Drum Potato Harvester

A potato and harvester technology, which is applied to digging harvesters, harvesters, excavators, etc., can solve the problems of unfavorable potato harvesting mechanization, reduction of potato economic value, and limited depth of cutting soil, so as to improve the utilization rate of harvesting power, The structure is simple and the effect of improving the conveying efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

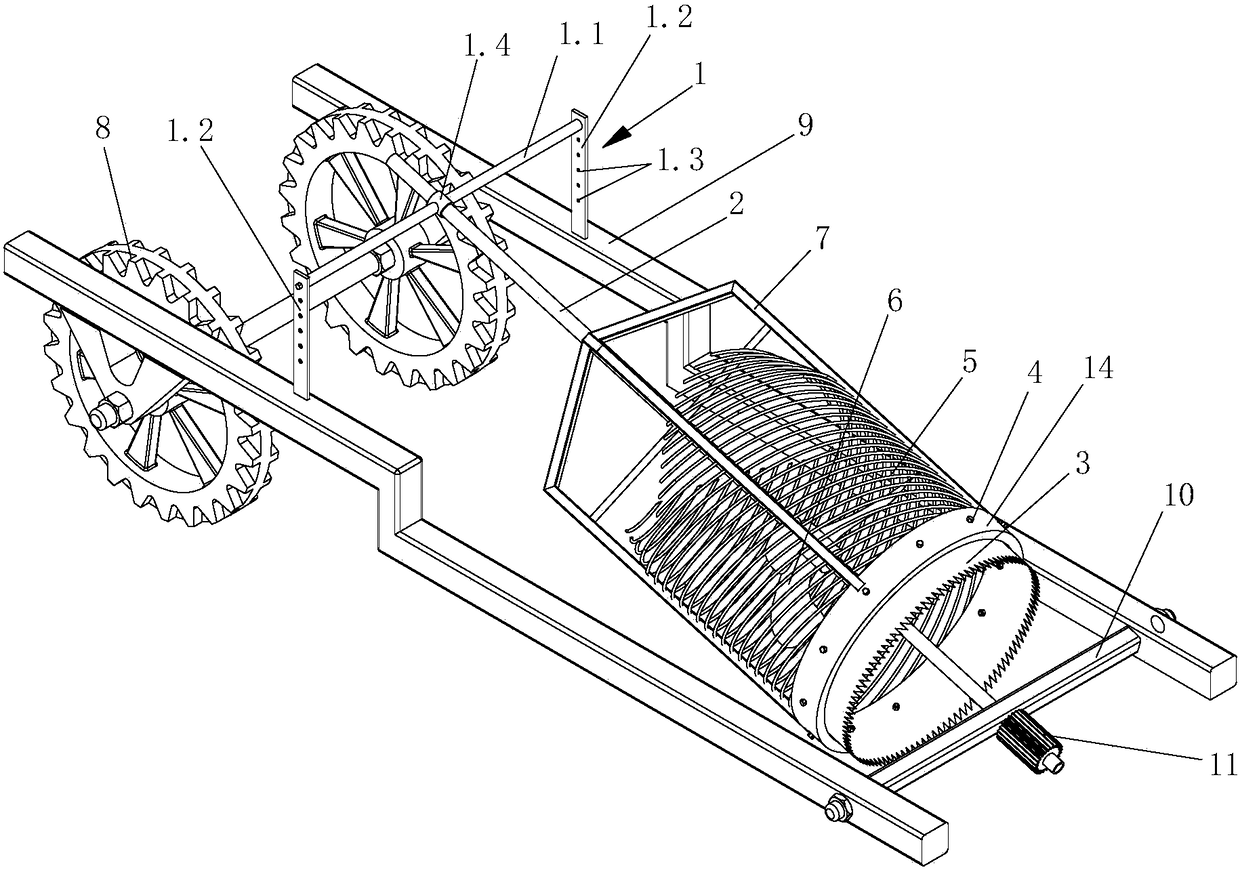

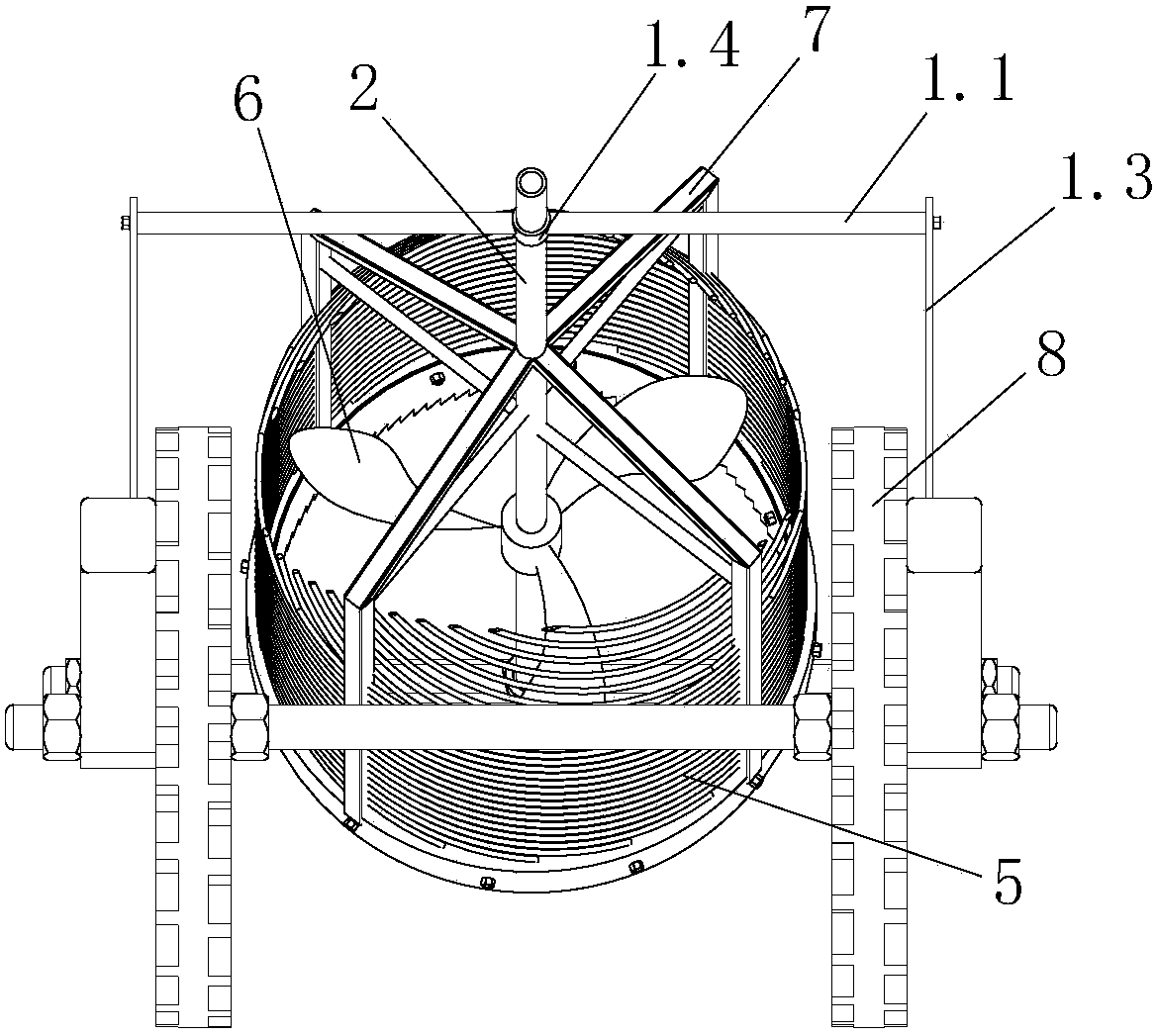

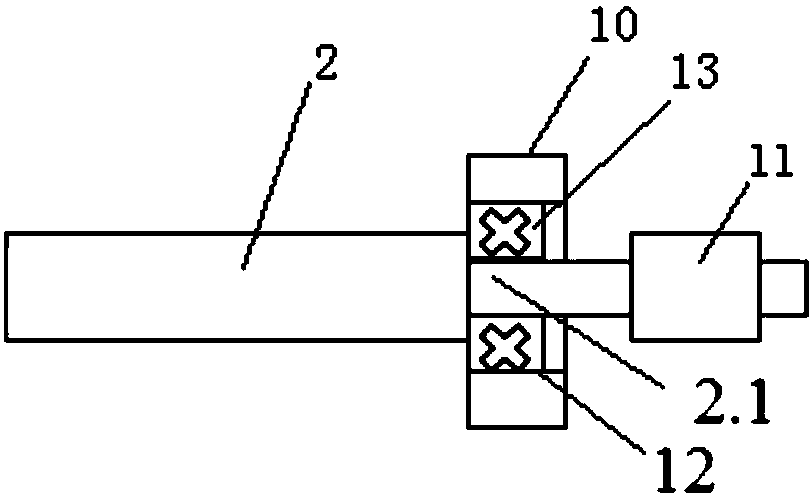

[0015] Such as Figure 1~3 Described drum-type potato harvester, it comprises fixed frame 9, rotating shaft 2, the screen frame 7 that is fixed on the rotating shaft 2, the annular soil cutting blade 3 that is fixed on the front end of screen frame 7, is fixed on the rotating shaft 2 The blade 6 in the middle, the spiral filter screen 5 fixed in the filter screen frame 7 in the circumferential direction, the wheel 8 arranged at one end of the fixed frame 9, the limit cross bar 10 fixed at the other end of the fixed frame 9, and the fixed frame 9 on the angle adjustment frame 1, wherein, one end of the rotating shaft 2 is rotatably connected with the angle adjusting frame 1, the other end of the rotating shaft 2 passes through the through hole 12 of the limit cross bar 10, and the rotating shaft 2 and the through hole 12 is rotationally connecte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com