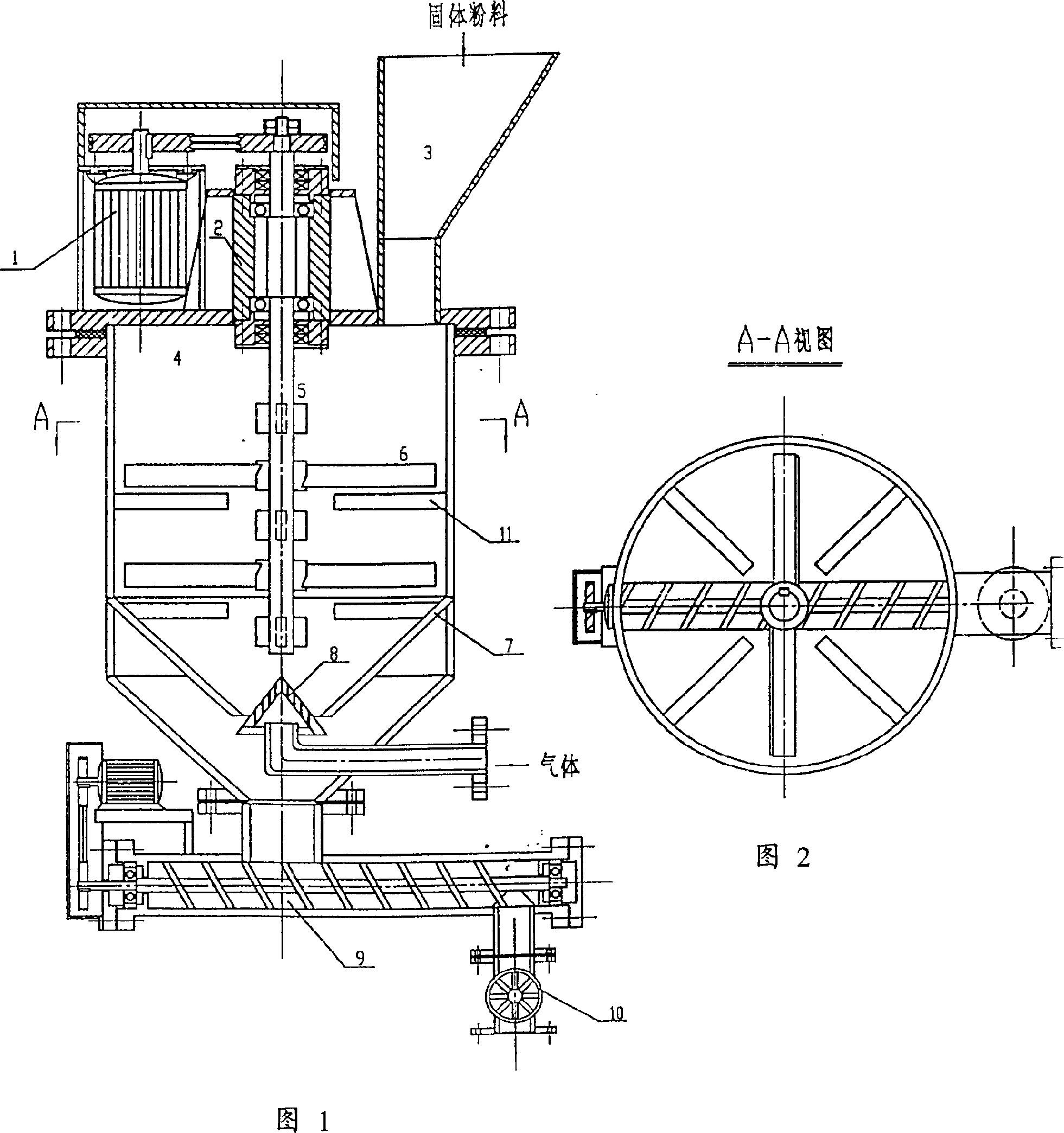

[0028] This example shows that: using the reaction kettle provided by the present invention to carry out gas-solid reaction can obtain relatively ideal reaction efficiency.

[0029] A gas-solid reaction kettle is manufactured according to the description of the present invention. The height of the barrel part of the reaction kettle is 1.0m, and the diameter is 0.3m; the height of the barrel part is 1.0m, and the height of the conical part is 0.15m; The porosity is 20%; the bottom angle of the cone-shaped solid unloader is 45°, and the diameter of the lower end surface is 0.22m; the stirring paddle adopts a single-layer airfoil type two-blade blade, the length of the blade is 0.08m, and the speed of operation is controlled at 5~ 10 rpm. During installation, the end face of the inverted cone gas distributor and the lower end face of the truncated cone solid unloader are on the same plane; a single-screw conveyor is used, and the outlet air-seal slide valve is an 8-leaf slide va...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com