Production method and production equipment of high-uniformity fiber

A technology of production equipment and production method, applied in the field of fiber spinning, can solve the problems of large coefficient of variation of elongation at break, uneven monofilament fineness, many broken ends, etc. The effect of surface temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

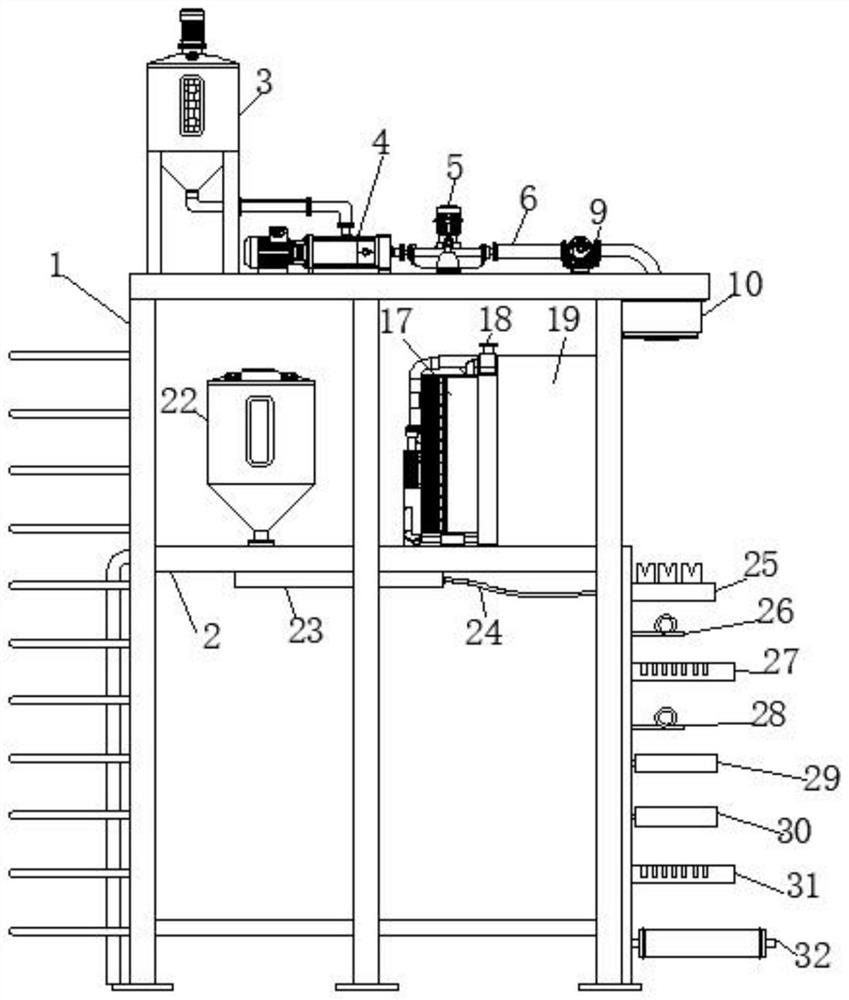

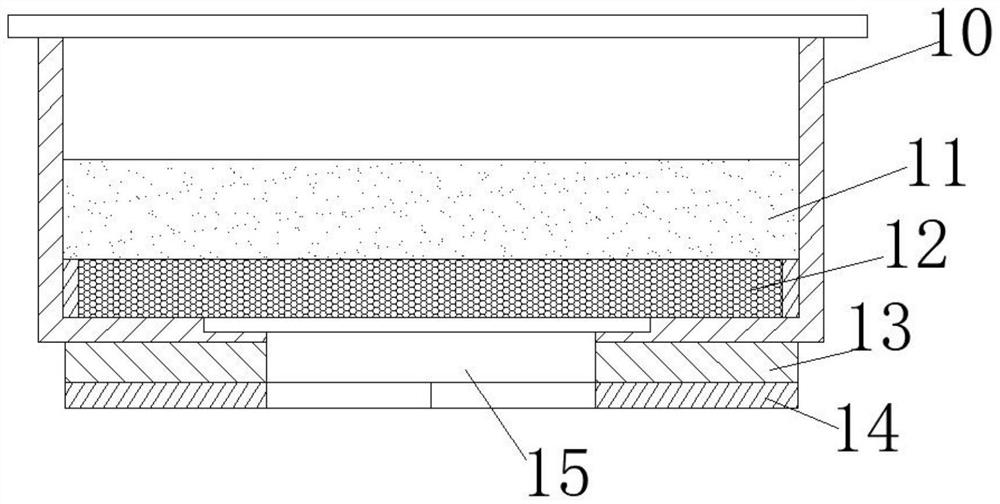

[0045] like Figure 1 to Figure 7As shown, the embodiment of the present invention provides a production equipment for high uniformity fibers, including a steel frame 1, the inner side wall of the steel frame 1 is fixedly connected with an intermediate platform 2, and the rear wall of the steel frame 1 is provided with an escalator for maintenance and feeding; The molten material barrel 3, the screw extrusion pump 4, the booster pump 5, the static mixer 6 and the metering pump 9 are fixedly connected to the top of the steel frame 1 in sequence from back to front. The inlet and outlet ends of the screw extrusion pump 4 pass through the The pipeline is communicated with the outlet end of the melt barrel 3 and the inlet end of the booster pump 5, and the inlet end and the outlet end of the static mixer 6 are communicated with the outlet end of the booster pump 5 and the inlet end of the metering pump 9 through the pipeline respectively;

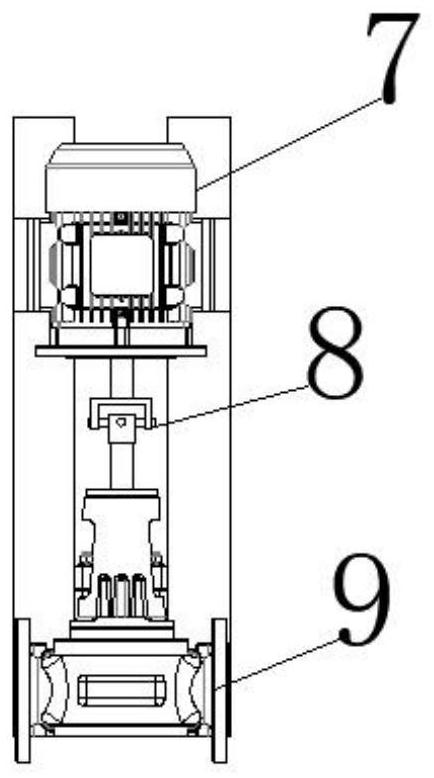

[0046] The drive motor 7 is fixedly conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com