Ceramic waxing and polishing machine

A technique for polishing machines and ceramics, which is applied in the direction of grinding/polishing equipment, grinding/polishing safety devices, and parts of grinding machine tools, etc. It can solve the problem that the contact area between the polishing belt and the ceramic sheet is small, affecting the dimensional accuracy of the ceramic, and polishing Thickness adjustment and other issues to achieve the effect of ensuring the quality of waxing, small mechanical loss, and stable work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to make those skilled in the art better understand the technical solutions of the present invention, the present invention will be described in detail below with reference to the accompanying drawings. The description in this part is only exemplary and explanatory, and should not have any limiting effect on the protection scope of the present invention. .

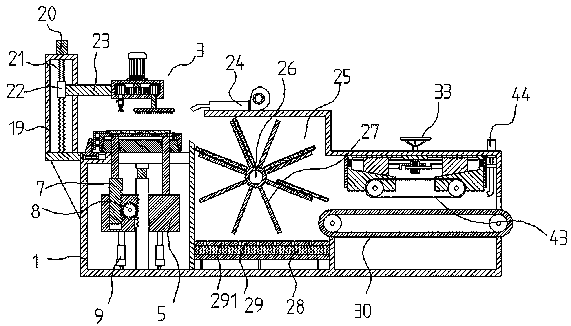

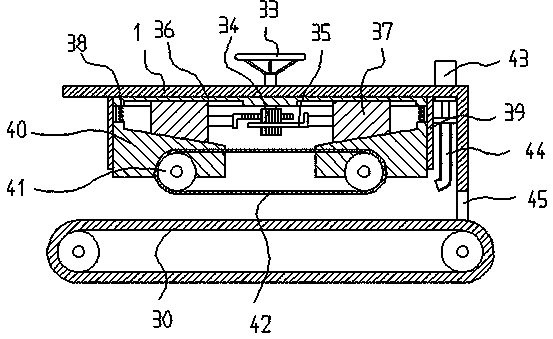

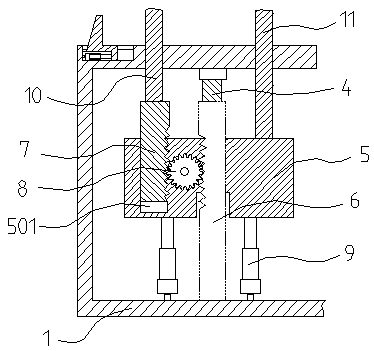

[0034] like Figure 1-Figure 8 As shown, the specific structure of the present invention includes: a body 1, a worktable 2, a conveying mechanism 30, a waxing mechanism 3 located at the upper end of the worktable 2, and a polishing device located at the upper end of the conveying mechanism 30; The device includes an adjusting wheel 33 with a gear part 34 arranged on the side end of the body 1, a group of tooth plates 35 are meshed on both sides of the gear part 34 of the adjusting wheel 33, and an upper sliding table 36 is arranged on the inner wall of the body 1, so A group of upper pressing blocks 37 are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com