Processing equipment for aluminum panel for light-weight aluminum panel curtain wall

A technology for processing equipment and aluminum veneers, applied in metal processing equipment, grinding/polishing equipment, machine tools suitable for grinding workpiece planes, etc., can solve problems such as low work efficiency, and achieve good grinding effect and good grinding effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be described in further detail below in combination with the accompanying drawings, and specific implementation methods will be given.

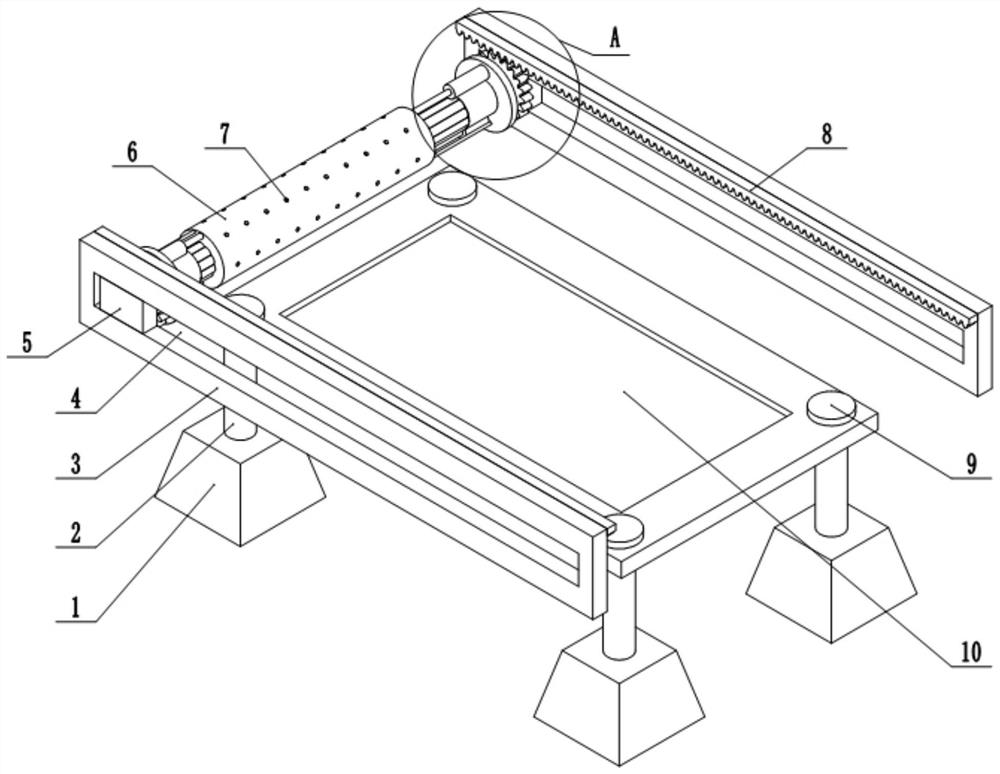

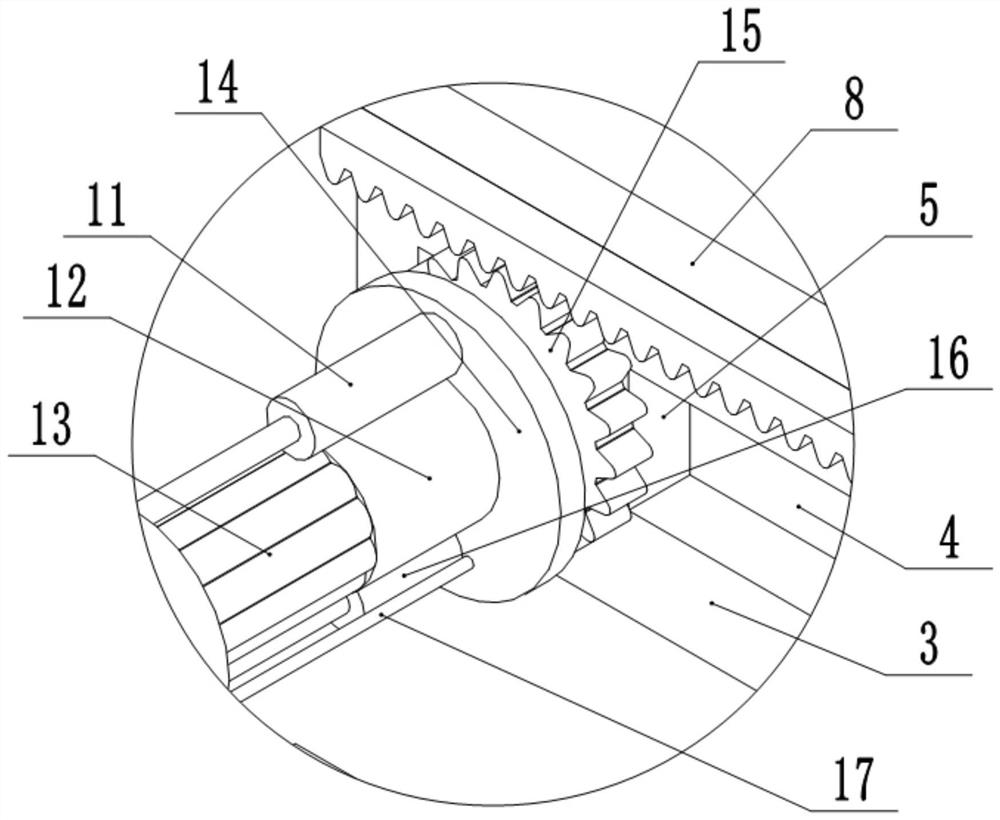

[0034] Such as figure 1 , figure 2 As shown, an aluminum veneer processing equipment for lightweight aluminum veneer curtain wall includes a frame on which a horizontally placed workbench is installed. Specifically, four support legs 2 are fixed on the frame, and the support legs The lower ends of 2 are fixed with a square base 1, the upper end of the support leg 2 is provided with threaded grooves, and the four corners of the workbench are provided with threaded holes, and the workbench is placed on the support legs 2, so that the threaded holes and threaded grooves After alignment, connect by bolt 9. The upper surface of the workbench is provided with a groove 10 for embedding the aluminum veneer, and a fixing mechanism for fixing the aluminum veneer is installed on the workbench, and the fixing mechanis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com