Hybrid drive apparatus

A driving device and hybrid technology, applied in the direction of power devices, hybrid vehicles, pneumatic power devices, etc., can solve the problems of high relative speed, influence of transmission efficiency of hybrid drive devices, increase of rotation difference, etc., and achieve effective transmission , effective regeneration, power transmission loss suppression effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

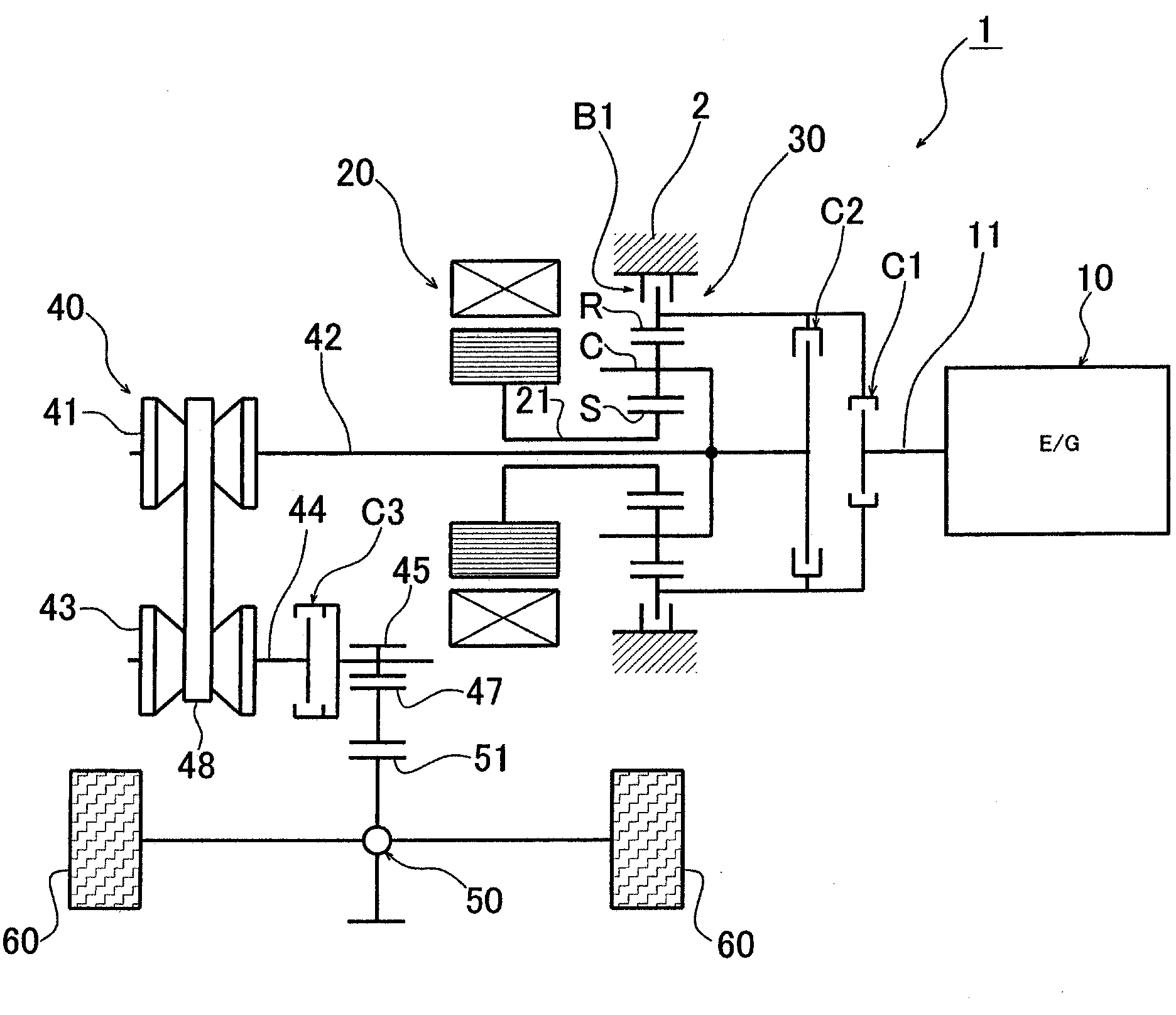

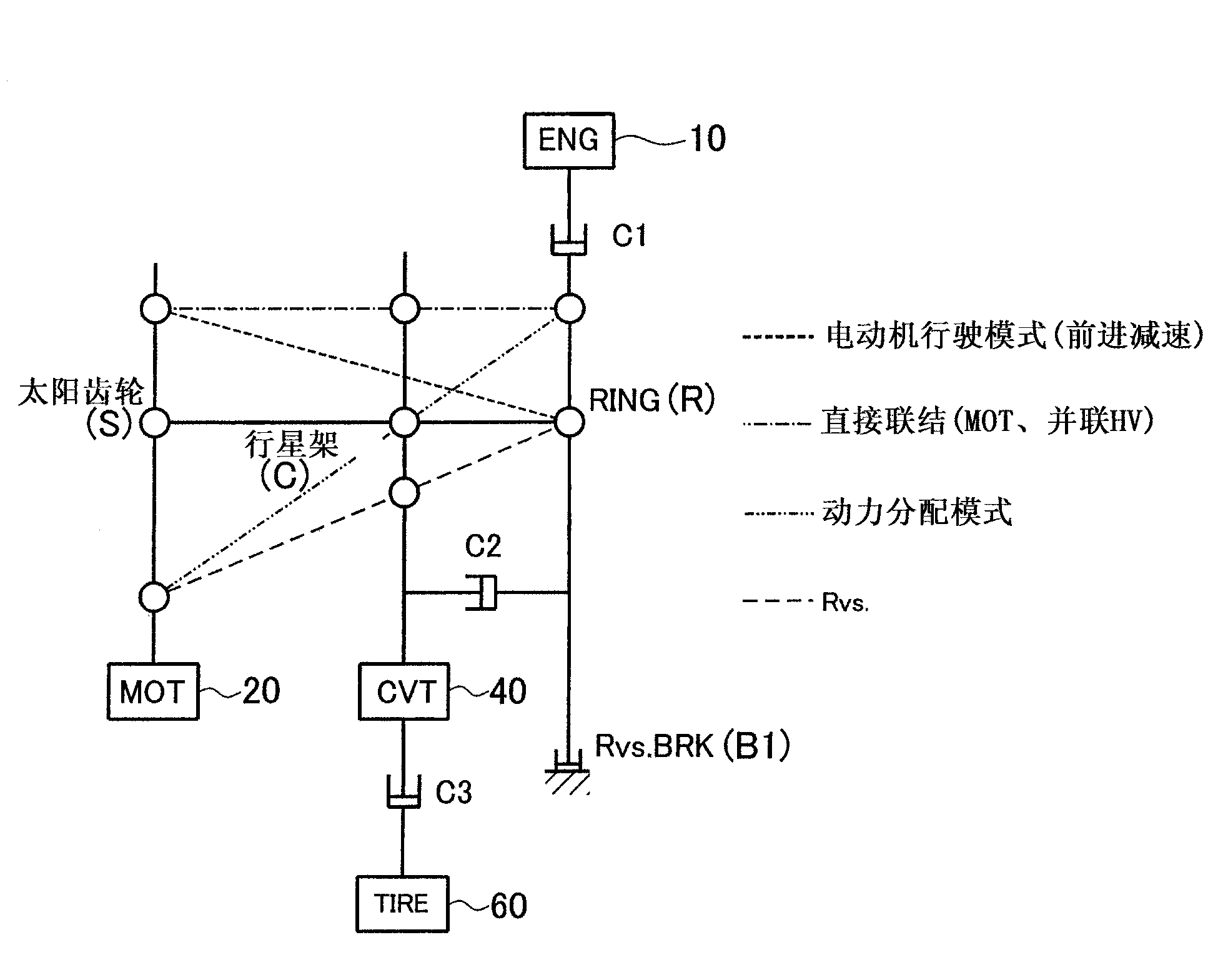

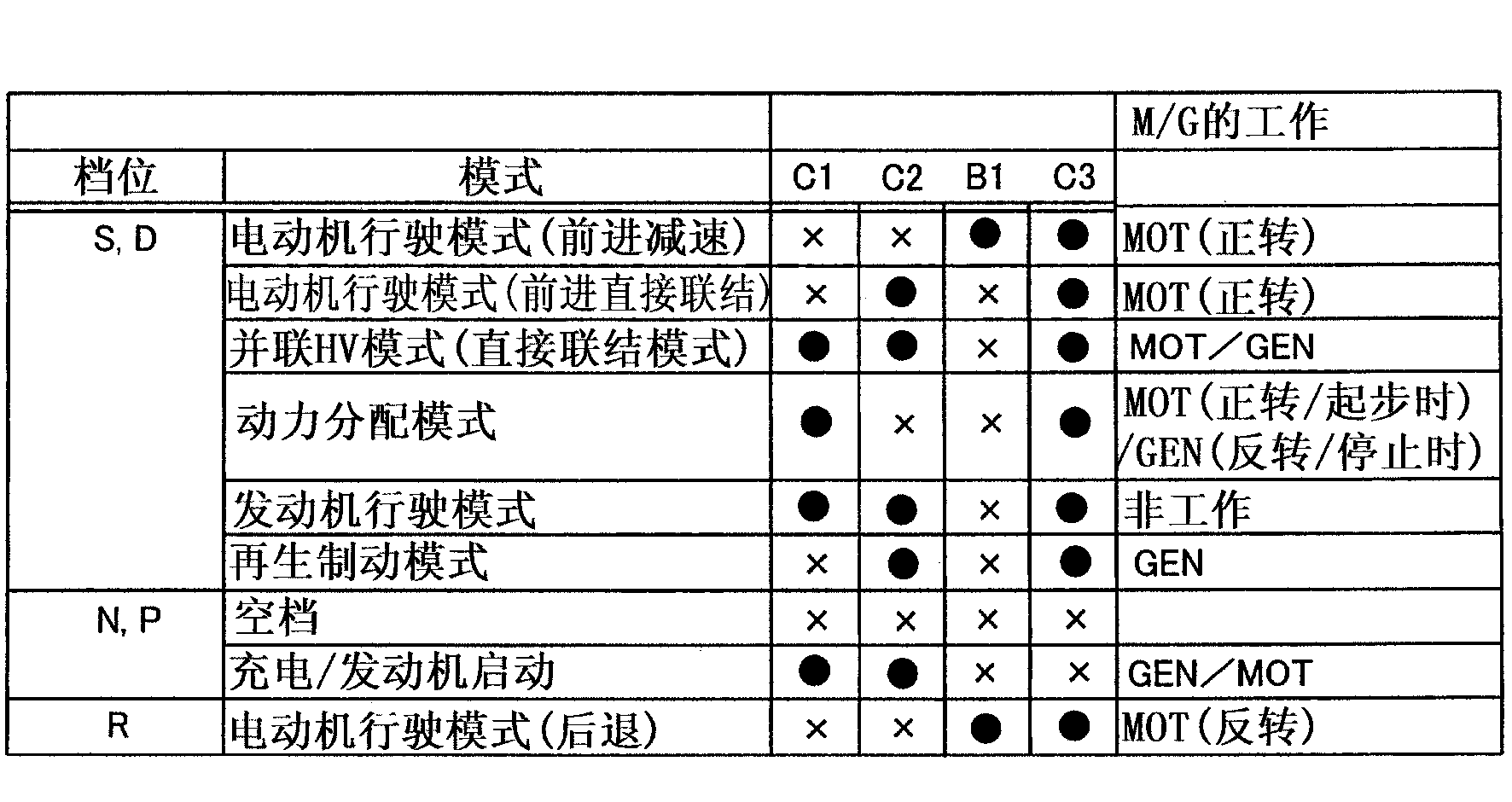

[0054] figure 1 It is a schematic diagram showing the configuration of the hybrid drive device according to the first embodiment of the present invention. also, figure 2 It is a nomographic diagram (velocity diagram) showing the velocity relationship of each element of the planetary gear mechanism included in the hybrid drive device. figure 1 The illustrated hybrid drive device 1 is configured to include: an engine 10 that generates power by burning fuel; a motor generator 20 that functions as an electric motor and a generator; a single-planetary planetary gear mechanism (planetary gear ) 30 having three elements of the sun gear S, the ring gear R, and the carrier C;

[0055] The output shaft (rotation shaft) 21 of the motor generator 20 is connected to the sun gear S of the planetary gear mechanism 30 , and the input shaft (first rotation shaft) 42 connected to the drive pulley 41 of the continuously variable transmission mechanism 40 is connected to the carrier C. In add...

no. 2 Embodiment approach

[0077]Next, a second embodiment of the present invention will be described. In addition, in the description of the second embodiment and the corresponding drawings, the same reference numerals are assigned to the same or corresponding structural parts as those of the first embodiment, and detailed description of these parts will be omitted below. In addition, matters other than the matters described below are the same as those of the first embodiment.

[0078] Figure 5 It is a schematic diagram showing the configuration of a hybrid drive device 1 - 2 according to the second embodiment of the present invention. In the hybrid drive device 1 - 2 shown in the figure, it is provided between the sun gear S and the carrier C of the planetary gear mechanism 30 (the output shaft 21 of the motor generator 20 and the input shaft 42 of the continuously variable transmission mechanism 40 between) the additional second clutch C2′ set to replace the figure 1 In the hybrid drive device 1 ...

no. 3 Embodiment approach

[0081] Next, a third embodiment of the present invention will be described. Figure 6 It is a schematic diagram showing the configuration of a hybrid drive device according to a third embodiment of the present invention. In the hybrid drive device 1 - 3 of the third embodiment shown in the figure, another third shaft provided on the input shaft (first rotating shaft) 42 connected to the driving pulley 41 of the continuously variable transmission mechanism 40 is provided. Clutch C3′, to replace the figure 1 In the hybrid drive device 1 of the first embodiment shown, the third clutch C3 is provided on the output shaft (second rotating shaft) 44 connected to the driven pulley 43 of the continuously variable transmission mechanism 40 . Other configurations are the same as those of the hybrid drive device 1 of the first embodiment.

[0082] In the hybrid drive device 1-3 of the present embodiment, the third clutch C3 is provided on the input shaft 42 of the continuously variable ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com