Grinding and pressing fixing frame of a ball mill

A fixed frame, ball mill technology, applied in grain processing and other directions, can solve the problems of material cracking, poor grinding effect, insufficient material contact, etc., to achieve the effect of reducing space and avoiding damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] The ball mill is the key equipment for crushing the material after it is crushed. This type of grinding machine is filled with a certain number of steel balls in its cylinder as the grinding medium. It is widely used in cement, silicate products, new building materials, refractory materials, chemical fertilizers, black and non-ferrous metal beneficiation, glass ceramics and other production industries, for dry or wet grinding of various ores and other grindable materials. Ball mills are suitable for grinding various ores and other materials, and are widely used in mineral processing, building materials and chemical industries. They can be divided into dry and wet grinding methods.

[0034] However, when steel balls are used as grinding media, the steel balls will fall to the top along with the vortex inside the roller. On the one hand, insufficient contact with the material will result in poor grinding effect. On the other hand, the steel balls will fall Dropping is ea...

Embodiment 2

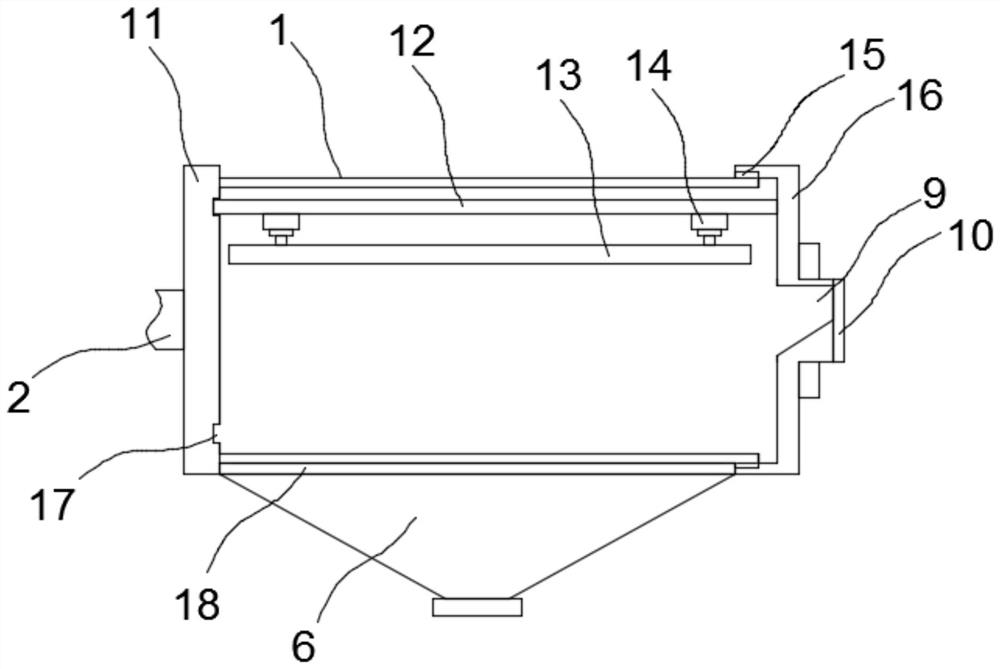

[0049] The embodiment of the present invention is further limited on the basis of embodiment 1.

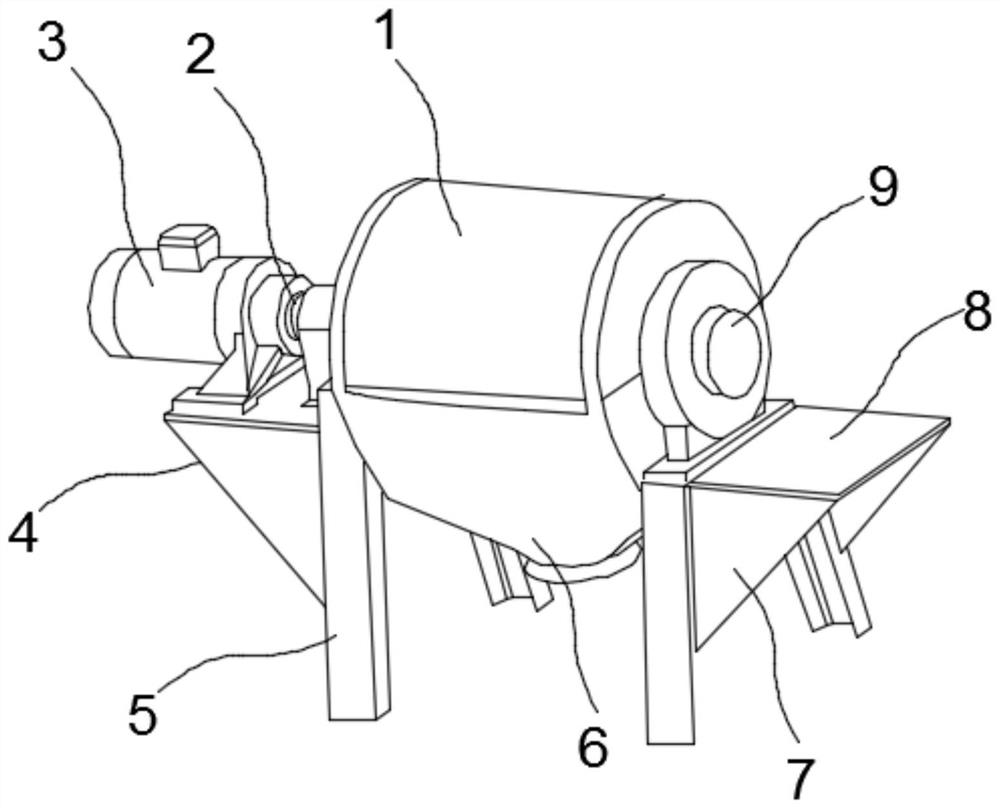

[0050] see figure 1 , the roller 1 is installed on the support frame, and the support frame is composed of two side support frames 4 distributed in parallel, and the transmission shaft 2 is fixed on the roller 1, and one end of the transmission shaft 2 is fixed on the output of the motor 3 On the shaft, and the motor 3 is fixed on the side support frame 4.

[0051] Optimally, a support plate 8 is provided on the side support frame 4 , and a support leg 5 is fixed at the lower end of the support plate 8 , and a reinforcing triangular plate 7 is installed between the support leg 5 and the support plate 8 .

Embodiment 3

[0053] The embodiment of the present invention is further limited on the basis of embodiment 1 and embodiment 2.

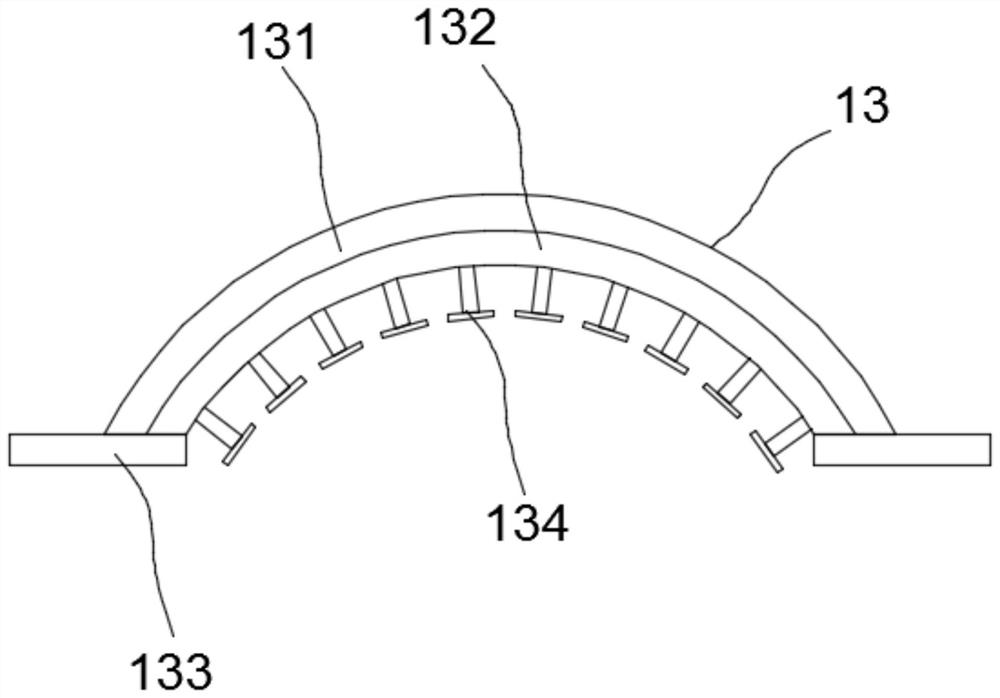

[0054] see image 3, the pressing plate 13 is composed of an outer fixing plate 131 and an inner reinforcing plate 132 arranged at the lower end of the outer fixing plate 131, and a plurality of unit support column structures 134 distributed in an array are installed at the lower end of the inner reinforcing plate 132.

[0055] Optimally, the unit support column structure 134 is provided with a support column, and a buffer plate is fixed at the lower end of the support column, and the support column is a telescopic rod, and a spring is sleeved outside the support column.

[0056] Furthermore, during the working process of the ball mill, the unit support column structure 134 can utilize springs for shock absorption, which avoids the steel balls being damaged when they violently hit the pressing plate 13 as the grinding medium.

[0057] The working principle of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com